10. Molding and casting¶

Learning Outcomes:

- Design appropriate objects within the limitations of your process

- Demonstrate workflows used in mold design, construction and casting

Group Assignment:¶

For the group assignment we experimented with different materials and molds.

-

Objective: Review safety data sheets for molding and casting materials, make and compare test casts with each material, and compare printing vs milling molds.

-

Materials Tested: Gypsum, Mold Max 60 (silicone mold rubber), and Smooth-Cast 305 (polyurethane casting resin).

-

Safety Precautions: Wear appropriate protective gear and ensure proper ventilation.

-

Process Steps for Each Material: Measure components, mix thoroughly, pour into mold, tap to remove air bubbles, allow curing, and demold.

- Comparison of Printing vs Milling Molds: Small 3D file of a cube used to demonstrate differences. Printing takes approximately 2 hours, while milling takes about 30 minutes. Printing using SLA offers a smooth surface finish with high accuracy/resolution, suitable for intricate designs. Milling provides precise and accurate results, suitable for functional prototypes.

Introduction:¶

During the molding and casting week for Fab Academy, my primary objective was to enhance the realism of suture practice pads, which led me to explore various molding and casting techniques. Initially, I aimed to create a comprehensive solution by molding an entire hand and integrating 3D printed bones into silicone for lifelike practice products.

The concept sought to strike a balance between authenticity and feasibility, with the integration of 3D printed bones offering intricate detail and practicality for suturing practice.

Project Planning and Preparation:¶

To kick things off, I outlined my main goal: making suture practice pads more realistic using molding and casting. I did some digging to find the best materials and techniques for the job. This included looking into what would make the casts durable, flexible, and detailed.

I also needed a good 3D model of human hand bones to start with. Getting the size right was key to making sure the casts looked and felt real. I checked out different 3D printing methods, like SLA and FDM, to see which would work best for making the bones and molds.

Before diving in, I wanted to test out my plan on a small scale. So, I made some simple molds and poured in silicone to see how it turned out. This helped me figure out what might work and what might need tweaking.

General Safety Precautions¶

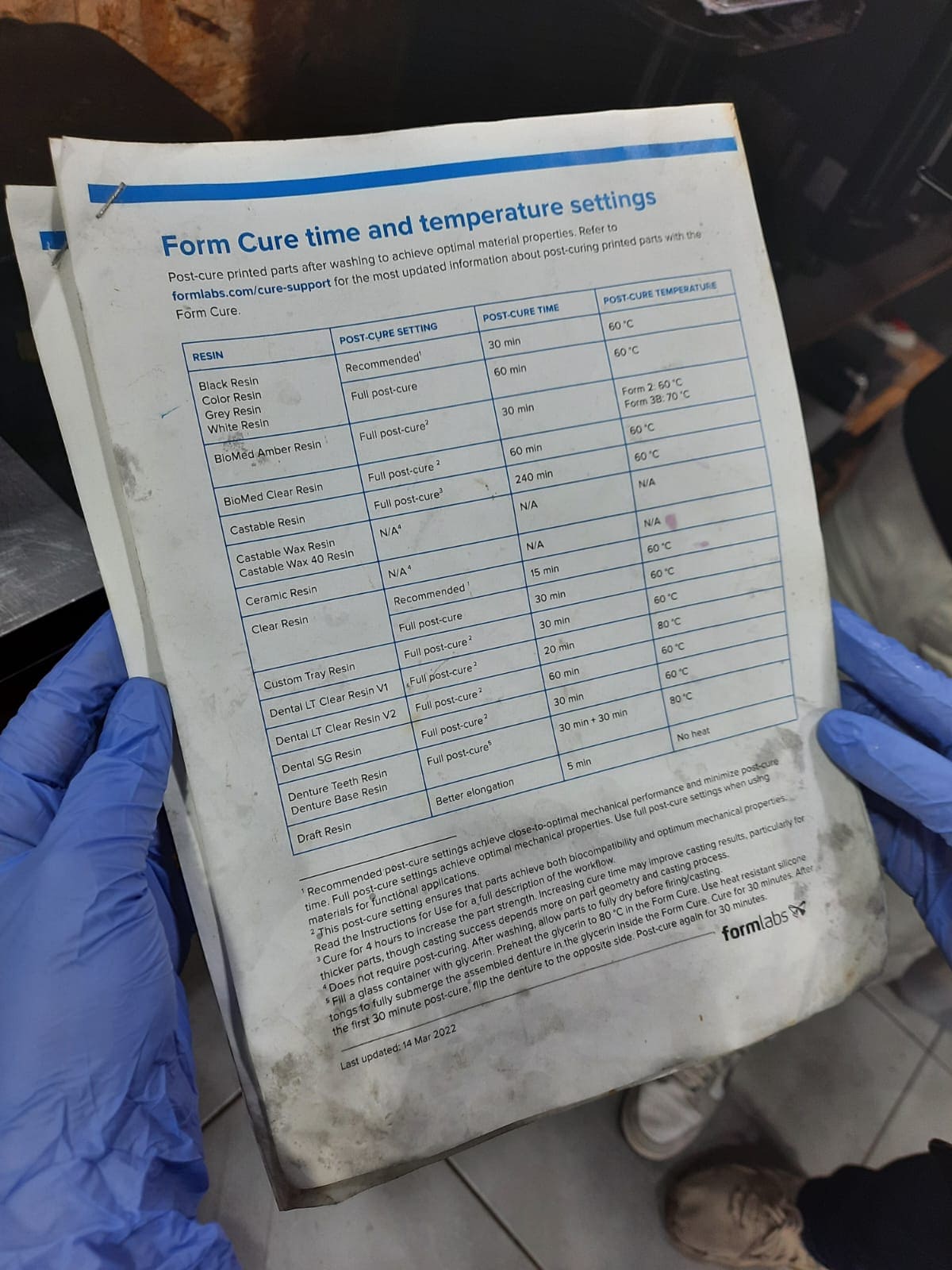

When working with casting materials such as Sorta Clear and Dragon Skin, it’s crucial to follow general safety precautions to ensure a safe and healthy working environment. Below are the safety guidelines you should adhere to:

- Personal Protective Equipment (PPE): Always wear appropriate PPE, including nitrile gloves, safety goggles, and a lab coat or apron to protect your skin and eyes from contact with the materials.

- Ventilation: Work in a well-ventilated area to avoid inhaling fumes. Use a fume hood or an exhaust fan if available.

- Avoid Skin Contact: Avoid direct contact with the silicone materials. If contact occurs, wash the affected area with soap and water immediately.

- Mixing Ratios: Follow the manufacturer’s recommended mixing ratios precisely to avoid incomplete curing or adverse chemical reactions.

- Measuring Tools: Use dedicated measuring tools for each component to avoid cross-contamination.

- Storage: Store materials in their original containers, tightly sealed, and in a cool, dry place away from direct sunlight.

- Disposal: Dispose of any waste material and contaminated tools according to local regulations for hazardous waste.

BONES:¶

I began by researching and finding a highly detailed and accurate 3D model of a human hand with bones. It was crucial that the model was to scale to ensure the final product would be as realistic as possible. After some thorough searching, I found a model that met these criteria.

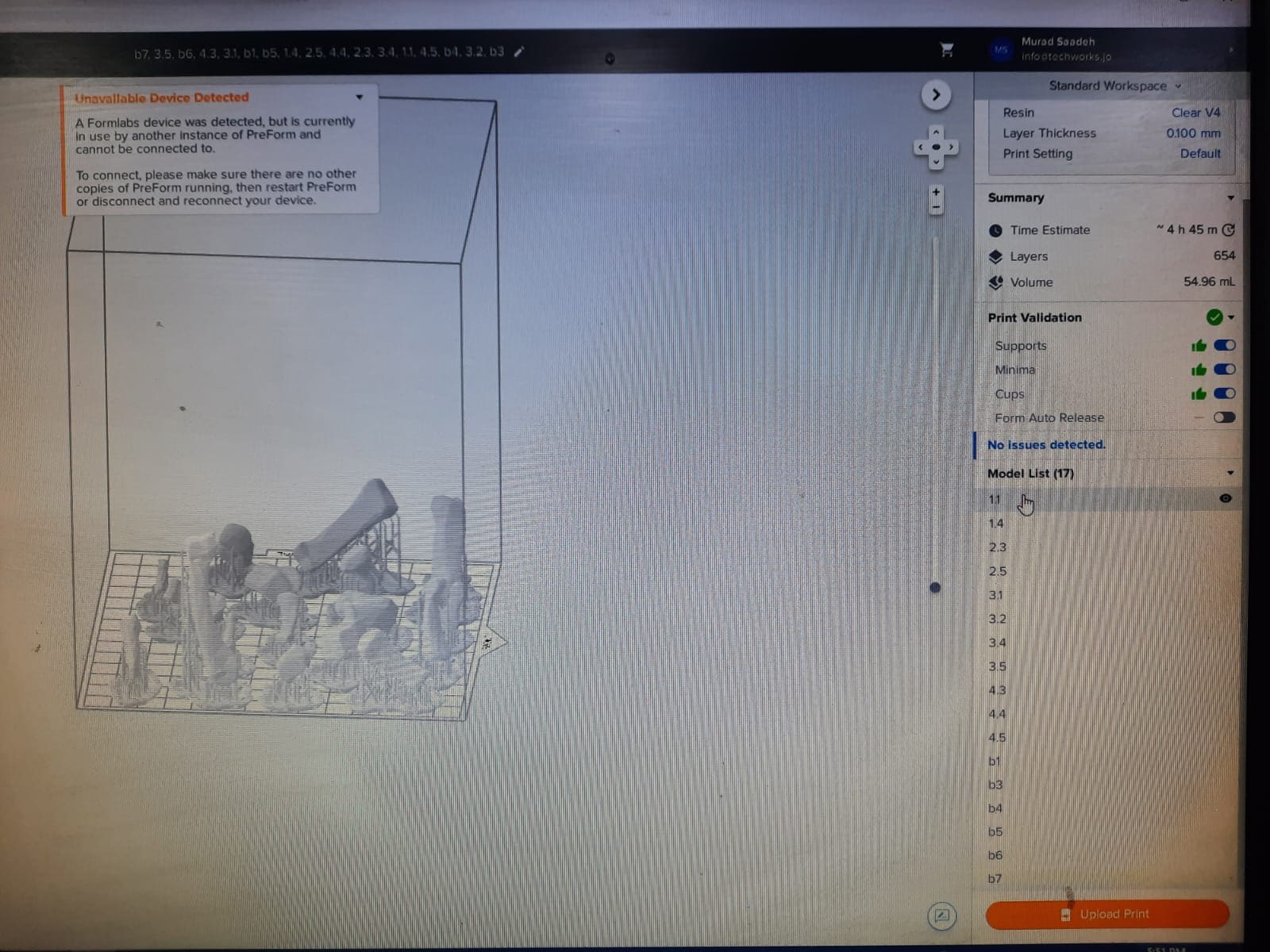

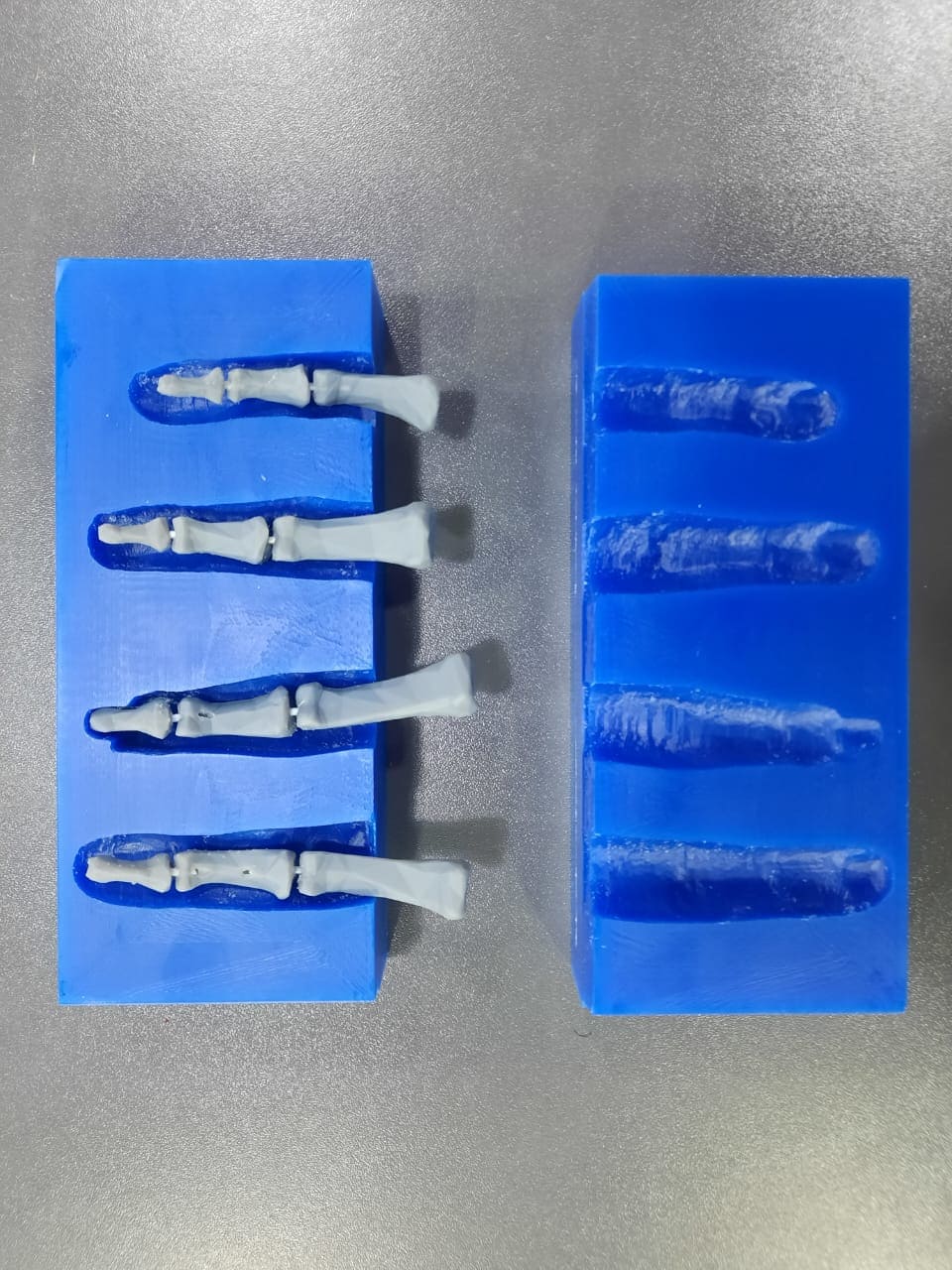

Next, I moved on to slicing and printing the bones using the SLA on the Form 3 printer. The SLA printer was chosen for its ability to produce high-resolution prints, which was necessary for capturing the intricate details of the bones. Once the bones were printed, I washed them to remove any residual resin and then cured them to solidify the material fully.

To mimic real joints and allow for some movement between the bones, I decided to test a method for creating joints. I drilled a small hole at the end of each bone and connected them using short pieces of filament. This setup aligned the bones correctly and provided some flexibility, much like a real joint.

The test was a success, showing that this method could effectively simulate the movement of real joints. Encouraged by the positive results, I applied this technique to all the fingers, ensuring that each bone segment was properly aligned and could move realistically.

3D Model¶

Slicing¶

Printing¶

Wash and Cure¶

Result¶

Joint¶

FDM MOLD TEST:¶

Designing and Printing the Test Mold

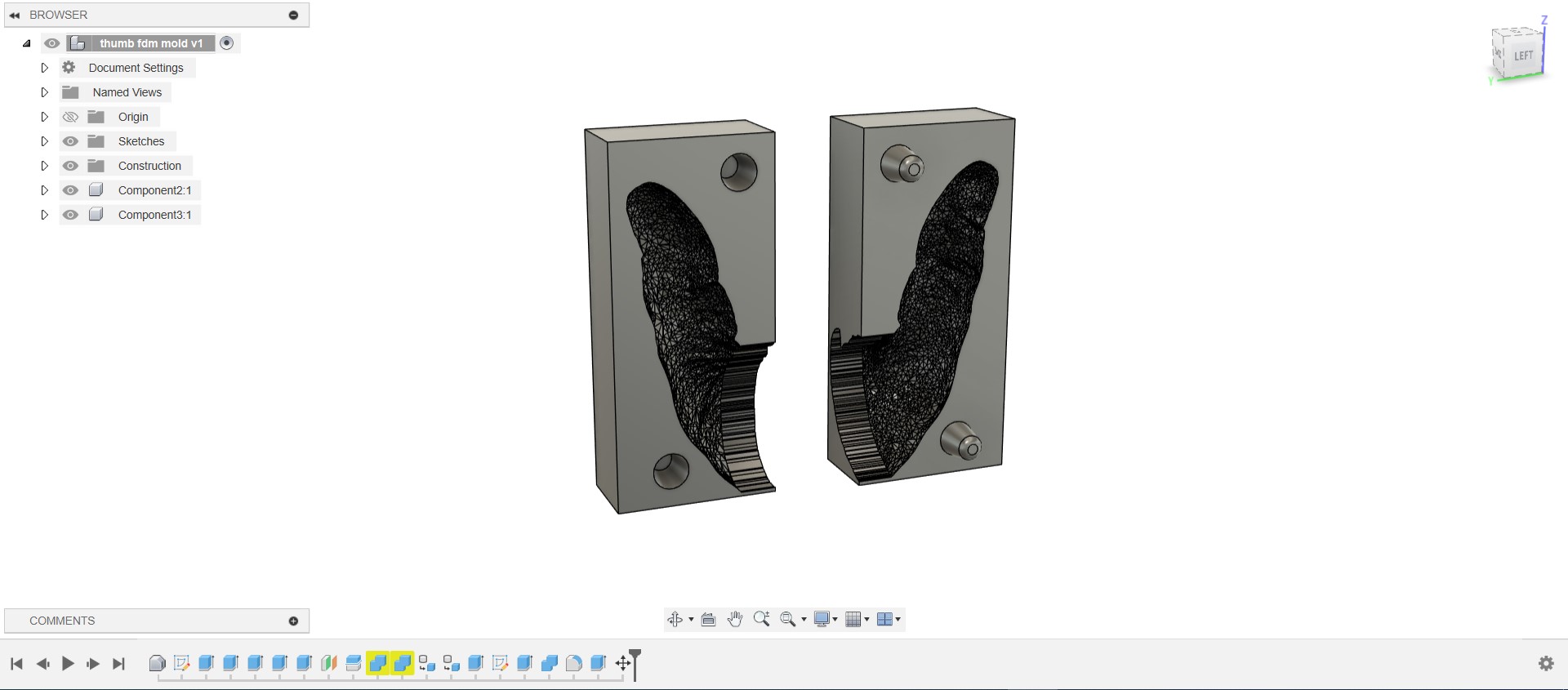

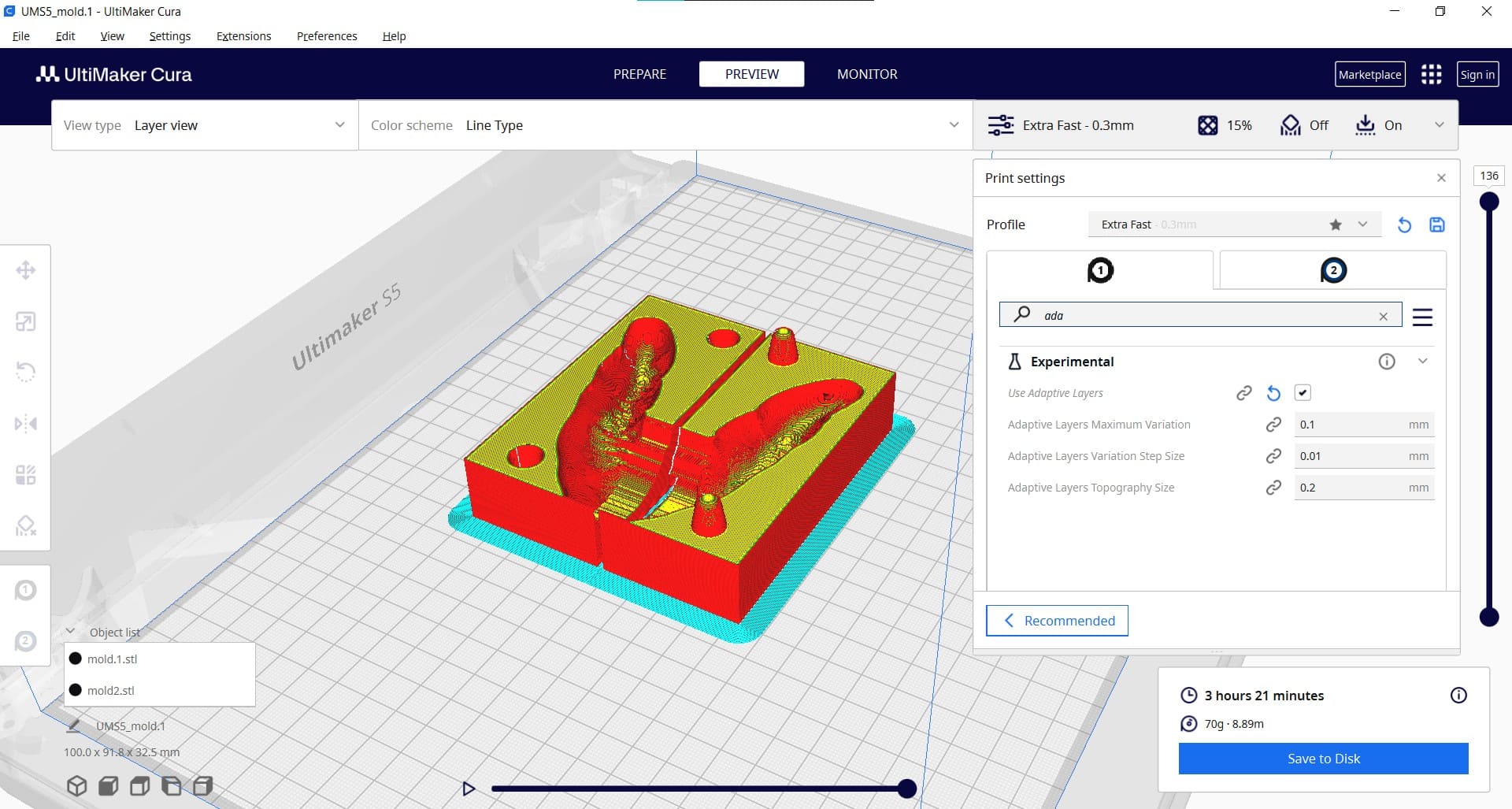

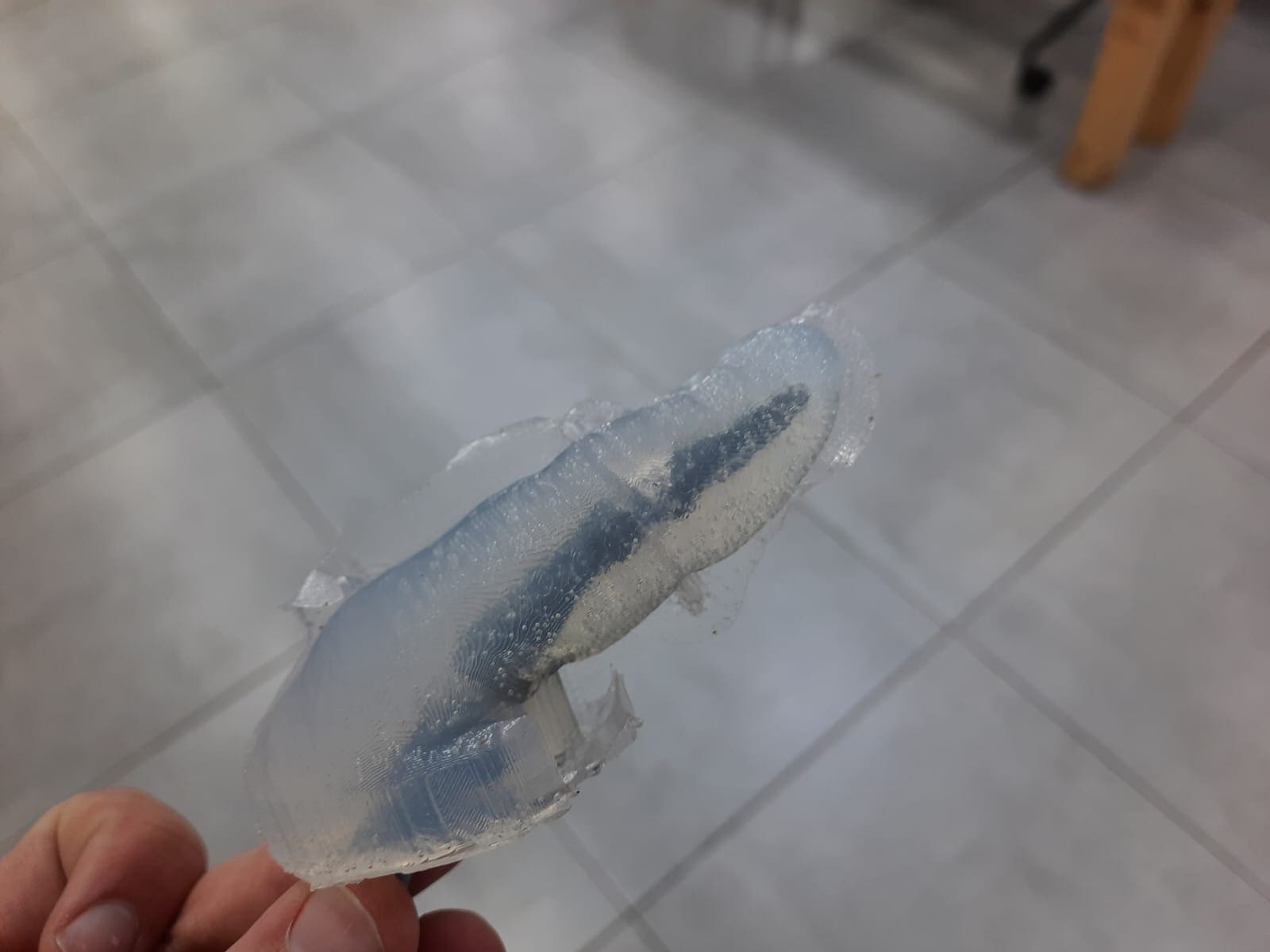

For a preliminary trial, I decided to design, slice, and print a test mold of the thumb using an FDM printer, specifically the Ultimaker S5. This approach offered a quick and accessible way to assess the feasibility of the casting process before committing to more complex molds.

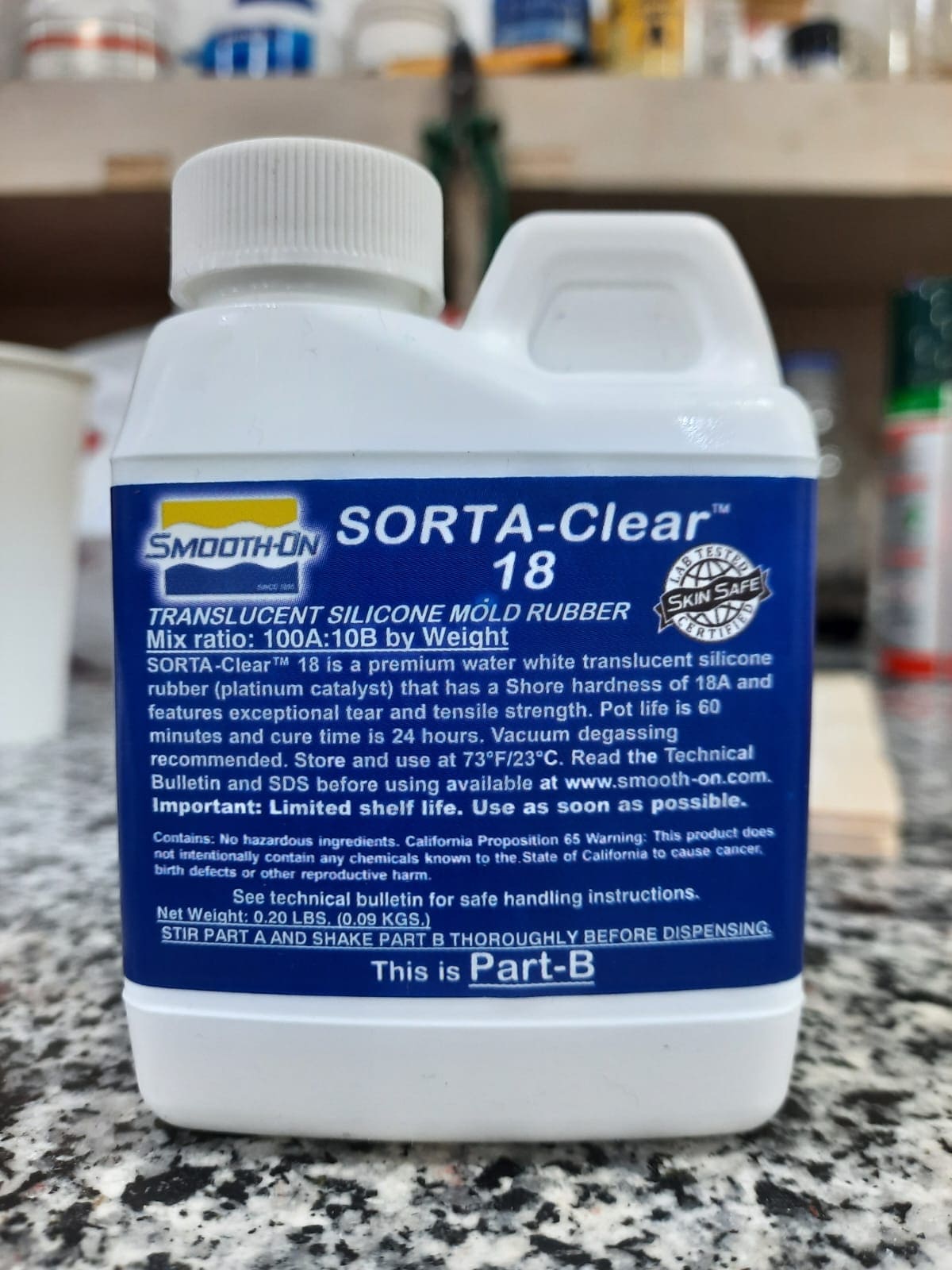

Once the mold was printed, I carefully inserted the previously printed bones into their designated positions within the mold. To create the cast, I opted for Sorta Clear silicone, chosen for its transparency and flexibility, which would allow for accurate replication of the bones’ details.

To minimize the presence of bubbles in the cast, I experimented with using a vacuum chamber during the pouring process. While this technique is commonly used to remove air bubbles from liquid materials, I encountered some challenges due to the absence of vents in the mold. As a result, the vacuum chamber was not entirely effective, and some bubbles persisted in the cast.

Despite the presence of these bubbles, the test provided valuable insights into the casting process and highlighted areas for improvement in mold design and execution. This experience informed subsequent iterations and refinements, contributing to the overall development of the project.

Design¶

Slicing¶

Printing¶

Setup¶

Pouring¶

Steps for Mixing and Pouring Sorta Clear Silicone for FDM Mold¶

-

Preparation:

- Ensure your mold is clean and free of any debris.

- Apply a mold release agent if necessary to facilitate the demolding process.

-

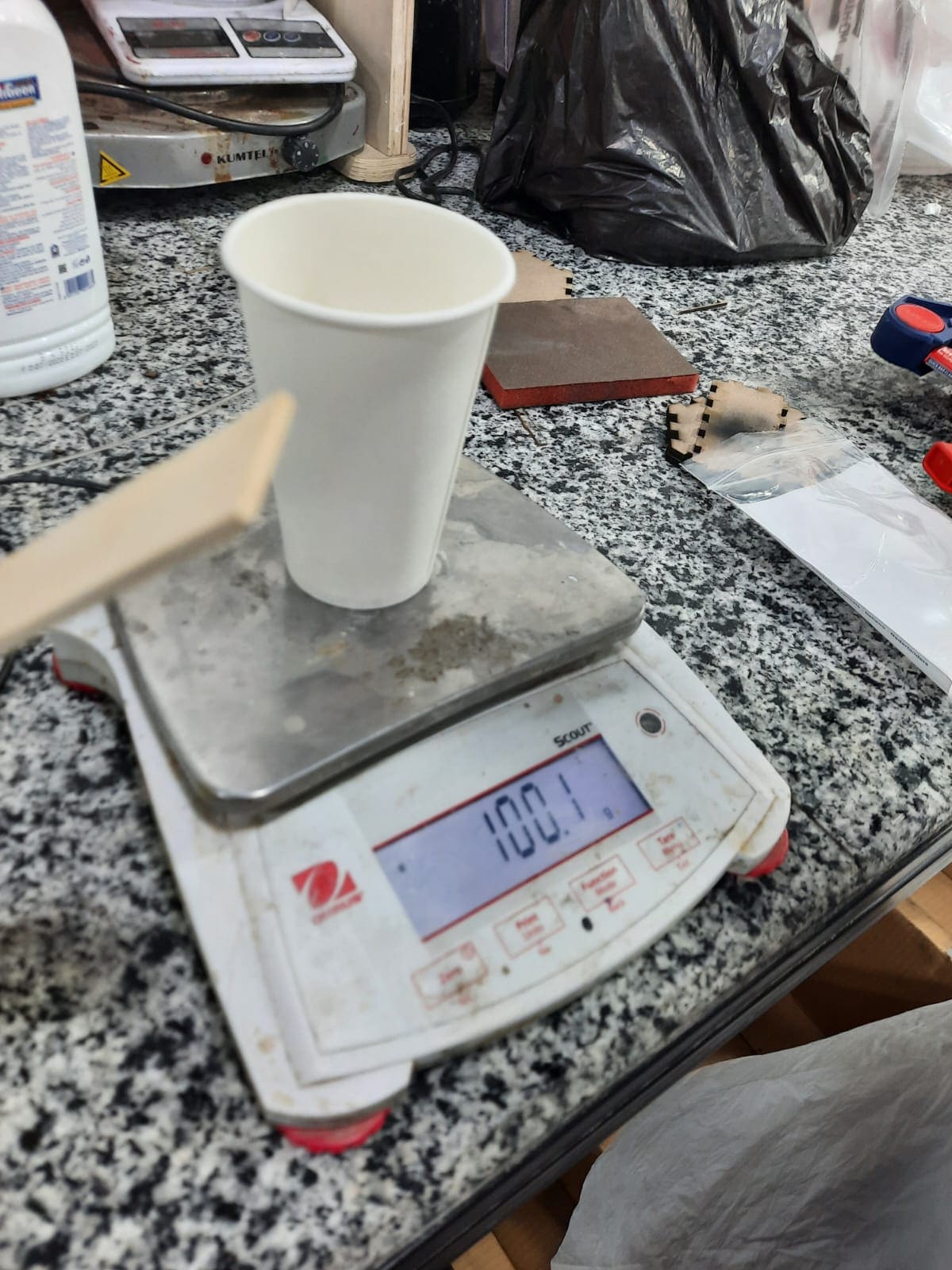

Measuring:

- Measure the required amounts of Part A and Part B according to the manufacturer’s instructions.

- Use separate measuring tools for each part to avoid cross-contamination.

-

Mixing:

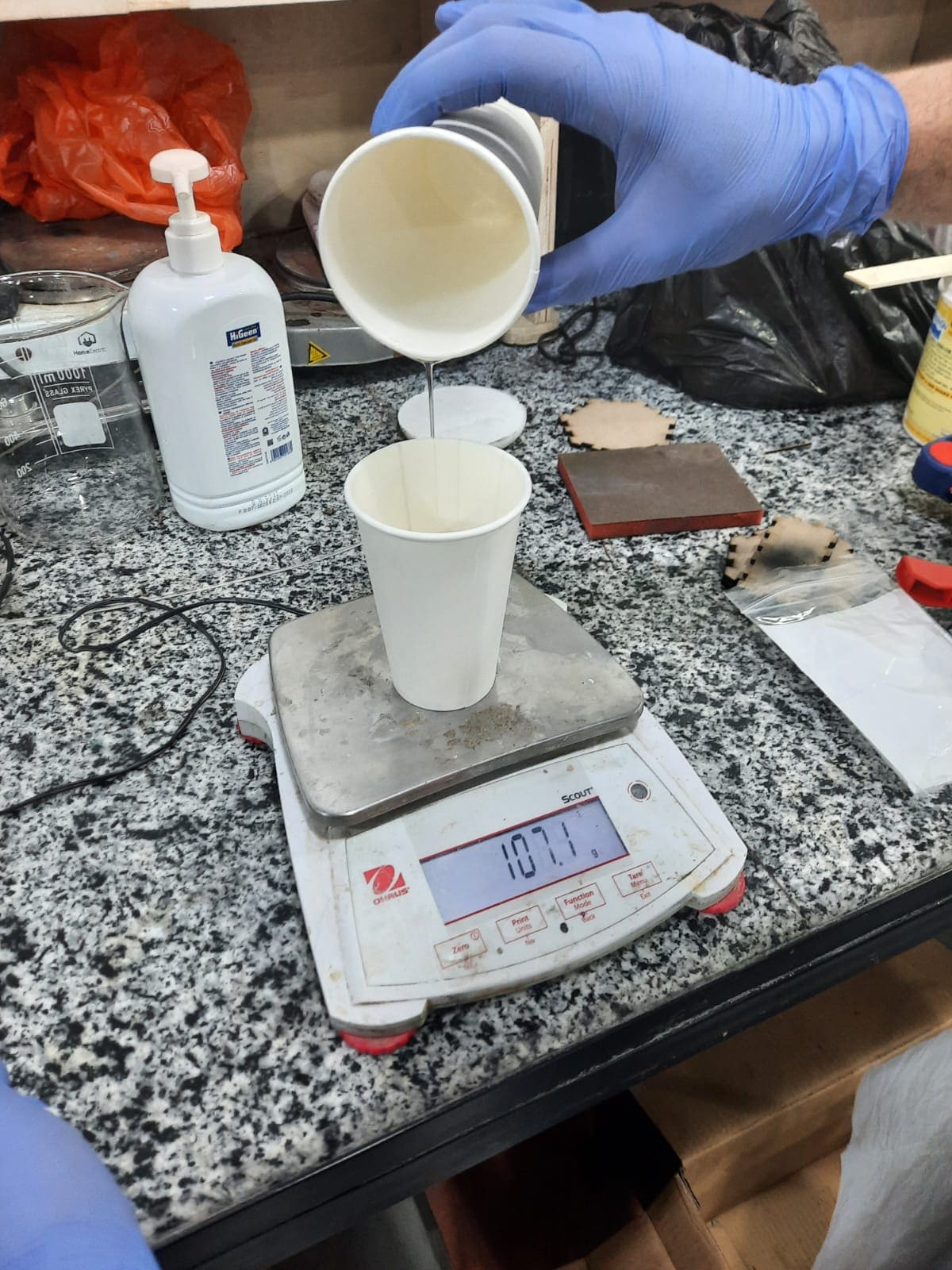

- Pour Part A into a clean mixing container.

- Add Part B to the container.

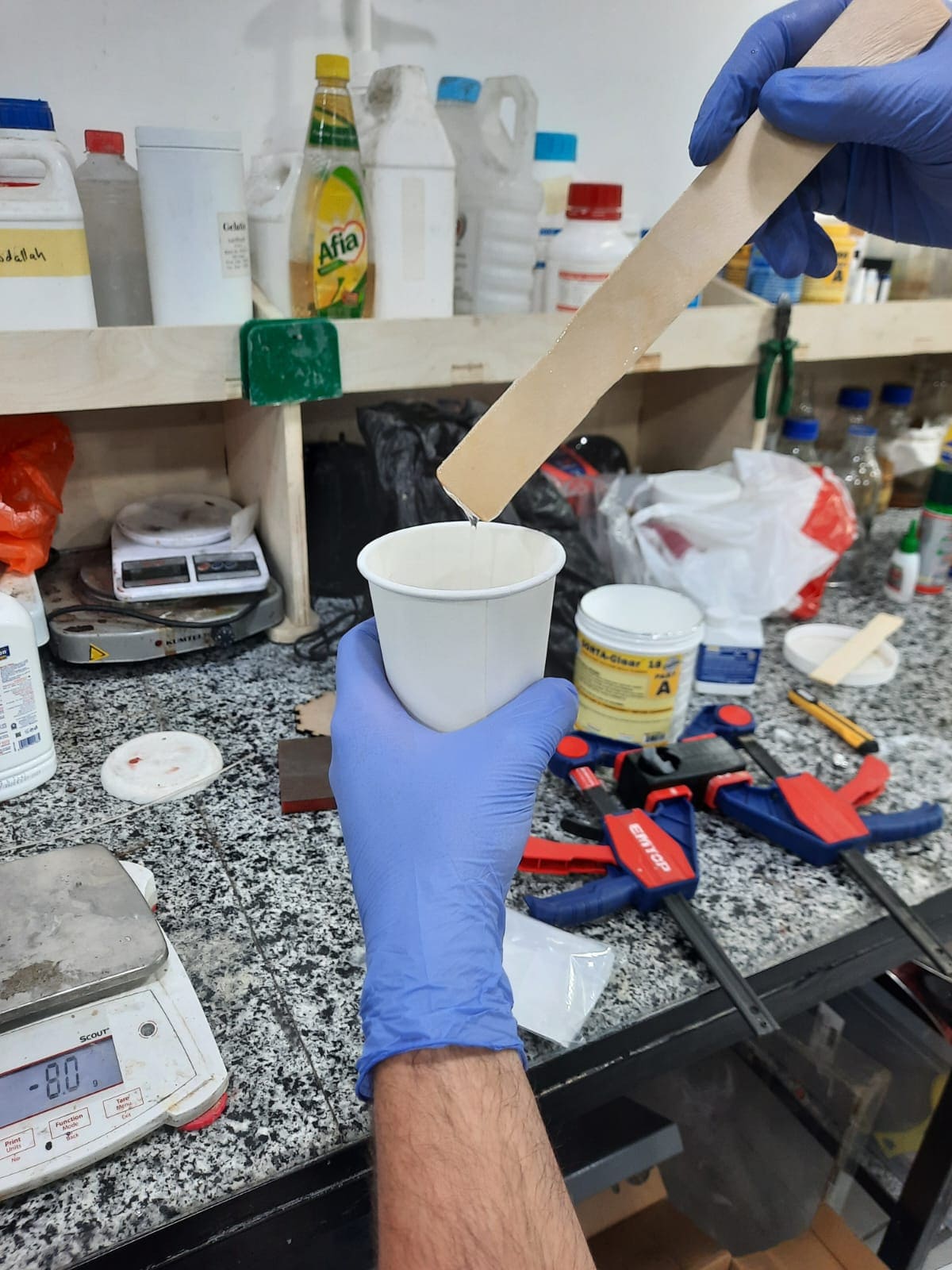

- Stir thoroughly for at least 3 minutes, scraping the sides and bottom of the container to ensure a uniform mix.

-

Degassing:

- If available, use a vacuum chamber to remove any trapped air bubbles from the mixed silicone.

-

Pouring:

- Slowly pour the mixed silicone into the mold, starting from one corner and allowing it to flow naturally to avoid trapping air bubbles.

- Fill the mold completely and let it cure according to the manufacturer’s recommended curing time.

SLA MOLD TEST:¶

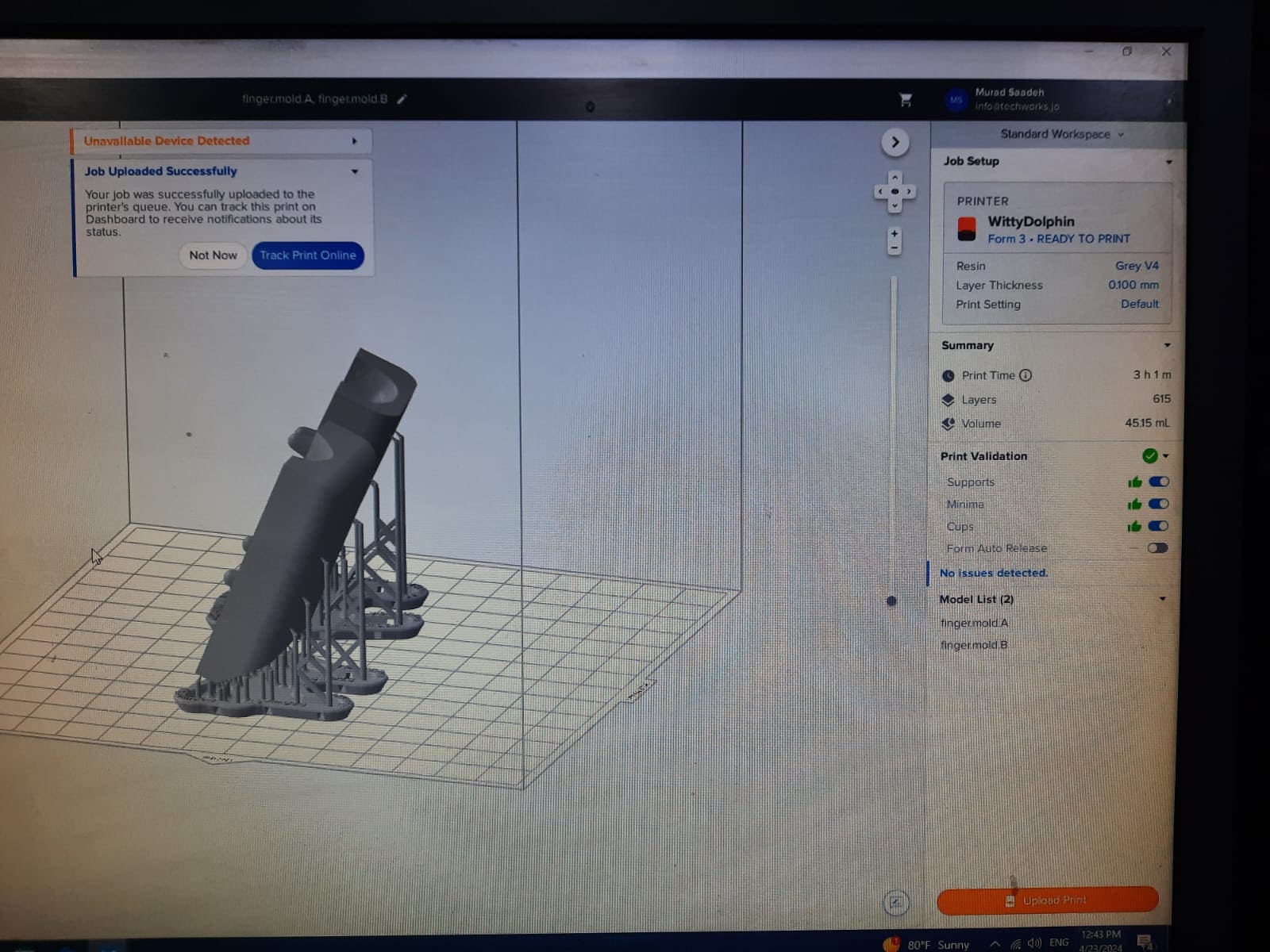

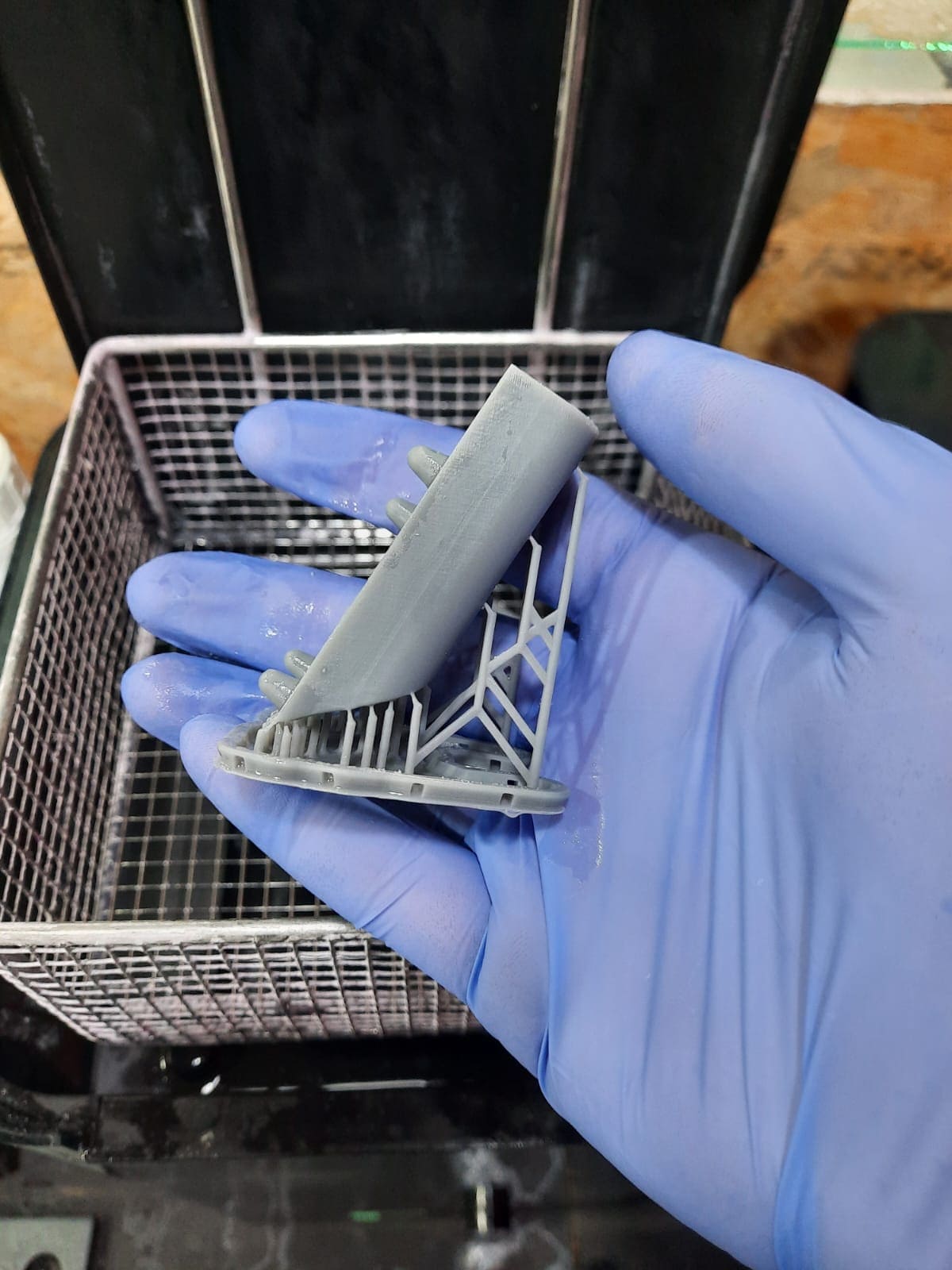

For a more refined test, I decided to explore the use of SLA printing for creating a mold, focusing on the pointer finger. Utilizing SLA technology offered the advantage of higher precision and smoother surface finish compared to FDM printing.

I began by designing the mold, incorporating features on the two sides to facilitate alignment and ensure a snug fit when joining the halves. These alignment features were crucial for maintaining accuracy during the casting process.

After completing the design, I sliced the model and initiated the printing process using the SLA printer. The printer meticulously deposited layers of resin, gradually building up the mold with intricate detail.

Once the printing was complete, I carefully removed the mold from the printer and inspected it for any imperfections. Satisfied with the quality of the mold, I proceeded to pour the casting material.

For this test, I chose Smooth-On Dragon Skin silicone, renowned for its flexibility and durability. The mold halves were carefully aligned and securely clamped together before pouring the silicone.

The addition of alignment features proved to be effective, ensuring that the two halves of the mold aligned perfectly and minimized any potential leakage during the casting process.

Slicing¶

Printing¶

Pouring¶

Steps for Mixing and Pouring Dragon Skin Silicone for SLA Mold¶

-

Preparation:

- Ensure your mold is clean and free of any debris.

- Apply a mold release agent if necessary to facilitate the demolding process.

-

Measuring:

- Measure the required amounts of Part A and Part B according to the manufacturer’s instructions.

- Use separate measuring tools for each part to avoid cross-contamination.

-

Mixing:

- Pour Part A into a clean mixing container.

- Add Part B to the container.

- Stir thoroughly for at least 3 minutes, scraping the sides and bottom of the container to ensure a uniform mix.

-

Degassing:

- If available, use a vacuum chamber to remove any trapped air bubbles from the mixed silicone.

-

Pouring:

- Slowly pour the mixed silicone into the mold, starting from one corner and allowing it to flow naturally to avoid trapping air bubbles.

- Fill the mold completely and let it cure according to the manufacturer’s recommended curing time.

CNC MACHINING MOLD TEST:¶

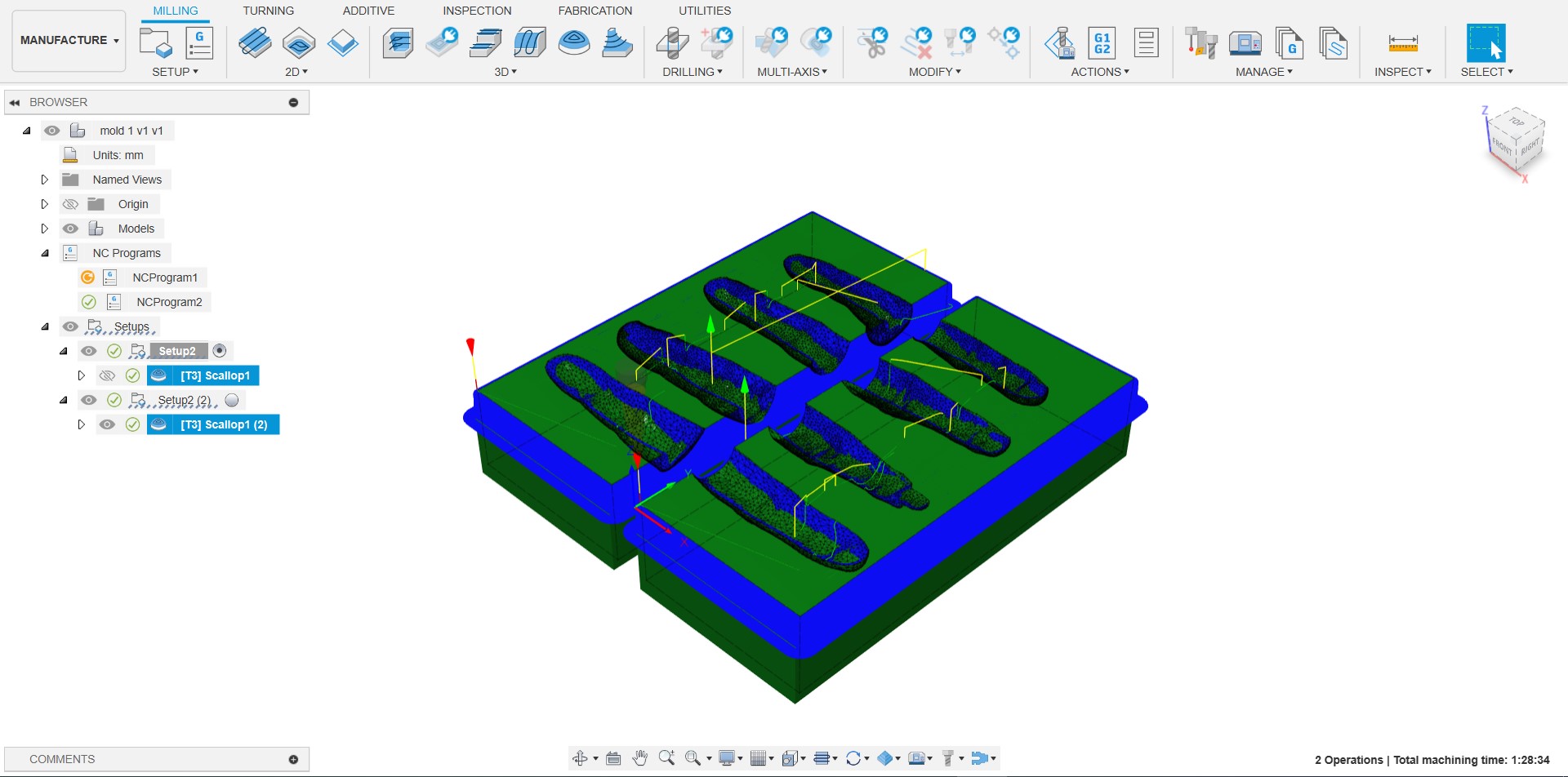

Designing and Machining the Mold for Four Fingers

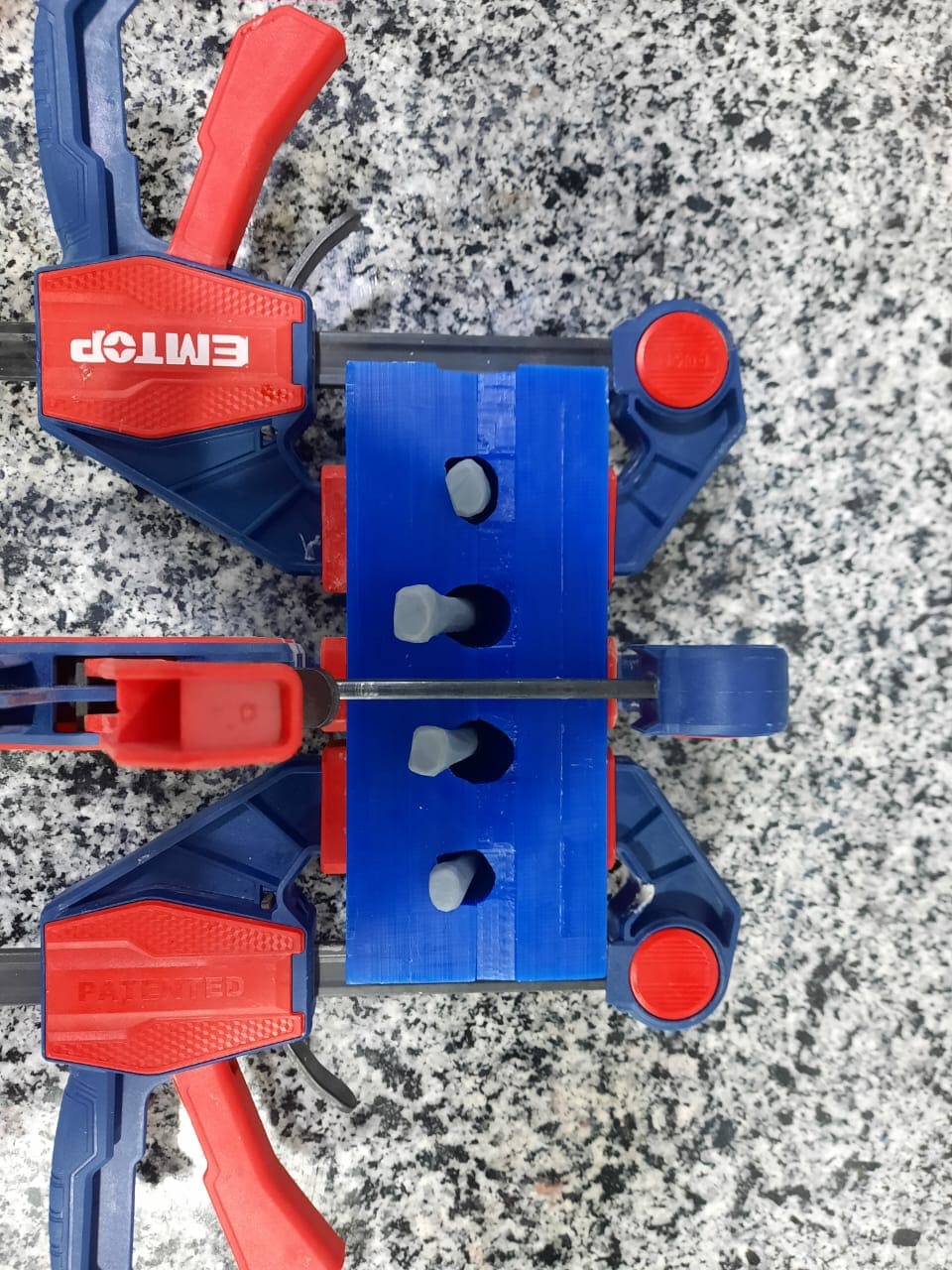

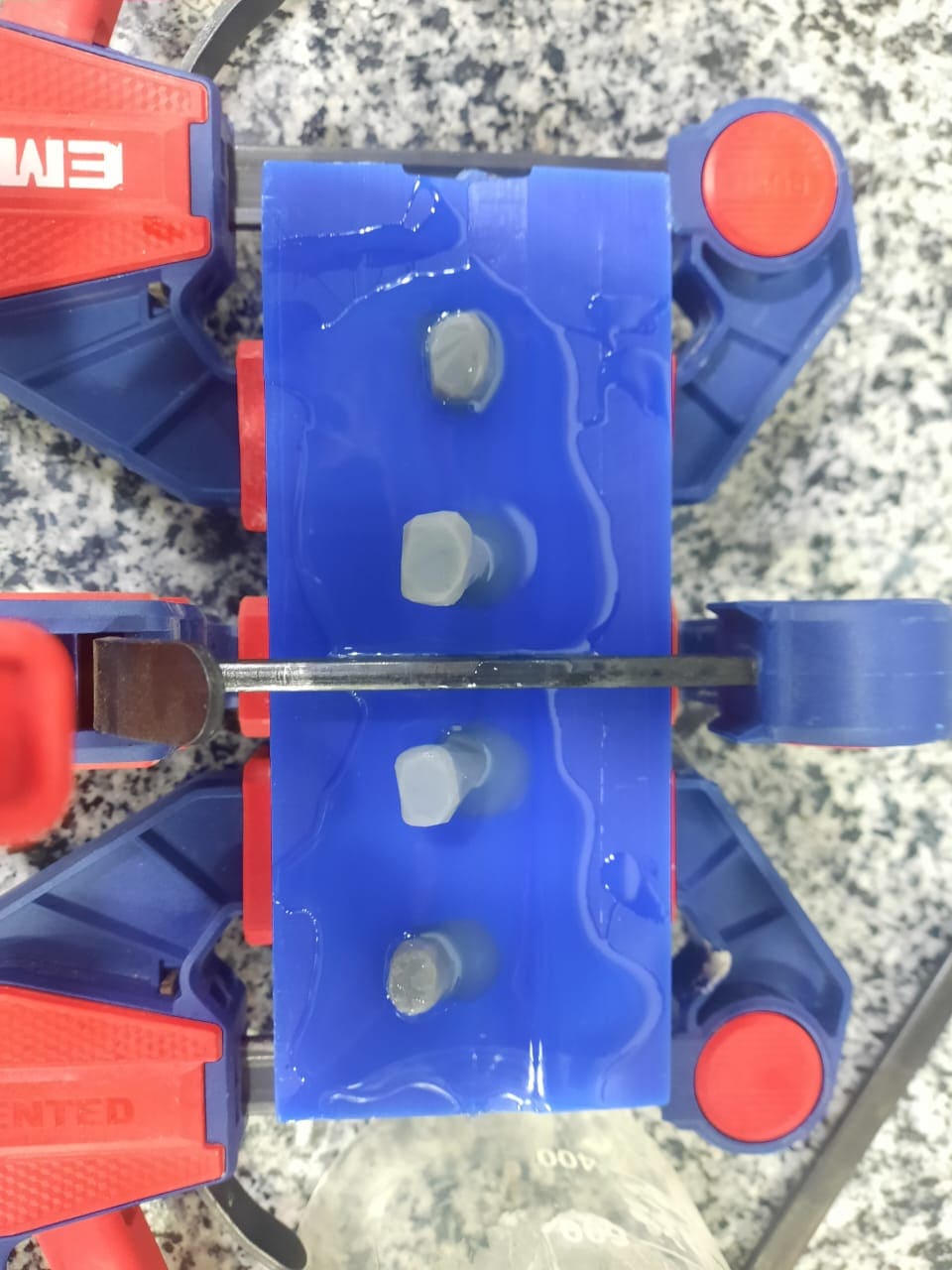

In pursuit of a more efficient production process, I ventured into designing a mold capable of accommodating four fingers, intending to machine it from two wax blocks on the ShopBot CNC machine. This approach aimed to leverage the precision and repeatability of CNC machining for consistent mold quality.

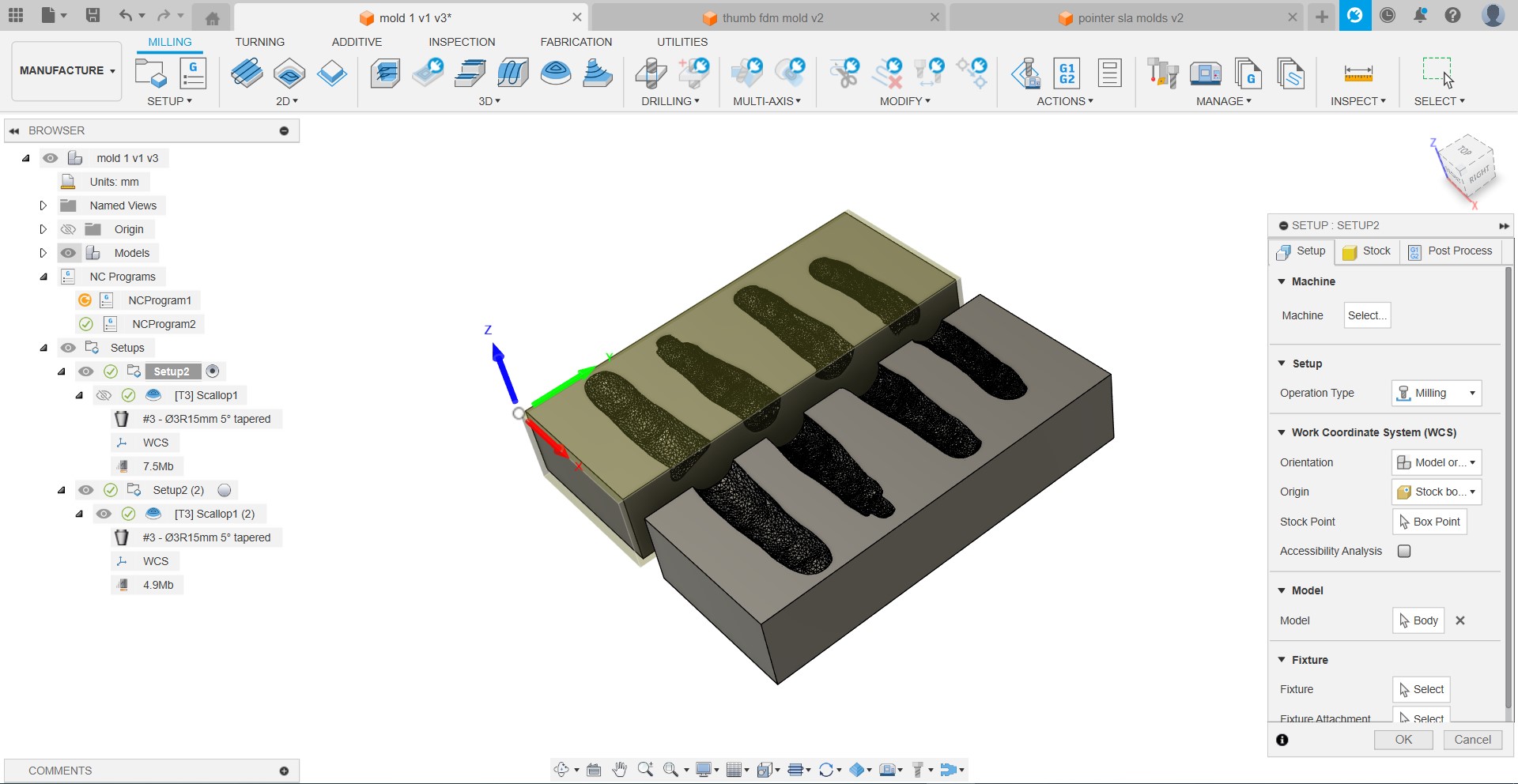

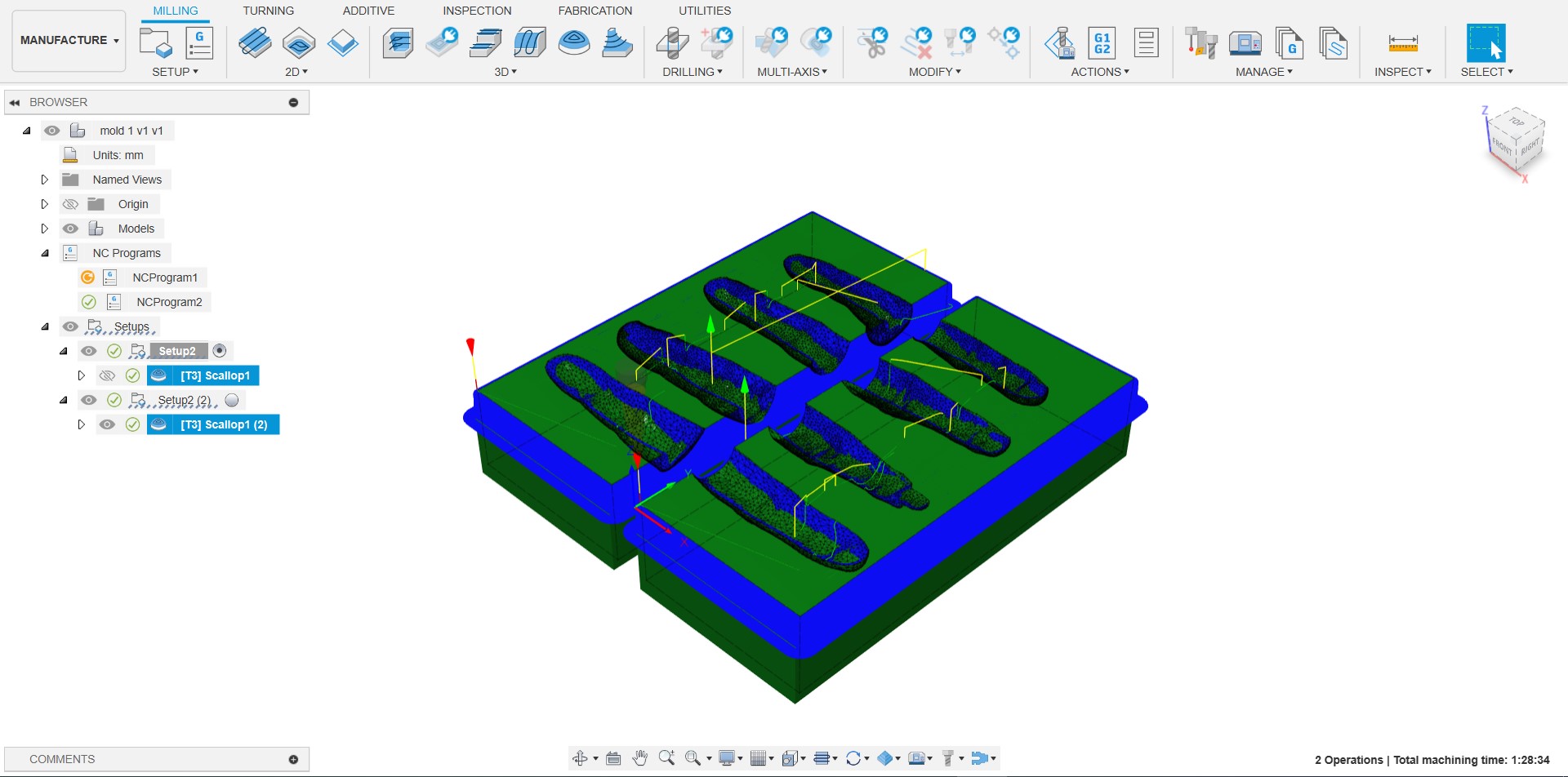

Using Fusion 360, I designed the mold, ensuring it could accommodate all four fingers while optimizing material usage and machining efficiency. Additionally, I generated toolpaths within Fusion 360, selecting a scallop toolpath and thoroughly simulating it to anticipate any potential issues.

Toolpath Generation in Fusion 360¶

After finalizing the mold design in Fusion 360, I switched to the Manufacturing workspace to create the necessary toolpaths for CNC machining. Here’s a detailed breakdown of the steps:

-

Setup:

- I created a new setup, selecting the appropriate milling operation.

- Defined the stock size based on the dimensions of the wax blocks.

- Set the work origin to the top corner of the stock to ensure accurate alignment during machining.

-

Tool Selection:

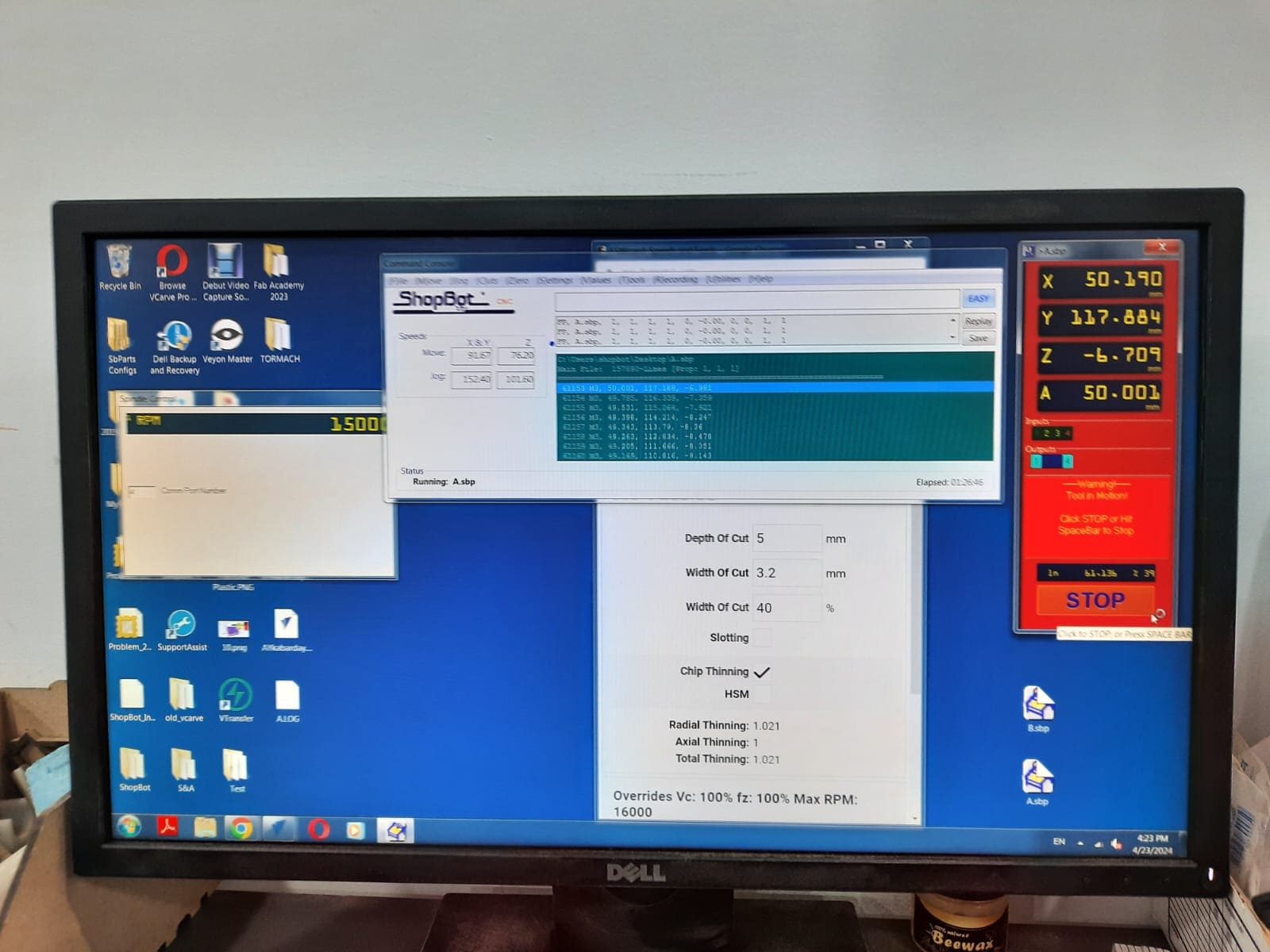

- Chose a 3R15mm 5-degree tapered endmill for the operation.

- Configured the tool parameters, including a spindle speed of 15000 RPM and a rapid feed rate.

-

Scallop Toolpath:

- Selected the

Scalloptoolpath from the 3D toolpath options. - Specified the tool parameters and ensured that the toolpath would efficiently cover the entire mold surface without unnecessary retractions.

- Adjusted the stepdown and stepover to balance machining time and surface finish quality.

- Selected the

-

Simulation:

- Ran a thorough simulation of the toolpath to identify and rectify any potential issues.

- Ensured that the tool movements were smooth and free of collisions or overcut areas.

CNC Machining Process¶

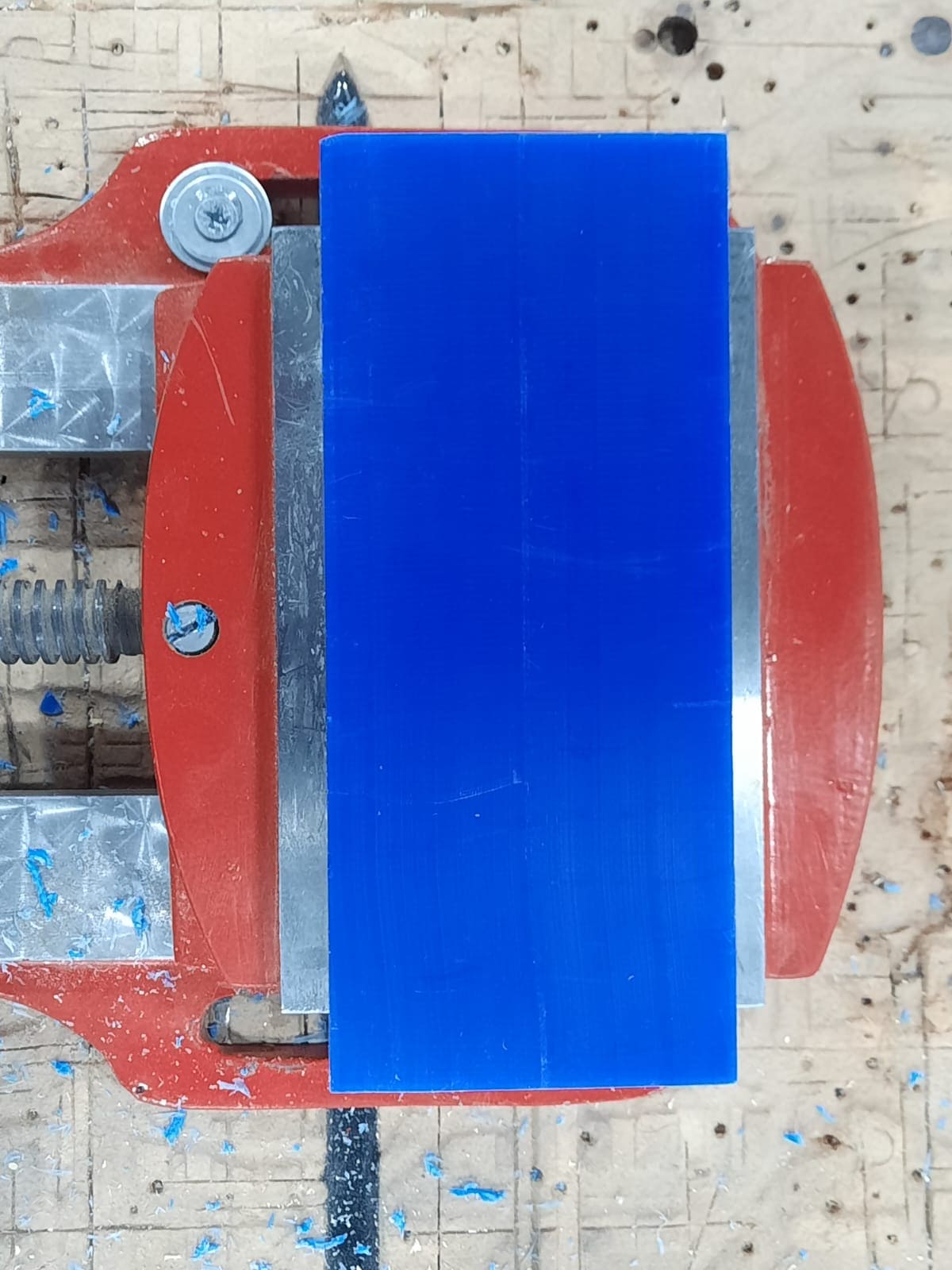

With the design and toolpaths finalized, I proceeded to set up the ShopBot CNC machine for machining. This involved attaching a vise to the machine bed to securely hold the wax blocks in place. Prior to machining, I zeroed the machine and verified the setup to guarantee accuracy during the machining process.

Executing the program, I carefully monitored the machining progress, ensuring that each pass was executed precisely according to the predetermined toolpaths. Upon completion, I inspected the machined surfaces and was pleased to find a flawless finish, indicative of the CNC machine’s capabilities.

Mold Assembly and Casting¶

With both halves of the mold successfully machined, I proceeded to join them together, clamping them using clamps, and sealing the seam between the halves using hot glue to prevent any leakage during casting. Subsequently, I poured the fingers using Smooth-On Sorta Clear silicone, inserting the previously printed bones into their designated positions within the mold.

The outcome surpassed expectations, with the CNC-machined mold producing casts of exceptional quality and detail. This approach not only streamlined the production process but also ensured consistency and reliability in the final products.

Steps for Mixing and Pouring Sorta Clear Silicone for CNC Machined Mold¶

-

Preparation:

- Ensure your mold is clean and free of any debris.

- Apply a mold release agent if necessary to facilitate the demolding process.

-

Measuring:

- Measure the required amounts of Part A and Part B according to the manufacturer’s instructions.

- Use separate measuring tools for each part to avoid cross-contamination.

-

Mixing:

- Pour Part A into a clean mixing container.

- Add Part B to the container.

- Stir thoroughly for at least 3 minutes, scraping the sides and bottom of the container to ensure a uniform mix.

-

Degassing:

- If available, use a vacuum chamber to remove any trapped air bubbles from the mixed silicone.

-

Pouring:

- Slowly pour the mixed silicone into the mold, starting from one corner and allowing it to flow naturally to avoid trapping air bubbles.

- Fill the mold completely and let it cure according to the manufacturer’s recommended curing time.

Conclusion¶

Throughout this molding and casting week, I gained a wealth of new skills and techniques that will be invaluable for future projects. I explored various aspects of 3D printing, from using SLA printers to produce detailed bone models to designing and slicing molds with alignment features for accurate assembly.

I experimented with different mold-making methods, including FDM printing for initial tests and CNC machining for more complex molds. Each method provided unique insights into the advantages and challenges of different fabrication techniques. The CNC machining process, in particular, taught me how to create precise molds and use advanced software like Fusion 360 for designing and generating toolpaths.

Despite time constraints preventing the creation of a complete hand, working on individual fingers allowed me to refine my casting skills. I learned how to effectively use silicone materials, such as Sorta Clear and Smooth-On Dragon Skin, and the importance of mold design in minimizing air bubbles and achieving high-quality casts.

Overall, this week has been a tremendous learning experience, equipping me with a diverse set of skills in molding and casting. These new techniques will undoubtedly enhance my capabilities in future fabrication projects, enabling me to tackle more complex and ambitious endeavors with confidence.