1. Principles and practices¶

Assignment

Plan and sketch a potential final project

| Documentation |

|---|

| 1. |

This week I worked on defining my final project idea. I’ve started getting used to the documentation process and I rommed around to see what’s available in the lab.

1.1 First Sketch of my final project¶

Context¶

At Icam we are implementing a new way of becoming an engineer. It’s a distributed program focused on a problem based learning pedagogy. The students work every year on a project and study it part after part.

We are currently running the first year and we are planning for the second and third one. The project for these years is going to be an autonomous boat. I’ll make my own version of the boat as a prototype, the students and staff can work with.

First idea of the project¶

To this date, the team in charge of the program has just started to define the pedagogical inputs for the boat.

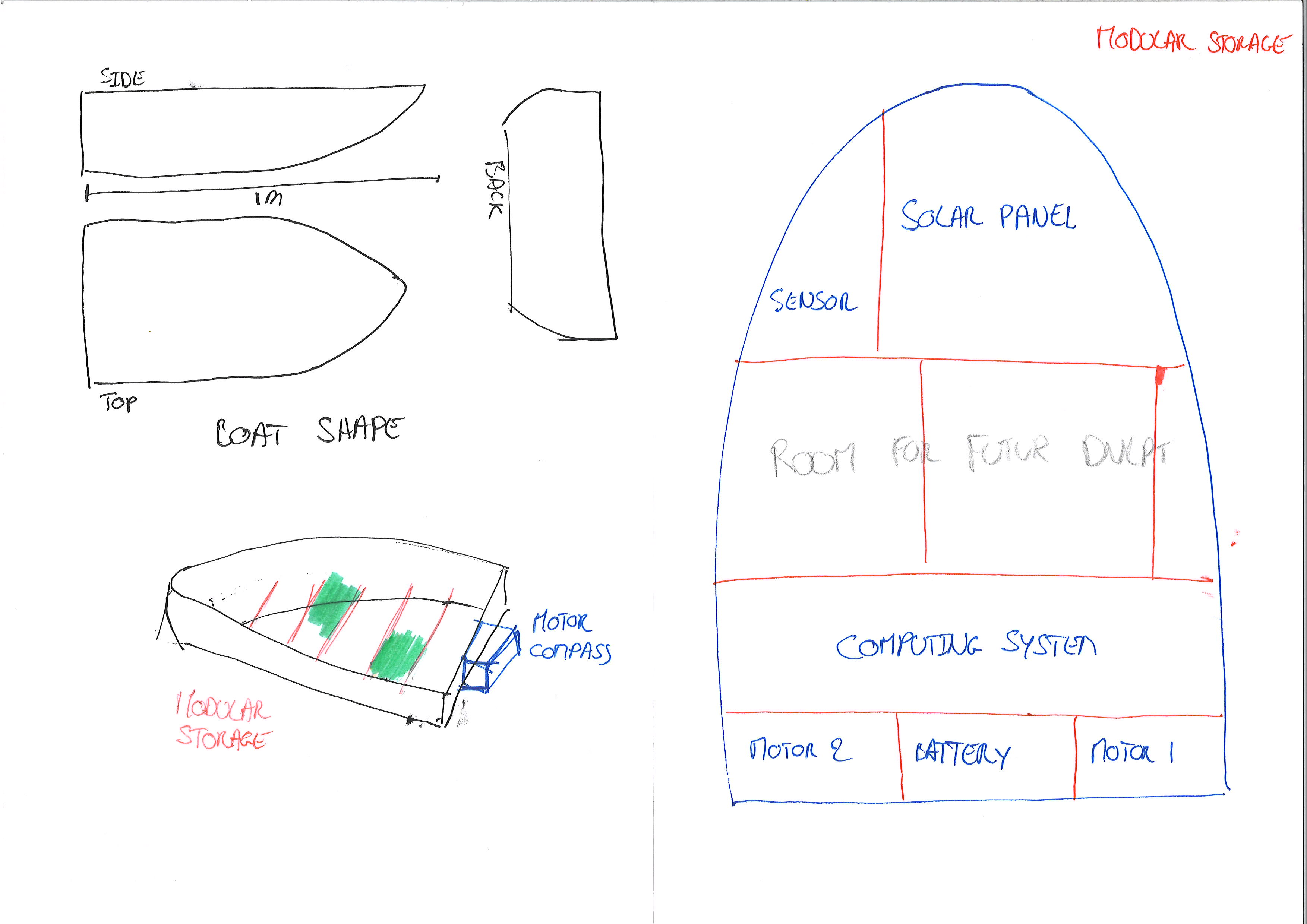

Here are some of the constraints :

- It must have an electrical management system

- The boat will have lots of sensors in it to monitor the boat as well as check its environment

- The motor will be controlled with a compass and two motors

- The boat must get some of its energy from its environnement (solar pannel)

- The communication protocole is yet to be defined

- The shape of the boat is free

I would like my boat to look like a small boat that could be hybrid and become a sailing boat. I’ll not make a full scale boat but rather something big enough to put all the different systems in it and still have some room for modification.

Here is a first sketch for the boat :

Note : It’s better to scan hand writting documents than to take photos of it.

In adittion of all that I have lots of freedom to make the boat the way I want. I would like to add some characteristic to it. We will see during the project what ideas I’ll have.

I still have some questions about key factors :

- How to make it waterproof ?

- How to protect all the electrical components to still make a reliable project ?

- How to design the boat as I’m not a naval engineer ?

Possible technologies involve¶

I can use a variety of technologies for this project :

-

Electronics

- Any Opensource platform

- Own design PCB with microcontrollers and sensors

-

CAD modeling

- 3D Modeling using Fusion 360

- 2D modeling using Autocad or Inkscape

-

Communication

- Wifi module

- Bluetooth module

- Lora module

- Radio frequency module

-

User interface

- To be defined

Possible processes involve¶

I can use a variety of technologies to make this project :

- CNC Milling to make the shape of the boat

- Laser cutting to make the modular storage and the cover of the storage

- Casting and moulding to make modular base for the different components

- 3D printing the different cases to protect the electronics components

- Thermo forming and/or vaccum forming for the base of the boat

- Everything else I can experiment in the Fablab

Possible materials involve¶

I can use a variety of materials for this project

- Wood for the boat

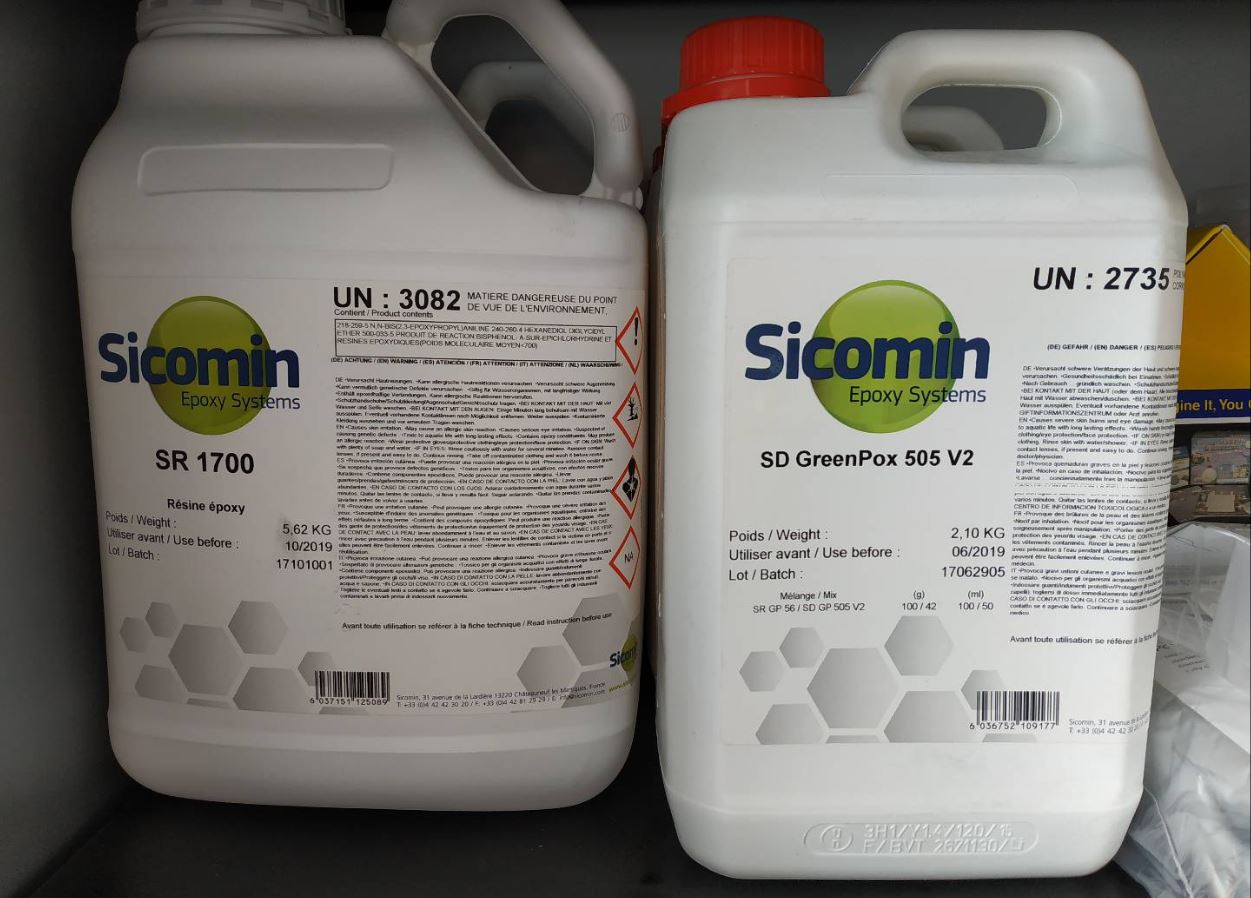

- Resine and composite to make it waterproof

- PLA (or other 3D printable material) for 3D printed parts

- PCB board and components

1.2 The possibilities in the digiscope fablab¶

Available machines¶

We do have lots of possibilities already in the lab.

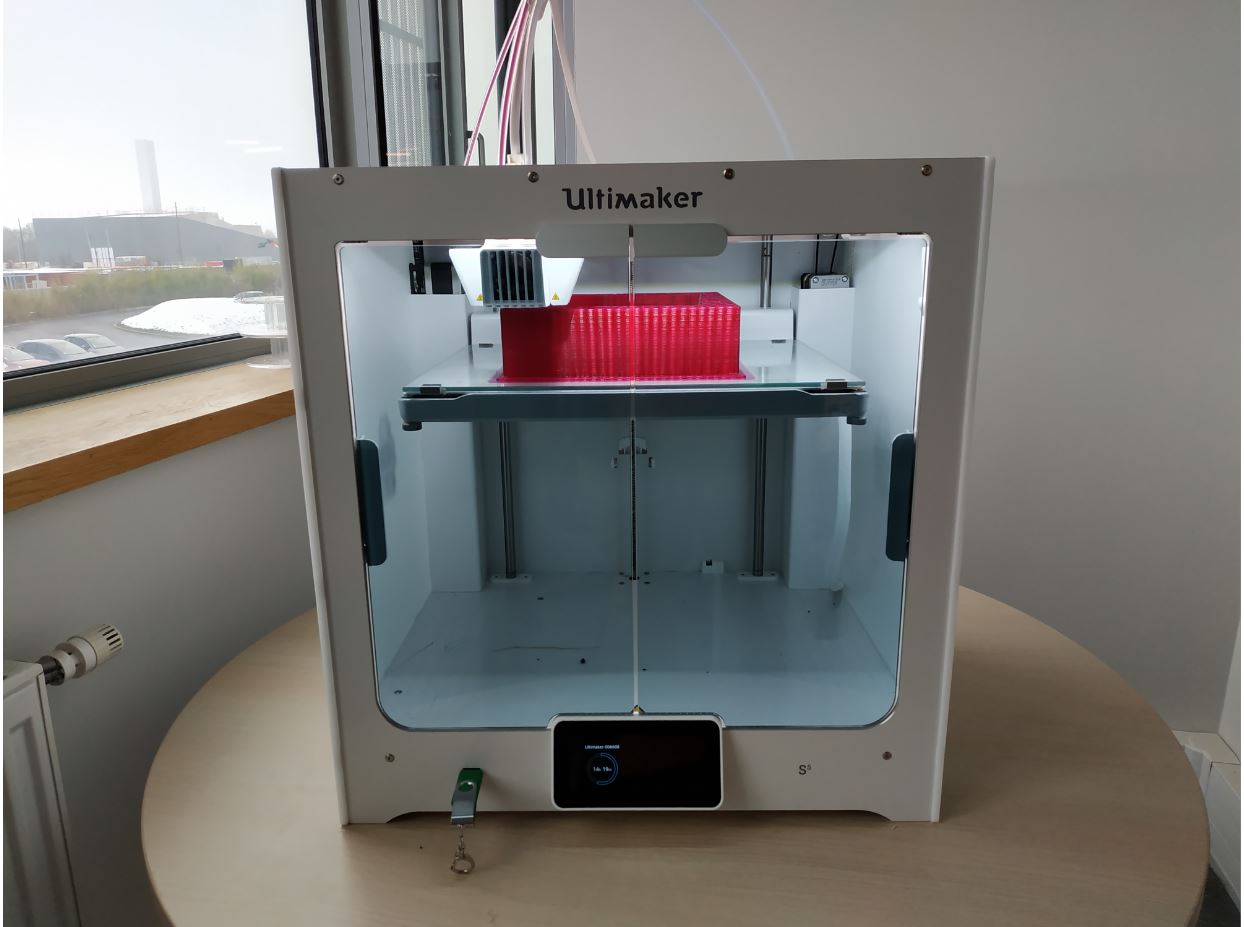

- FDM 3D printers

1. Ultimaker 3 - Build volume 215 x 215 x 200 mm - Dual extrusion 2. Ultimaker 3 Extended - Build volume 197 x 215 x 300 mm - Dual extrusion 3. Ultimaker S5 - Build volume 330 x 240 x 300 mm - Dual extrusion

- SLA 3D printers

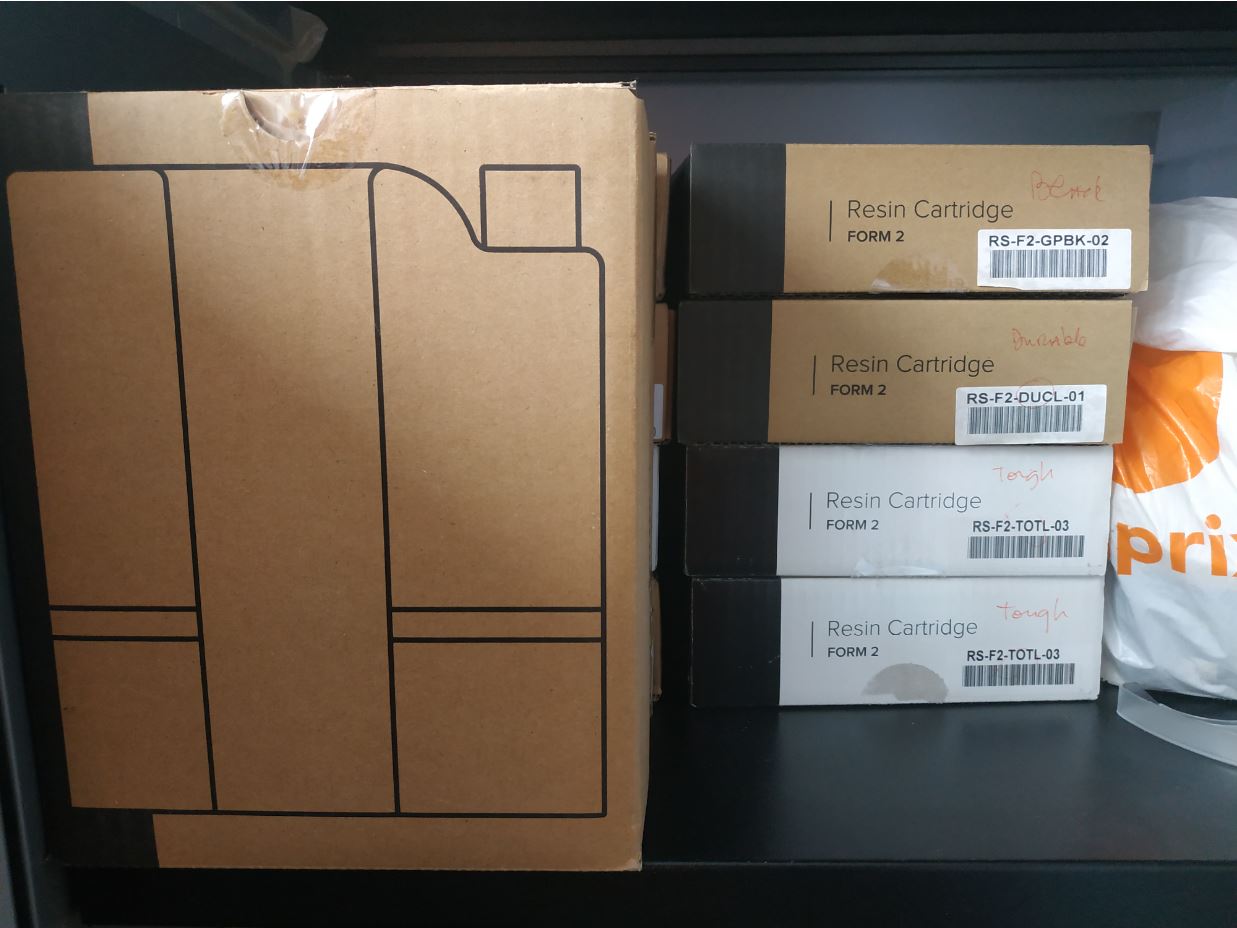

1. Formlabs form2 - Build volume 145 × 145 × 175 mm 2. Cure station 3. Wash station

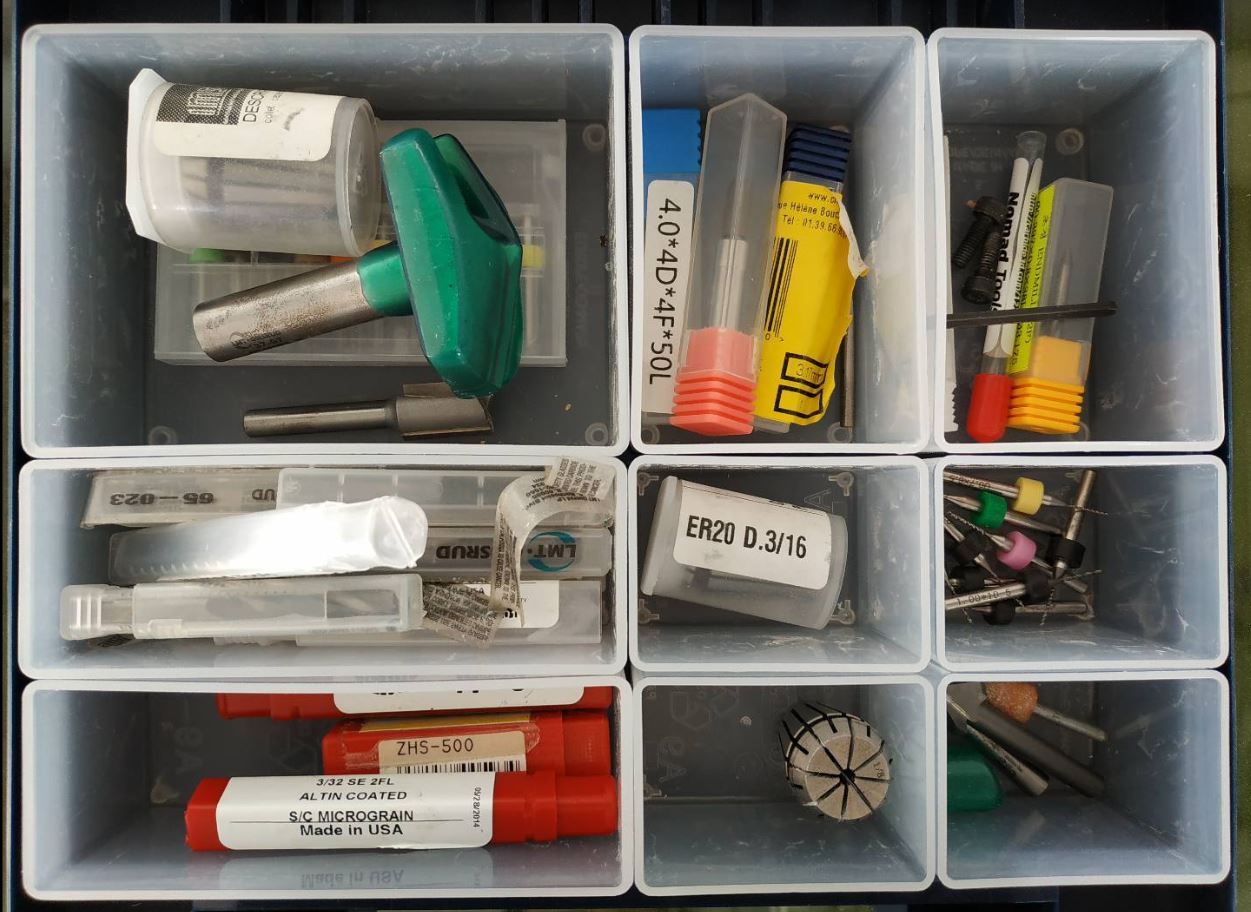

- CNC milling machine

1. Shopbot desktop - Build volume 600 x 450 x 40 mm 2. Roland ModelA MDX40A (for PCB) - Bed size 300 x 300 mm

Many tools are available to mill and engrave

- Laser cutter

1. Epilog mini 40W - Laser source : C02 - Bed size 600 x 300 mm 2. Epilog fusion M2 - Laser source : Fiber and C02 - Bed size : 1000 x 700 mm

- Vaccum former machine

1. Mayku FormBox

Everything else I haven’t seen yet in the lab.

Available materials¶

We do have lots of possibilities already in the lab.

For the Shopbot :

- Wax

- Beech wood - 40mm thick - 30mm thick - 20mm thick

- Blue foam - 50mm thick - 80mm thick

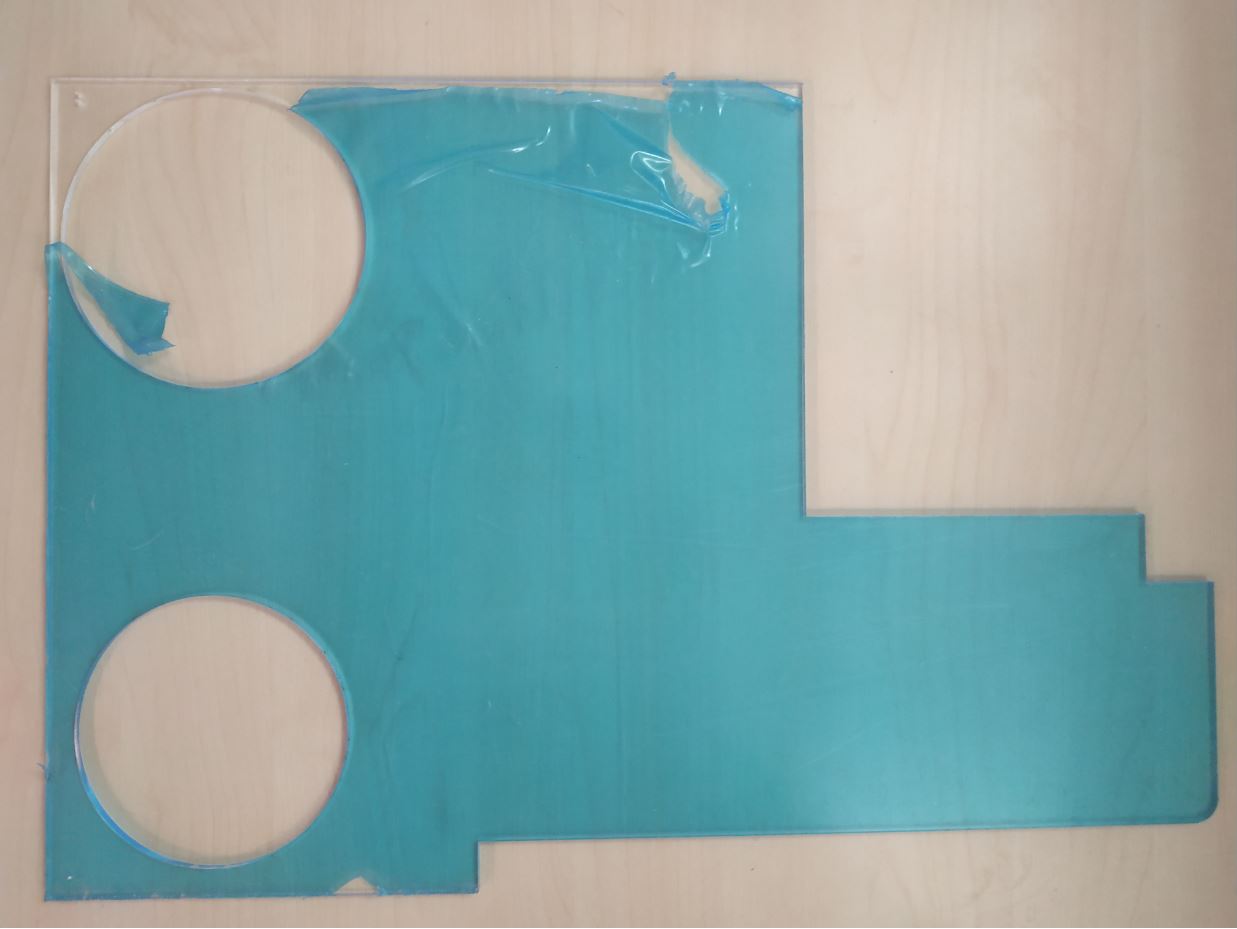

For the laser cutter :

- Beech Wood - 5mm thick - 10mm thick

Acrylic

Cardboard and any other material we can put in a laser cutter

For the 3D printers :

All type of spool material we can put in an Ultimaker FDM printer

All type of resin material we can put in a Formlab SLA printer

Epoxy material for casting and moulding :

Everything else I haven’t seen yet in the lab.

Ce(tte) œuvre est mise à disposition selon les termes de la Licence Creative Commons Attribution - Pas d’Utilisation Commerciale - Partage dans les Mêmes Conditions 4.0 International.