WEEK 04 : ELECTRONICS PRODUCTION: FabISP

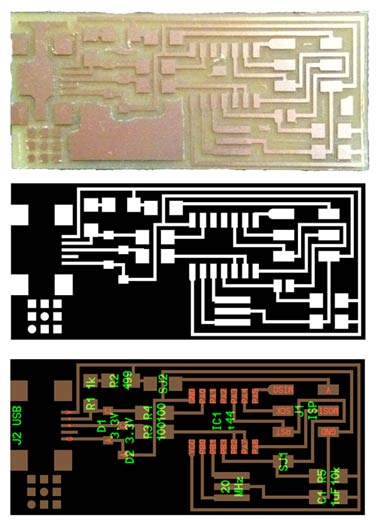

The task for this week was to create our own In-System Programmer or ISP. I understand this small device to act as the bridge, between a computer and another programmable device. The ISP houses a micro-contoller that will hold information that can then be tranfered to other devices in a way that a computer cannot. The ISP houses a bumber of components with the Micro-controller at its heart. From the Fabacademy class wiki I chose a template called hello.ISP.44.res. The list of components is as follows:

Component List:

0. Copper Board

1. J2 = USB socket (used just for power

2. D1 = 3.3v Diode = The line inscribed on the casing indicates the orientation of the cathode

3. D2 = 3.3v Diode

4. R1 = 1k Resistor

5. R2 = 499 Resistor

6. R3 = 100 Resistor

7. R4 = 100 Resistor

8. R5 = 10k Resistor

9. IC1 t44 = Micro-controler

10. 20MHz = Resonator

11. J1 ISP = the 6 point socket type that the board type is named after

12. C1 1uf = Capcitor of 1 (u)micro (f) farad

13. SJ1 = Jumper 1 = A part of the circuit to be cut after the micro controller has been programmed

14. SJ2 = Jumper 2

Milling Notes

We used the Modela milling machine to cut out the patter for the circuit board. This meant using fabmodules to first turn the hello.isp.44.res. template into a usable path that the machine could understand. The fabmodule first turned the .png file into a readable format. There were various callibration tasks to perform before the cutting could proceed. Cleaning the copper plate / clamping the x64 cutting bit / setting the x.y.z zero points / manually resetting and zeroing the z axis by hand / changing the cutting setting to correspond to the x64 bit / toggling between views on the machine and finally changing to a drilling head and repeating the process to cut out the circuit.

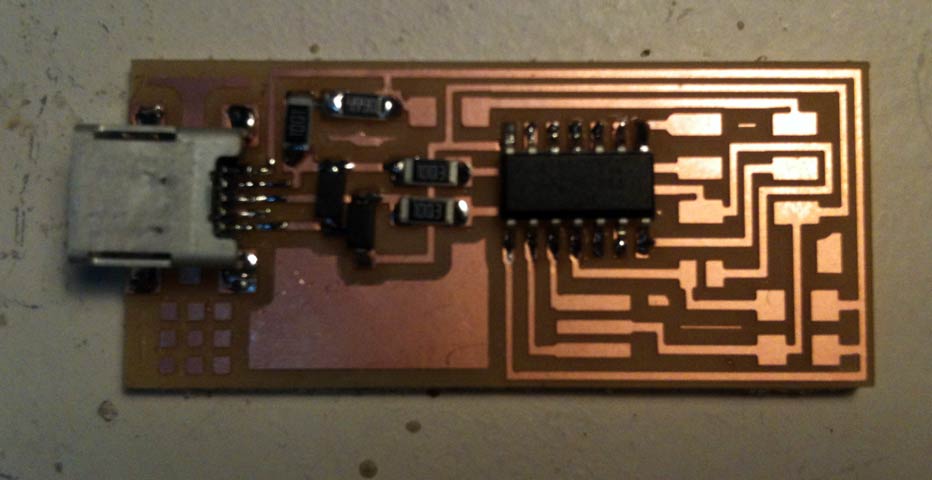

Soldering Notes

The FabLab BCN has a Weller PU81 soldering iron which allows a user to control the temperature of the contact tip. The tip also has quite a fine point. We set the temperature to 300 degrees centigrade for this job which is the middle of the temperature range. The solder used was of a thin grade. The trick was to heat the necesary parts first and then let the soldar run to it. After smoke testing the device all lights were greeen and go

Programming

The horror! Download 1. Crosspack AVR; a development environment for programming AVR microcontrollers, this was to be installed. Download 2. 'Make' could be installed by using Xcode. Xcode is software that is used to program applications on the mac. In turn this could be installed through the mac app store. (A whopping 1.65 gig!) Next was to follow the adafruit tutorial to access the Crosspack AVR tools. Finally following the terminal comands on the Wiki allowed me to program the AVR microcontroller. However even after the terminal responded correctly, the device failed to be recognised by the computer.

KEY RESOURCES:

Week 4 Class Lecture : Electronics Production

Week 4 Homework Review

Week 4 Blog Post : Assembling Acronyms.