Assignment 01_principle & practices

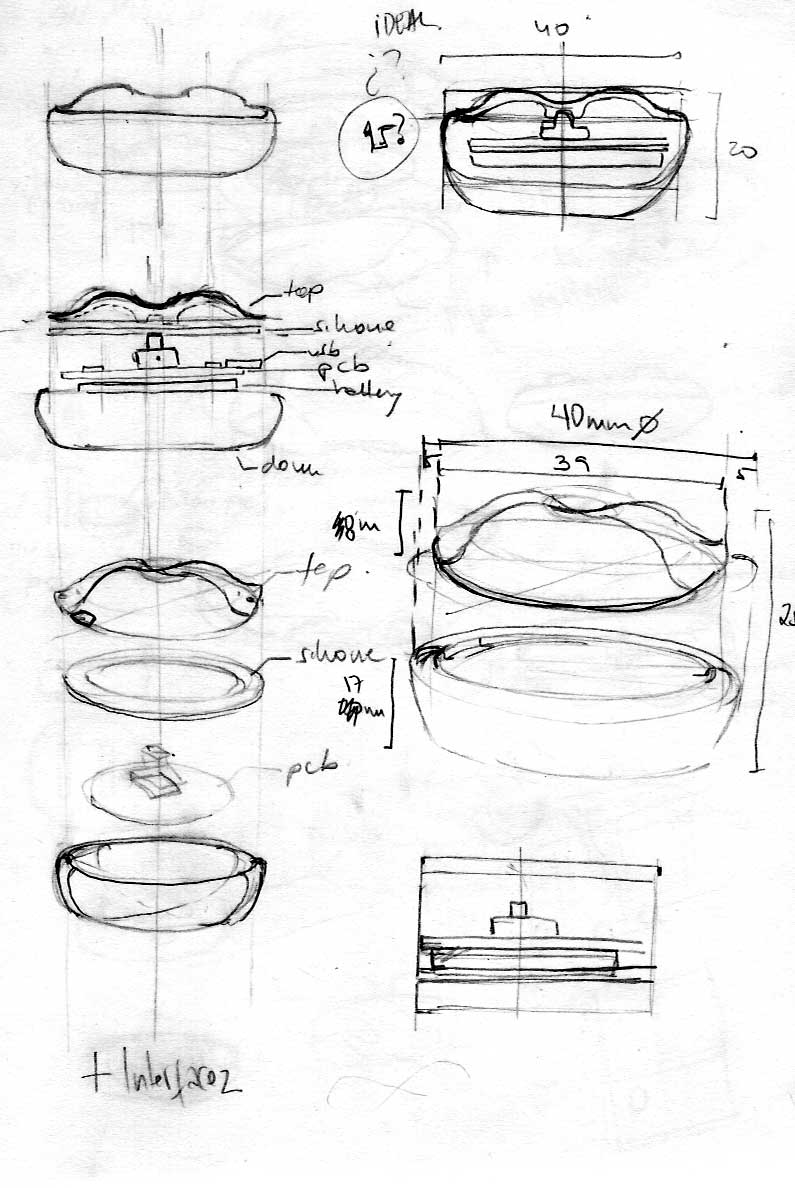

First idea for final project

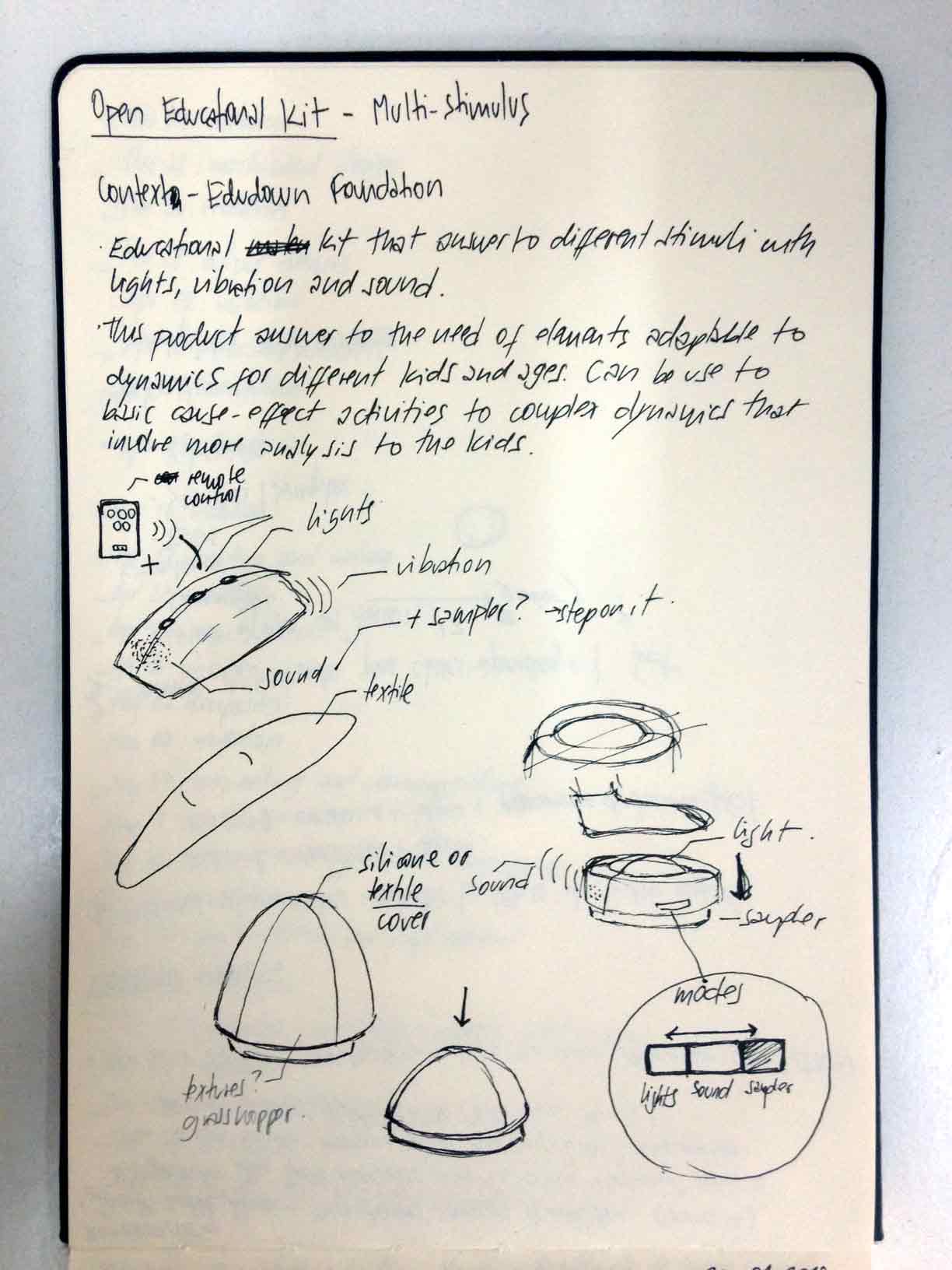

Multi-Stimulus

Thinking about my final project I decided to continue with a project that started last year. Last year, in Fab Lab Santiago, we work with Edudown Foundation, a non-profit corporation that attends children and young people with Down syndrome.

We develop with them inclusive educational material at low cost in the fab lab. The project is now paused looking for ways to continue financing it, so the projects stayed in beta.

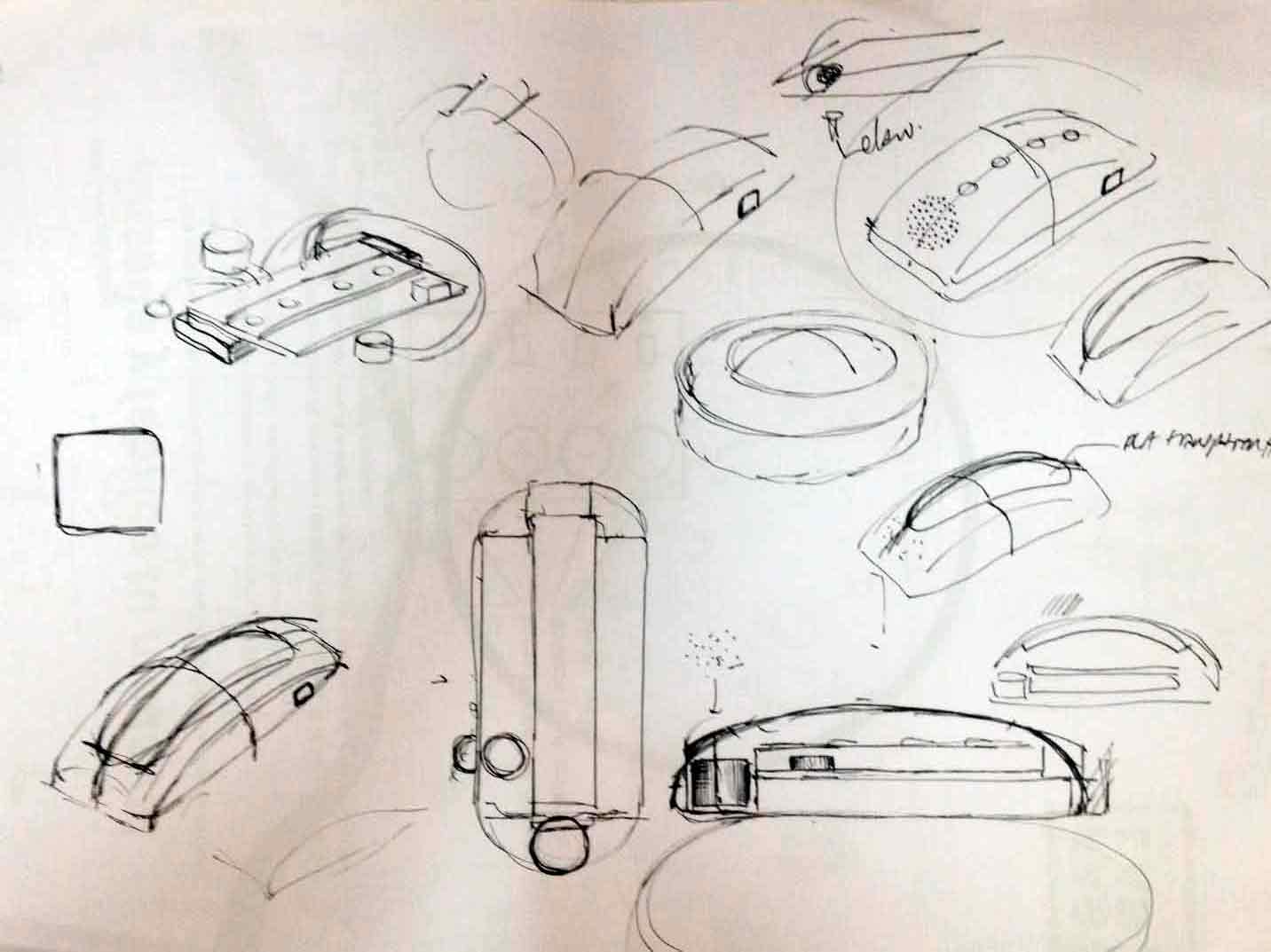

My idea is using FabAcademy to continue developing the project, specifically the "Multi-stimulus Kit" (still working on a name). The idea of this object was to respond to different stimulus with lights, vibration and music. The product answer to the need for elements adaptable to dynamics for different kids and ages. Can be used for basic cause-effect activities or for complex dynamics that involve more analysis to the kids.

Is an object that can be used to a lot of activities with children, not just in Edudown Foundation.

In the first kit I work with an engineer that fabricate the electronic, but for this, I want to learn how to do it and redesign the actual electronics.

The first kit includes a remote control that the teacher can use and but for the second version, I want to fabricated self-sufficient. In addition to improving the interface and explore the possibilities of transforming it into a wearable.

EDUCATIONAL CNC MACHINE

Finally, the week of mechanical and machine design, I decided to change my project to the Educational CNC Machine ( I project, I also had developed previously). This decision answer to seize the assignments of machine design and networking for the Educational CNC Machine. Also, I want to use this project in workshops with kids in winter camp (Fab Lab Santiago's project), so I need it to develop this device.

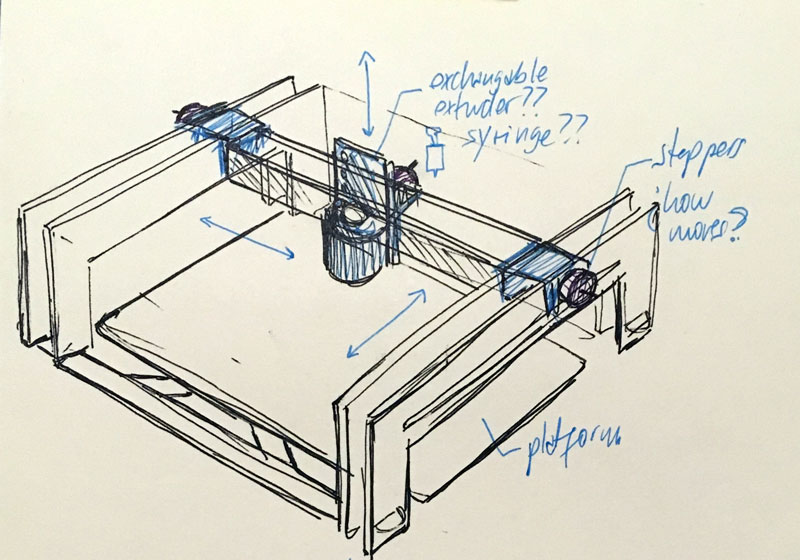

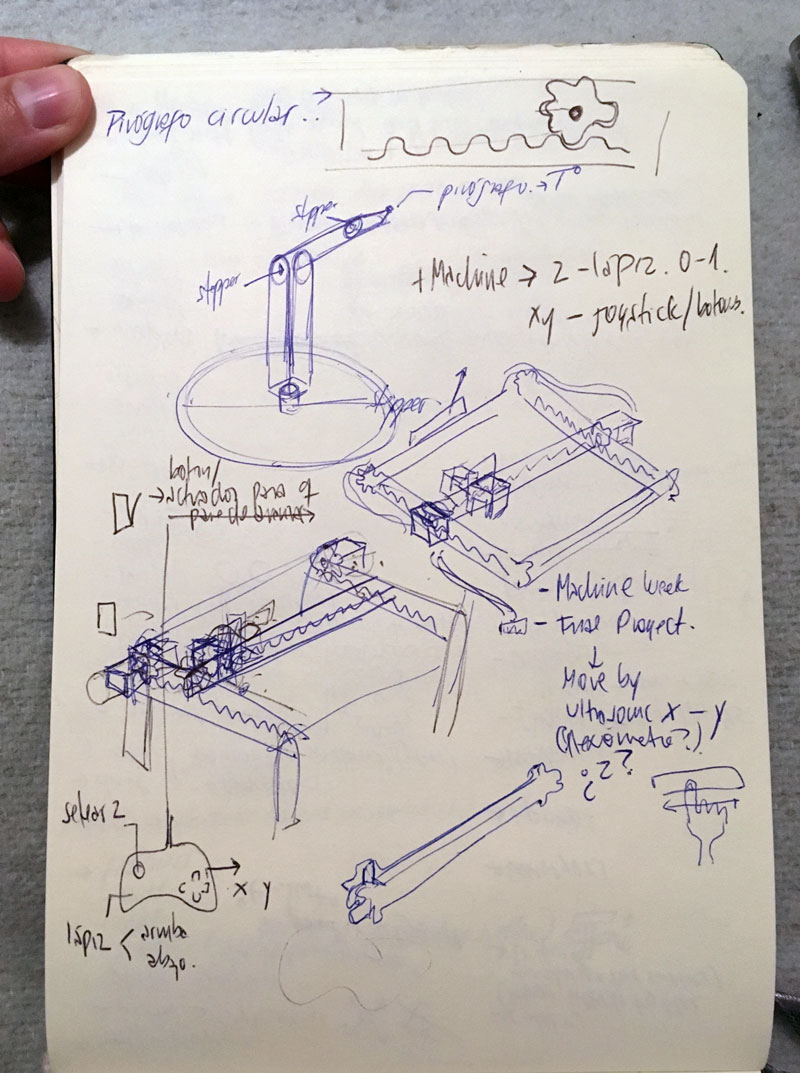

Draft of Educational CNC Machine for final project

Pre-development no-digital machine

The idea of this machine born a few years ago from a necessity I observe in several workshops and talks of digital fabrication that I had done to kids. Where the kids were very excited about 3D printing, but just about printing anecdotic objects, like a case to the cellphone or little toys. I wanted they could understand that a CNC machine is a fantastic tool to fabricate whatever you want, not just plastic, you can use infinite materials, with different devices to make infinite solutions to necessities they had.

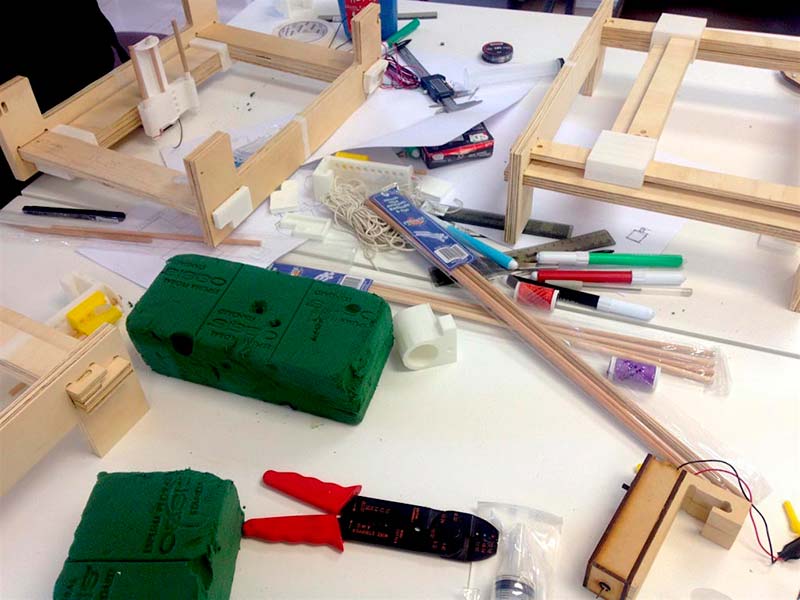

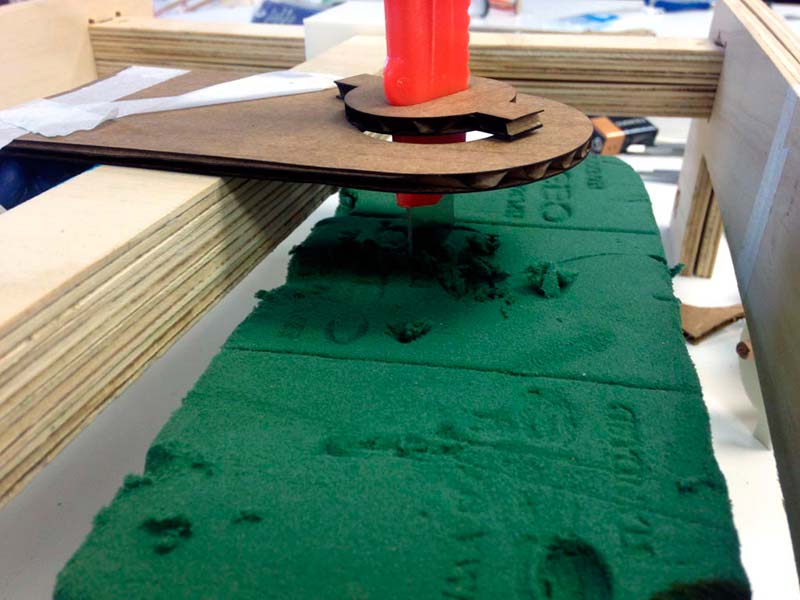

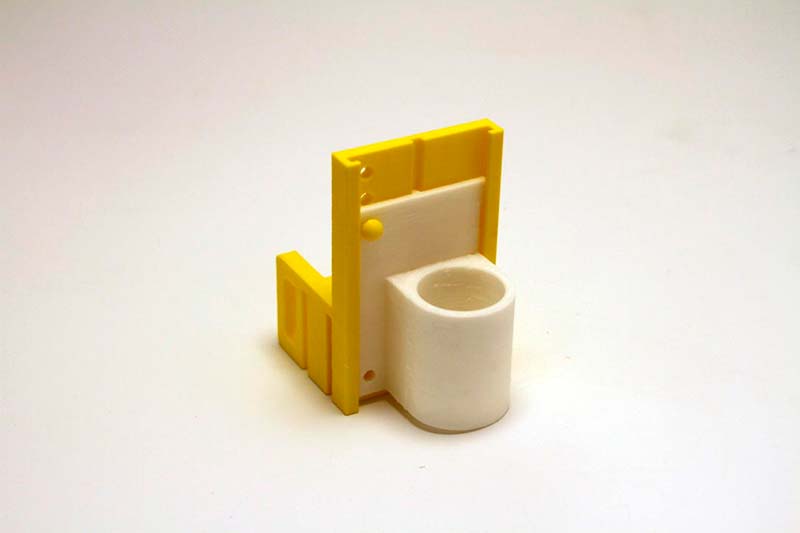

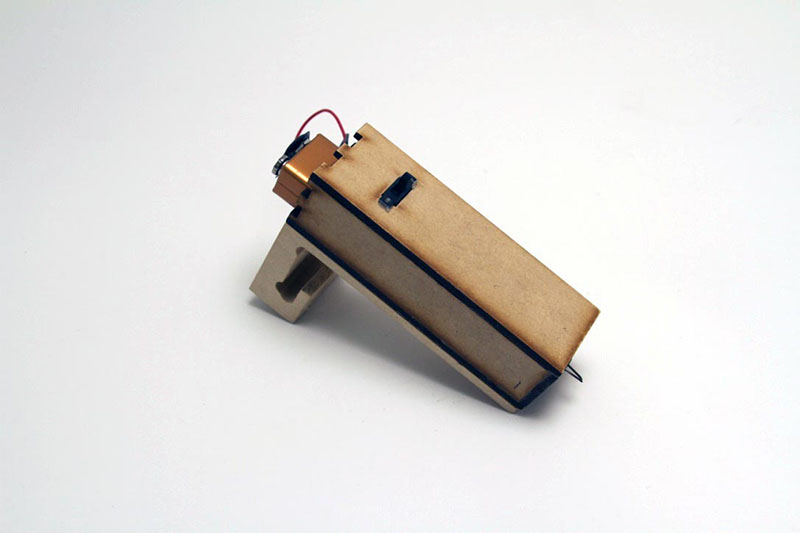

That why I developed a year ago, the abstraction of a CNC machine in just laser cut MDF that you can assemble and a 3D printed extruder where you can collect a syringe to extrude sand and glue.

These are some pictures of that workshop:

The kids could assemble the Tiny-CNC and understand how it works, and then they could understand the principles behind the desktop 3D printer that was working in the classroom.

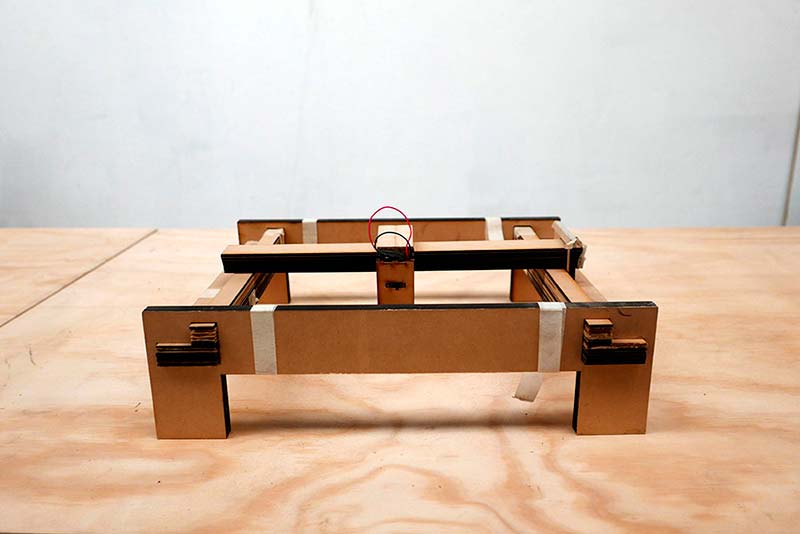

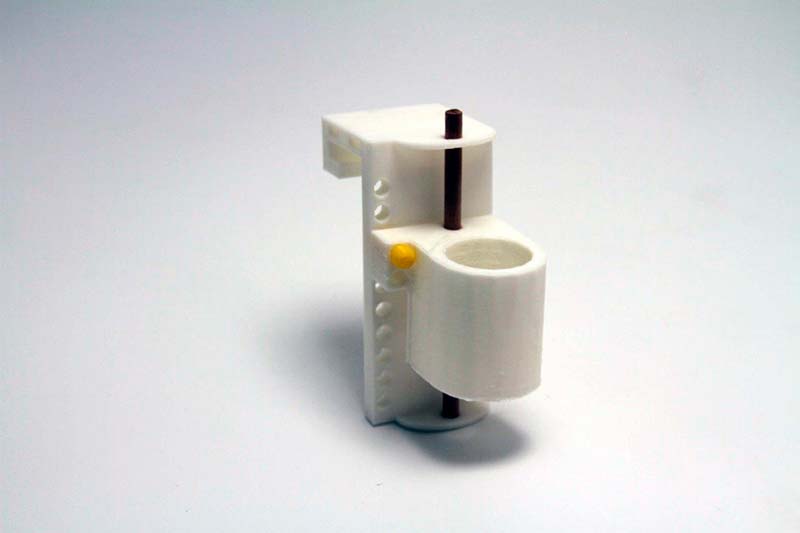

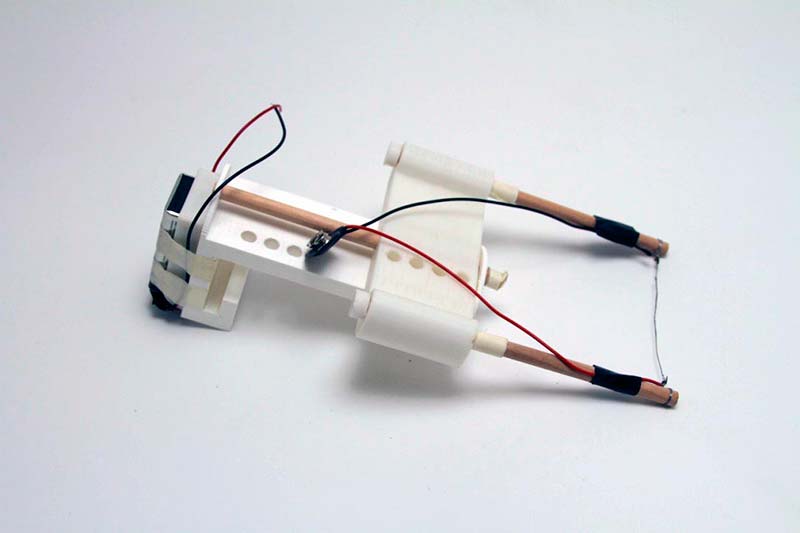

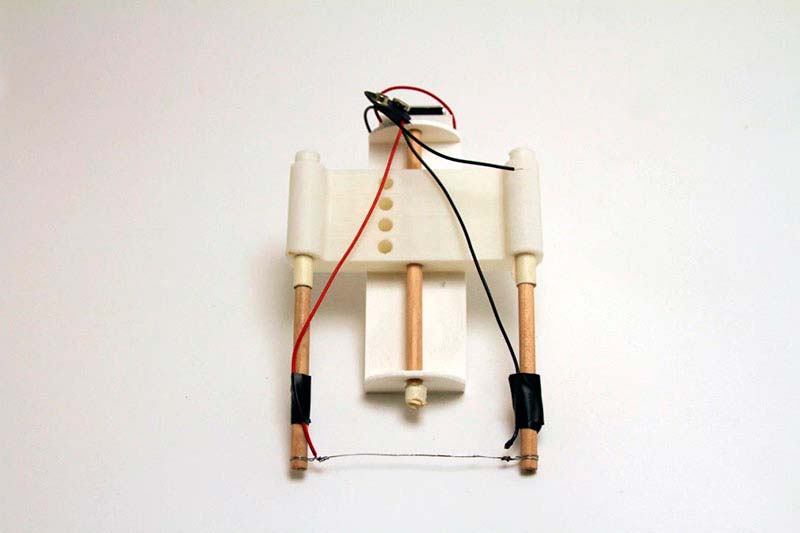

After that workshop, I continue developing the idea, increase the scale of the machine. My plan was developing different extruders that could be exchangeable depending on what you were working. Also, this aloud to the kids to experiment creating their extruder for the CNC machine. I give a workshop of this machines on Fab13, where all the participants could build their extruder for the devices.(images)

This is a timeline of the evolving of the project:

Timeline of the evolving of adhesion extruder:

Timeline of the evolving of adhesion extruder:

Wire cutter extruder:

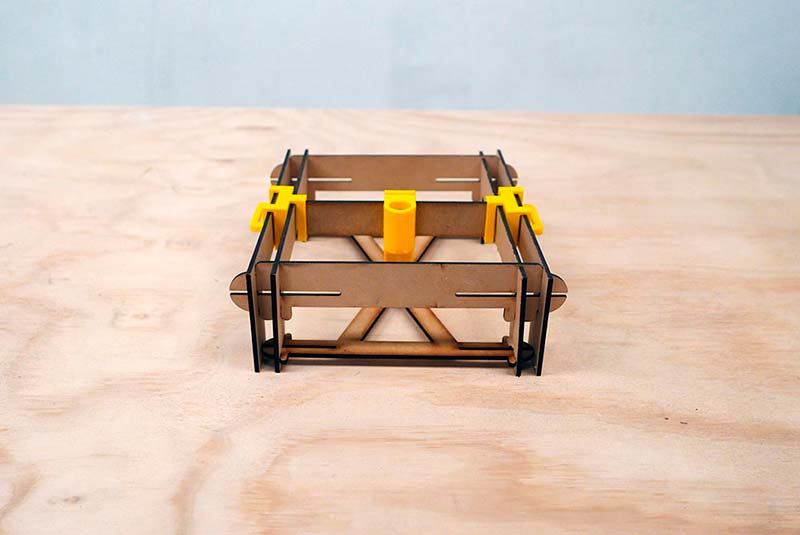

Last few months I had focused on developing a better way to assemble the machine, to make it easier to understand, more stable and more adaptable to future extruders.

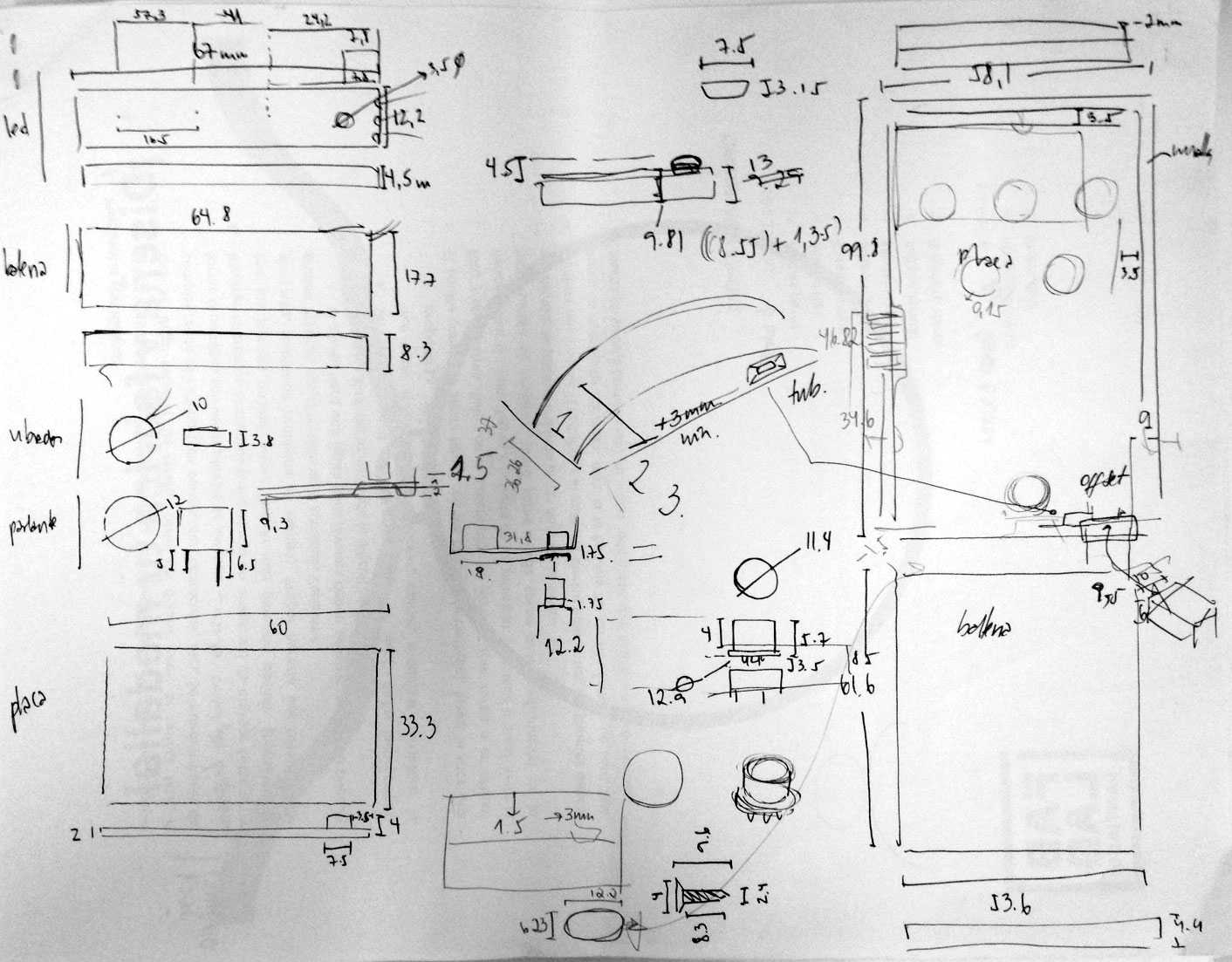

So, these are the details of the last version of the analogue machine:

Analogue Machine for Education from Pilar Bolumburu on Vimeo.

Educational CNC Machine

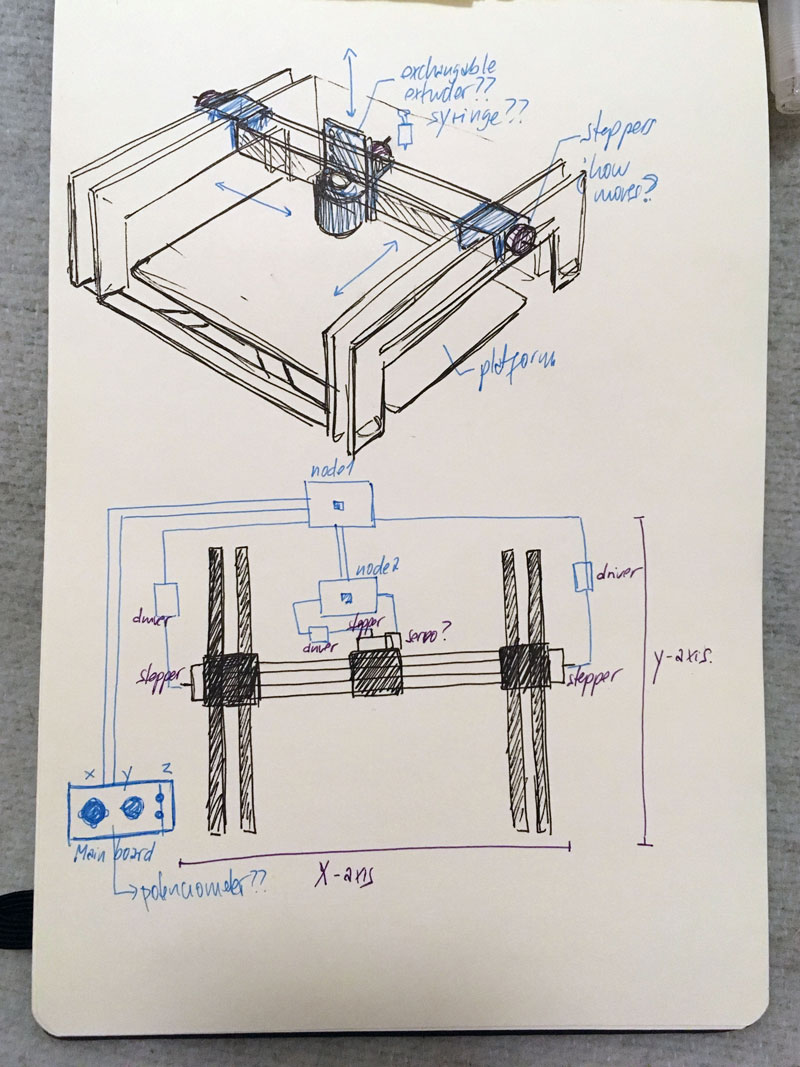

Even the no-digital machine project is meant to keep analogue; I decide to make 2.0 version. In this version, where you can hack the same machine to be controlled by steppers and aloud kids to manage and understand the machine even more.

First, I want the machine still be very cheap an easy to fabricate. So I try that most of the framework was on laser cut MDF, some pieces in 3D printing, and inputs/outputs devices.

The Educational CNC Machine will:

Educational goals:

- Evidences the logic of operation of the CNC technology.

- Children can easily understand how it works and how to handle the machine.

- Allows and facilitate the customization of the extruders.

Technical goals:

- Steppers controlled by buttons automatize the X and Y axis.

- Mini Servo controlled by button automatize the Z axis.

- The extruder is interchangeable.

- The machine is cheap and easy to fabricate.

Este obra está bajo una licencia de Creative Commons Reconocimiento-NoComercial-CompartirIgual 4.0 Internacional.