5. Electronics production¶

This week I I built a USB to serial adapter with LEDs. I learned how to solder and mill a board.

Group Project¶

Th group project this week was learning how to use the milling machine. We had to mill a test for the bit to see how small of a cut it could make.

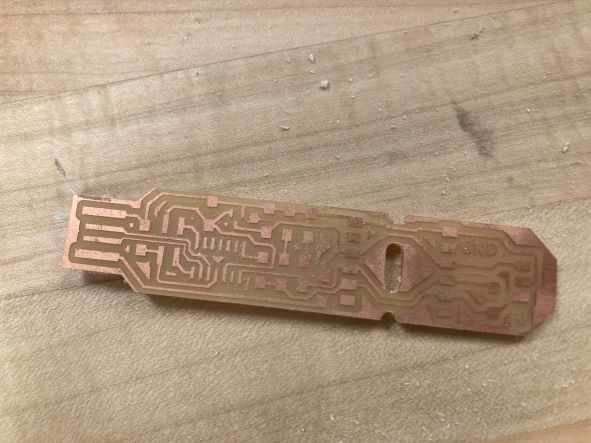

Milling the board¶

I milled the board on a SRM-20 by Monolabs. It took me three tries to successfully mill it. The first time I didnt leave enough room for the bit to cut the full board outThe second time I put the bit to far into the copper and found out that I needed to invert the design so it cut around the traces not on the traces.

Link to instructions used : https://docs.google.com/document/d/1IBKZu-5q0hexmYGWNFWA64giY4mmglZQRK6Q2b19Nos/edit

Link to instructions used : https://docs.google.com/document/d/1IBKZu-5q0hexmYGWNFWA64giY4mmglZQRK6Q2b19Nos/edit

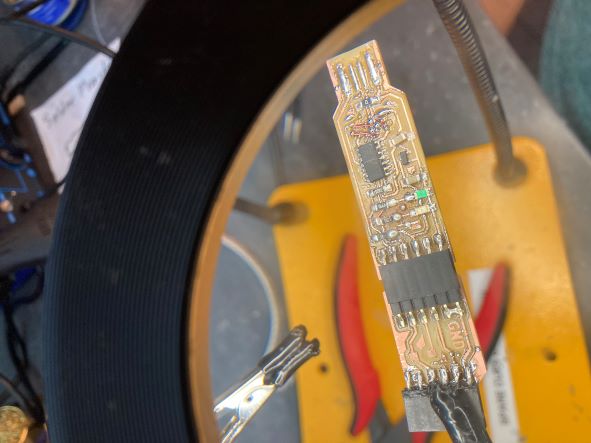

Soldering¶

Learning how to solder was fun but frustrating at times especially when my pieces blew away or when I accidentily melted some solder paste that I didn’t mean to. The copper braid was useful for removing extra solder.

I accidentily broke a piece of my board off including some copper pads so I tried fixing it with some copper wires

It did not woek so I’m going to make a whole new board

Programming¶

Did not complete as I have to build a new board. I did already set up ardino on my computer