Juan Ranera

Fab Academy 2013 Participant

Composites

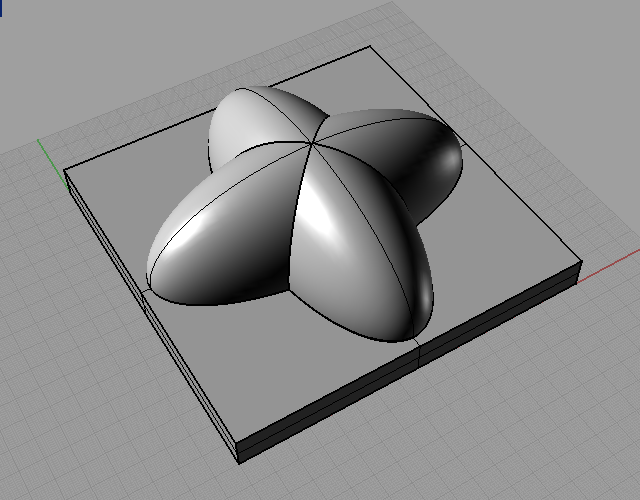

Our last assignment for last week was to design and make a 3D mold and test composite materials.

I've designed the mold in Rhino. The material with whih we had to make the mold, it was something small,

so I decided to do a little star-shaped container.

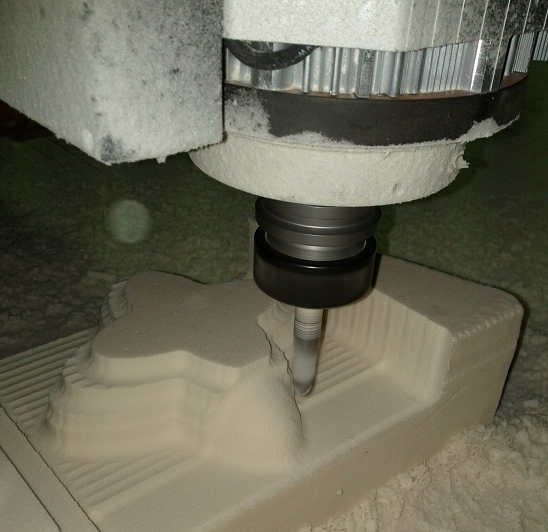

I've milled the mold with Shopbot machine. It has his own software called PartWorks. I've used a 12mm drill bit and I like a lot his precision.

It is important to take account design depth. Should never be greater than the length of the drill.

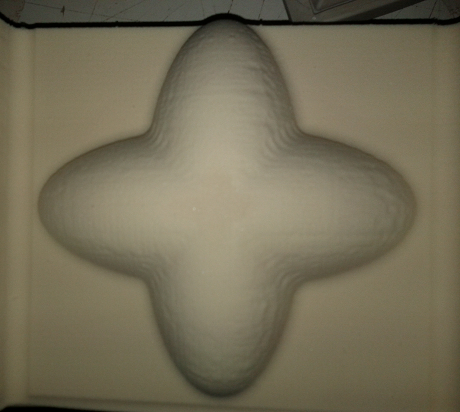

Finally, this is the mold:

I've used "linen" and "raffia" matrix to fabricate my piece. I've cutted these pieces using the Epilog 36EXT laser cutter.

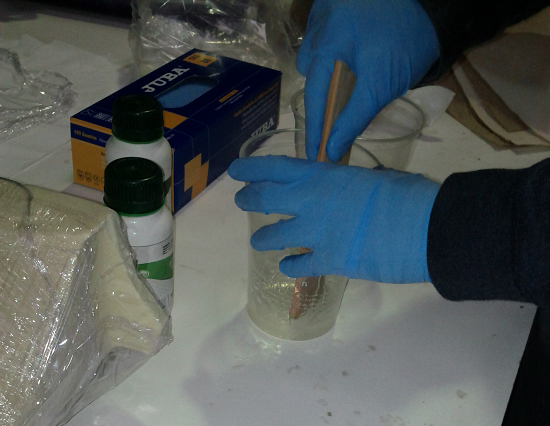

There which spreads the fabric pieces with epoxy resin mixed with a hardener. You have to pour 2 Parts Resin + 1 Part Hardener

Stir for 2 minutes...

And then you have to extend over the mold covering all the layers with plastic film.

Finally you have to put the whole package inside the vacuum bag, and wait...

6 hours later...