Week 15: Mechanical Design

Time has come. Time of our first group project. This time we shall construct a machine, which will be later programmed and get some functionalities. By programming I mean putting a soul inside of empty box, which is not able to move without help (yet). Fitting pieces, deep considerations, smart approaches are our challenges.

Requirements for this week are:

- design a machine that includes mechanism+actuation+automation

- build the mechanical parts and operate it manually

- document the group project and your individual contribution

Group Assignment

Members: Arash, Gleb, Marjo, Perttu and me

This is unusual week. This time our group work may be find under this link: CLICK ON ME!. On my web page I will only describe my personal contribution.

Individual Assignment

My contribution

I can happily say that VitaFab was my concept. Nevertheless, I didn't invent such cool name. I desired a device, which may be used with school children and show them importance of being patient (fit pieces together), learn programming (brain of our device) and study electronic components and systems (movable parts).

The drawback is that I felt responsible for it and more importantly responsible that it will look fancy and operates smoothly and in an efficient way.

I was taking very active part into designing part and group photos are a nice prove. I was trying to explain my ideas to the rest of our team. I also felt in charge of troubleshooting on various moments and made decisions, whether we had some issues.

In general VitaFab is automated vitamin drink dispenser/maker. Every time you will put your cup with water inside and press the button - it will make you fresh vitamin drink. Especially useful in the Winter, when your body craves for it.

First of all, I managed to find or scavenge all parts, which we would need in future:

- Arduino UNO - heart and brain of our device

- Servo motor - in order to dispose tablet

- 4-phase stepper motor - cup moving mechanism

- Motor driver - as this part cannot be powered from Arduino board

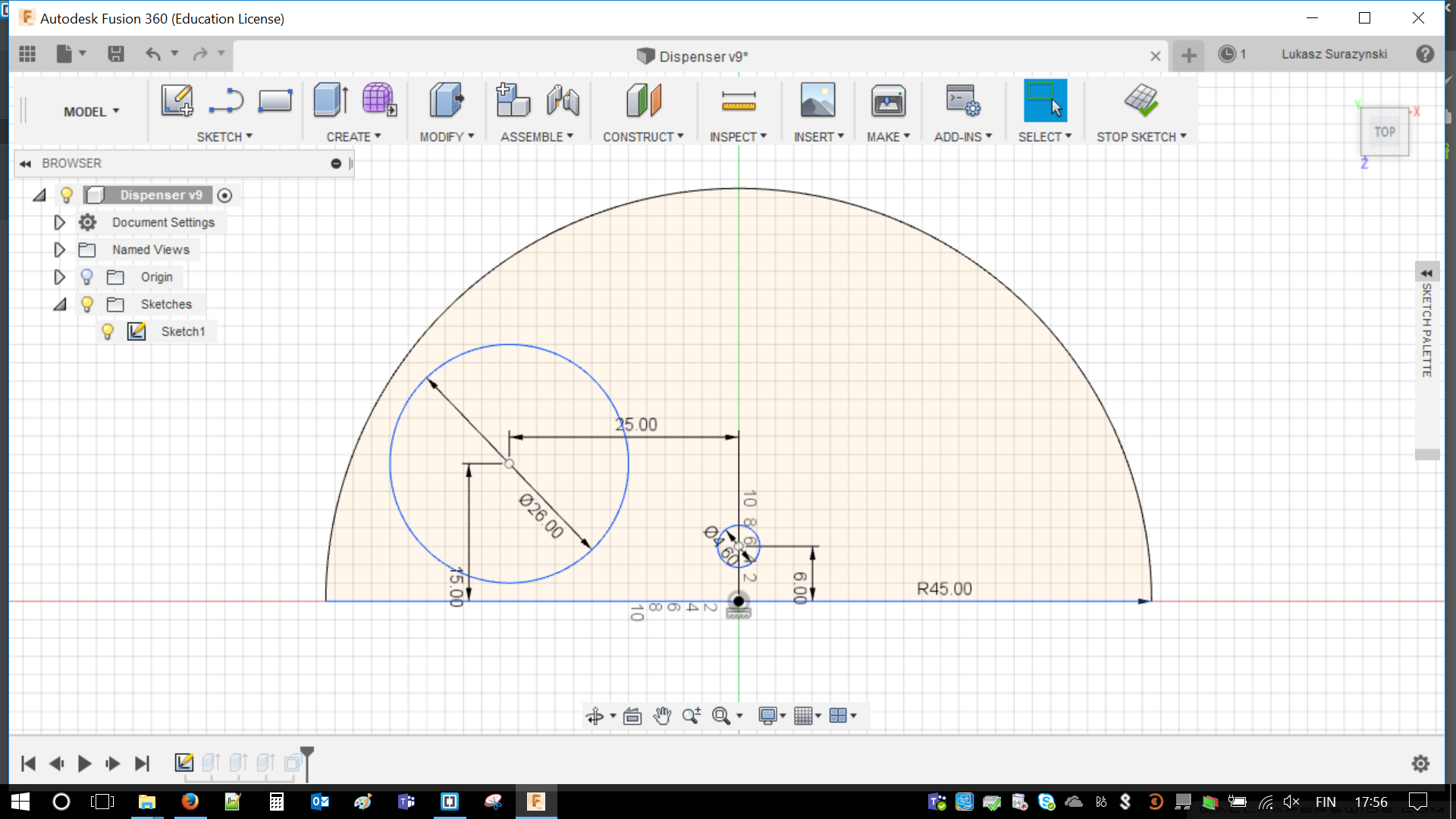

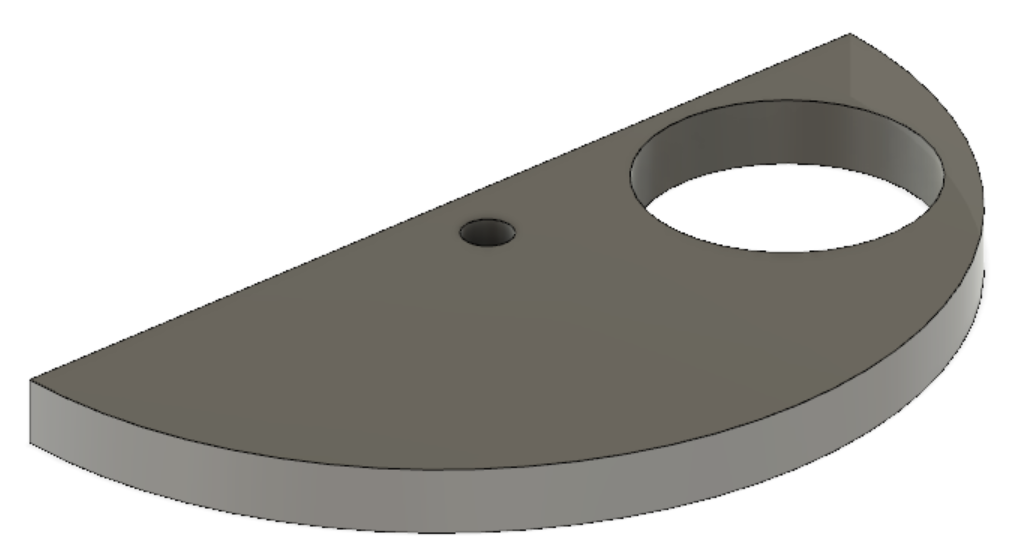

When the tasks were distributed and we agreed on VitaFab size I started to prototype dispense mechanism. We had an idea to fabricate it using 3D printer. This element supposed to be moved by servomotor and should make full 180 degrees spin. Part was fairly simple but the dimensions were crucial.

Somehow I was keeping tightly idea to print only 180 degrees circle, to save material and printing time. However, it proven it creates issues as vitamin tablets were stuck. It was later changed by full circular shape. All issues were removed this way. Moreover, it was easier to laser cut the hole to drop the tablet (just opposite direction to attaching pin).

Second most crucial factor after the shape was the height. It should be a bit higher than a tablet. This way tablets were not blocking anything and breaking itself. The side note is: tablet dimensions are standardized. Those depends on the press.

Maybe my contribution was just a small piece but important one. The next step was checking if all dimensions are right and we are able to drop tablet inside the cup. There is even one fancy movie in group work section.