Final project - modular structure¶

Files and resources¶

Conceptual design¶

The aim here is to provide a modular and low-cost structure, that could be adapted for multiple types of measurement typically used in soft robotics (video 3D tracking, force measurement, …). I want this structure to be:

- Modulable

- Low cost

- Compatible with classical material and tools used for tests benches (i.e. optical breadboards and mechanical equipment)

I found some inspiration on Denis’ site, who happens also to be my special instructor.

Bill of materials¶

Laser-cut structure¶

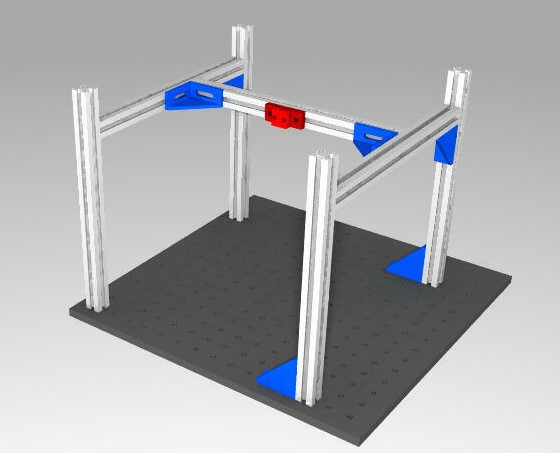

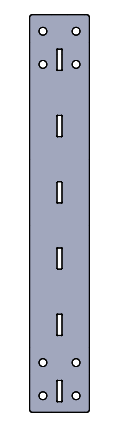

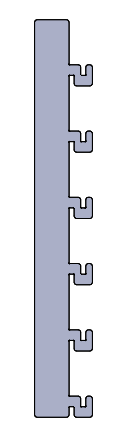

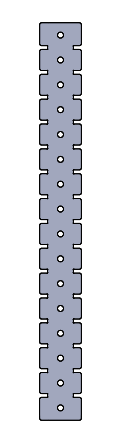

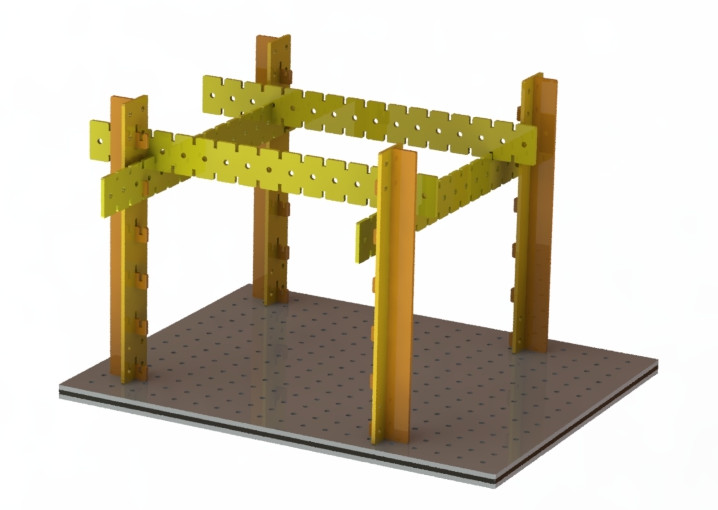

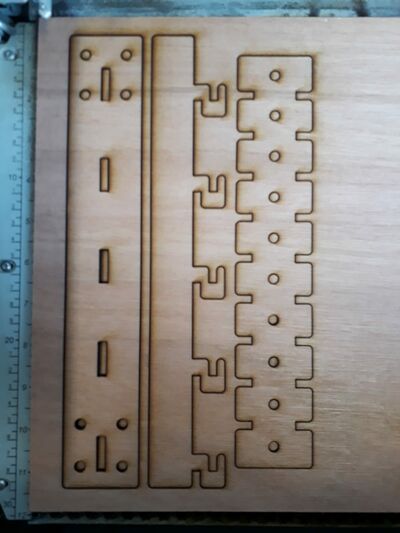

Usually, those kind of structure are mode using aluminium profiles, but the extruded profiles cannot be made (of course) in a fab lab. A first version of the design (but bot based on laser-cutting) was developed in week 3, and an improved version is documented in week 4. So, I tried to design an alternative. I replaced the profiles by 3 types of pieces, 2 vertical and 1 horizontal. This is not a “clean” design, but this is supposed to be as modular as possible. I tried first with FreeCAD, using multiple files sharing a “master spreadshet”, but the too many bugs and the often closing software convinced me to let it go and use Solidworks, a tool that I master. Of course, I made all the design perfectly parametric.

And when laser cut on 5 mm multiplex wood:

Good! This solution seems OK! I am not totally satisfied since I feel like the structure could be simpler, but this design is rigid enough for the moment, and is very modular!

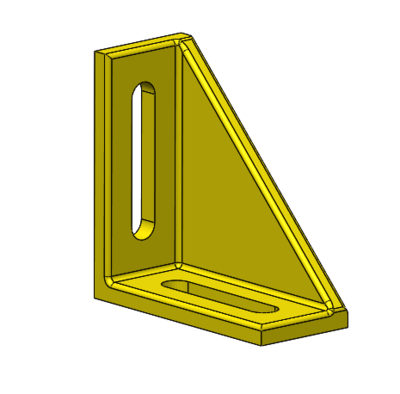

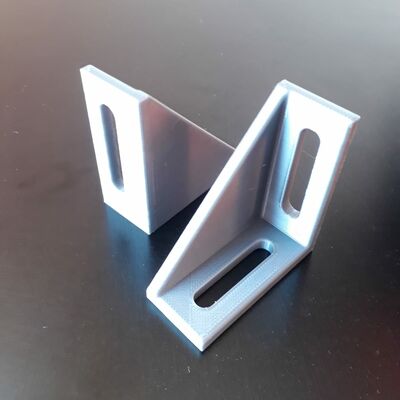

I also need fixations to fix the structure on optical breadboards. Here is the designed fixation, printed in 3D. I tried in parallel to print it with and without support, and the result was very similar, let’s avoid to waste material into supports!

And assembling the structure

A dark sheet was also added to allow to take nice pictures of the soft robot.