1. Principles and Practices¶

Final Project Proposal¶

Assignment¶

Plan and sketch a potential final project

The first exercise of the Fabacademy 2022 was the initial definition of our final project. We were asked to define ideas, make initial skecthes of our final project, find references and try to schedule various steps and requirements to arrive at the final prototype.

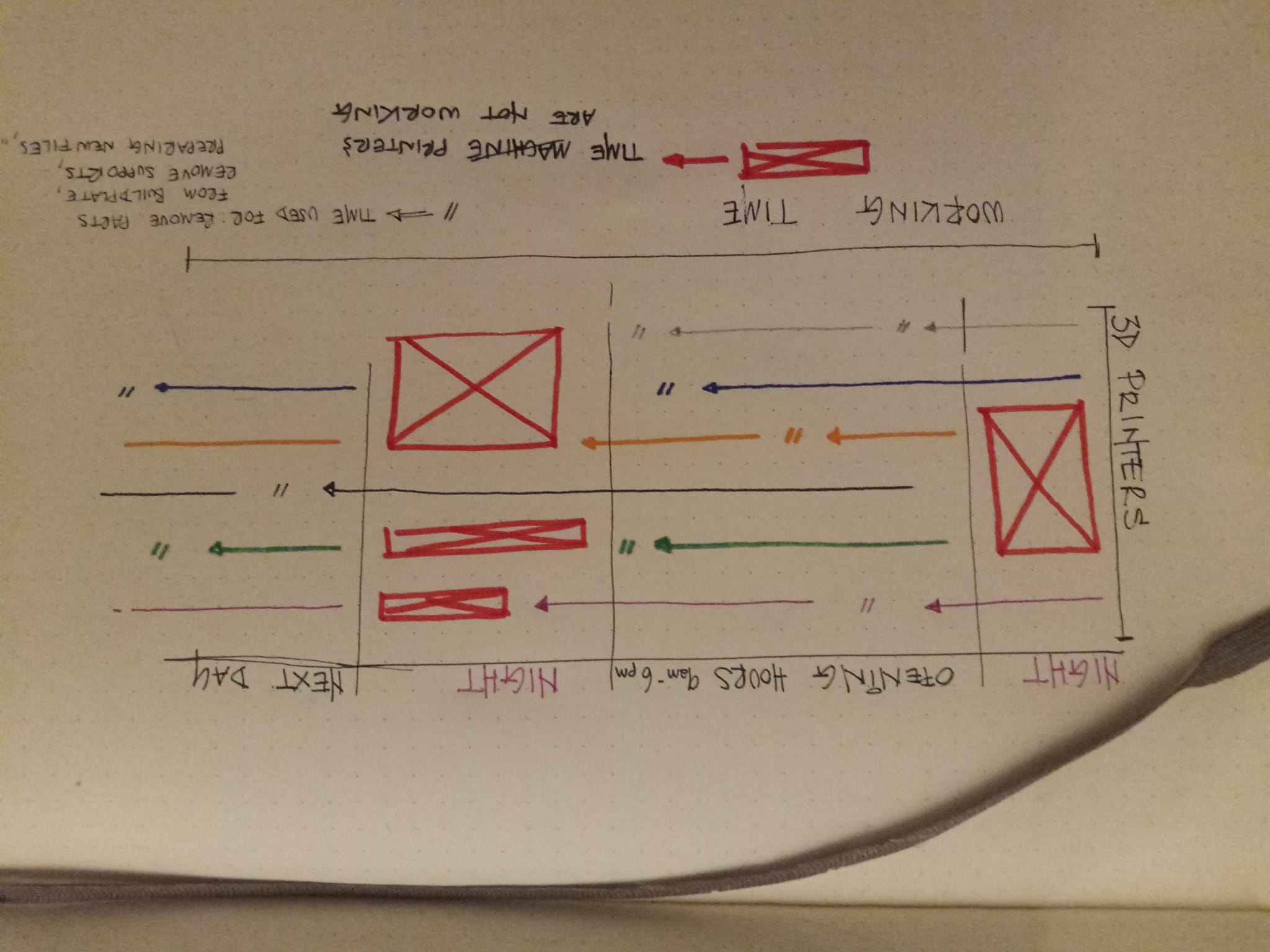

My final project takes its cue from a reflection on the 3D printing service that is provided to students, considering the print queues, the fact that, outside the opening hours of the laboratories (from 9 am to 6 pm), often the machines, at night, remain unused once the current print is finished.

Automated 3D Printing Service¶

Giving students the opportunity to learn the rules of 3d modeling for rapid prototyping (3d printing, cnc milling, …) can only be useful if they can really put what they have learned into practice, but, currently, the technical staff trained and employed for this service and the opening hours of the prototyping laboratories do not allow us to satisfy the requests that arrive daily.

The consultancy for the setting of the print, the control of the 3D model and, above all, the setting up of the machine (the removal of the piece from the printing plate and the restarting of the next printing cycle) are operations that require time and a physical presence in the spaces used for processing. In addition to all this, the problem remains that when we are not in the Laboratory we cannot start new prints.

Even if we managed to bypass the graphic analysis phase, using specific software, the second part requires a continuous commitment that we are not able to satisfy (at the moment).

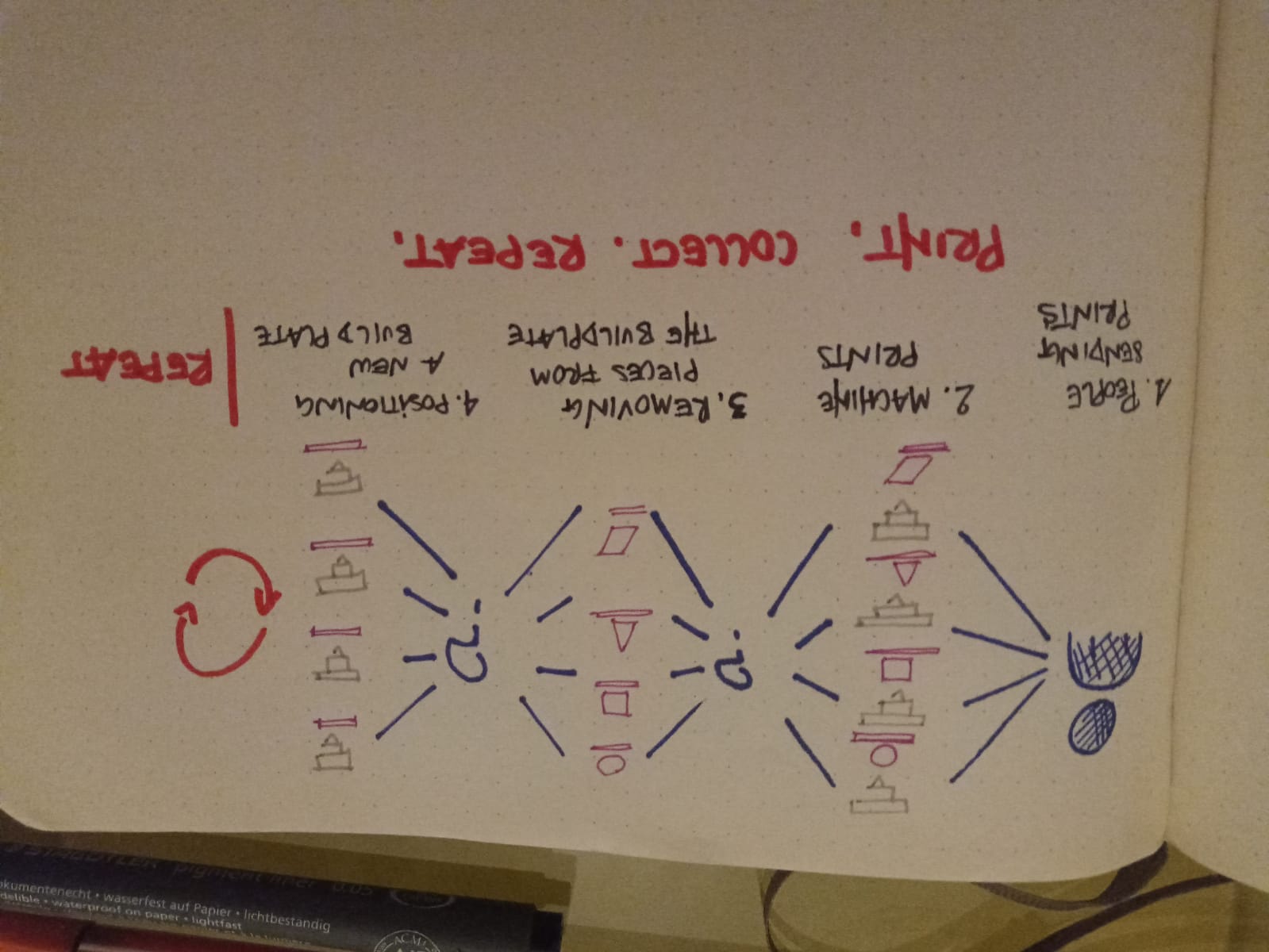

So we thought of designing and realizing a “demonstrator” that can solve part of these problems, such as starting a new print if the printer is free, removing the print plate occupied by the piece produced, positioning a new buildplate

We still don’t know how we’ll do it. We still don’t know IF we will succeed. For the moment we limit ourselves to hypothesizing several solutions:

To date, the only fixed points we have are the type of machines in our possession (Ultimaker 3 and Wasp Delta 2040) and the fact that we cannot rely on models already made for serial production because ours is a production of unique pieces.