Week 4 - Computer Controlled Cutting

Assignment

group assignment:

- characterize your lasercutter, making test part(s) that vary cutting settings and dimensions

individual assignment:

- cut something on the vinylcutter

- design, lasercut, and document a parametric press-fit construction kit,

accounting for the lasercutter kerf, which can be assembled in multiple ways

Week 3 plans

Investigatge screen printing with laser cutter hole mechanism Half toning - with lights - without lights

Construction kits - parametric

- Box with compartments - parameters : width x height x depth x number of columns x number of rows x thickness of material x open depth ratio

- Kerfball document from last year - add git book page on kerf and how to avoid/account

- Multiple jointing methods - clipping tabs

- Basic paper craft model press fit joints

- Fusion & Dynamo - Parameters

Links (Thoughts for This Week)

Individual Assignment

Laser Cut Construction Kit

I had many ideas this week concerning a construction kit, and had to really struggle over the parameters which seemed to me to remove the potential for creating something truly useful such as a box set or a desk tidy type thing.

I always kept coming up agains the requirement that the kit be assemblable in multiple ways.

I initially wanted to make a construction kit for making a pen holder desk tidy, with parameters for number of holes, height, width, etc.. Although without just simply having mirrored parts which could be assembled in multiple ways, but that seemed like a cop out.

I then started thinking about half tone images and light. Which got me thinking about Zoetrope animations, so I started thinking and drawing out images to explore whether creating a Zoetrope was possible.

Zoetrope

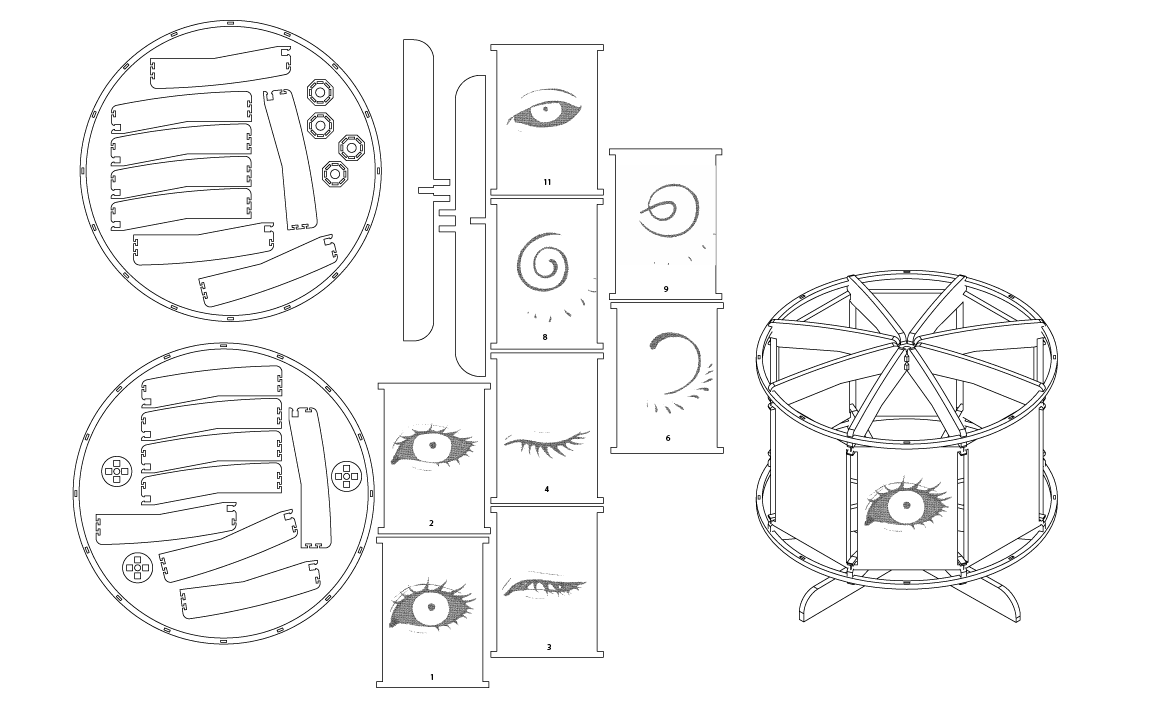

Above is a link to the Zoetrope documentation page, the parts are within the image below in pdf form - the default material is 3mm thick.

Here is the final render of the CAD model for this Zoetrope.

Plant Pot

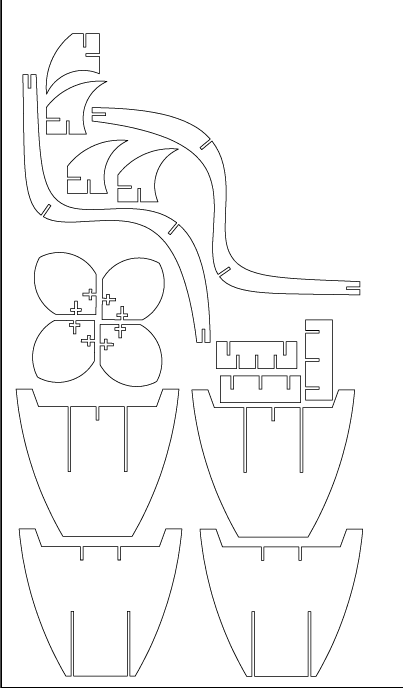

Above is a link to the 'Plantpot' construction kit. The basic idea is that the hole in the centre could be resized to fit different sized pots - this is designed to be a more aesthetic frame to an unappealing pot.

As a photographer I really like the fine camera controls within Solidworks to do with the lens and focal depth.

Here is a link to the parts - this is an adobe illustrator file

This is the constructed 'pot'

some further images

Group Assignment - Kerf

Here is some documentation of the group project for this week involving the characterisation of the equipment with regards to the laser kerf. This is for the purpose of having better slot joints and part fittings.

This is my Kerf calculation using parts cut by Michael