Molding & casting

The assigment page

The goal of this week was to design a model for casting, mill the mould and use to cast your design.

⇝ 3D modelling in Fusion ⇝ Milling ⇝ Casting

For this assigment, I've struggled to find something interesting to make.

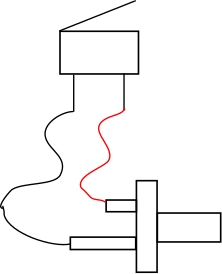

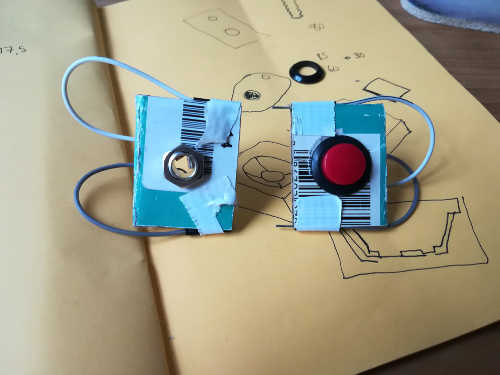

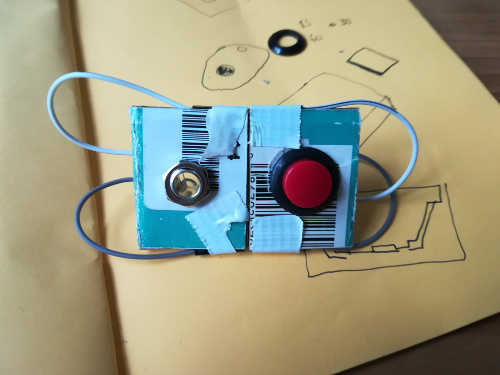

And I bought this rythmbox, an Alesis 16. It can be triggered with a simple footswitch, when you are playing guitar for exemple. One On/Off button to a female jack:

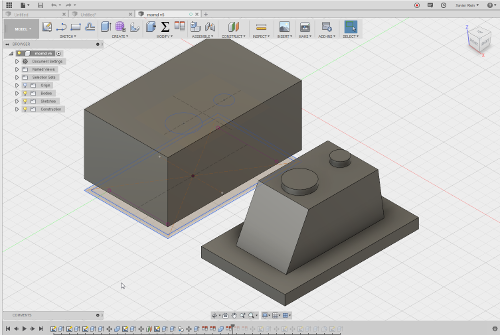

So the plan was to cast the pedal enclosure with 1 15,7mm hole for the on/off momentary button and 1 9mm hole for the female jack:

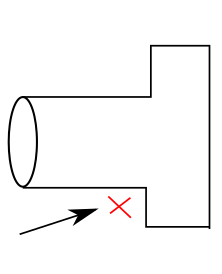

But the jack's hole needs to mill a counterpart like this:

It's impossible to mill below. So I put the 9mm hole on the top and manage to model the counterpart:

But a big problem comes in. Because of the lenght of the female jack, enclosure's depth needs to be minimum 23mm.

And 2 or 3mm end mills I have at my fablab are maximum 20mm. And I can't double the size because of holes...

I've tried some other ways (like those separables modules) but I couldn't manage to find a way to fix this problem.

Buuuuuuut I will keep the idea for the final project.

I abandoned this idea and I was sad. I thought for something useable for my final project. I will need some knobs (it's a new word for me and...... I really love it).

So the plan was to make a knob suitable for these potentiometers (6mm diameter):

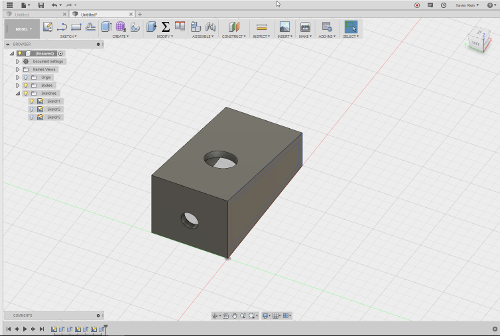

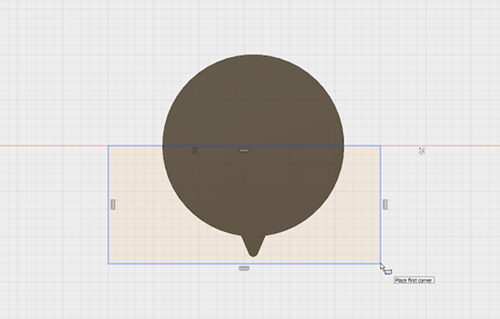

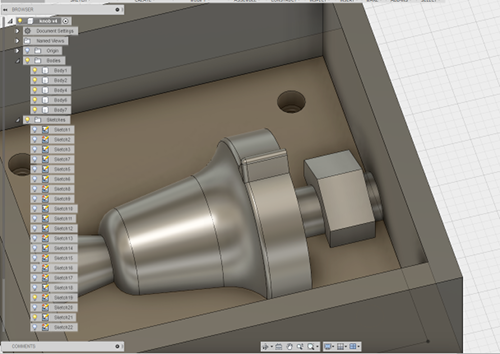

In Fusion, I started to model a simple, but funny pot using only extruded circle and smoothing with filet:

I abandoned the smile because I was scared that it will be complicated to mill.

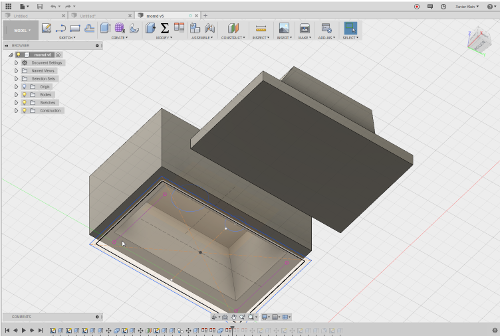

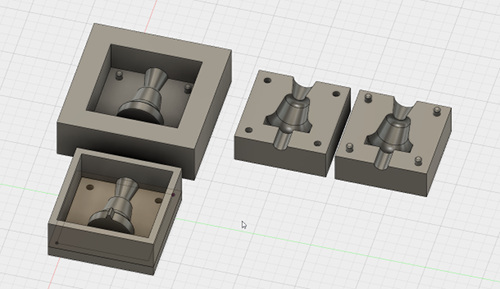

First I cut the pot in half with an extrusion.

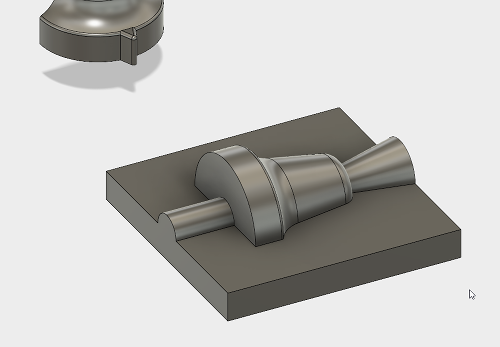

I put it on another body and make the funnel form, the hole where the material will flow. Notice that there's another form. It's for making an hole in the knob by putting a 6mm screw.

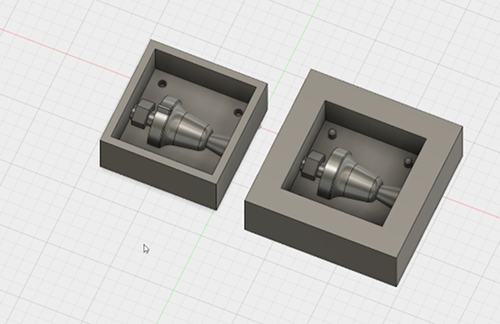

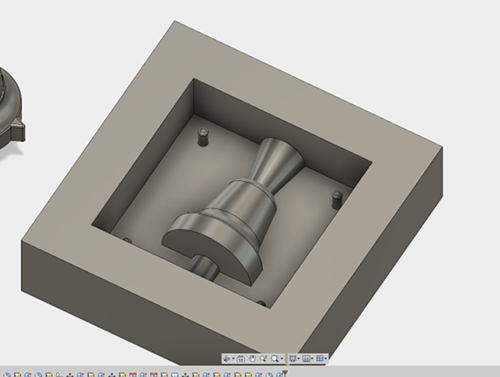

I've putted a wall around the form, make some pins and try to simulate a cast. Everythings seems to be good:

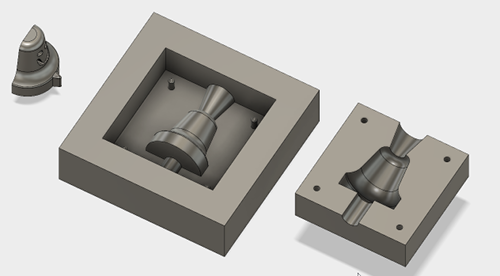

I repeat the operation for the second face:

For maintening the srew in place, I made a nut counterform:

It's reading for milling!