Week 12 Output devices¶

This week we had group assignment and an individula assignment

Group assignment¶

For the group assignment we had to measure the power consumption of an output device. For more information about the individual assigment click here.

Individual assignment¶

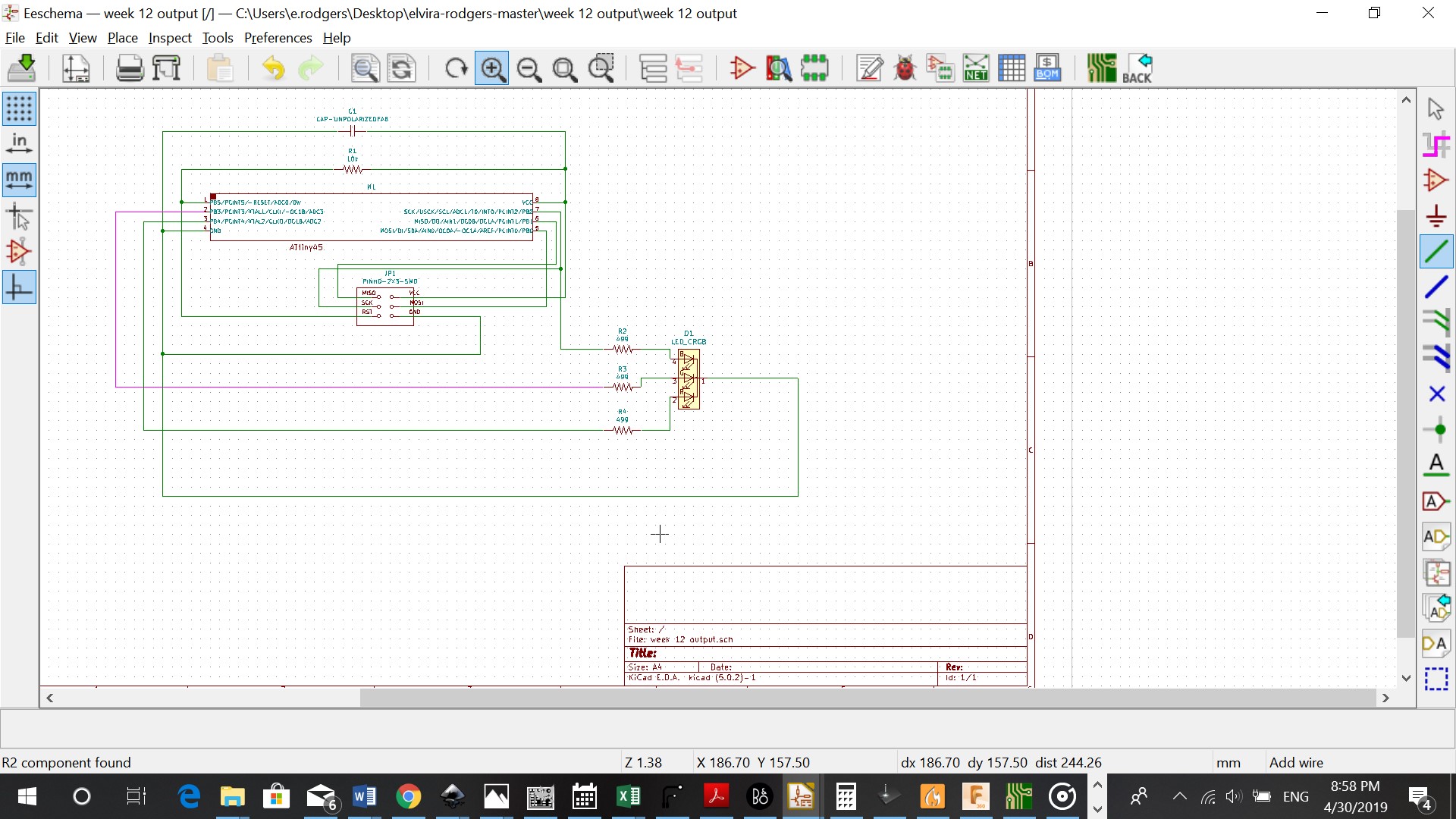

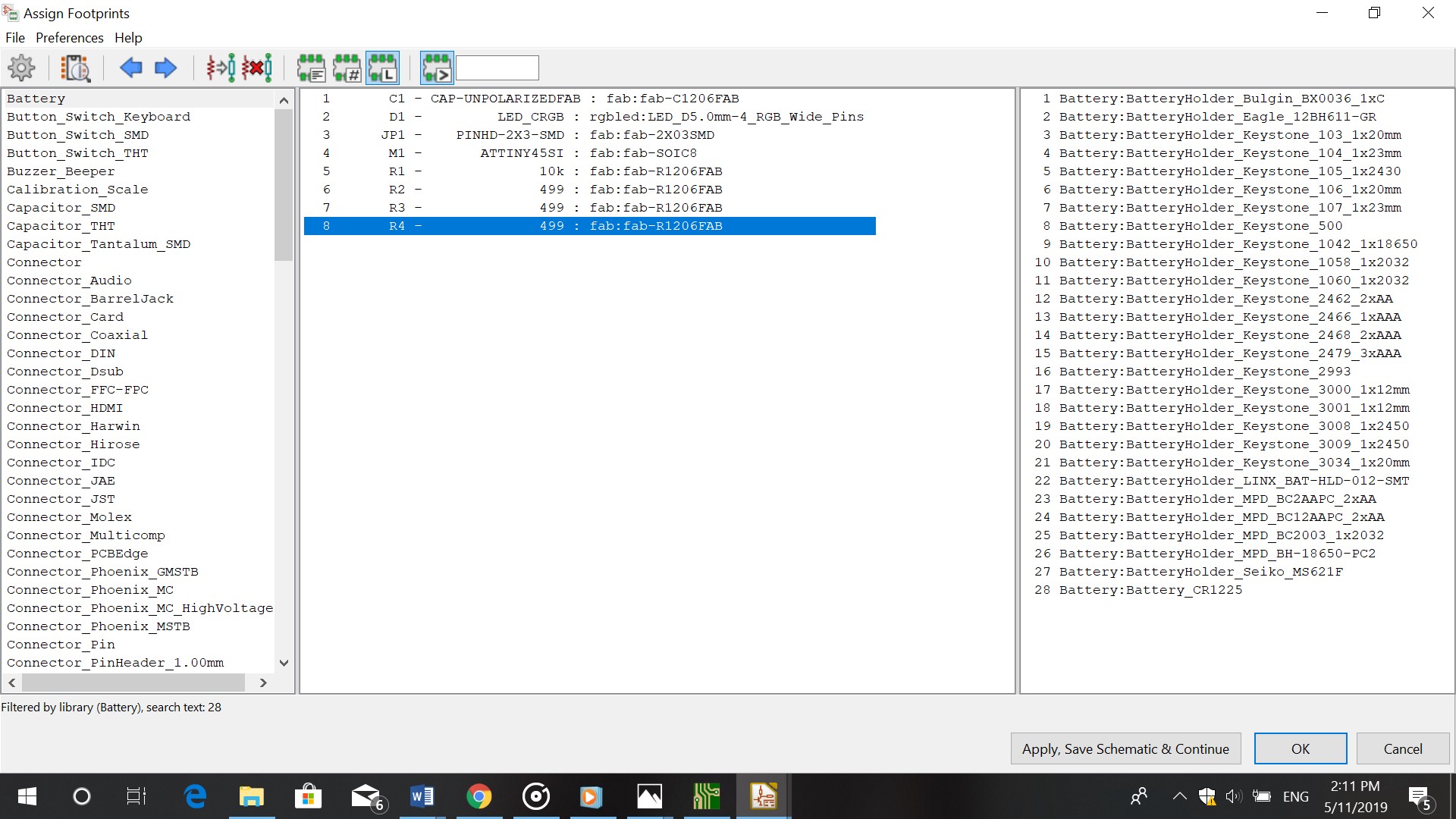

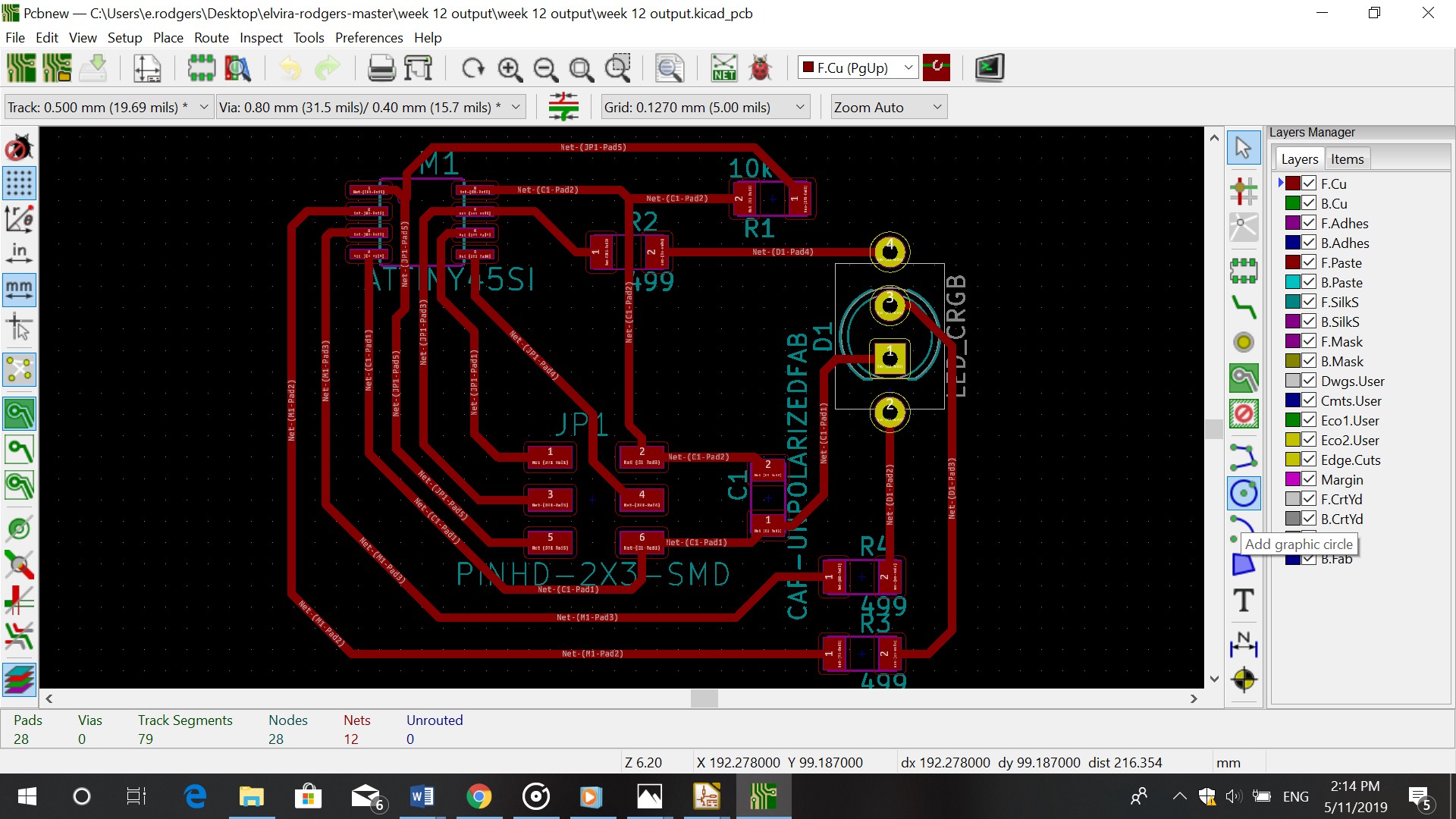

For the individual assignment we add an output device to a microcontroller board you’ve designed, and program it to do something. I used the Led relay board on the fabacademy site but instead of 15 LED, I made a schematic in Kicad with 4 multicolored LED’s.

Designing¶

The components that I used for this assignment are:

-

Capacitators (1)

-

Resistors 10K (1), 499 (3)

-

RGB led (multicolored)

-

Attiny45 microcontroller

-

AVRISPSMD, 2x3 header

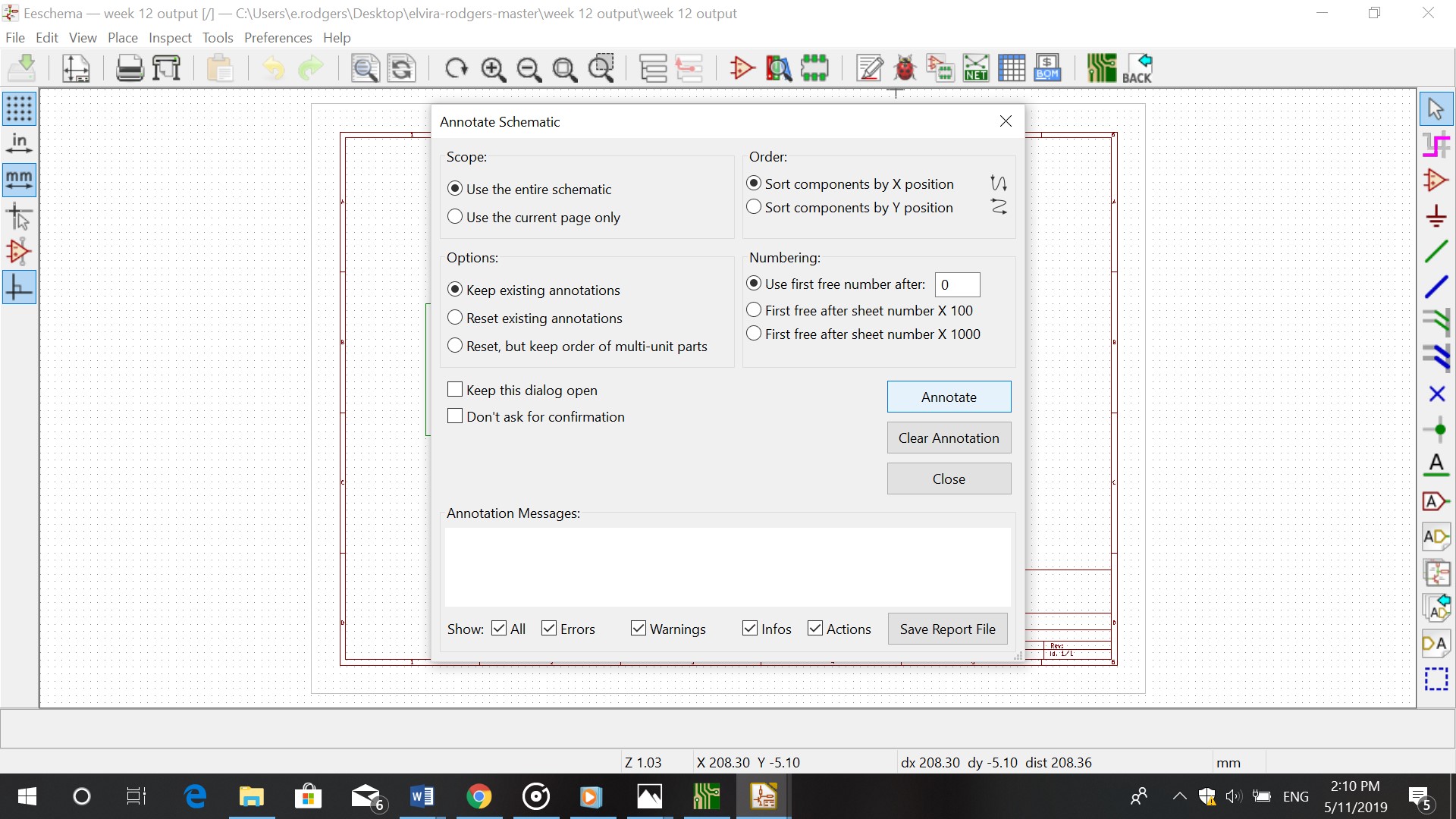

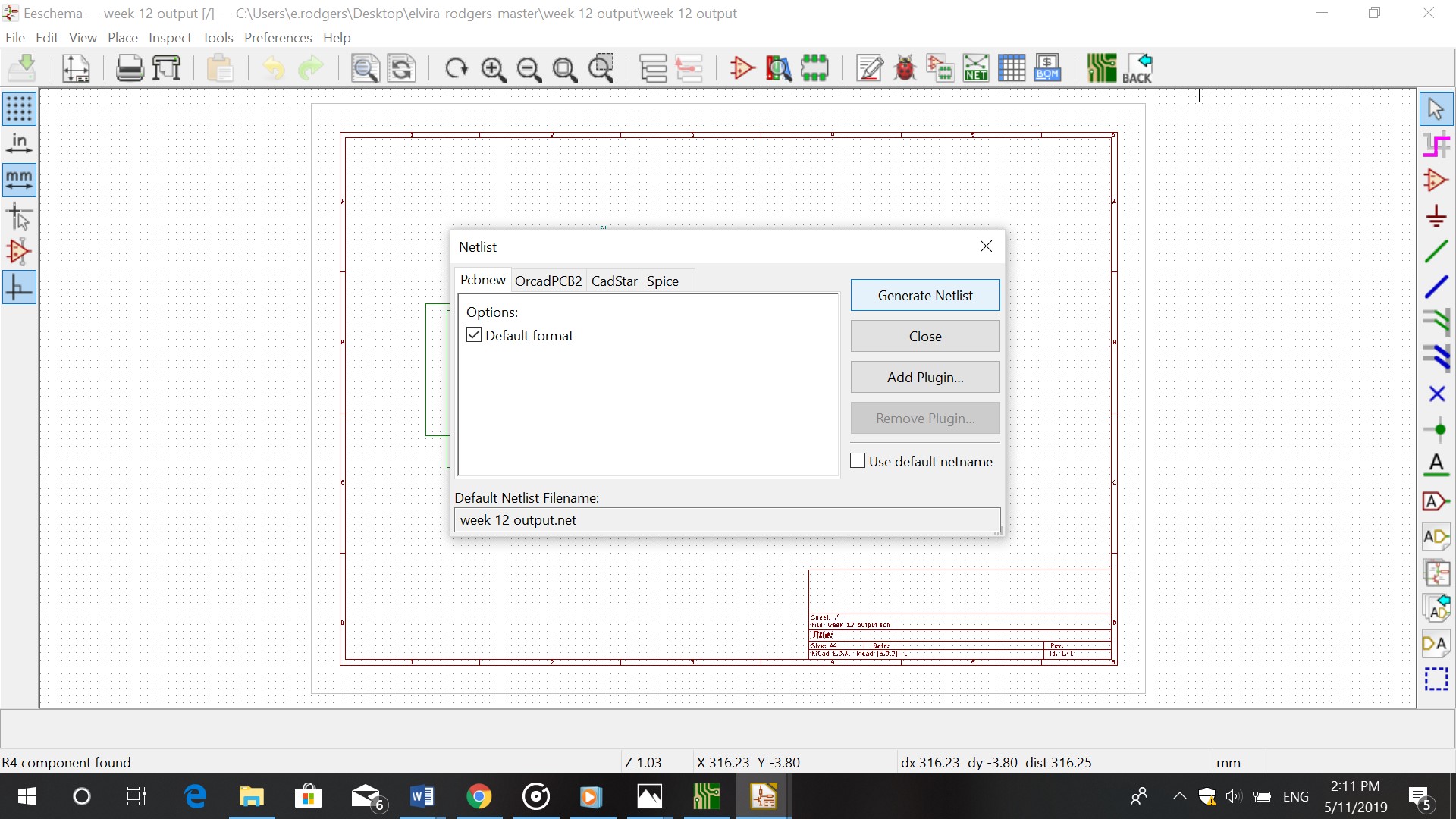

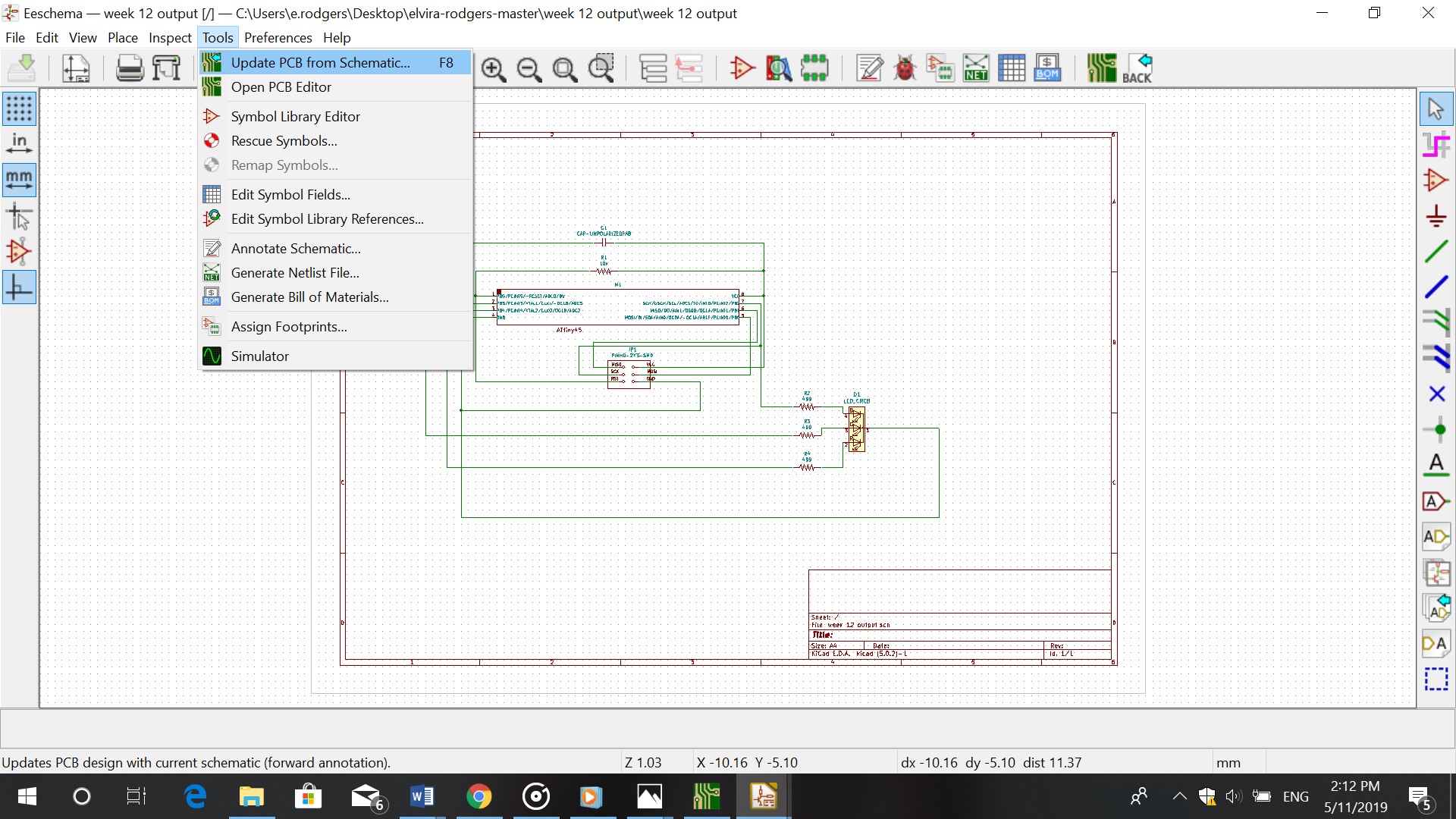

Just like week 11 I followed the same steps to make the schematics for the board and generate it.

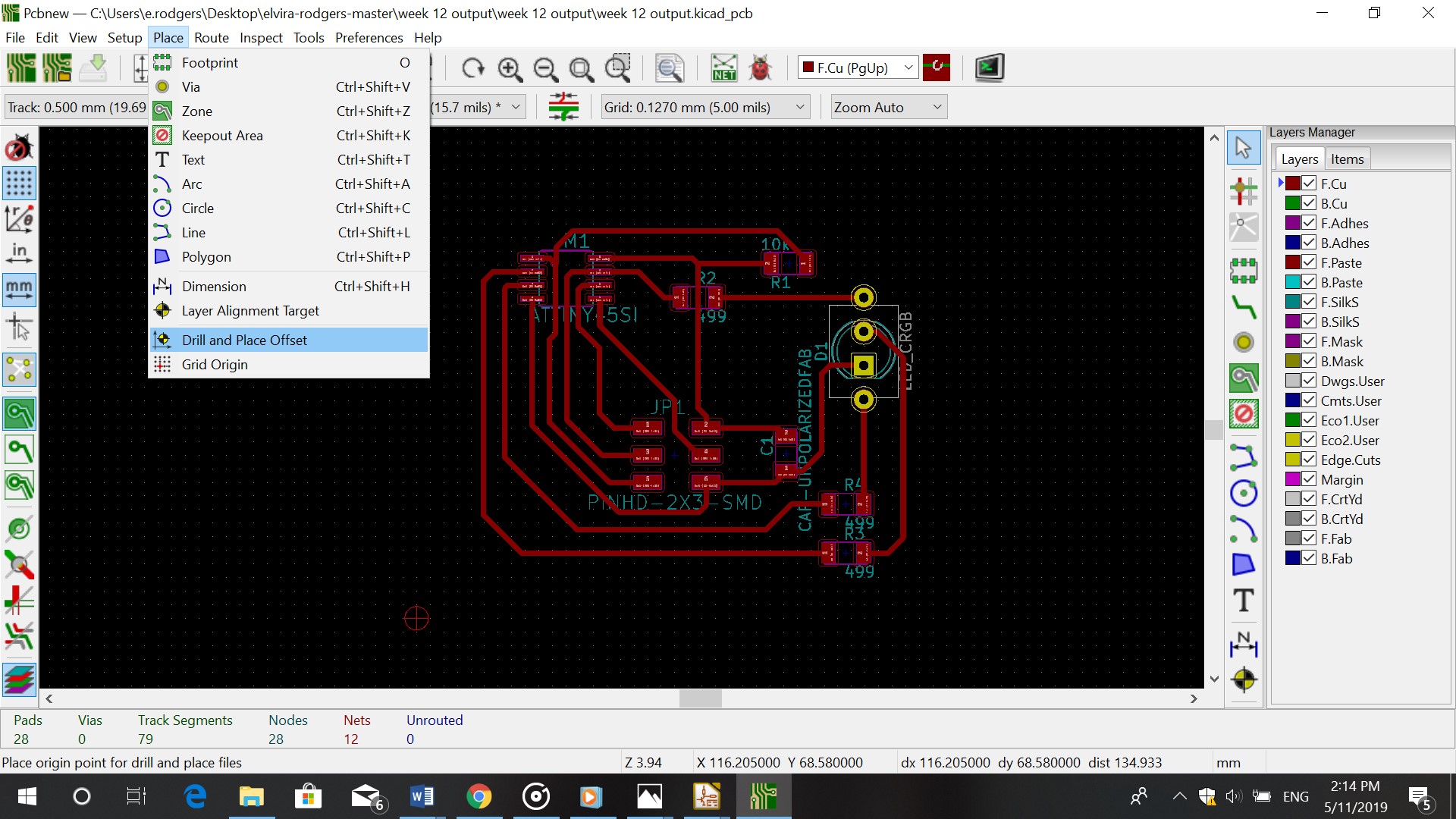

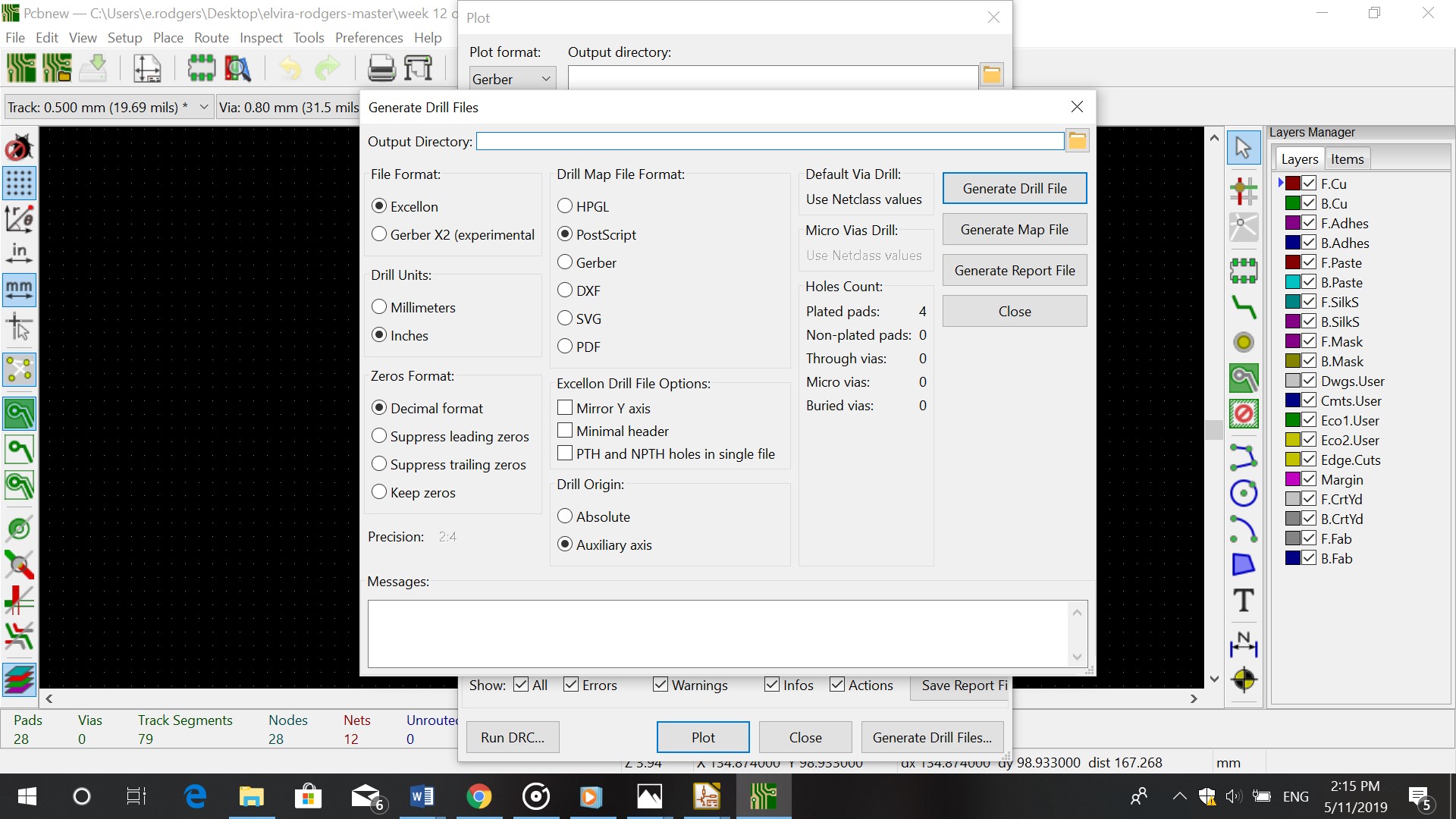

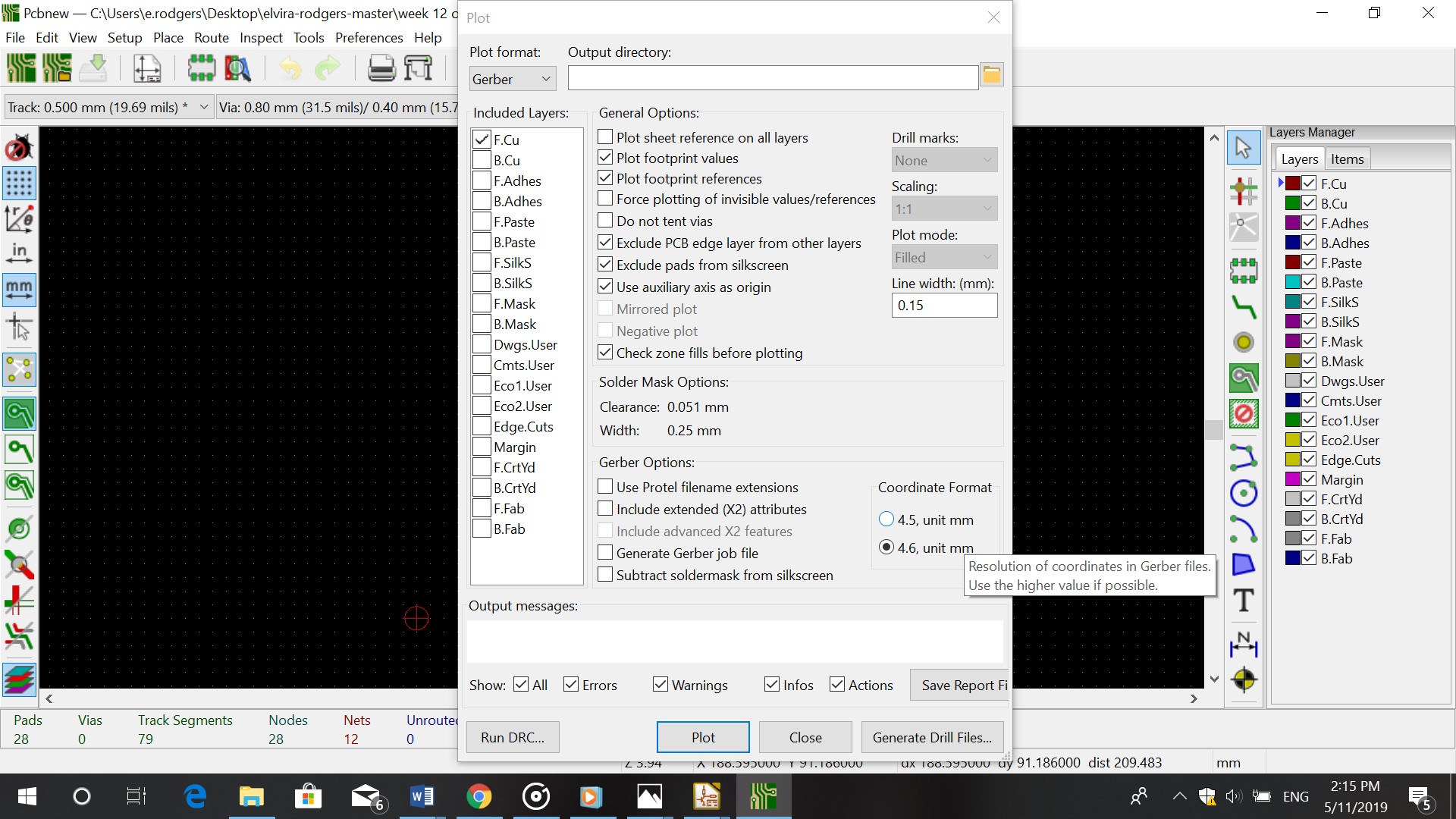

After applying the schematic I put in the tracks. Set the drill ofset and plotted the schematic.

Flatcam¶

Tracks¶

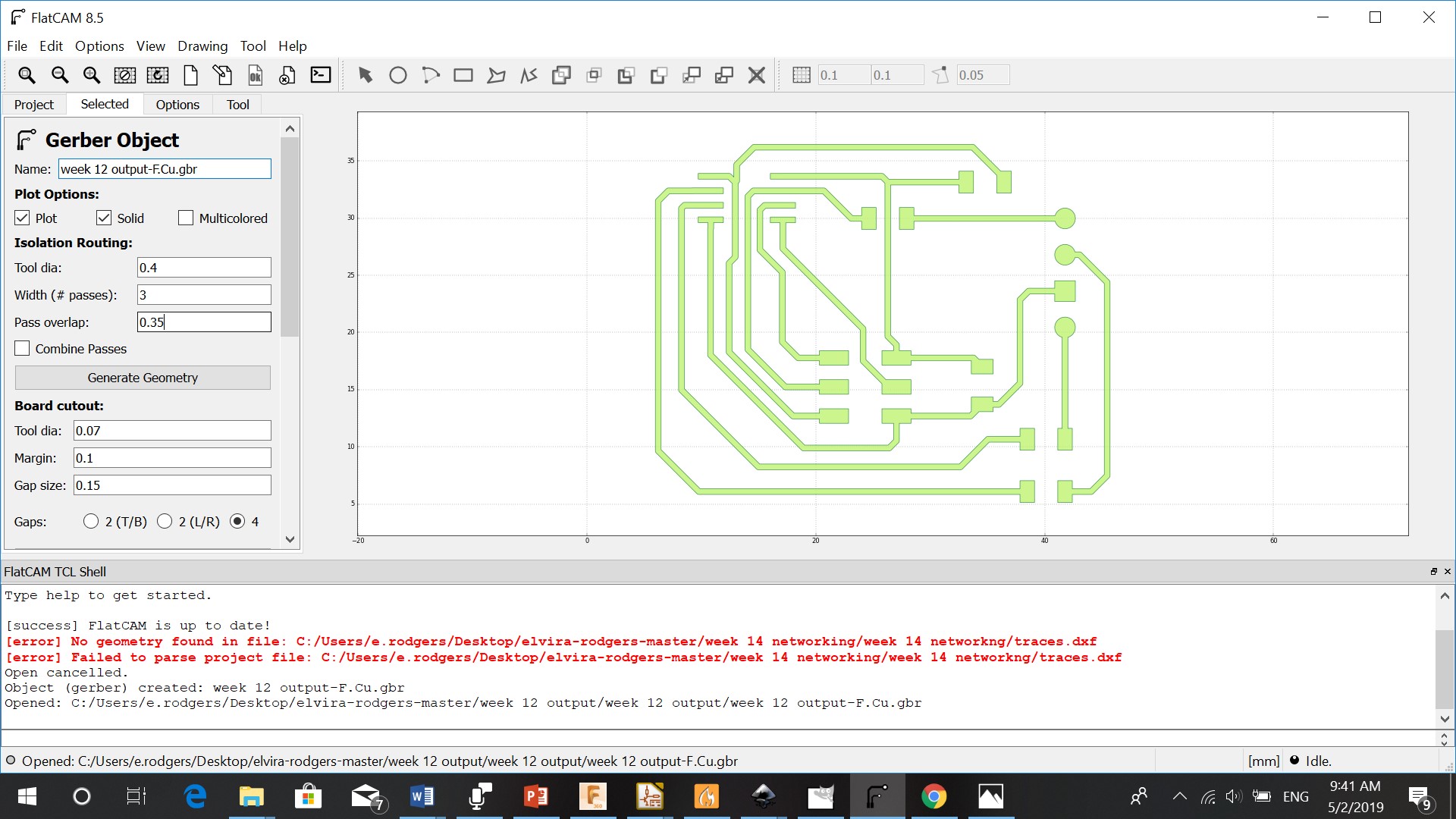

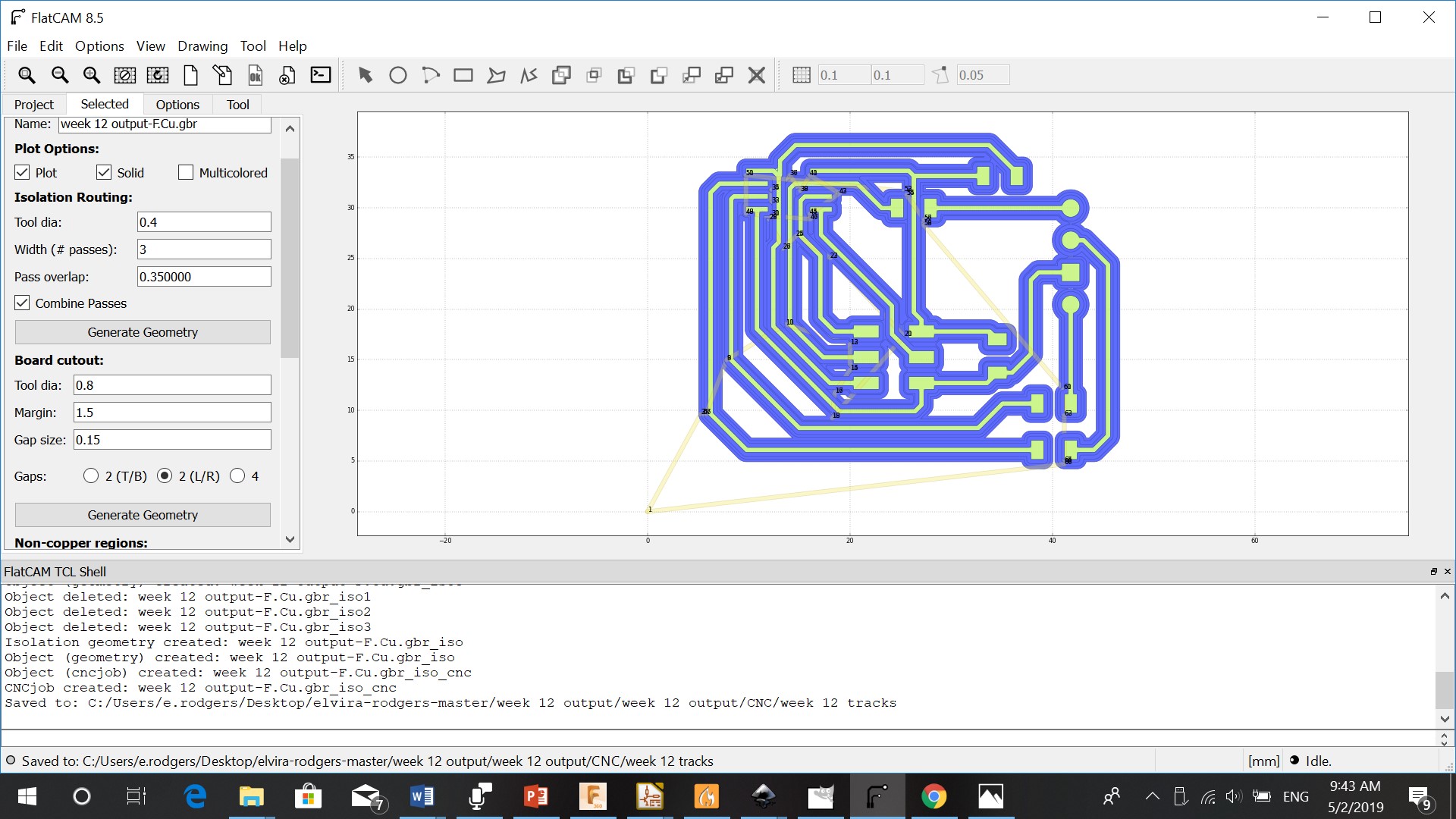

I opened the Gerber file in FlatCam (the one ending with F.Cu.gbr)

In project I double clicked on the name of the Gerber file and set the parameters

Tooldiameter: 0.4 mm

Width: 3

Passes overlap: 0.35

I then generated the Geometry

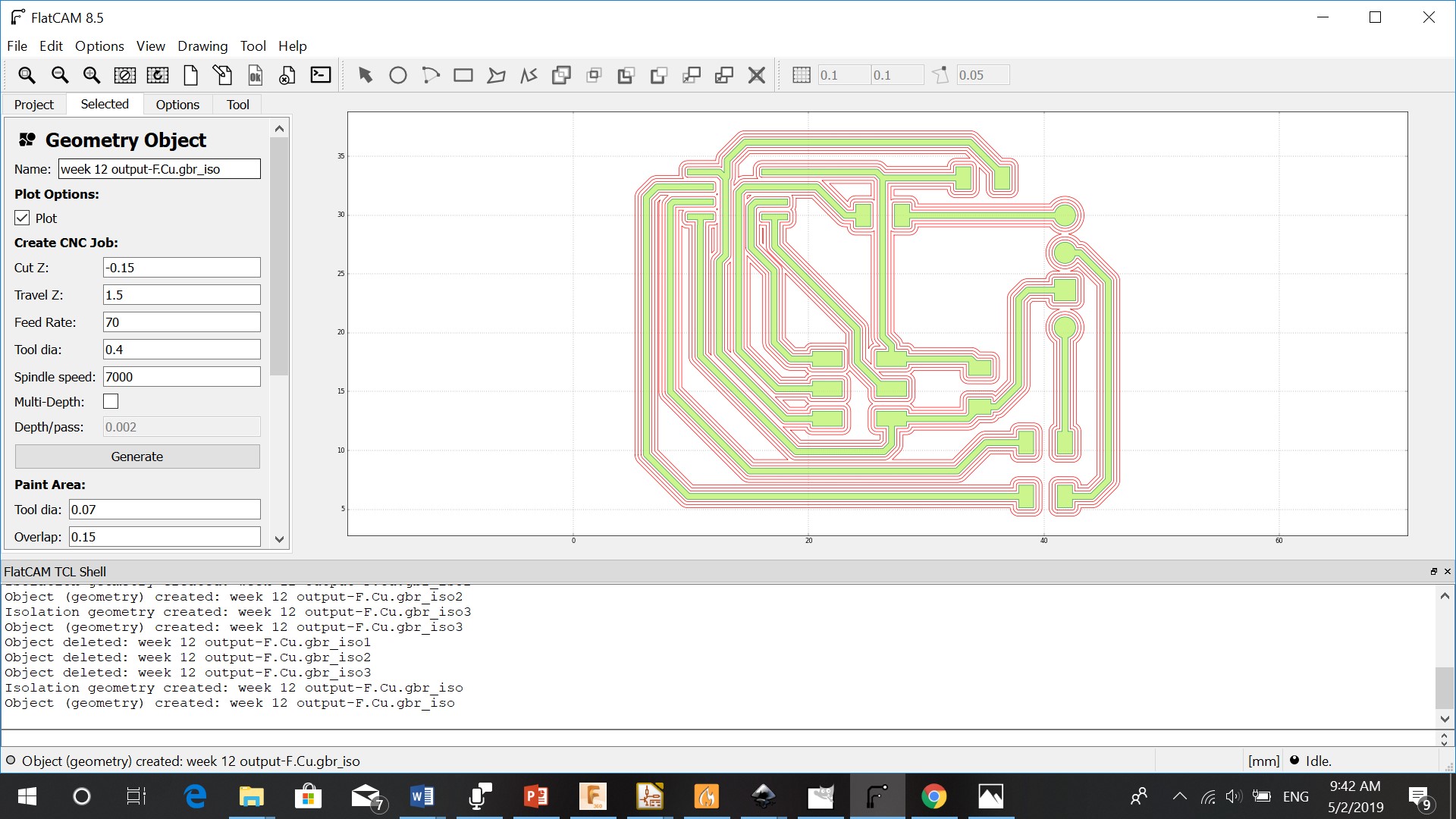

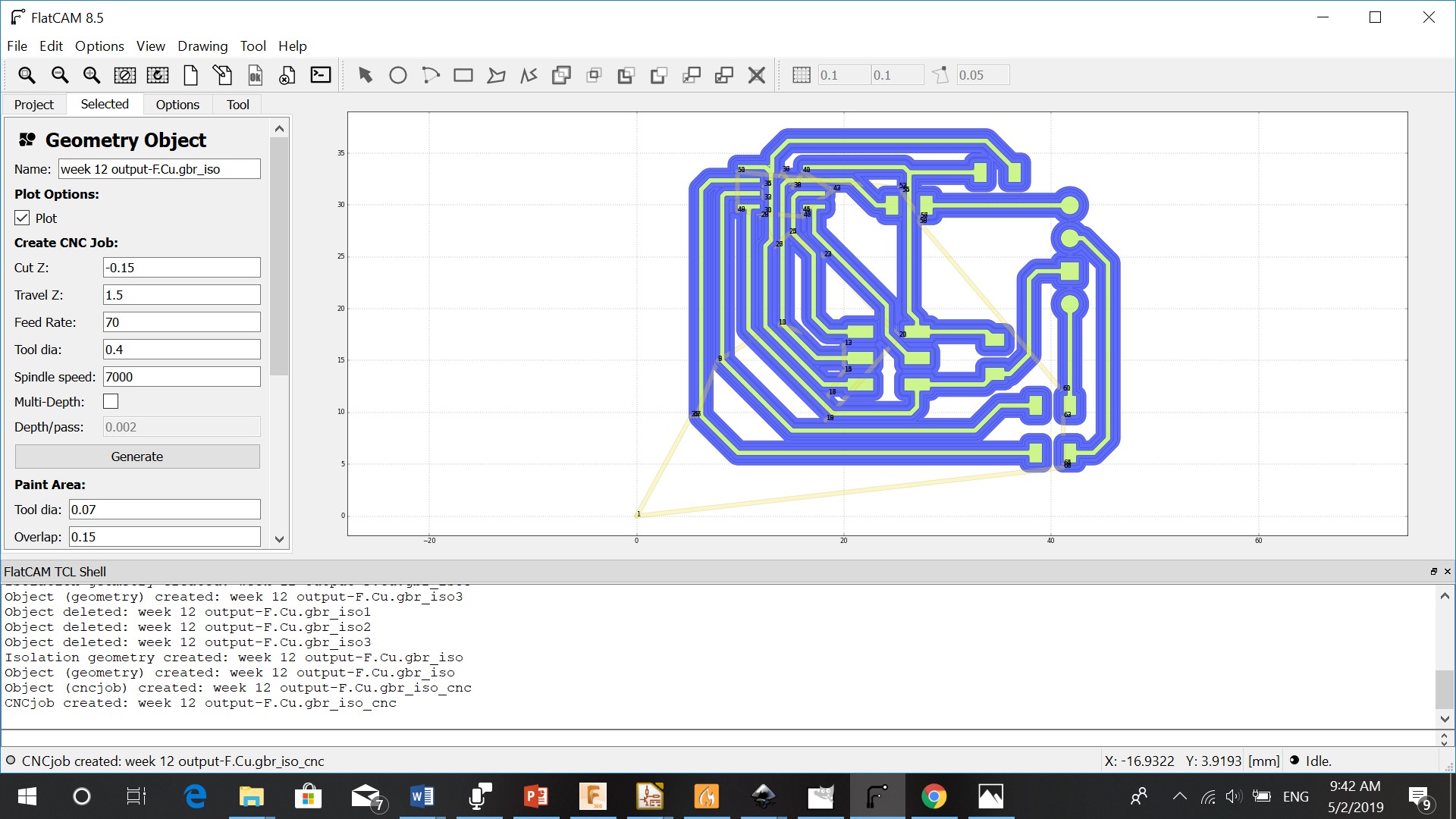

I went to project again and clicked on the file ending with _iso

The parameters that I used are:

Cut Z: - 0.15

Travel Z: 1.5

Feedrate: 70

Tooldiameter: 0.4

Spindle: 7000

I generated the file

Cutout¶

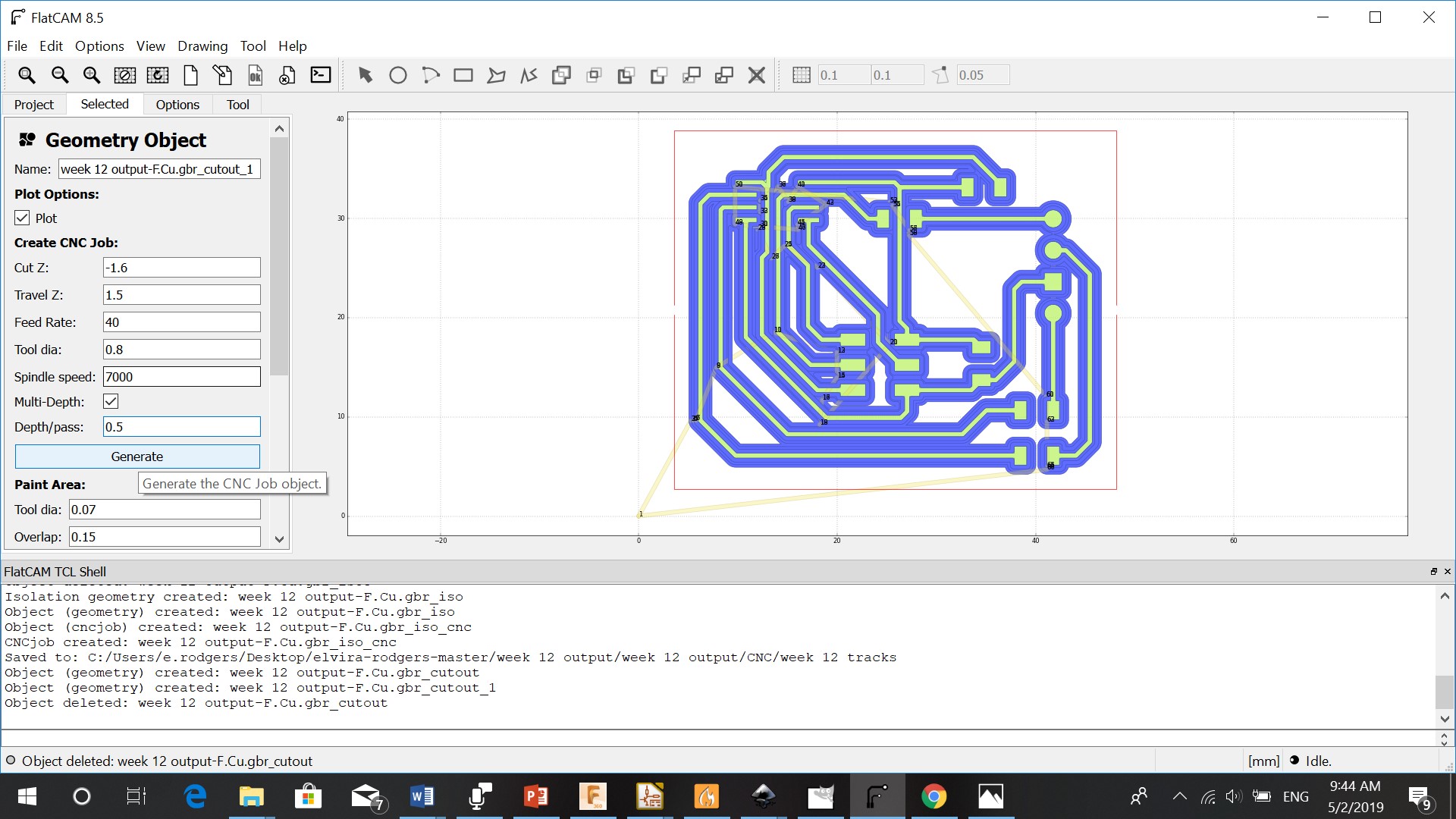

For the cutout I clicked on the Gerber file in Project. I changed the tooldiameter to 0.8mm and generated the file.

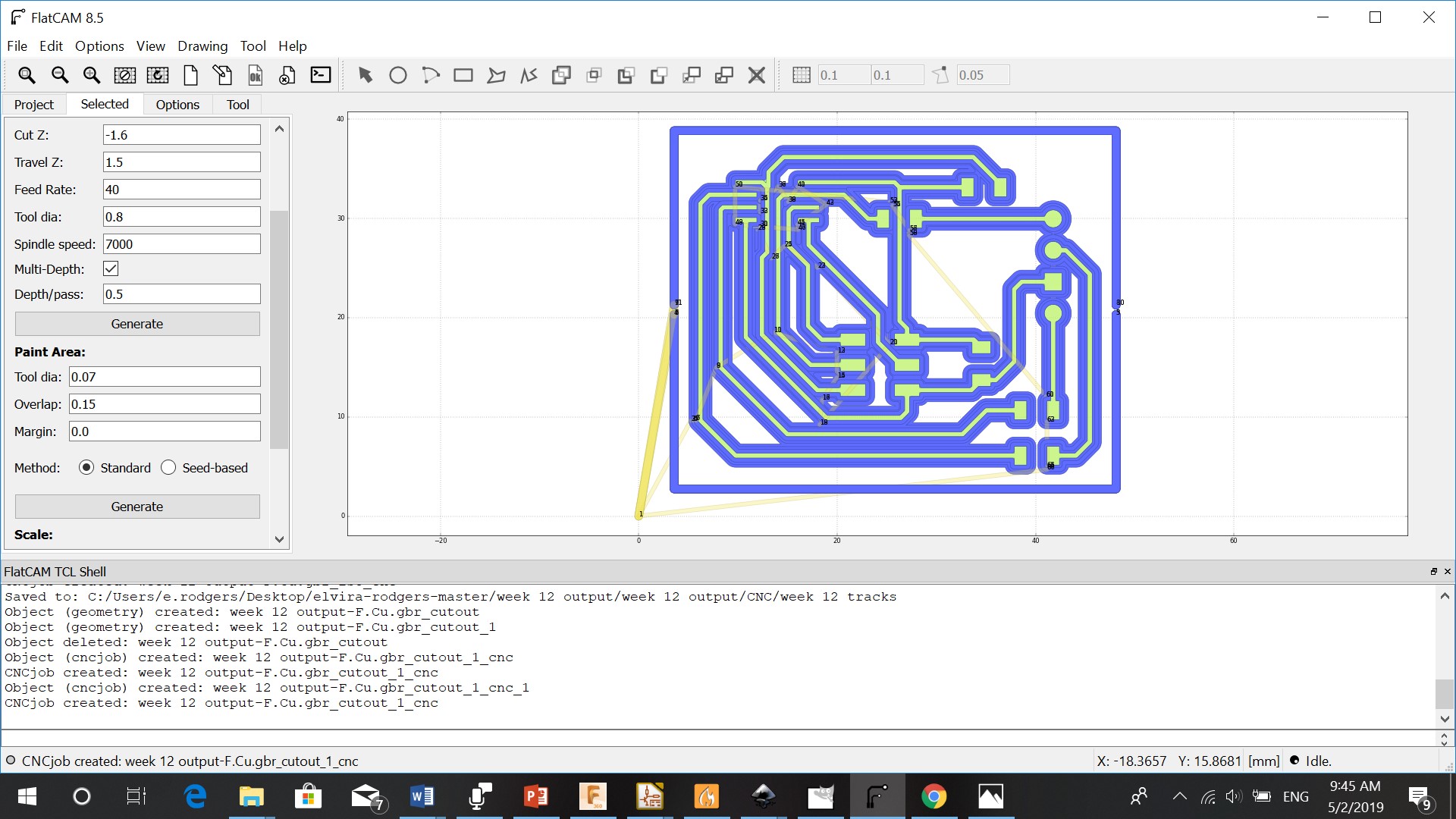

I went to project and clicked on the file ending with _cutout

I changed the parameters to:

Cut Z: - 1.6

Travel Z: 1.5

Feedrate: 30

Tooldiameter: 0.8

Spindle: 7000

Check multidepht and set it at 0.5

Generate

Milling¶

Just like in week 11 I set I set the X,Y and Z

Because the board can be oneven I had to set a heightmap. I used 4 for the X probe grid and 4 for the Y probe grid. This calculates the height of the board in 4 point to left (X), and 4 points to the back (Y)the heightmap

Soldering¶

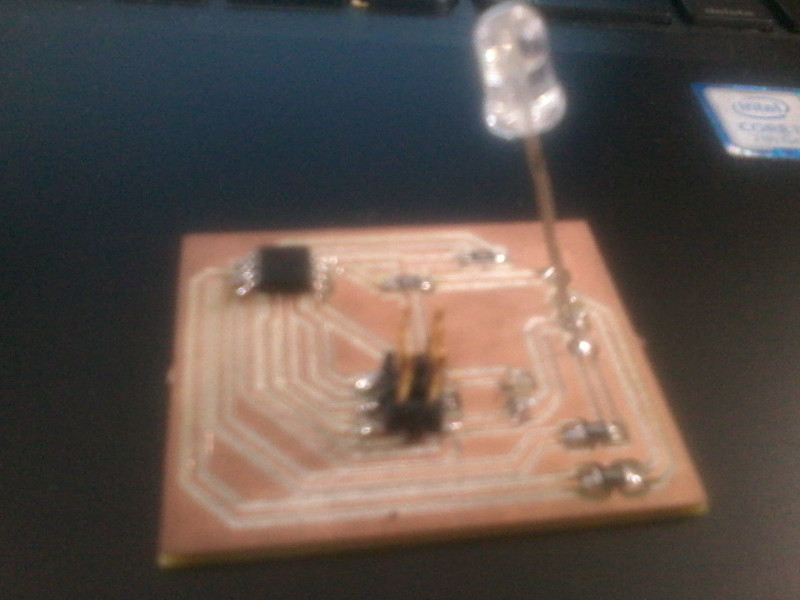

After milling the board, I soldered the components on the board

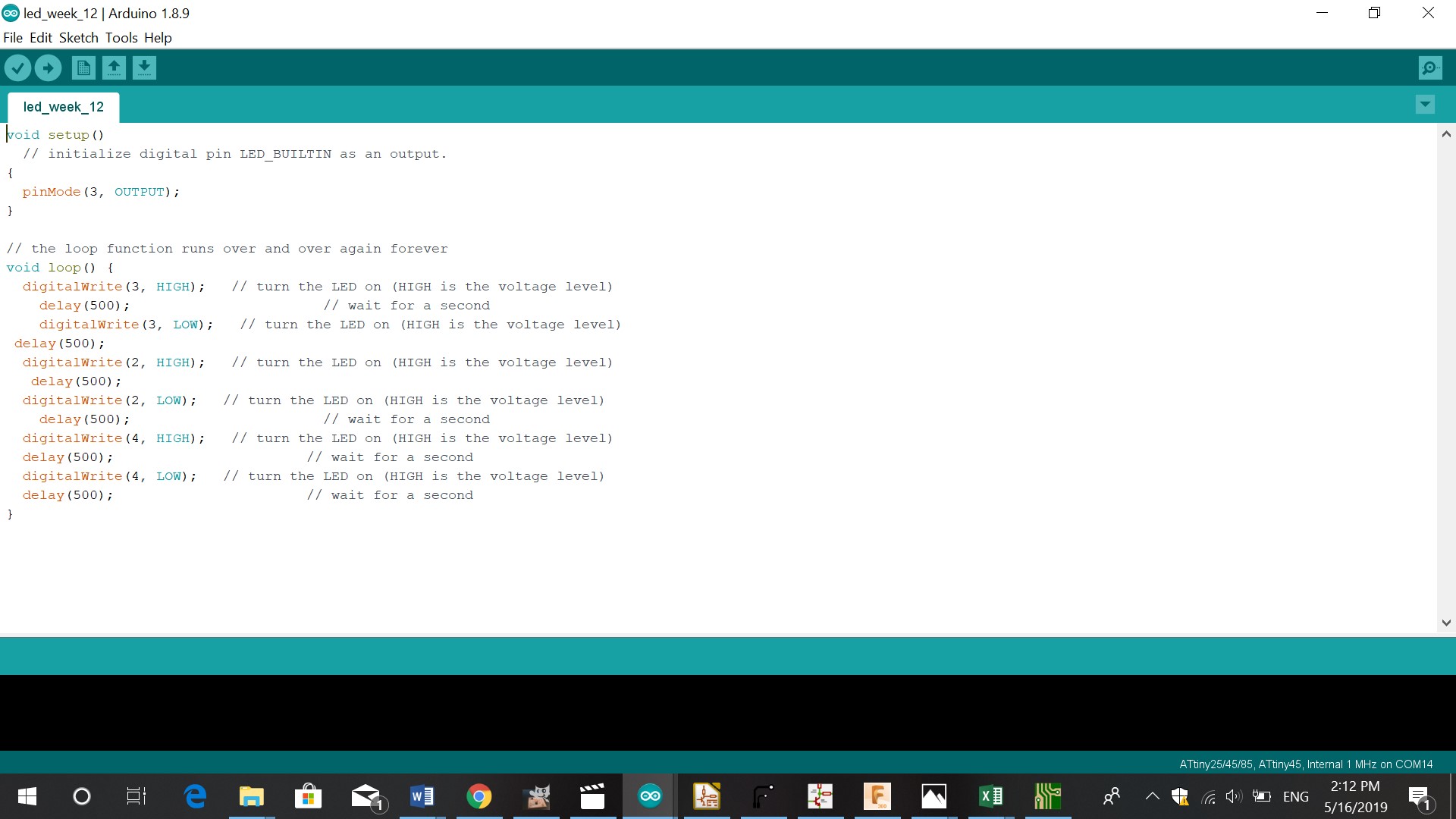

Programming¶

After soldering the components on my board, I used the multimeter to see if all connections were right. I opened a new file and checked the pinout of the Atttiny 45. I had to choose pin 2,3 & 4.

{

pinMode(3, OUTPUT);

}

// the loop function runs over and over again forever

void loop() {

digitalWrite(3, HIGH); // turn the LED on (HIGH is the voltage level)

delay(500); // wait for a second

digitalWrite(3, LOW); // turn the LED on (HIGH is the voltage level)

delay(500);

digitalWrite(2, HIGH); // turn the LED on (HIGH is the voltage level)

delay(500);

digitalWrite(2, LOW); // turn the LED on (HIGH is the voltage level)

delay(500); // wait for a second

digitalWrite(4, HIGH); // turn the LED on (HIGH is the voltage level)

delay(500); // wait for a second

digitalWrite(4, LOW); // turn the LED on (HIGH is the voltage level)

delay(500); // wait for a second

}

The code used this week is based on turning on a triple colored RGB LED. So above codes tell the LED to turn on and turn of after half a second (the delay), after that the same for the second and the third LED.

Problems¶

The LED didn’t get enough power, so only the green light lit. The blue and red light gave a tiny spec of light.