Group Assignment

1) Safety Training

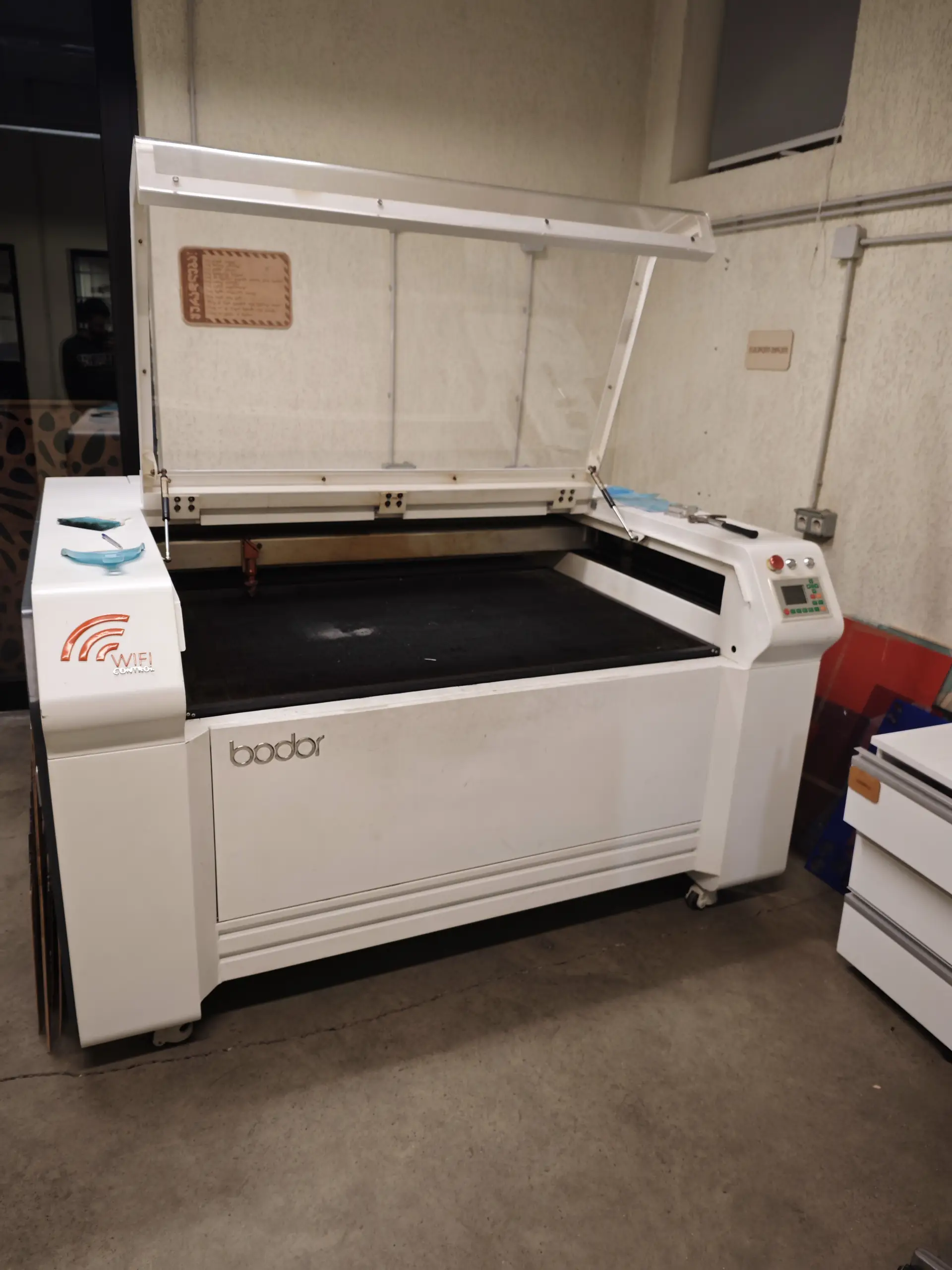

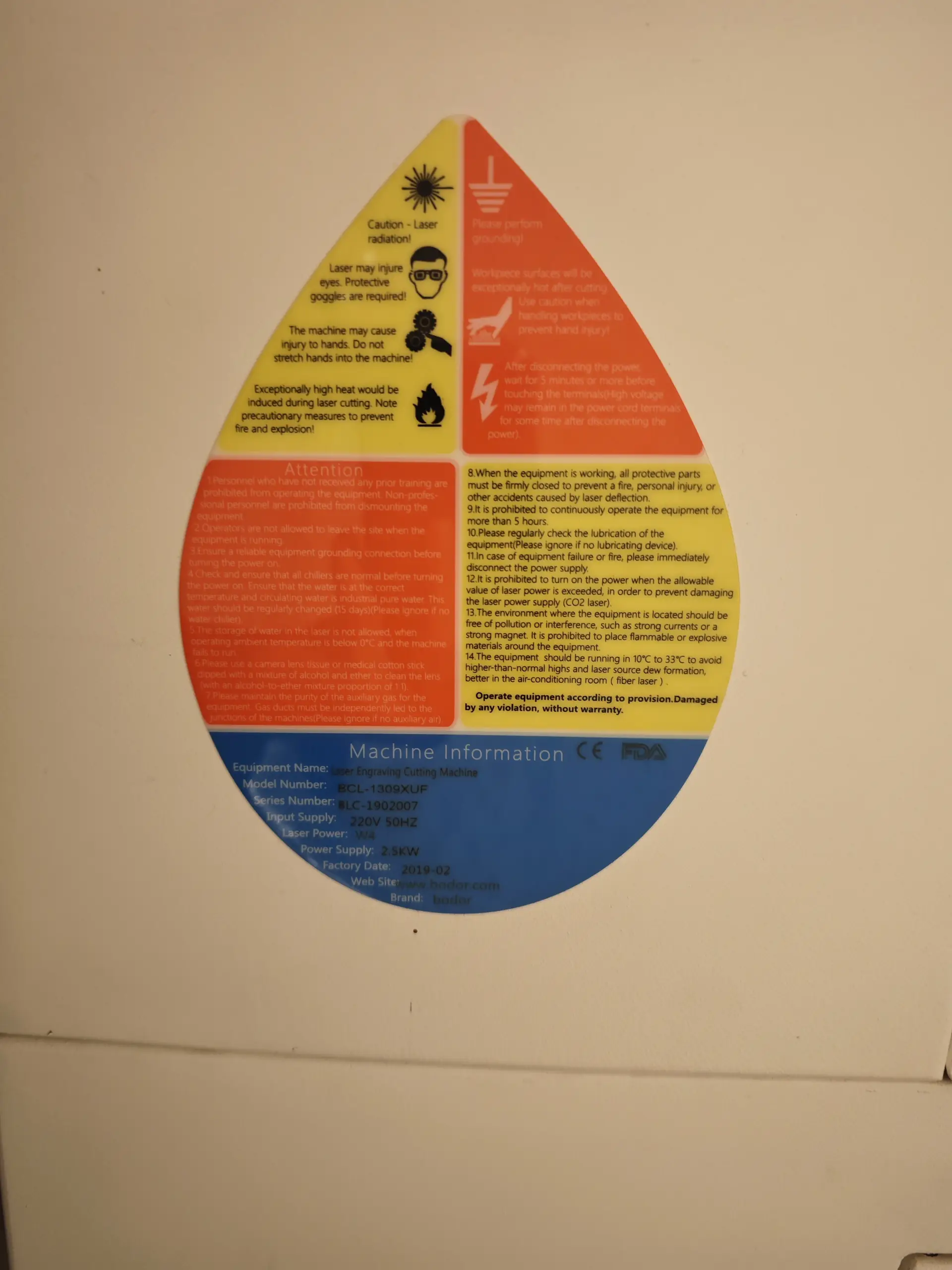

Before operating the laser cutter, we follow strict safety rules in our lab to prevent fire hazards, toxic fumes, and equipment damage.

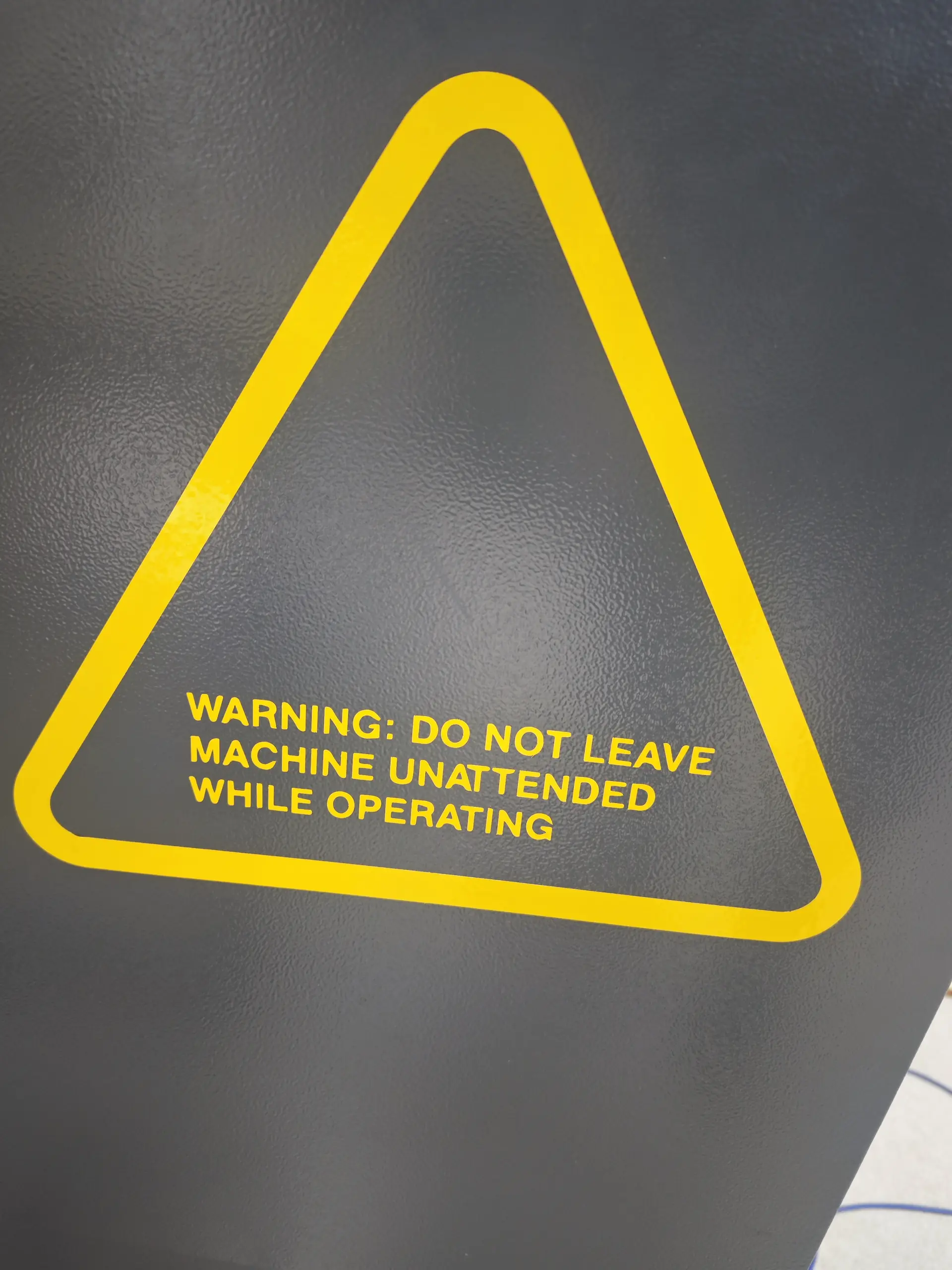

1. Never Leave the Laser Unattended

The laser cutter must never be left unattended while operating.

Even if the cutting job takes a long time, we stay in the same room and continuously monitor the process.

Laser cutting plywood or cardboard can ignite unexpectedly. Immediate reaction is critical to prevent fire.

2. Extra Care with Plywood and Cardboard

When cutting plywood or cardboard, we take additional precautions because:

- These materials are highly flammable

- Glue layers in plywood can ignite

- Cardboard can burn quickly if power/speed settings are incorrect

We carefully monitor flame formation and are ready to stop the machine immediately if necessary.

3. Industrial Ventilation System

Our lab uses an extra industrial ventilation module.

- The exhaust duct extends above the building roof

- This prevents smoke from spreading inside the building

- It protects other workers and nearby animals from harmful fumes

Proper ventilation is essential because laser cutting produces smoke and fine particles.

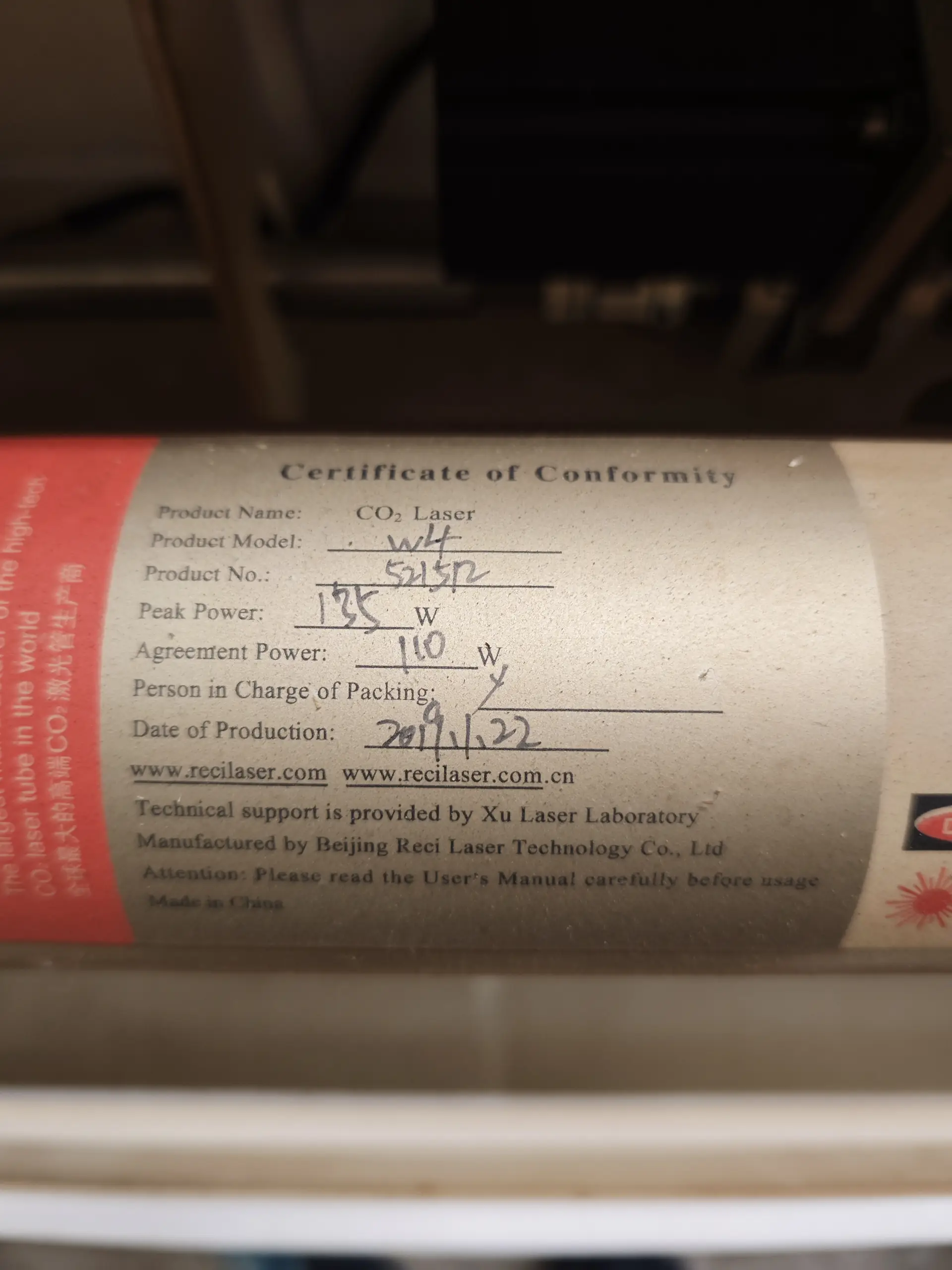

4. Water Cooling / Chiller System Check

Before every cutting session, we:

- Check the water cooling (chiller) system

- Confirm water circulation is working

- Ensure the temperature is within a safe operating range

Laser tubes can overheat and be permanently damaged if cooling fails.

5. Additional Safety Measures

- Never cut PVC or unknown plastics (to avoid toxic chlorine gas)

- Keep a fire extinguisher accessible

- Clean the cutting bed before operation

- Turn on air assist during cutting

Laser Cutting

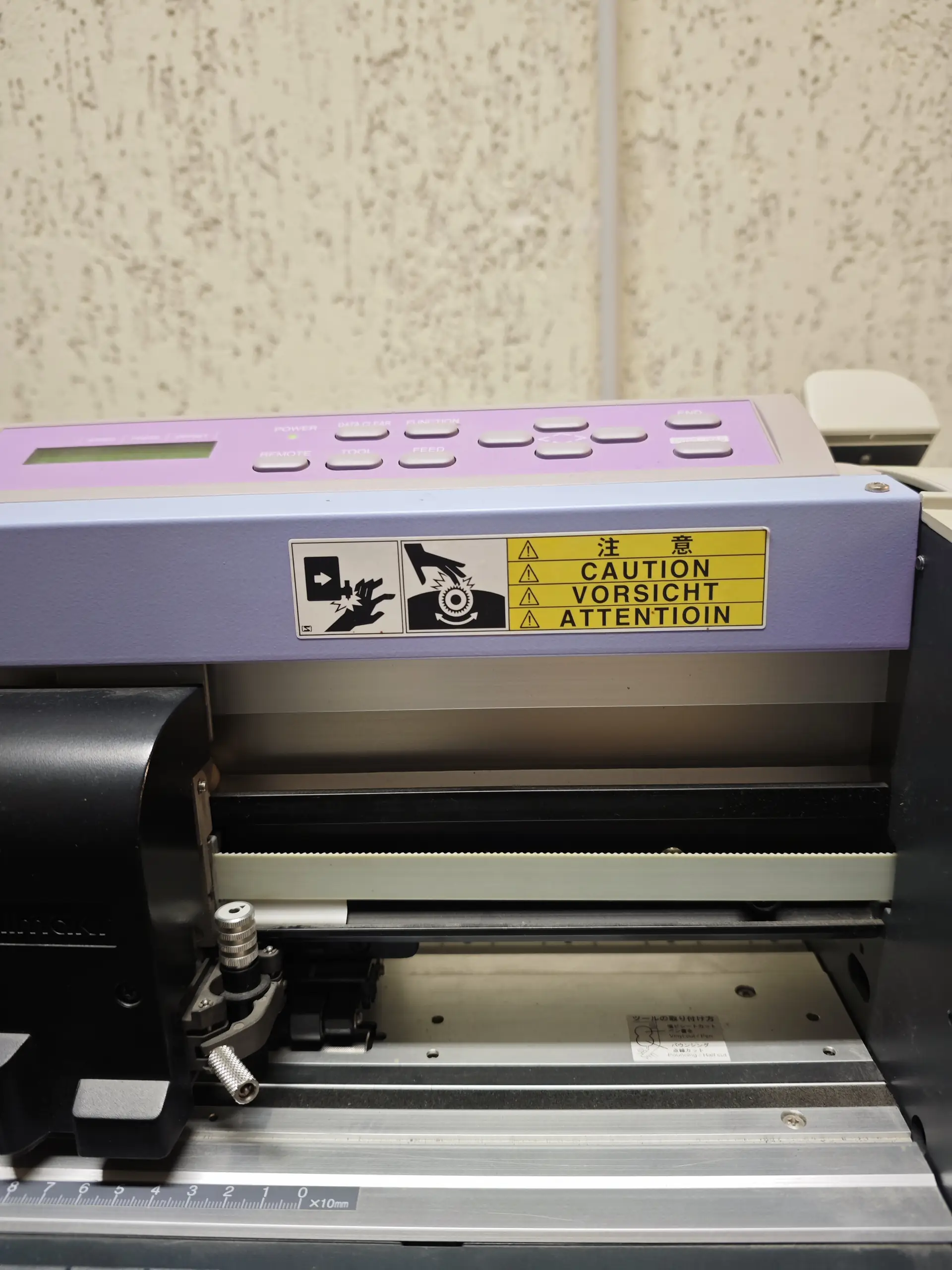

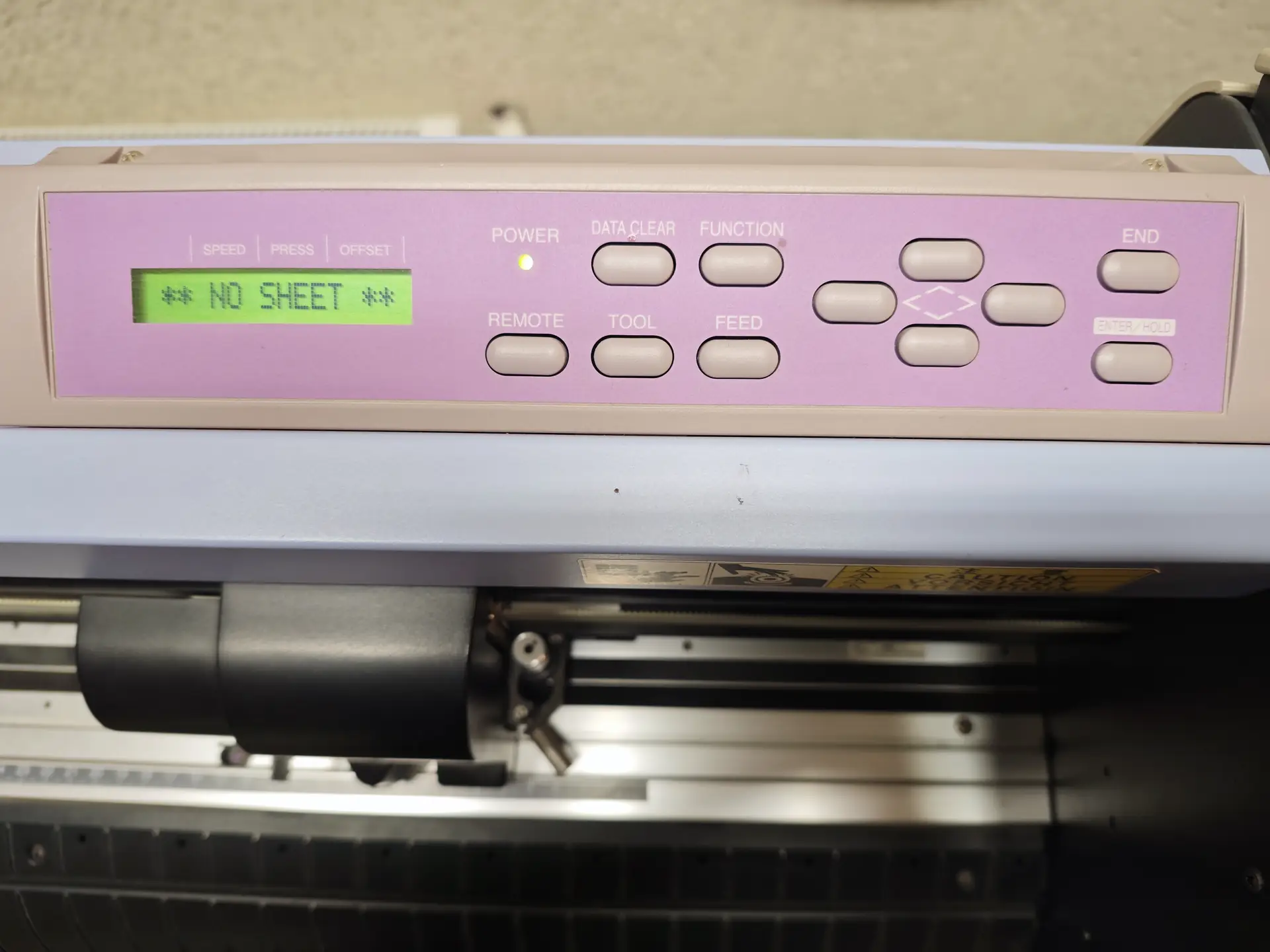

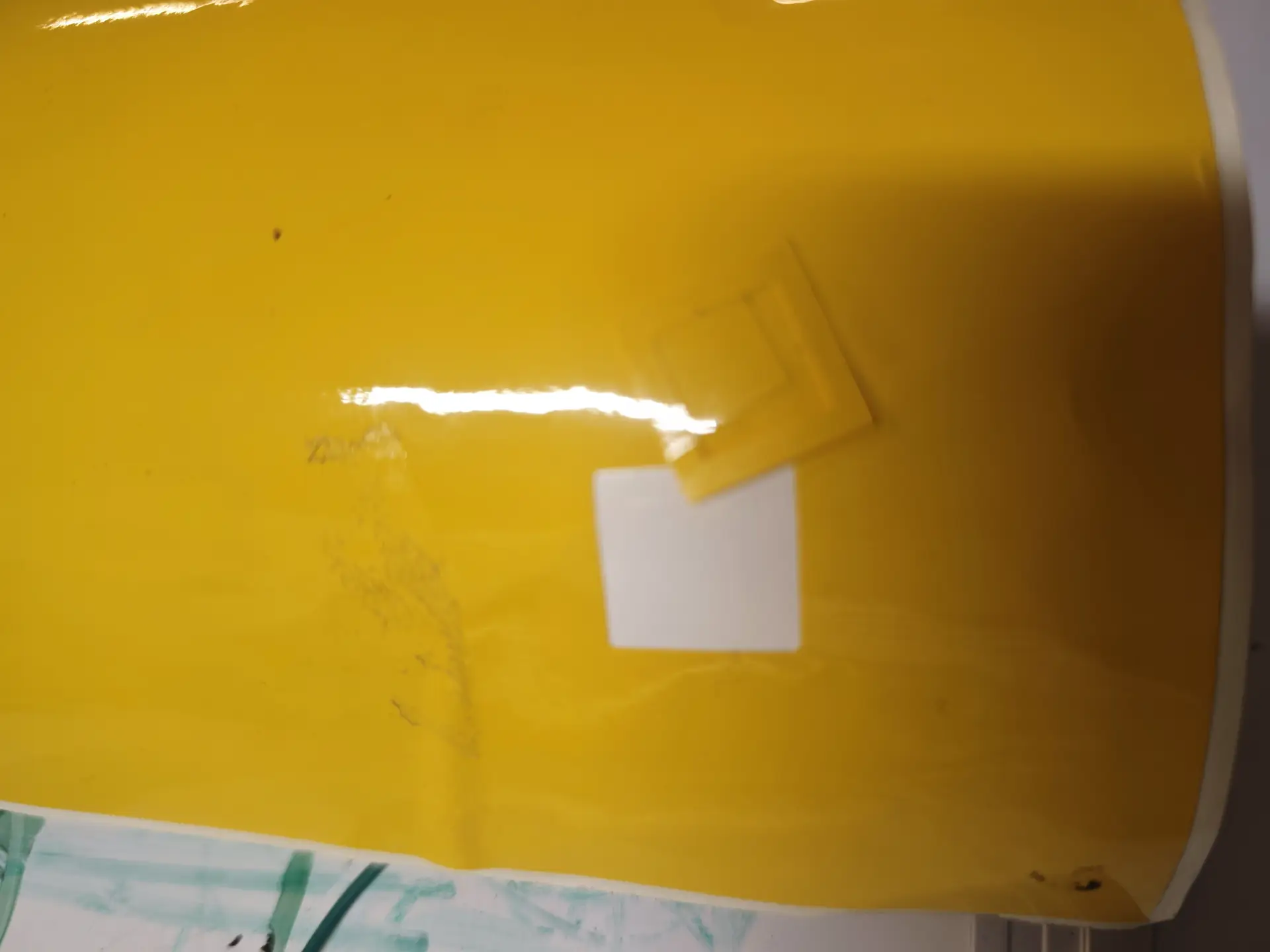

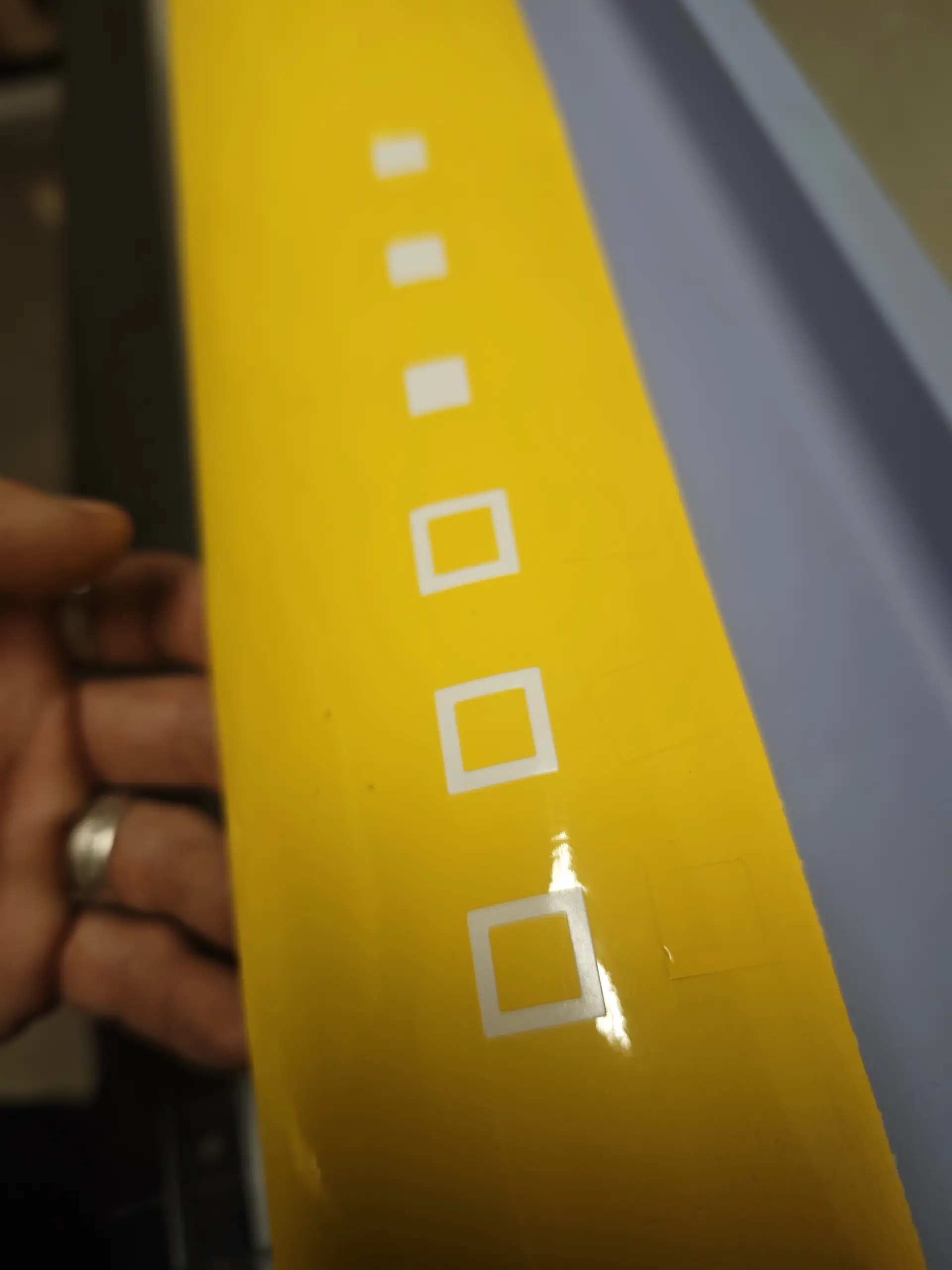

Vinyl cutting