Molding & casting

The assigment page

The goal of this week was to design a model for casting, mill the mould and use to cast your design.

⇝ 3D modelling in Fusion ⇝ Milling ⇝ Casting

High-Z S-720 CNC machine

For this assigment, I used another CNC machine. It's the old one (from 2012).

Some specs:

-Working aera: 720x420mmx110mm.

-Kress 1050W (10.000-30.000 rpm) spindle.

-Software: Galaad and DeskProto.

For more information, check wikimal page.

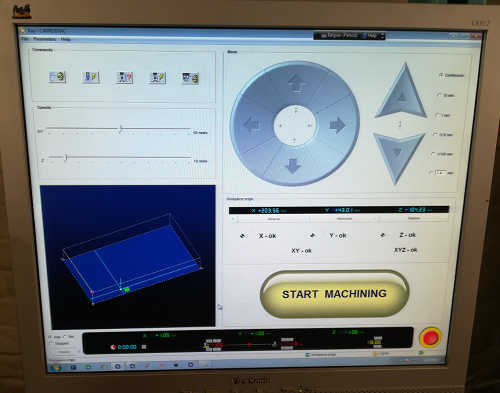

For controlling the machine, open Kay and switch on the controller. You can import Gcode and do the zero here:

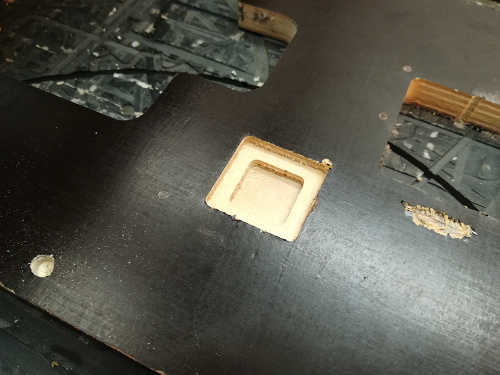

Before milling the wax, I've tried one 2d contour and one adaptive clearing on wood. And broke two bits...

One because I didn't turn on the spindle (the software told you if the spindle in on or off. I tell it that it was off and do nothing). The other one because the spindle speed was too low.

Here's the result:

Fusion360 CAM module

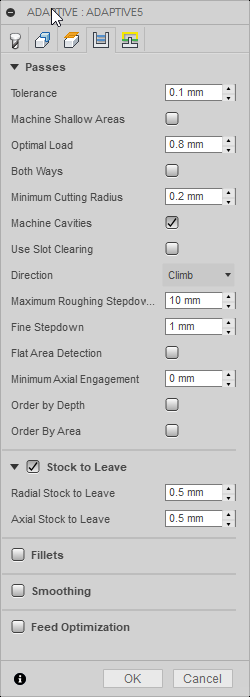

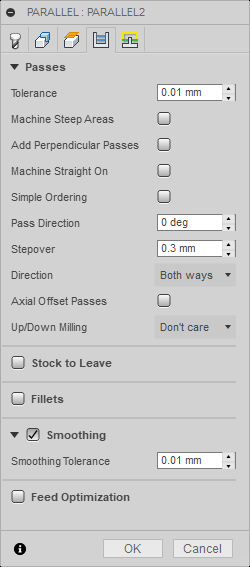

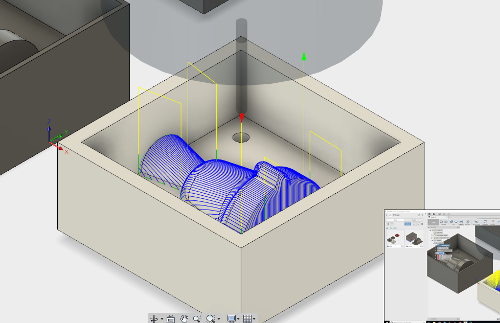

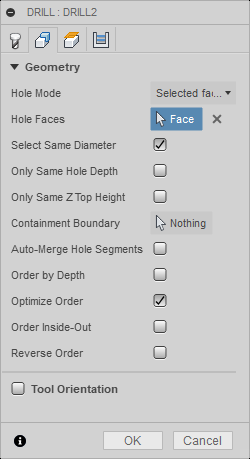

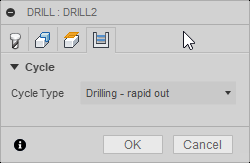

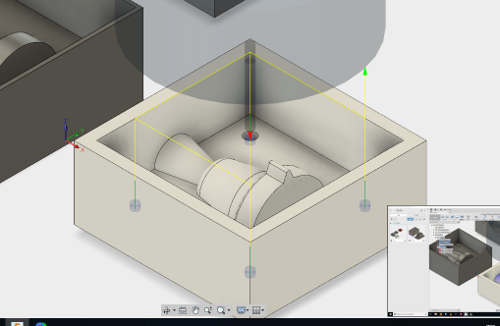

In the cam module I've setup three toolpathes. "Adaptive clearing" who's the equivalent of the rought job, "Parallel finishing" who's finishing the job and "Drill" for creating holes for the mould.

So I create a new setup, select the body, the stock point (More info here). After that, I create an Adaptive mill.

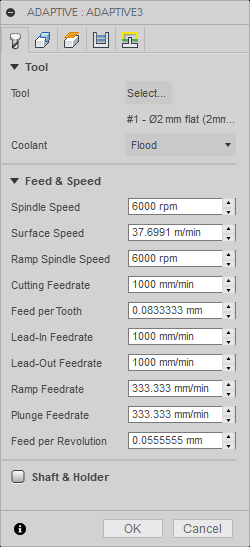

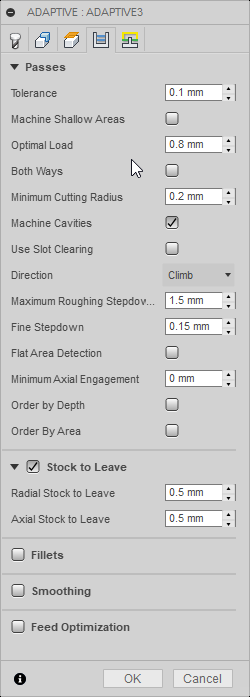

For the first test I use default settings:

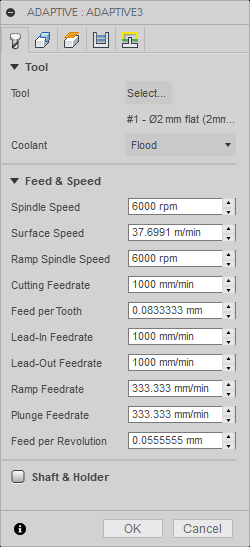

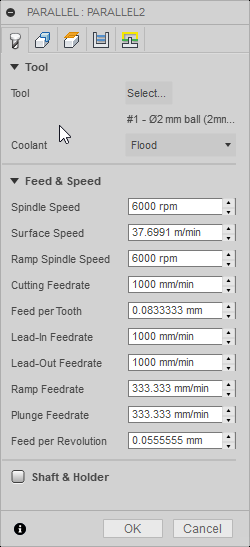

I just set the end mill, a 2mm flat one with a 6000 rpm spindle speed for avoiding wax to melt.

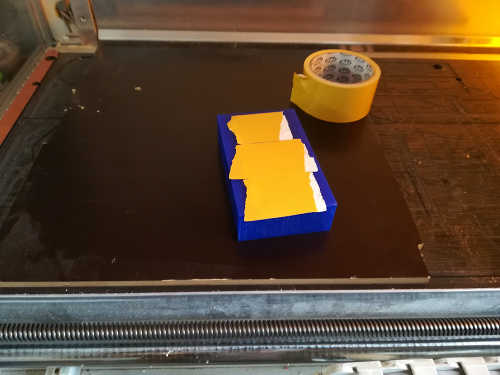

Ready for milling, I double-tape the wax, set the zero and start to mill:

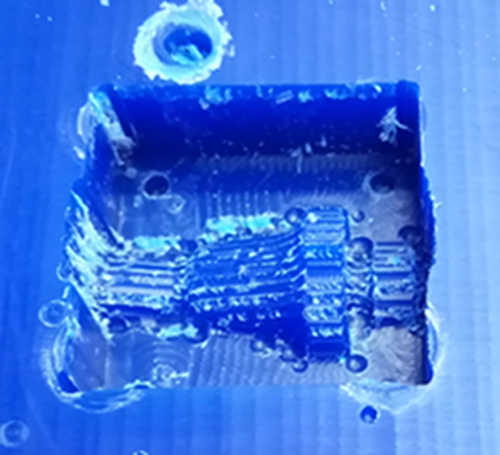

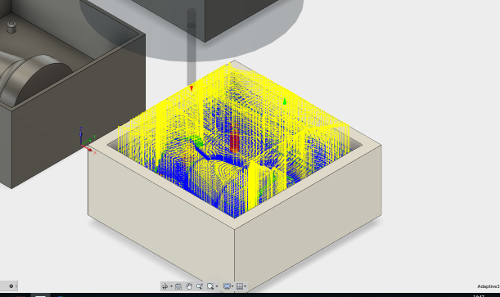

And the result is very very rought:

So I have to adjust a bit. First I used an 2mm end mill. I went in this lovely web page from a guy called David McCallum and steal his settings.

For adaptive (I used a flat end mill):

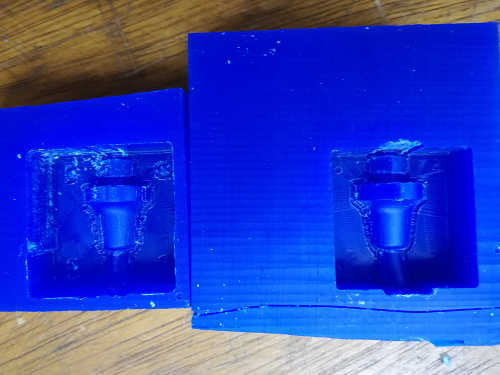

I try a second time and it's a lot better! But it still have stong path lines.

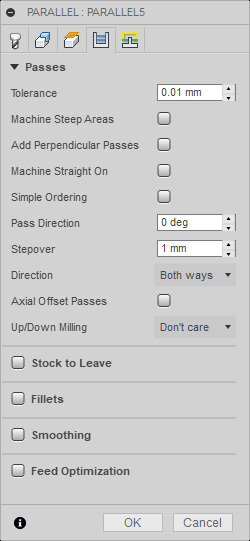

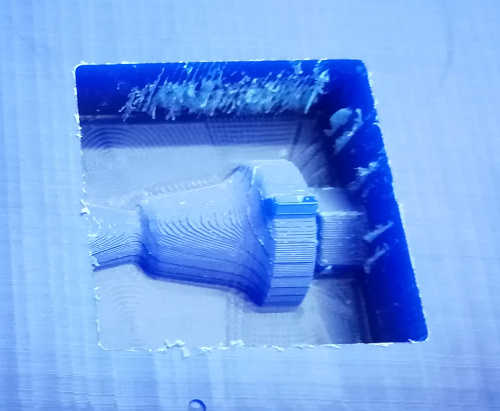

I clear a bit using parallel:

And I did holes using Drill:

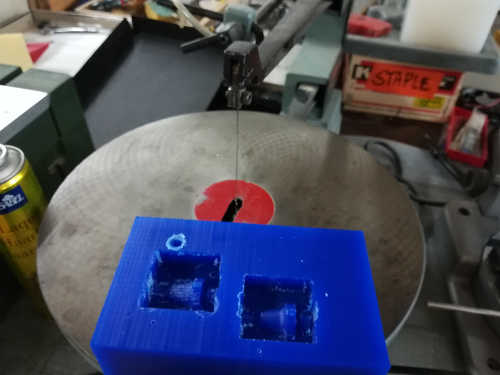

But now I don't have enough space for milling the second one... So I have to cut the wax in a half to mill in the other side.

I first tried with "la scie à chantourner", but the wax immediatly re-melt. So I cut it by hand with a saw.

And I mill the other one:

During the finishing, the end mill went a bit to far and did some holes around the edges...

It was difficult to 3D mill with this CNC and Fusion, it was also difficult because there's a lot of endmill, no infos on the purposes of each one and nobody to help.

It was kind of frustrating and I have to change it in the future.

So the result wasn't perfect but now I'm want to cast!