Molding & casting

The assigment page

The goal of this week was to design a model for casting, mill the mould and use to cast your design.

⇝ 3D modelling in Fusion ⇝ Milling ⇝ Casting

NOT!

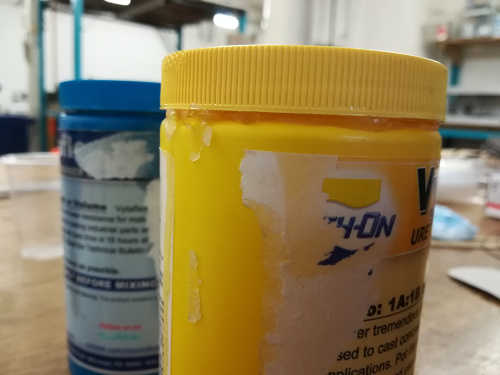

In the yellow bottle of VitaFlex-60, the liquid is solid and the cap is stuck.

So no casting for me this time:

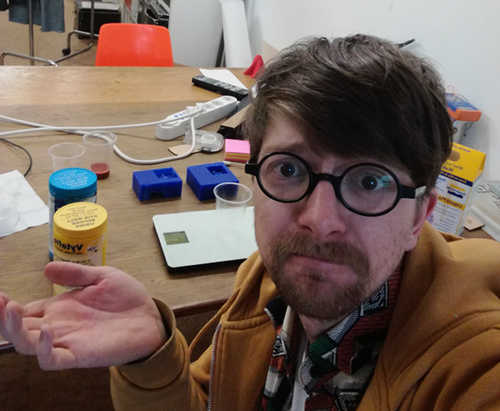

I managed the frustration using the power of Technology!

Thank you Gimp.

Casting for real

Some mouth later I had some resin to make the assigment.

I have 2 sorts of it:

-For the mold: Vytaflex 10 Urethane Rubber Compound from Smooth-On.

Mix ratio, 1:1, Pot life 30 min, Cure time 24hrs.

-For the object: Smooth-Cast 325 EU ColorMatch.

Mix ratio, 1:1, Pot Life, 2,5min, Cure time, 10min.

I first used my wax mold to make a flexible mold.

I prepared a clean space and put somes gloves. I worked under my kitchen vent. I opened the part A of the Vytaflex.

I poured 12g of it on disposable cup. I use an electronic scale to mesure it.

I poured 12g of part B in a second disposable cup. I poured part B directly into part A because I use few of the Vytaflex and mix the 2 parts using a wood stick.

It began to warm a bit, when the mix was clear, I started to poured it into my 2 waxes mould.

I had to wait for 24hrs and here's the result:

It worked well!

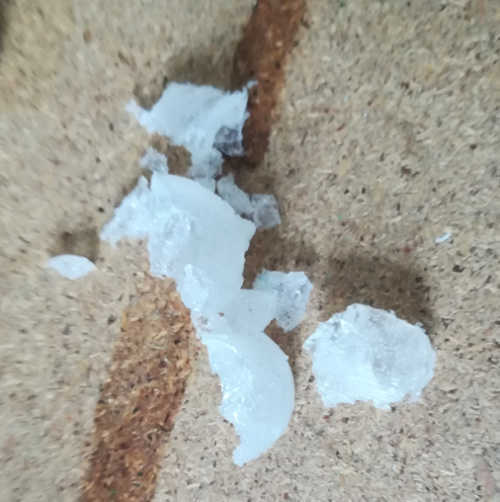

I had to clean the edges because like I said before the CNC made some extra holes. I first tried to sand it. Eventually I used a nail clipper to remove the extra materials from the mold.

So I was ready to casted my knob! I put the nut and the screw, who's perfectly fit, on the mold:

And I used some cardboards and a clamp to hold up the mold.

So I started to prepare the liquid plastic using the same process than before:

I did 3 attempts. The first one I forgot to put some vaseline in the mold. So the knob was completely glue to it. I also thought that I didn't mix well because it was still sticky and clear.

I also used too much plastic (12g for each).

The second was a bit better. But I clamped the mold to much so the knob was flattened. This time I putted 6g each. Still too much.

The first attempt was even better. I putted 3g each and it was good. The result isn't perfect, but the form is correct and it's actually work. The screw thing was a good idea!

So molding and casting are quite exciting techniques but I find those a bit complicated and stressfull. And it's generating a lot of chemical and plastic wastes.

I have to do it again, I think I will find some ecological solutions.