PROJECT DEVELOPMENT

This week is the second-to-last week before the final projects are due for presentation. The goal of this assignment is to ensure thorough preparation for the final project by compiling a summary and addressing some crucial questions. This week's task involves answering the following questions:

- What tasks have been completed, and what tasks remain?

- What's working? what's not?

- What questions need to be resolved?

- What will happen when?

- What have you learned?

What tasks have been completed, and what tasks remain?

Completed Tasks

There are several tasks and part in the final project that should incorporate the following:

- ✓ CAD design(2D & 3D)

- ✓ Subtractive manufacturing

- ✓ Additive manufacturing

- ✓ Electronics design & production

- ✓ Programming

- ✓ Interface development

- ✓ System Integration

CAD Design (2D & 3D)

The design are described on the final project page.

2D design was done:

- Electronics Box /Enclosure (Fusion/Inkscape)

- PCB Design (KiCad)

3D Design was done:

- Frame

- foot for the Box

- 4 shaft holder parts

- stepper motor holder

- 2 linear motion holder

- 3 system integration parts

- cable connector

Subtractive and additive manufacturing

As subtractive methods I used:

- Lasercutting (Electronics Box)

- Milling (PCB)

As additive methods I used:

- 3D Printing (Foot, shaft holder parts, stepper motor holder,linear motion holders,3 system integration parts,cable connector)

- Molding and Casting (Barometric connector)

Electronics design and production

The electronics I design and manufactured are described in week 04 and week 08

Programming

A part of the programming can be find in week 09 and week 11. A lot of the programming can be found on the final project page.

Interface Development

The Interface programming for my final project was already started in week 14. Nevertheless, there are still parts to imptrove and integrate in this interface.

System Integration

Everything about system integration can be find in week 16.

Remaining Tasks

Right now, I still have to finish the interface, as I really like the interface to have these functions:

- Get the start measurements to check if the muscle is fully relaxed in the beginning

- Start snd stop of the measurements

- Create a graph from the measurements

Additionally, the linear motion system needs some new parts as the tolerance of the parts is too big.

What is Working? What is not Working?

Most things are working:

- The stepper motor is moving and can be controlled by the interface

- The load cell measurements are taken by the PCB and can be send via UART

- The measurements of the barometric pressure sensor are taken by the PCB and can be send via UART

- The fixture of the artificial muscle is working

- The enclosure and frame are built and mounted together

- The system integration is finished

Some parts are not working as expected:

- The barometric sensor is not measuring the over 12 kPa even though I ordered a new one

- I had some issues with the female pins of the motor driver on the PCB as they broke of but I was able the soldering them on again

- Unfortunately, the load cell was destroyed during the transportation of the machine, but I ordered a new one.

What questions need to be resolved?

What to do about the barometric sensor and why is it not working? As I read some reviews about sensor, that problem seems to be a general issue. The reason could be counterfeit components. As the new sensor just measured value until 12 kPa, I decided that I will do the measurement until 12 kPa, which should be good enough to evaluate the machine.

When will the new load cell arrive? It will be there in two days and I still have five days until my presentation, therefore it is a little bit tight but possible.

What will happen when?

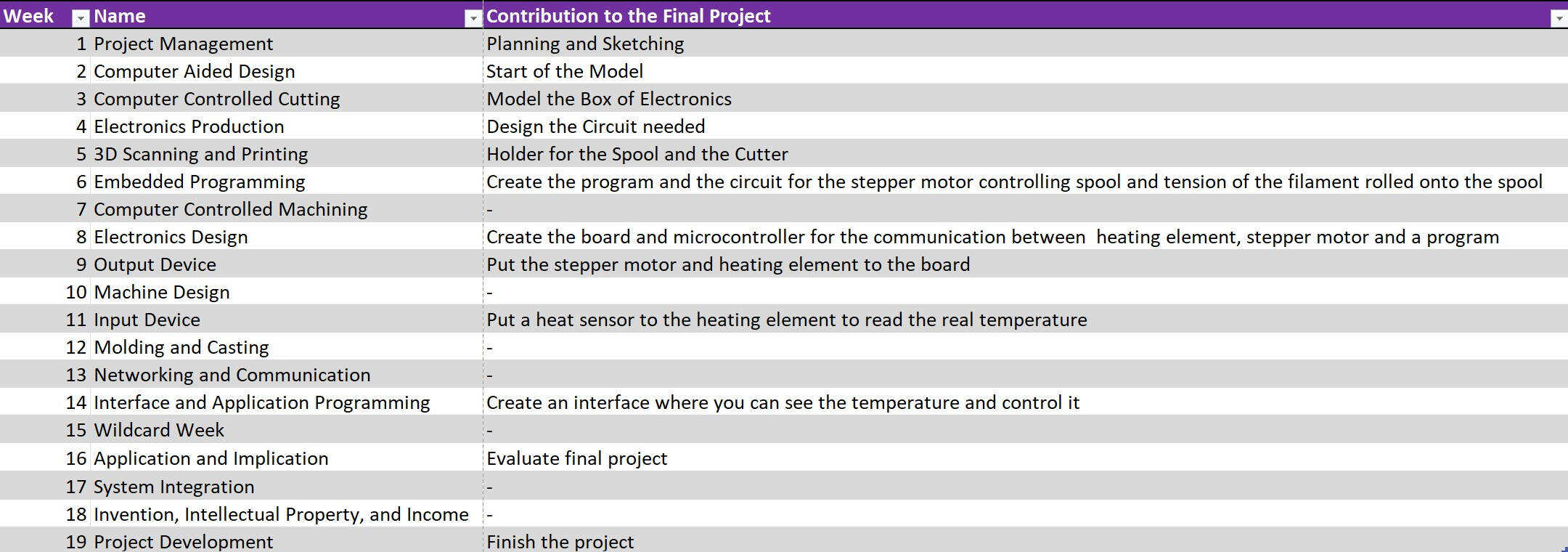

I made a final project plan in the beginning:

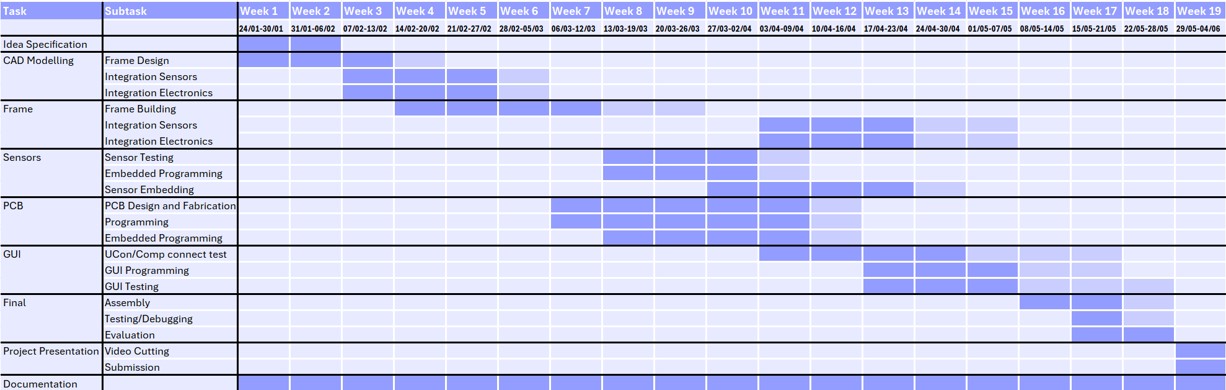

And I made one in the mid term:

Well... I was not very good in following these plans. The first one was not followed as it was more a raft and a lot of things changed.

For the second plan, the problem was mainly that parts did not arrived in time, therefore I had to start with tasks in a different order. (e.g. The interface programming started before building the frame).

For the last days I made a plan for the last tasks:

What have you learned?

I have learned so much during this experience that I can't even put it into words. Working on my project has been incredibly rewarding, and I absolutely loved every moment of it. I highly recommend Fabacademy to anyone interested in learning these skills and embarking on a similar journey!

Here are my standout:

- I learned elecronics design, theory and production

- I learned to use machines correctly and use them to embrace my creativity

- I learned more thing about problem solving