Mechanical Design

The assigment page

Design a machine and build the mechanical part that it can be operate manually.

I did a part of the work, CAM & Milling. You want the rest ? It's HERE.

I made a karaoke, baby.

Composed, played and sung by Xavier Klein. 2018.Last week,

A guy on the internet,

Asked us, to make a machine.

He told us,

to design a machine that includes mechanism+actuation+automation

He told us

to build the mechanical parts and operate it manually

He told us

to document the group project and your individual contribution

I waited for the files,

That Dima was making.

I went to Brico,

To buy two 12mm sheet.

1220X600mm baby

MDF ! The cheapest !

I'm making a Karaoke, Baby!

Finally, I went to my Fablab,

To cut the damn thing.

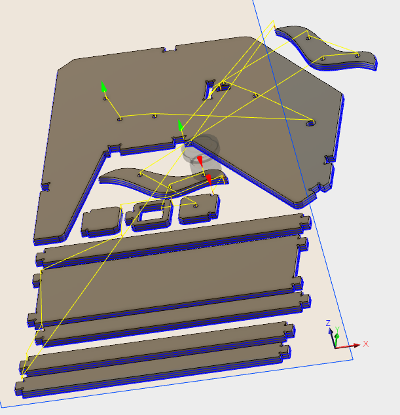

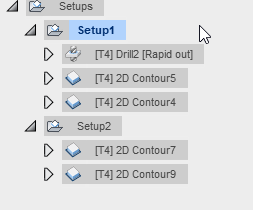

I prepared all the files,

Using Fusion360...

I made the nesting,

I divided into 2 files

2 setups, 2 sheets,

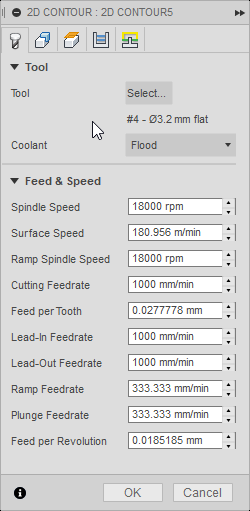

And using the 2d contours tool (I didn't use the drill).

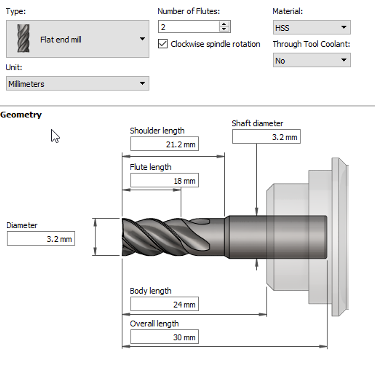

Cutting, with flat 3.2mm bit with 2 flutes

18000rpm spindle speed

1000 mm/min cutting feedrate speed

I'm making a Karaoke, Baby!

I used the machine as always

But I had some issues,

Someone change the bits.

The tool compensation,

was wrooooooooong !

In a machine with a tool changer, you have to set Tool compensation. Because you're making Z zero with the first tool.

When you're changing tool, depending of the end mill the bit lenght changes and so also the Z.

Too avoid this, before milling you have to trigger the T-Check command who will mesure each bit in order to compensate.

The machine ! Milled too far away!

It's took me 4 hours to solved!

Finally calling one of my collegue

He told me to check, tool compensation!

But finally, I made a Karaoke !

I bring back the machine to Amsterdam where we assemble it together.