6. 3D Scanning and printing¶

Group assignment:

WHAT IS 3D PRINTING?

3D printing, also known as additive manufacturing, is the process of creating objects through a succession of layers that are superimposed on each other until the desired part is achieved. Although the most commonly used materials in this type of manufacturing are usually plastic alloys, their production can be done with elements of any kind (from biocompatible fabrics to concrete).

A LITTLE OF YOU HISTORY

The 3D printing process was devised in the 1980s and was originally known as “rapid prototyping.” It allowed companies to develop prototypes faster and more accurately than with other methods. After more than 30 years of innovation, its uses are much more diverse today.

WE WILL USE AN ULTIMAKER 2+ PRINTER FOR OUR WORK

Ultimaker 2 Connect , a true industry 4.0 3D printer thanks to its network connectivity: via Wi -Fi or Ethernet, in fact, you can print remotely in the cloud safely for your files. The new Ultimaker 2 Connect filament 3D printer offers you simple and intuitive setup for immediate use. Setting up Ultimaker 2 Connect is simple with hardware installation taking minutes and an on-screen guide for each step. In addition, the feed lever of the new Ultimaker 2 Connect 3D filament 3D printer is more ergonomic and the assisted leveling of the build plate has been improved.

TECHNICAL SPECIFICATIONS

• technology: Fused Filament Manufacturing (FFF) • XYZ axis resolution: 12.5, 12.5, 5 microns • extruder block: simple extruder with removable nozzles • layer resolution with 0.25 mm nozzle: 150 – 60 microns • glass printing plate temperature: (20 – 110 °C) • layer resolution with 0.4 mm nozzle: 200 – 20 microns • nozzle diameter included; 0.4mm • layer resolution with 0.6 mm nozzle: 400 – 20 microns • compatible nozzle diameters (sold separately): 0.25, 0.6, 0.8 mm • layer resolution with 0.8 mm nozzle: 600 – 20 microns • emitted noise: < 50 dBA • power supply: 100-240VAC, 50-60Hz • Connectivity: Wi -Fi, Ethernet, USB • overall dimensions of the machine: 342 x 460 x 580 mm • weight: 10.3kg • cutting software included: Ultimaker Cura, Ultimaker Digital Factory (print management cloud) • Supported systems: macOS, Windows, Linux.

WILL USE ULTIMAKER CURA 4.13.1

LET’S INVESTIGATE

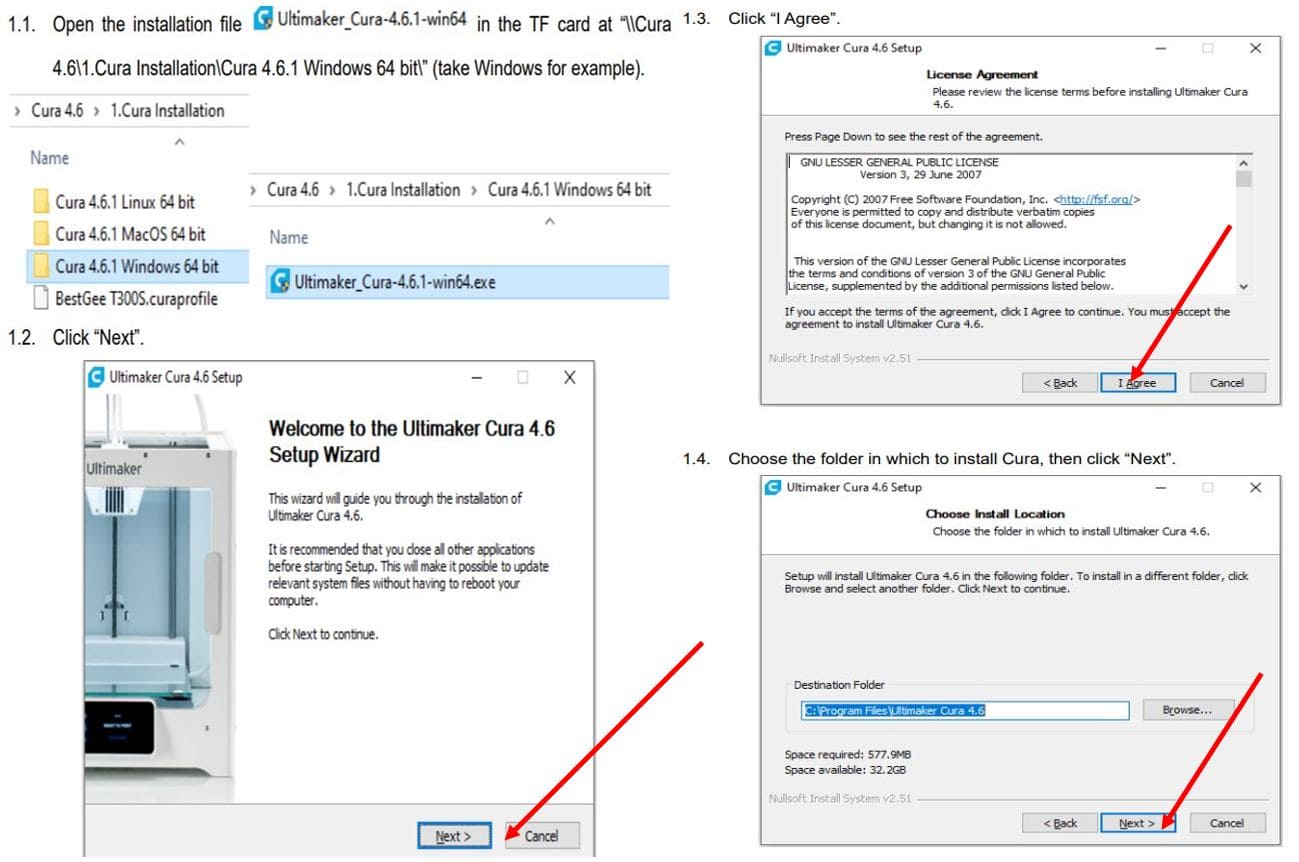

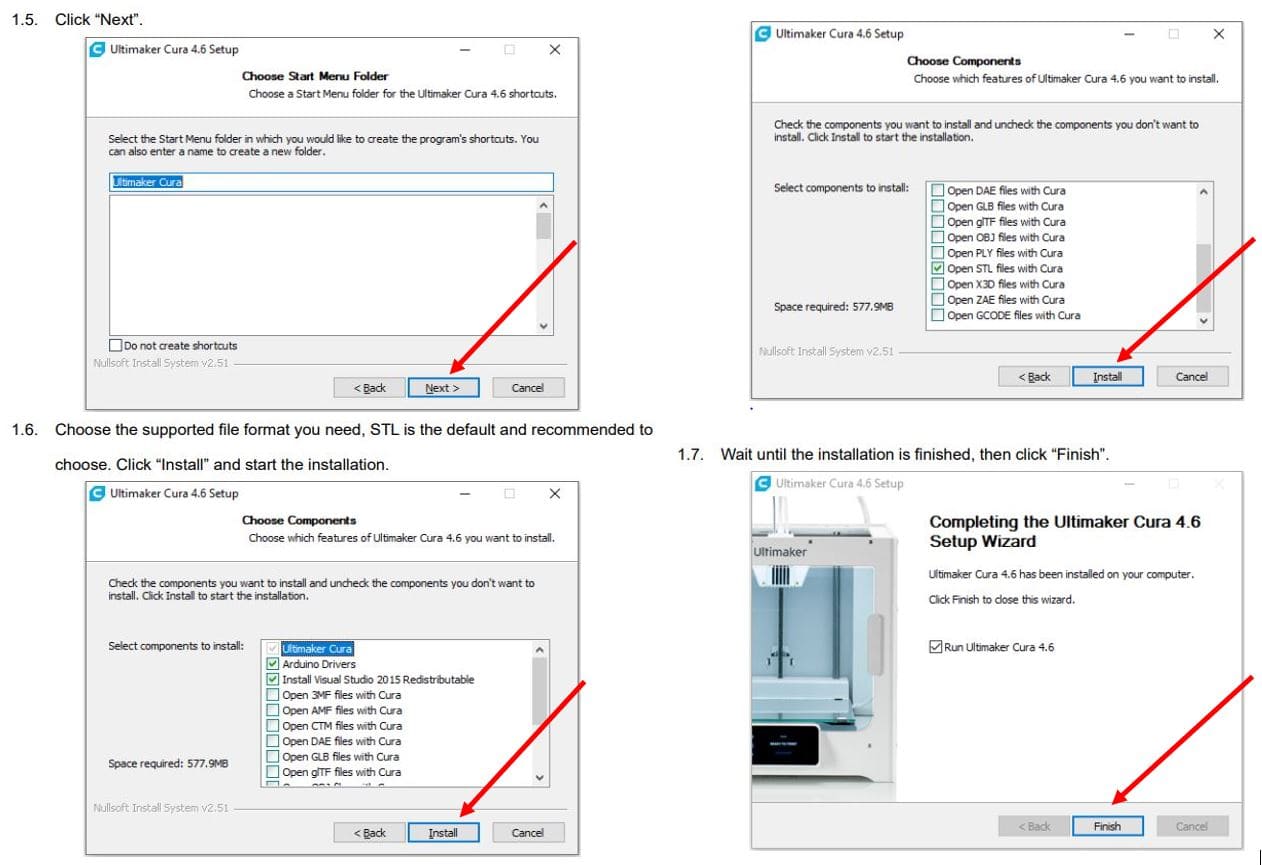

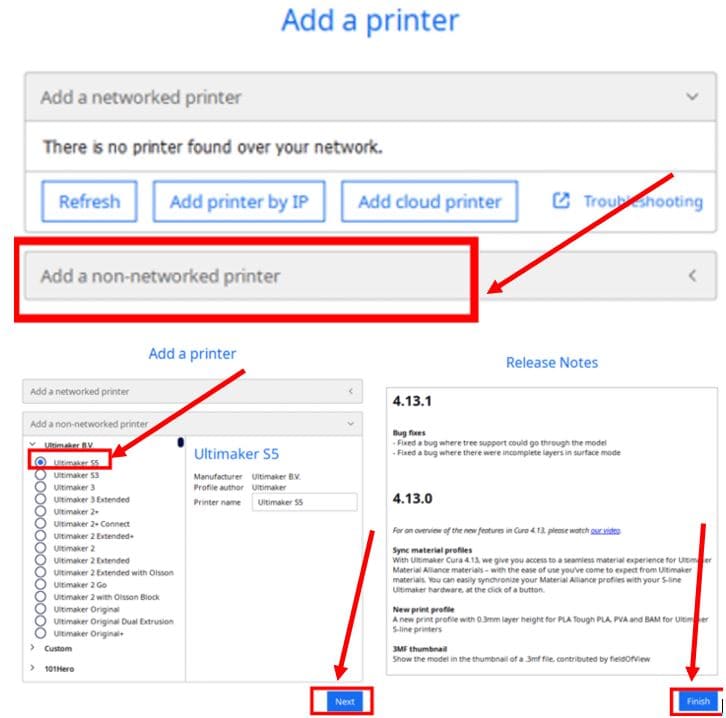

It is open source software, probably the most widespread in the world market for additive manufacturing. The latest version of Cura is 4.5. One of the main advantages of Cura is its ease of use, support for different file formats and compatibility with many 3D printers. Supported formats are STL, OBJ, X3D and 3MF. Although Cura is part of the Ultimaker ecosystem , printers from other manufacturers can use it as well. The software is not only 100% free, but it is also available in 15 languages, so users around the world can easily use it. Another feature is that it is compatible with the most common operating systems: Windows, Mac and Linux. We downloaded and installed the software and these are the steps we followed, as you will see in the following images.