7. Electronics Design¶

Group Assignment¶

Use the test equipment in your lab to observe the operation of a microcontroller circuit board

Assignment¶

Redraw an echo hello-world board, add (at least) a button and LED (with current-limiting resistor) check the design rules, make it, and test that it can communicate. Extra credit: simulate its operation

And so it begins… After having experienced electronics and soldering for the first time…this week we’ll try to design a PCB!

For this week’s assignment we had to re-draw an echo hello-world board, add (at least) a button and LED (with current-limiting resistor), check the design rules, make it, and test that it can communicate.

To design my first time I tried Autodesk Eagle. After following the lesson of Antonio Garosi, our local instructor (essential lesson: I would not know where to start!).

Initially I would have liked to learn how to use Kicad since it is an open source program and is more performing from an industrial point of view even if much more difficult to learn how to use. But after the lesson of I thought it would be better to use Eagle so in case of problems I could ask for help.

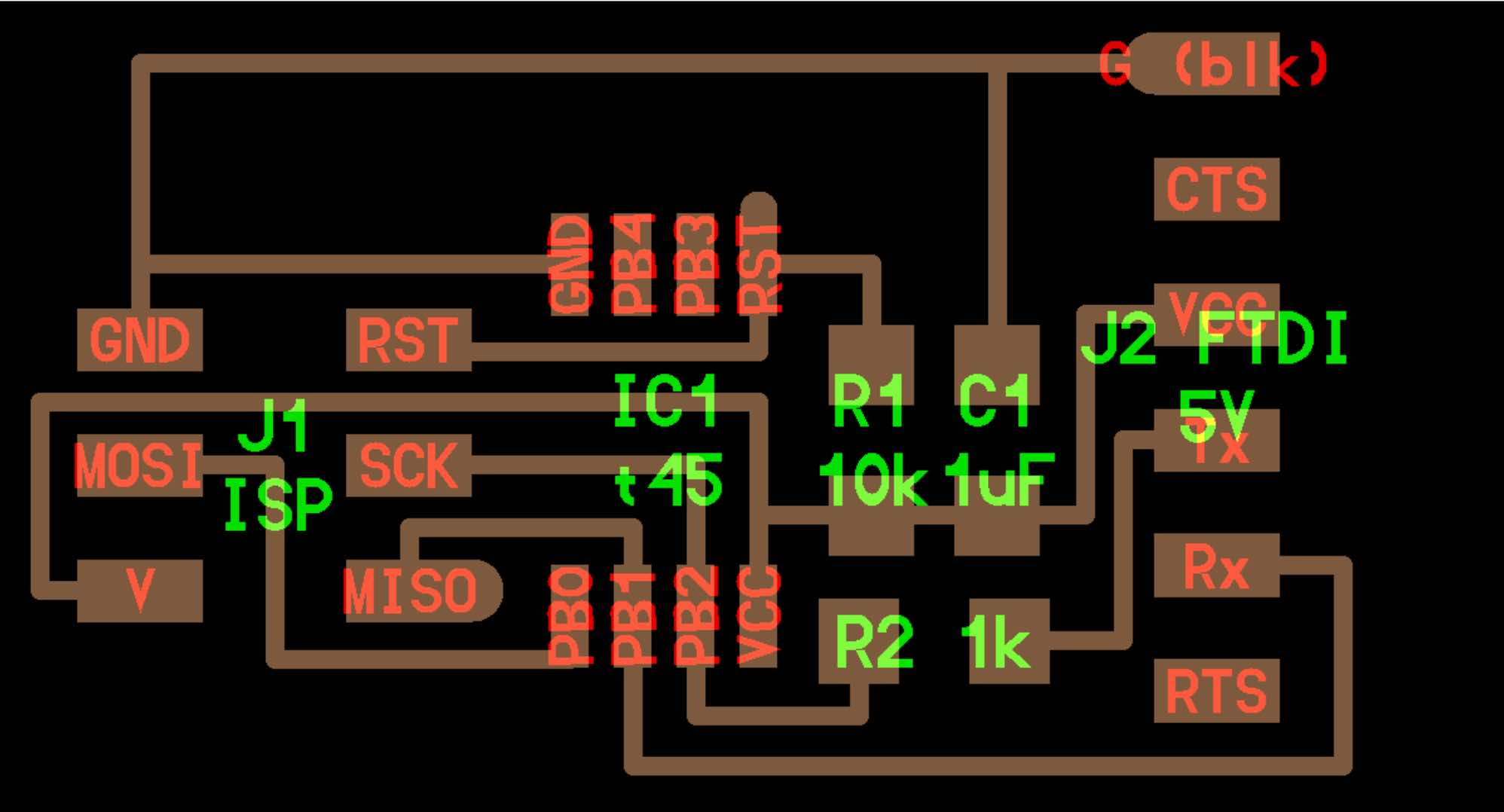

I decided to mill an attiny45-echo board that I found in Neil’s documentation, I downloaded Eagle.

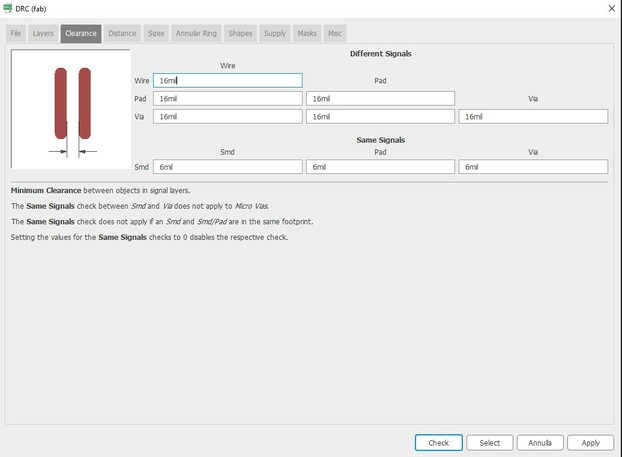

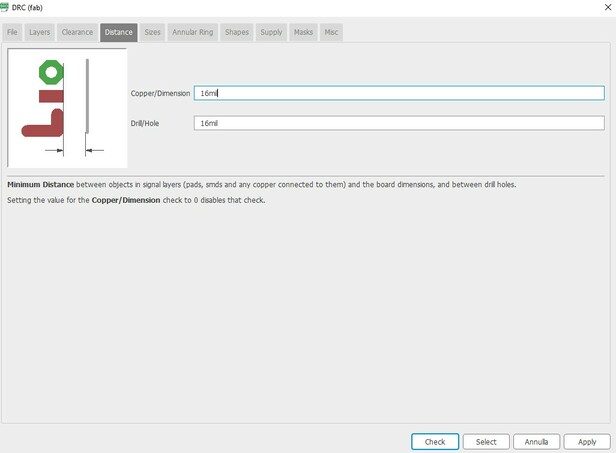

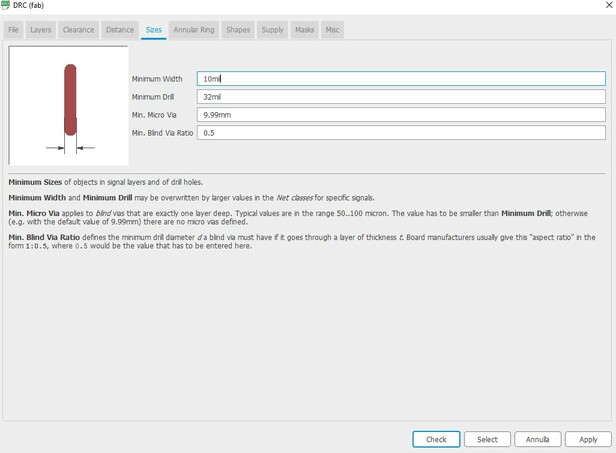

Before starting, I download and add the “Fab Library” inside the Eagle Library and the “Fablab Design Rules” (.dru) to be sure to obtain an output similar to the one that will be produced in the other Fablabs. Clearly we can change them according to our project but a “standard” is always welcome.

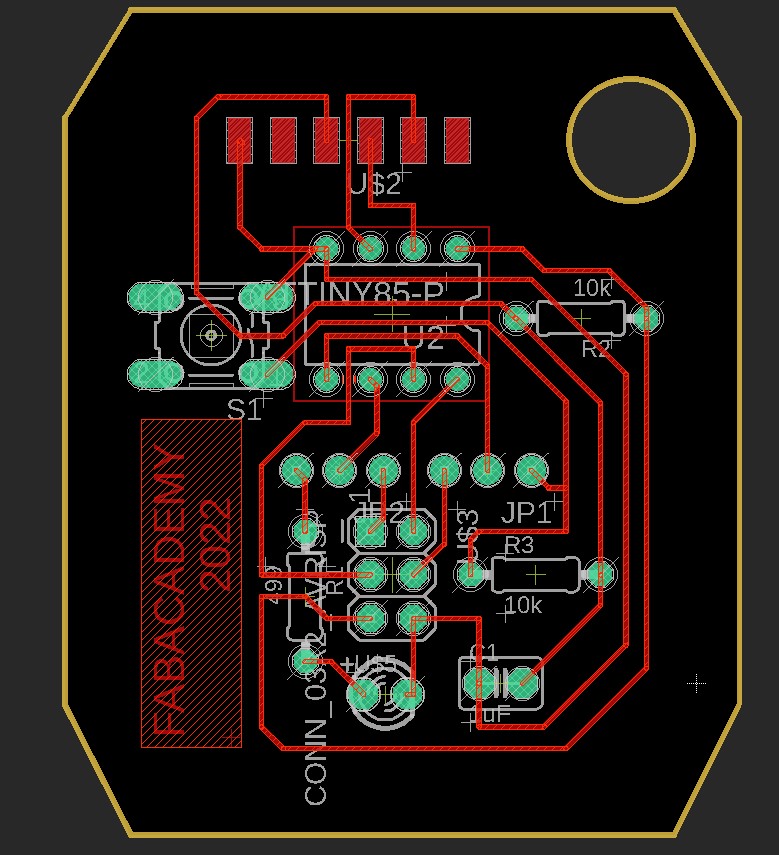

Then I start to add on the schematic page the different components of Hello Board. And here begins my journey…because knowing that I would’t be able to go to the Fablab the days after the lesson, I decided to use all the electronic material that I can find in my workplace. Saddenly we use just “passing-through” components! So I ended up drawing a full passing-through Hello World Board with an Attiny85!

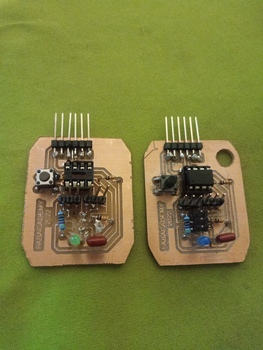

I soldered all the components

And…It didn’t work!

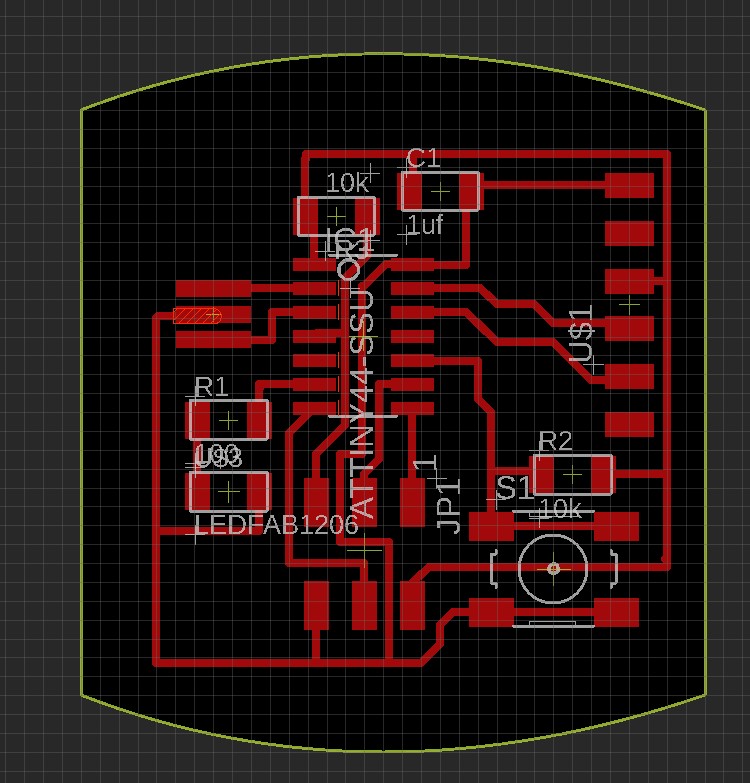

I’m still trying to figure out what didn’t work but in any case I decided to redesign a PCB, this time with SMD components, around an Attiny44.

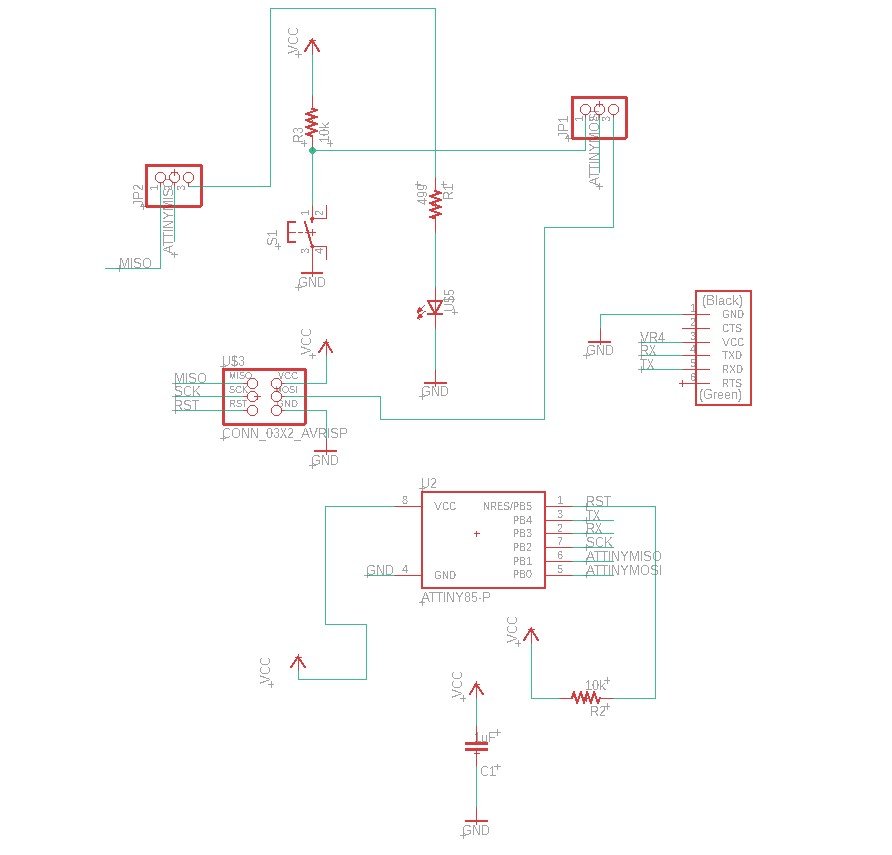

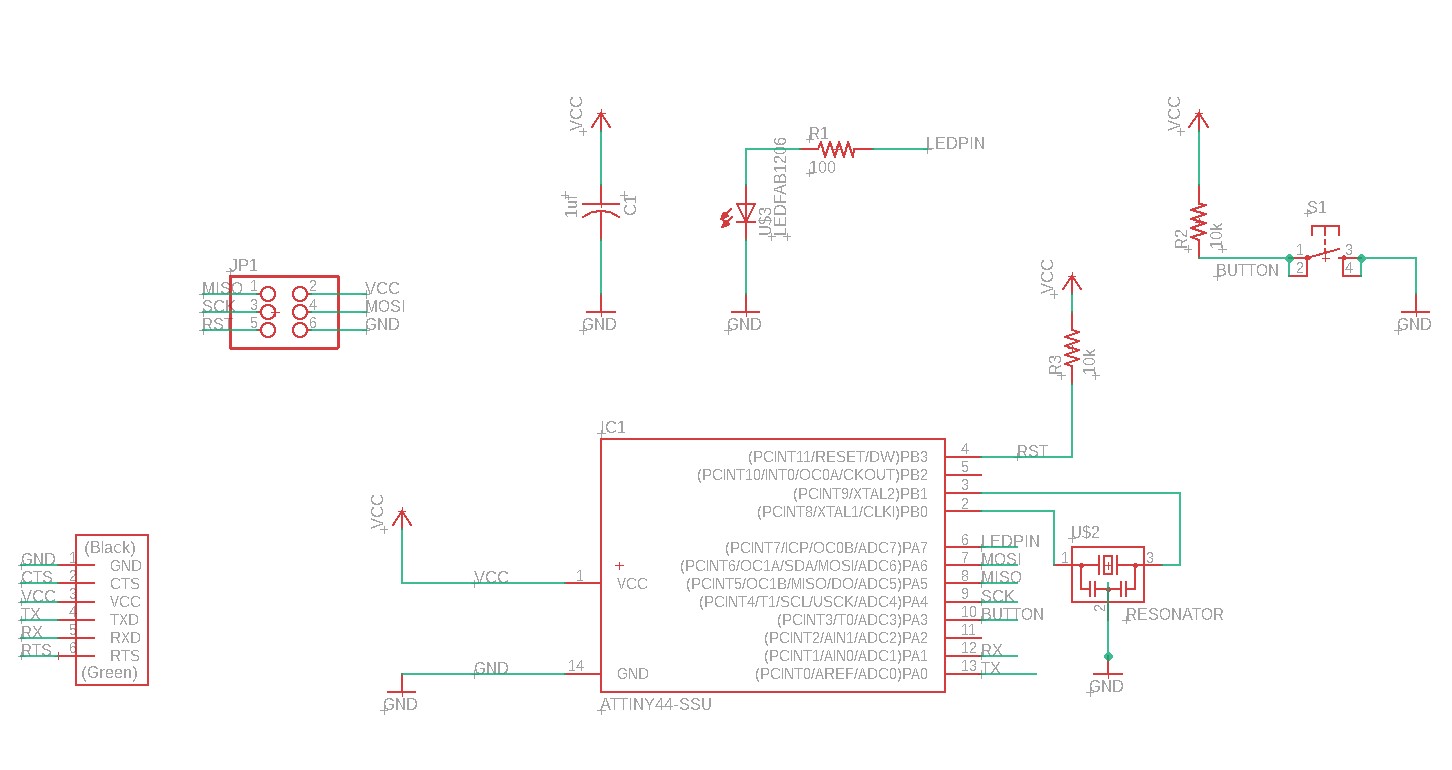

For this I follow this schematic on Fabacademy page and proceed to add some parts as required (leds, switches, capacitors, resistors,…)

I created and rename all the net before passing to the Board part of software where I spent…about two hours to find a satysfing solution. I think there’s something very Zen in this work (if you can success…if you cannot there will be frustration for you! A lot of).

I tried autoroute but the function doesn’t work very well with one-side PCB.

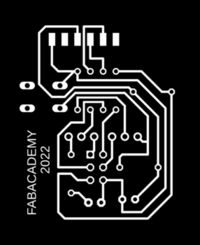

Before cutting the PCB it’s always better to check for the design rules (width, clearance etc.) essential to obtain a correct and clean output file to be welded.

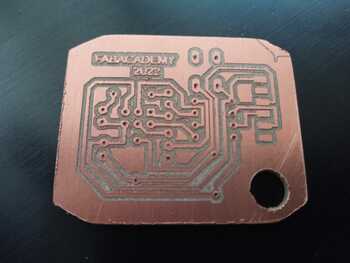

Production process is the same as in the “electronic production” week. You will use Fabmodules to draw the machine job (Roland MDX-40A) and then proceed to cut traces and outline.

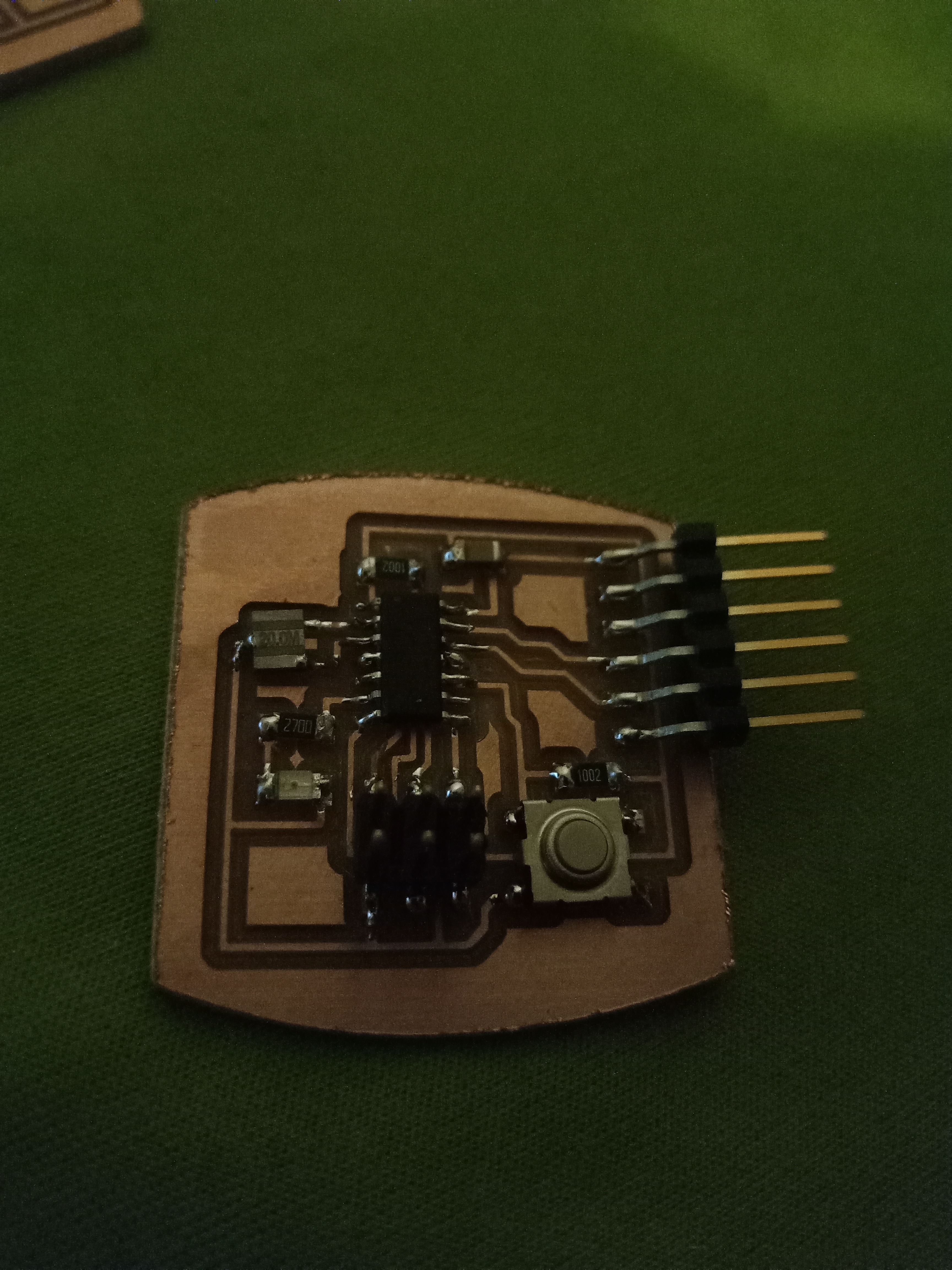

After having soldered all the components this is the final result.

In week 9 we’ll learn how to program the board to make (at least) the LED blink. For the moment I don’t know if it’ll work (I just checked al the traces with the multimeter ad it seems ok…but…who knows!)