Week 17: Applications and Implications

Assignment for this week:

Propose a final project that integrates the range of units covered,

answering:

What will it do?

Who's done what beforehand?

What will you design?

What materials and components will be used?

Where will come from?

How much will they cost?

What parts and systems will be made?

What processes will be used?

What questions need to be answered?

How will it be evaluated?

Your project should incorporate:

2D and 3D design,

additive and subtractive fabrication processes,

electronics design and production,

microcontroller interfacing and programming,

system integration and packaging.

Where possible, you should make rather than buy

the parts of your project

Projects can be separate or joint, but need to show individual

mastery of the skills, and be independently operable

What will it do?

It will measure indoor air quality using sensors for Temperature, relative humidity and volatile organic compounds (VOC). It will give an output like light signal which should give the information about the state of the air quality. Nowing this, user should know when to open an close the window. This in winter esspecialy important to save heating energy.Who's done what beforehand?

There are many products available for measuring of indoor air quality: Netatmo, Foobot, Awair, .... None of them combine the indoor air quality with the topic of energy efficiency. Onother important point of my final procect is not considered by other products which is usability for elderly and disabled person. I would like to design a product which would signalize on many different ways if the air quality changes.Netatmo

Foobot

Awair

What will you design?

I will design airing assistant which tells us continuiously how is the indoor air quality. Using this information I can decide to open the window (door) and to do fast ventilation of the room air. When the air quality becomes well I become the information about it and can close the window (door) again. On this way I can save heating energy during the winter.What materials and components will be used?

Materials:ABS/PLA for 3D printing

Vacuum forming material

Vinyl cutting foil

Solder

Components:

Diferent Sensors (VOC, temperature, humidity, CO2, CO, Dust)

Copper coated epoxy

SMD electronics

Bluetooth module

Where will come from?

This question can not be answered as the sensors consists out of number of components and are produced in many different countries.How much will they cost?

The great part of the cost will be caused by the sonsors, which cann not be self made.Here you can find a list of the costs for different sensors I planed to install.

CO2-Sensor: CO2 sensor at amazon

Dust-Sensor: Dust sensor at amazon

VOC sensor:

CO sensor:

Temperature Sensor:

Humidity Sensor:

Vibration Motor:

Servo Motor:

LED:

Bluetooth module:

What parts and systems will be made?

I am going to design new PCB for the final project as the old one does not have enough pinns for all actors and sensors I would like to install.I am also going to make a cacing for the airing assistant and and inside ot this appropriate mesh for placing the sensors and actors in convinient way.

What processes will be used?

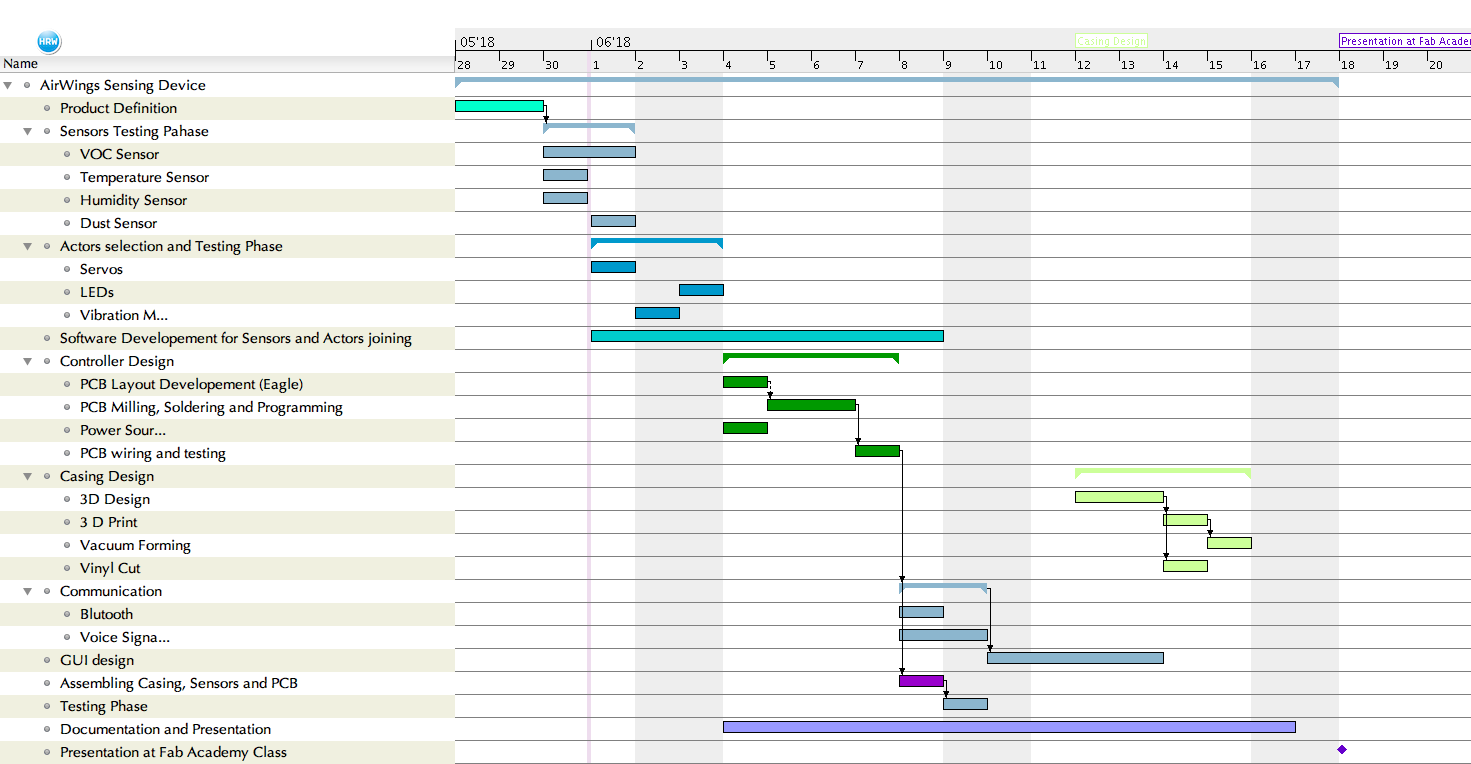

Airing assistant will consist out of diferent sensors (temperature, humidity, CO2, VOC and dust), PCB, powersupply, bluetoth communication device and casing. I am going to design PCB and 3d casing. This is the schedule I made for my final project using the free gantt software ganttproject.biz . It was easily to handle rather than some other big spreadsheet programm:

What questions need to be answered?

How good are the measured values of each sensor?What are the influence faktors on the measurement data?

Is there a influence of the housing on the measurement data?

Which housing material, form and pattern will be appropriate to ensure the best air circulation through the housing and so the right air flow through the sensors.

How cann I toggle all those sensors for measuring in the software without influencing each other?

Which position in the casing should have each of those sensors in order to avoid the influence to each other?

How high is the power consumption of all sensors? Which power socket will I need to install to supply all sensors sufficiently?

How will it be evaluated?

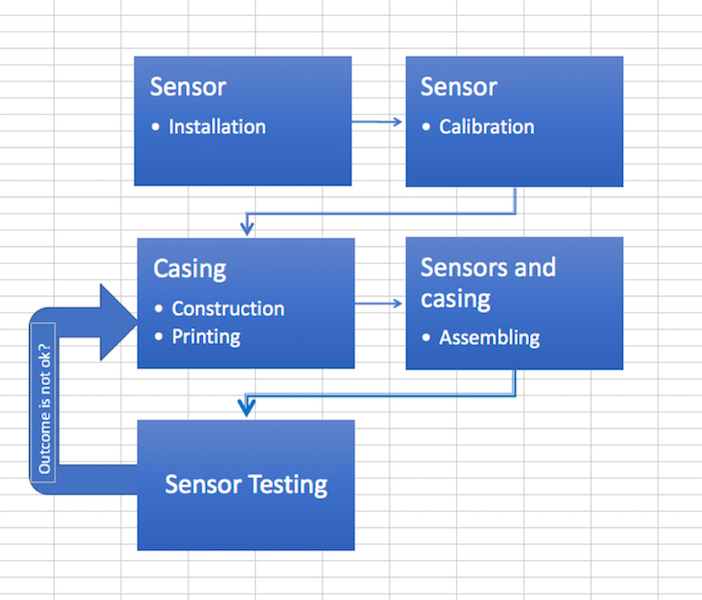

It will be needed to log the sensing data or to make them comparable on other ways with data of reinforced sensors. Air flow through the sensor casing has to be proofed in order to ensure fast raction of the sensor to the air quality changes.Loging data should be evaluated for measuring with and without casing.