Week 1 assignment

Principles and practices, project management (Jan 28)

Week 2 assignment

Computer-aided design (Feb 4)

Week 3 assignment

Computer-controlled cutting (Feb 11)

Week 4 assignment

Electronics production (Feb 18)

Week 5 assignment

3D scanning and printing (Feb 25)

Week 6 assignment

Electronics design (Mar 4)

Week 7 assignment

Embedded programming (Mar 11)

Week 8 assignment

Computer-controlled machining (Mar 18)

Week 9 assignment

Molding and casting (Mar 25)

Week 10 assignment

Input devices (Apr 8)

Week 11 assignment

Output devices (Apr 15)

Week 12 assignment

Composites (Apr 22)

Week 13 assignment

Networking and communications (Apr 29)

Week 14 assignment

Mechanical design, machine design (May 6)

Week 15 assignment

Interface and application programming (May 13)

Week 16 assignment

Applications and implications (May 20)

Week 17 assignment

Invention, intellectual property, and income (May 27)

Week 18 assignment

Project development (Jun 3)

Week 19 assignment

Project presentation (Jun 10)

Computer-aided design (Feb 4)

Summary:

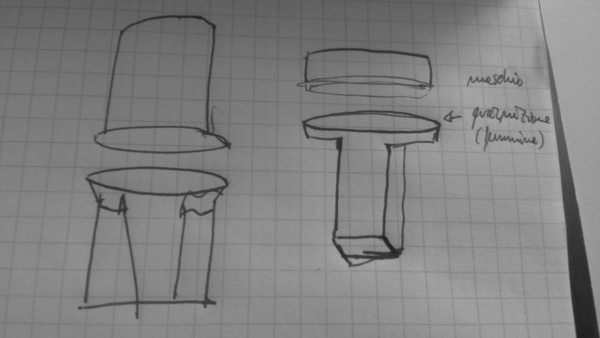

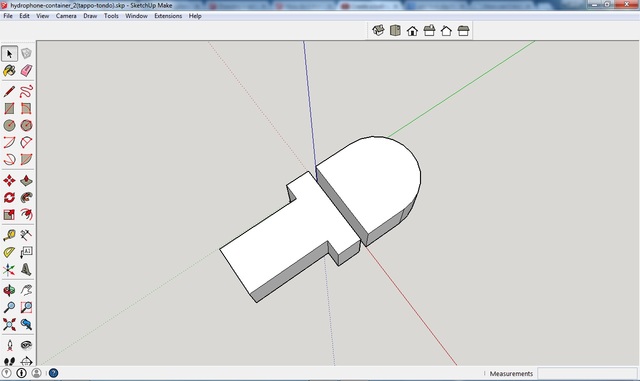

This week I tried to design the waterproof container which will host the electronic board of my device. I though about something like this below but with some modifications. You can find all the files at the bottom of this page.

In the last days I read more about hydrophones and I think I will use it for my final project. I will use a piezo to do the hydrophone. Ideally the piezo would be in direct contact with water, but obviously it cannot. It will be connected to the board with all the electronic. Therefore the piezo would adhere as much as possibile to the waterproof container. In this way it will reveal at his best the pressure waves inside water. According to this and also looking at this project and the images below I thought to modify the shape of the container.

This is my hand-writing sketch about the modification of the container in the first image of this page.

Adding a parallelepiped shape in the lower part of the container will make easier to do something that adhere to the container as much as possibile and that it is closer to the water.

This week I have too much images to resize one by one. I followed this page to resize multiple images

Resize Multiple images in a folder (Batch Image Resize) in Ubuntu

My SketchUP experience

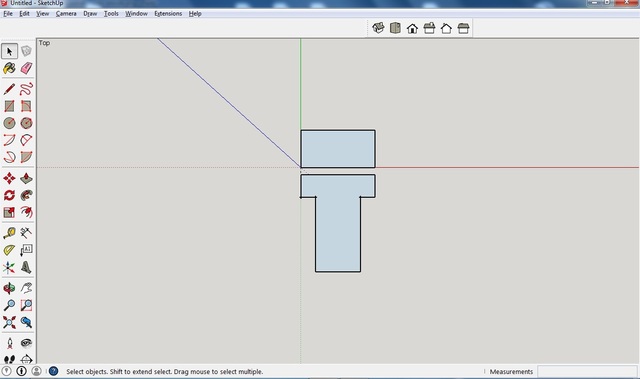

I started using SkecthUP with simple shapes.

Here below some screenshot of the steps I followed with

SketchUP. They are

quite self-explanatory.

I did something simple with top view:

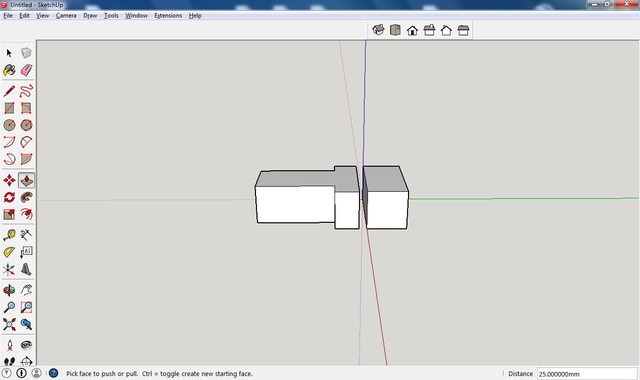

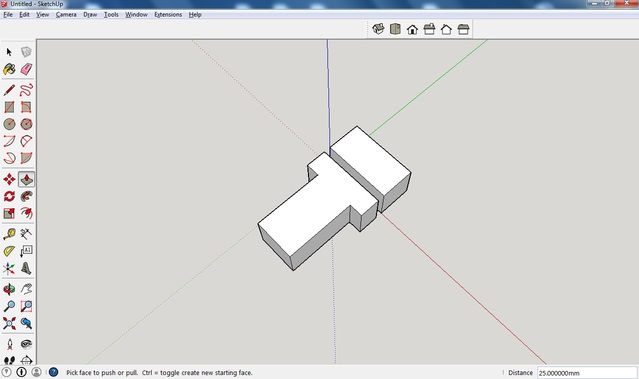

then I did the extrusion to have the idea of thickness

another view of the same object above

here below I added half-circle (extruded)

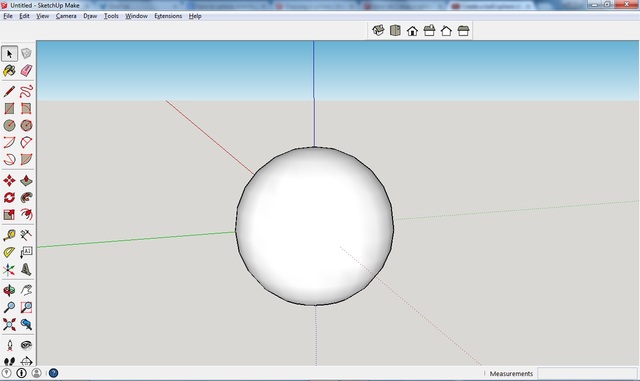

At this stage I realized I need to learn how to do a real hemispheric cap. I

discovered the “follow-me” tool in SketchUP and I liked it :)

Following this quick tutorial I learnt how to do a sphere. I know, it looks a planet :)

.jpg)

Here it is a real sphere

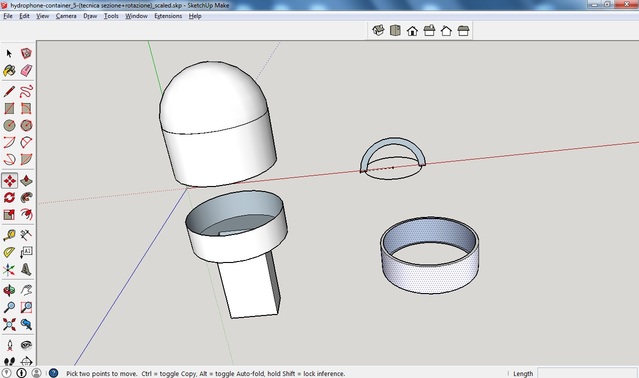

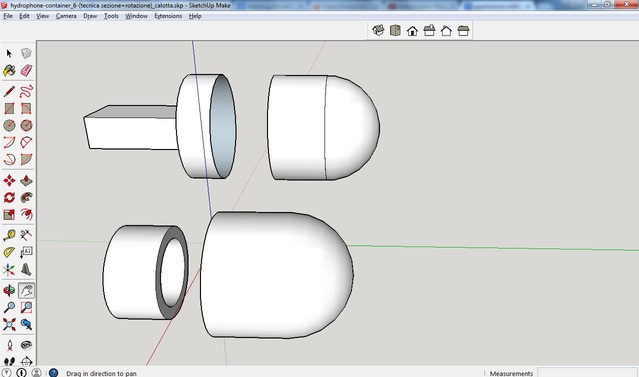

First I did the container all rounded. Later I will do the lower part with

rectangular shape.

.jpg)

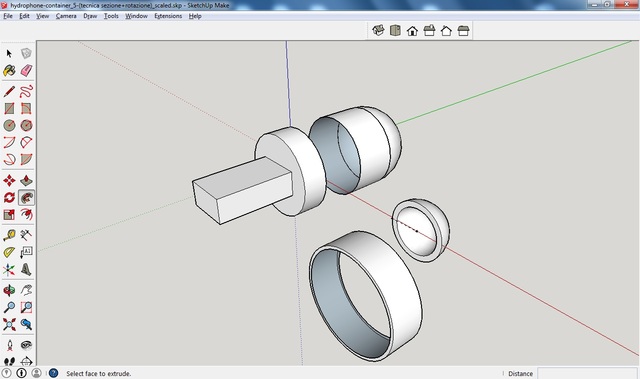

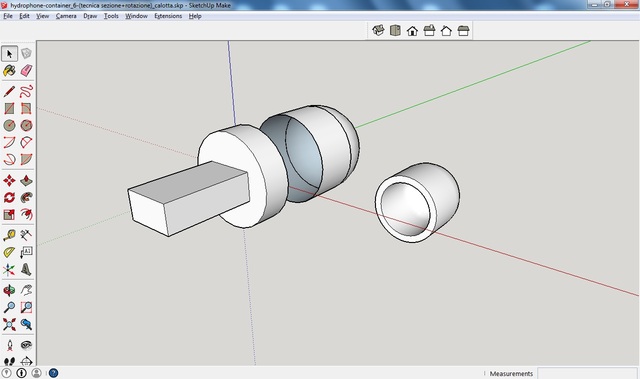

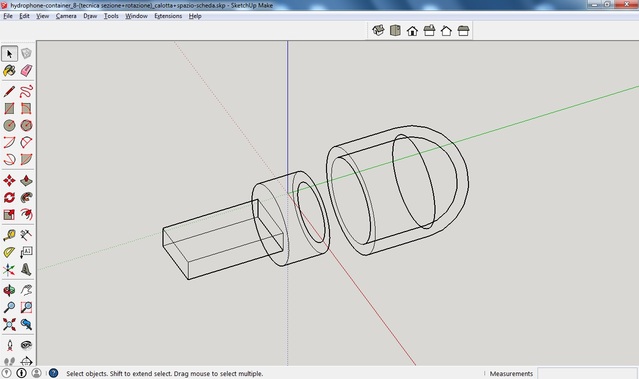

When I learnt follow-me tool better I did something more complex

using an arc and the tool. Thanks to my local instructor suggestion ;)

At this stage I learnt to give a thickness to my objects. You can see the cylinder below.

Below you can see the hemispheric cap with thickness. Here the cap is in two

pieces

Here the cap is in one piece

Here is the first piece of the lower part of the container.

You can always see the difference with the container without thickness in the

upper part of the figure.

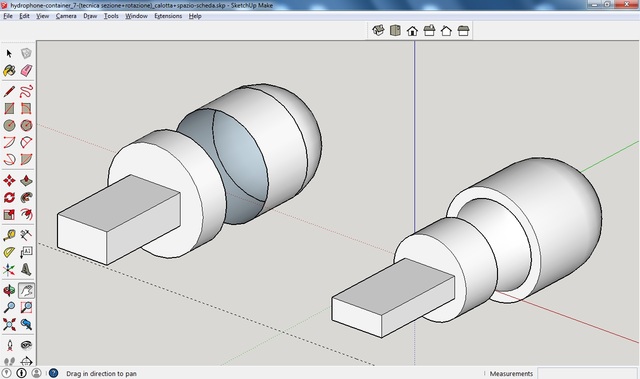

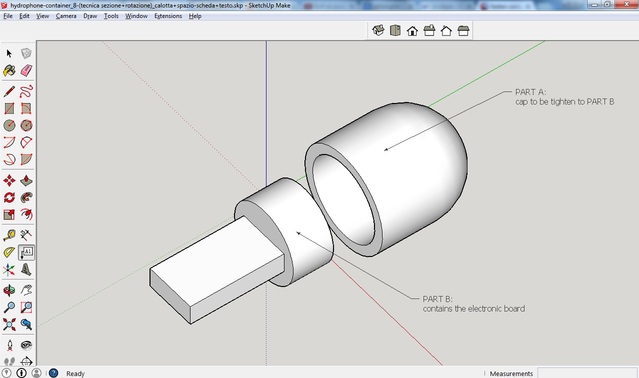

Here below you can see the final version of the container.

You can notice that in the lower part there is the area where I want to put my

electronic board.

Here is the final version with text description.

Another image where you can see inside the container with wireframe tool of

SketchUP

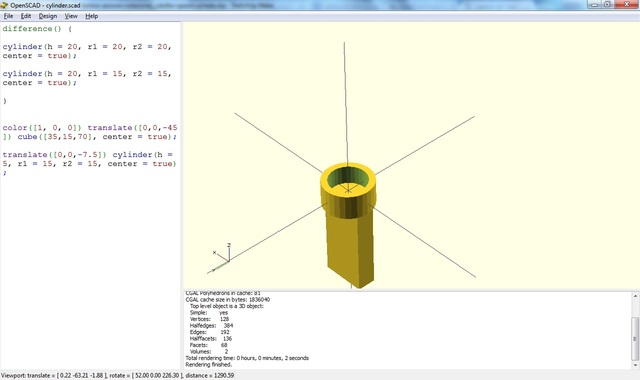

My OpenSCAD experience

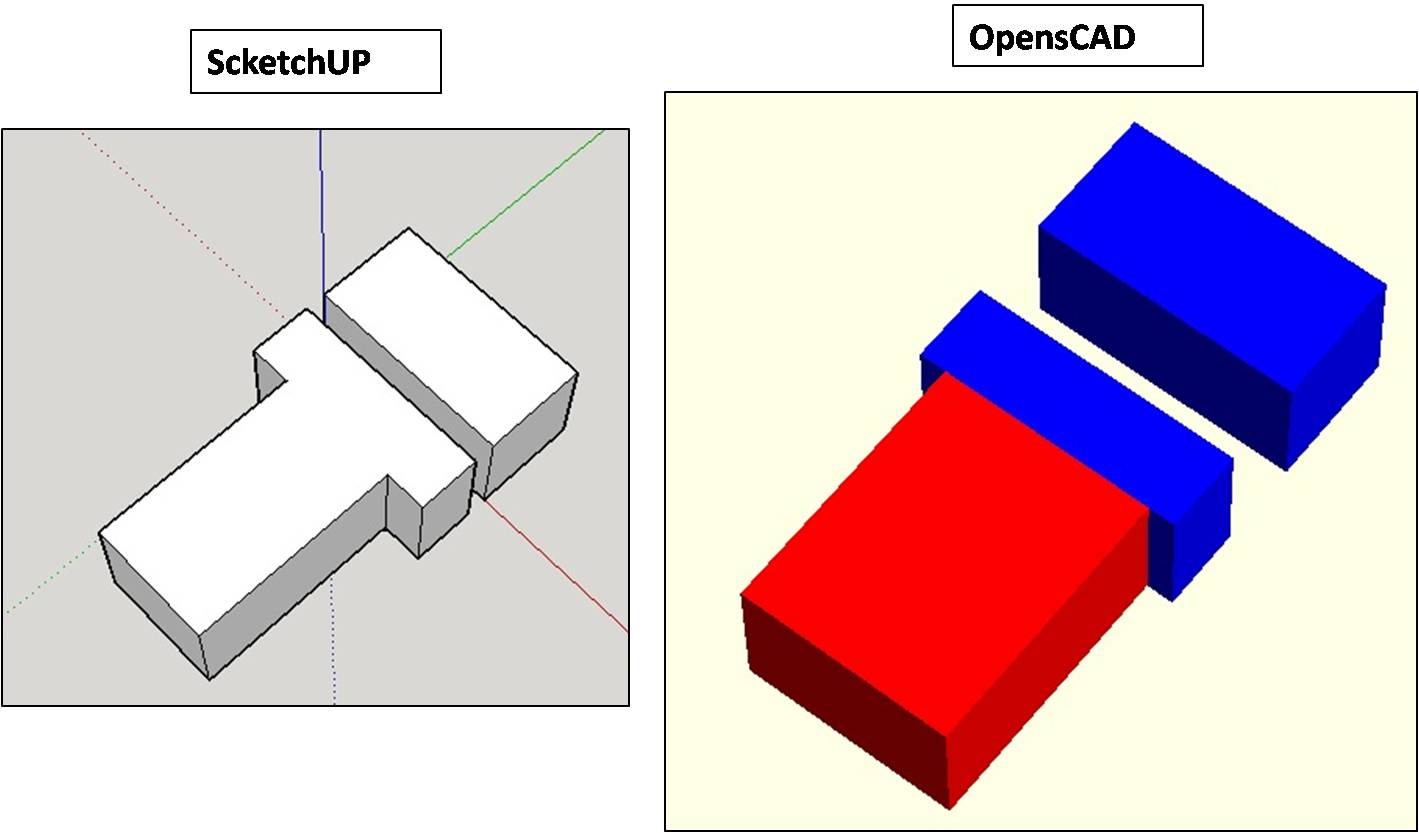

Here it is my first step with openSCAD and the comparison with SketchUP.

I like writing code and obtaining real 3D shapes :)

After the experience with SketchUP I feel more confident and after the first

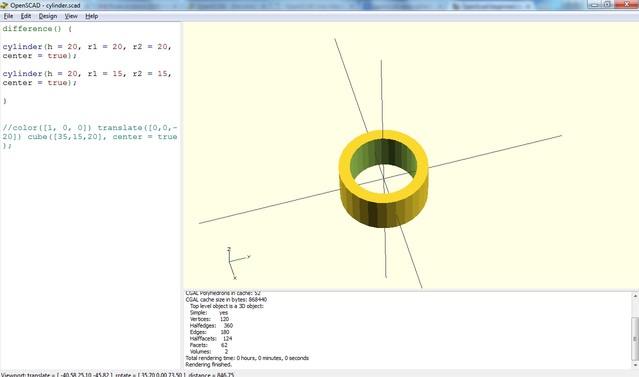

image above I did directly the cylinder with some thickness.

With openSCAD you can obtain a cylinder doing the difference between two

cylinders which have different radius.

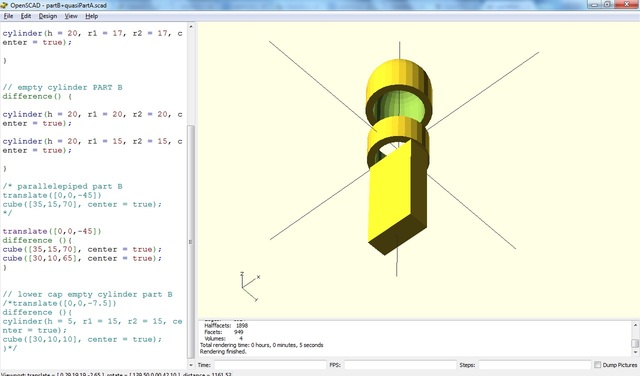

After this I added the PART B (the parallelepiped).

You can see that inside there is no area where I can put my electronic board. I

will do in the next steps.

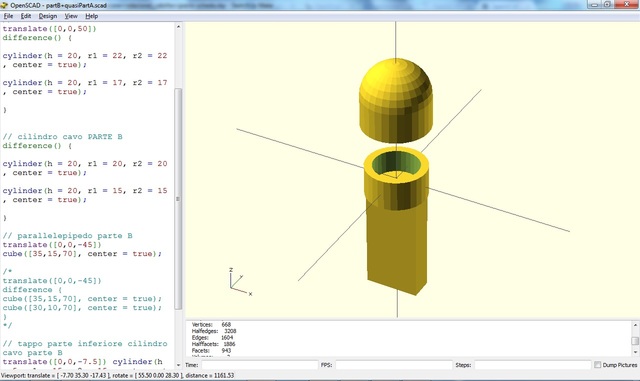

Here below I added the hemispheric cap. I did the hemisphere doing the

difference between two sphere with different radius and cutting the half of

the spheres with a big cube. Here you can notice an error because there is an

hole in part B. I solved it with something like a cap..a little cylinder

located at the base of the cylinder in part B. I know this is not an elegant

solution and maybe it could be a problem. I will remember it later.

Here is the code:

radiusBig = 25;

thickness = 5;

difference() {

sphere(radiusBig);

sphere(radiusBig-thickness);

translate([-50, -50, -100]) cube(100);

}

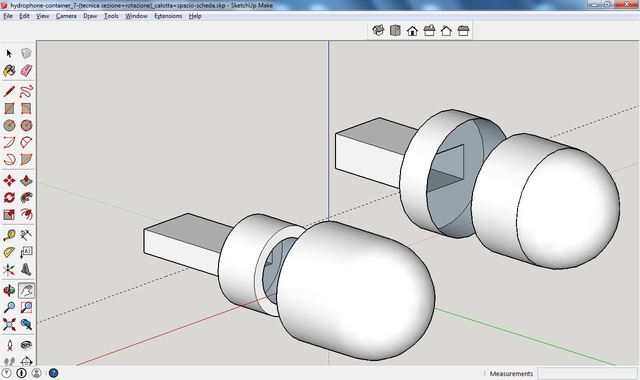

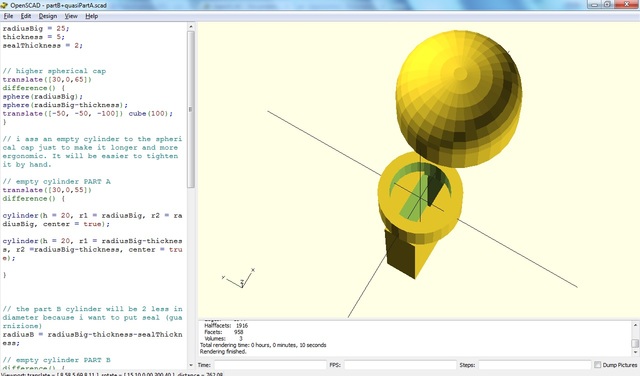

Here below you can see the container (PART A + PART B) almost complete BUT

there is no room inside for the electronic.

I did some space for the electronic inside the container :)

I used again the difference between two parallelepipeds.

My Antimony experience

I tried to install Antimony and it was

not so easy.

I am running Linux Mint 17.1 Rebecca and I followed the Linux

instructions

here

I found some problems after the make and here below I list the problems and

the solutions I found.

PROBLEM 1:

I had a problem of memory (I don’t remember the error message)

SOLUTION 1:

My local instructor suggested me to use simply make and not make -j8

PROBLEM 2:

fatal error: GL/gl.h: No such file or directory

SOLUTION 2:

sudo apt-get install mesa-common-dev

page where I found the solution

OR another solution I have NOT tested

PROBLEM 3:

/usr/bin/ld: cannot find -lGL collect2: error: ld returned 1 exit status

SOLUTION 3:

sudo apt-get install libglu1-mesa-dev -y

page where I found the solution

Project files

Here are the files of Sketchup and openSCAD.