Assignment 17_wildcard week

01 bioplastics & textiles

For this week I decided to work with bioplastic textiles. Both are topics that interest me a lot, and I have developed projects related to these.

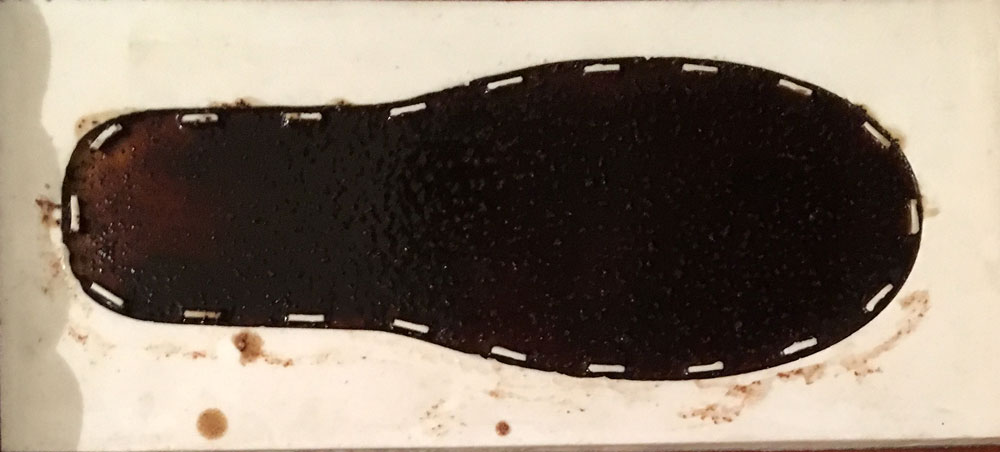

I decided to try a different way to develop a bioplastic for a shoe that I design a few years ago for an Open Textile's workshop when we start that project.

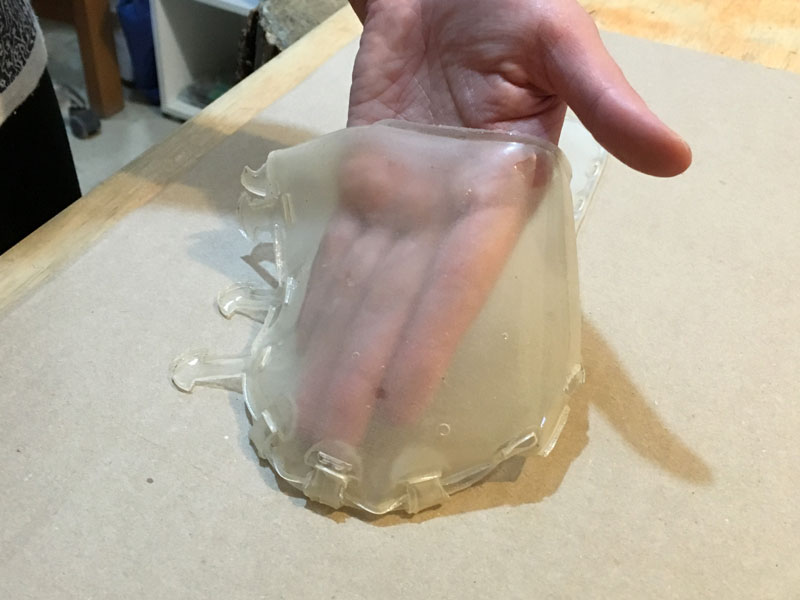

The shoe is composed of a sole and an upper cover that is joined to the sole by assemblies. The idea of the shoe was to be able to use any textile or sponge to cut it in the laser cutter and obtain a shoe.

Ther's two ways I know to create the sole and cover with bioplastic:

- Create silicone moulds for the specific shape of the design and pour the bioplastic into the mould.

- Create a bioplastic sheet/textile and cut it on the laser cutter.

This week I will try first one because is the one I had never done.

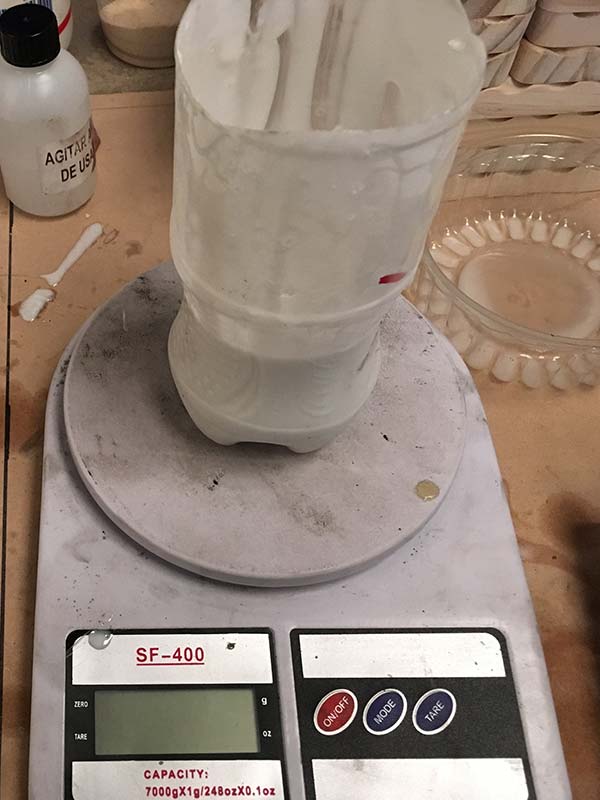

The materials I am going to use are:

- Glycerine

- Unflavored jelly

- Water

- Granulated cork (made from scraps).

The idea is to explore the possibility of re-using the scraps of the cork of the products that are made in the Fab Lab.

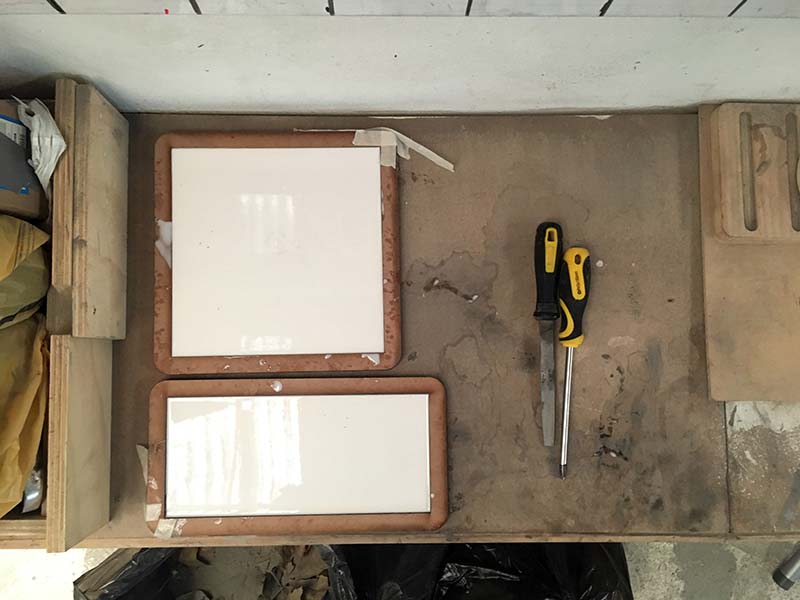

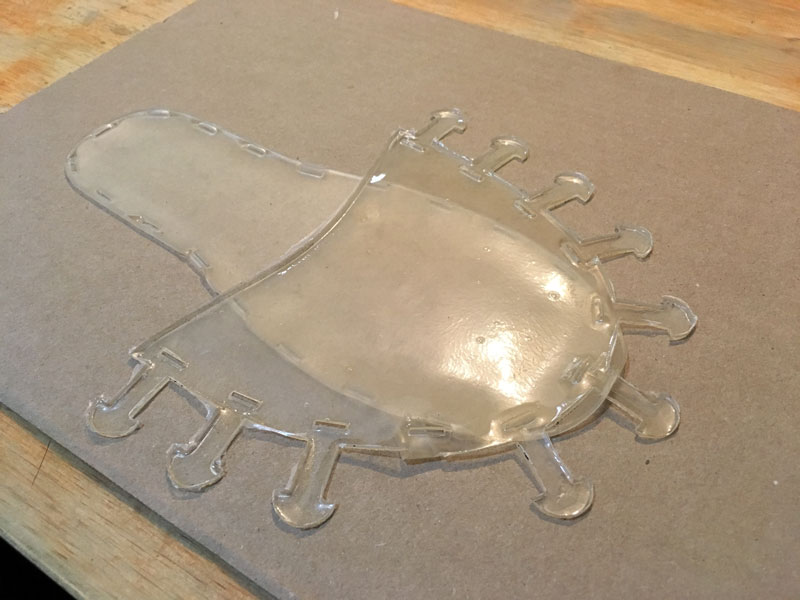

I first made the moulds for the sole and cover in 3mm MDF, and press the parts.

Then, I use the silicone to cast the mould (the one I use for Molding and Casting Week). This silicone is ready in four hours, so I cast the moulds in the morning and in the afternoon I check the mould and went pretty well.

Test 1

Recipe:

- 240 ml Water

- 40 ml Unflavored gelatin

- 15 ml Glycerin

- 1/2 cup Granulated cork (made from scraps).

I gathered and stirred everything until it boiled. Then I poured it into the mould. I cast the bioplastic on Friday at 9.30 PM. Now it is cold so it should take three to four days to be ready, so I left it curdling during the weekend.

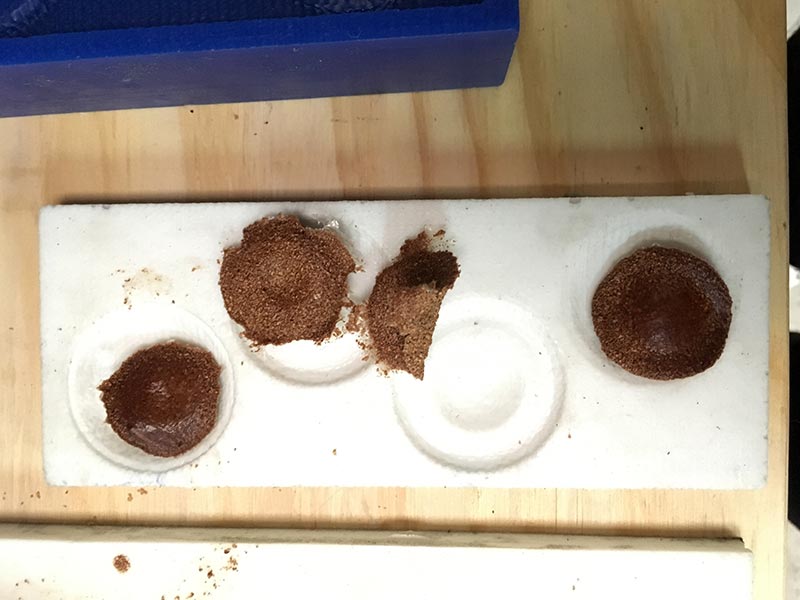

Results Test 1

I come back Monday at 10.00 AM and this were the results: The material was curved and out of the moulds. I curved the material and offered some resistance, but allowed it to curve. The texture was slightly granular, but more "plastic" than an industrial cork sheet.

Test 2

Recipe:

- 240 ml Water

- 40 ml Unflavored gelatin

- 15 ml Glycerin

- 1/8 cup Coffee

Again, I gathered and stirred everything until it boiled. Then I poured it into the mould.

Results Test 2

Test 3

Recipe:

- 320ml Water

- 50 ml Vinegar

- 75 ml Cornstarch

- 25 ml Glycerin

- 1 cup Coffee

For third time, I gathered and stirred everything until it boiled less the coffee. I add the coffe once the mix was transparent. Then I poured it into the mould.

Results Test 3

Test 4 | Back to Basics

Recipe:

- 200 ml Water

- 20 ml Unflavored gelatin

- 20 ml Glycerin

In this test, I decided to simplify the recipe and just use the essential to make the bioplastic: Glycerin, jelly without flavour & water.

Results Test 4

Shoes

Este obra está bajo una licencia de Creative Commons Reconocimiento-NoComercial-CompartirIgual 4.0 Internacional.