Summary

A manic couple of weeks, not much of a ‘Break’ as it was advertised to be ;). As always, a challenge to get your own individual part of the group project completed, as well getting it all to work together. The fun of making our film made it all worth while.

What I thought I knew before

From past experience with DIY projects and my studies in Special Effects Design I felt quite comfortable with the level of background knowledge I have. I have previously studied some basic engineering and materials science, together with design elements for making props and practical effects for film and TV. While previous projects have combined these together to create a complete system, it has always lacked an electronic element such as stepper motors and the like.

The learning part of this project for me (apart from the extra experience in things i know) will be watching how the others integrate the electronic part to this project.

Learning Outcomes

Theory and use of things i learnt from this assignment:

- Work and communicate effectively in a team and independently.

- Design, plan and build a system.

- Analyse and solve technical problems.

- Recognise opportunities for improvements in the design.

Lessons to take away

Group Assignment

- Design a machine that includes mechanism + actuation + automation.

- Build the mechanical parts and operate it manually.

- Actuate and automate your machine.

- Document the group project.

See group page.

My part in the project

- Document your individual contribution.

Upon dividing the parts / functionality of the machine I volunteered to build the ‘hand’ based on my experience in the past of designing a hand / arm that moved de to an air muscle being activated. We had already discussed a little what materials to use for the hand to keep it light enough and contain enough structural strength to not be a problem for the controlling motor. Based on my past experiences with casting materials it was probably a good idea for me for me to handle this in the small amount of time we had.

| Group Dependencies | What | Description |

|---|---|---|

| Arm | Measurements of the ‘Arm’ end of the wrist. Diameter of wire being used move the hand/wrist. | As part of making the ‘wrist hinge’ I will need to know some measurements and how the ‘Arm’ side will attach to the arm mechanism. |

| Arm / Electronics | What system will be used to control the hand and how will it attach to the hand. | Make provision for things like a pathway for ‘wires’ to be moved and what attach points are needed. |

| Materials | Description | Cost | Store |

|---|---|---|---|

| Foam-it III | 2 part urethane expanding rigid foam, expands many times original volume and develop a uniform cell structure. | €22,50 (ex. BTW) | Form X |

| Ease Release 2831 | Ease Release® 2831 is a wax-based non-silicone release agent. It has proven to be effective when used to release polyurethane foams elastomers. Ease Release® 2831 works with aluminum, steel, and elastomeric mold construction. | €26,60 (ex. BTW) | Form X |

| Mixing cups | Disposable plastic cups (with a little strength!) to mix the components in. | ?? | Action / Hema / Blokker / Amazon |

| Missing sticks | Rigid wooden sticks for mixing the components together. | ~€11.69 (100pc) (inc. BTW) | Action / Hema / Blokker / Amazon |

| Marigold washing up gloves | As the mould for the hand. | ?? | Action / Hema / Blokker |

| Glue / Epoxy | To attach the ‘hinges’ to the foam parts | ?? | Action / Hema / Blokker / Praxis / Gamma |

| Lid for bucket | To attach the washing-up glove whilst casting, also has the shape for the arm end as the cut out. | ?? | Make at Waag |

| Tools needed | Description |

|---|---|

| Hacksaw | Cut foam hand into joints. |

| Sandpaper | To work the foam. |

| Stanley knife | To do any fine cutting work in the foam. |

| Risk Assessment | Protection |

|---|---|

| Harmful Chemicals | Personal safety equipment (safety glasses etc) |

PLAN

- Cast Hand

- Work Hand

- Design Hinges

- Print Hinges

- Attach Hinges

- Attach Wrist to Arm + attach wires.

Cast Hand

Casting the hand will use a quick and dirty method, not the full ‘life cast’ of an arm, positive in plaster, make 2 part mould with core and cast material. This will consist of pouring 2 part urethane expanding foam into a ‘Marigold’ washing up glove to give a general shape of a hand.

I will experiment using a method to try and support the glove whilst pouring, as the washing-up glove can be seen as a rubber balloon and might lose its shape if excess foam is unable to escape from the end of the glove. I propose to suspend the glove in a bucket of water, which i believe will not only give complete equal support to the entirety of the glove, but hope the pressure and weight of the water pushing against the surface of the glove will ‘persuade’ the foam to expand upwards into the lower pressure air. To ensure this a slow and even pour of the liquid foam must be attempted.

Attaching the open end of the glove to a board with a hole the shape / diameter of the wrist and using this as a lid on the bucket should provide a way to get an approximate size for the attachment point to the arm.

Ease Release® 2831 is a wax-based non-silicone release agent. It has proven to be effective when used to release polyurethane foams elastomers. It is also the one recommended when working with silicone / rubber moulds. Polyurethane foam WILL stick to everything given the chance. A silicon rubber release agent will actually help the it to stick to the rubber glove.

FOAM-iT!™ 3 - has a 3lb. per cubic foot density, so it should be light. The mixture will expand many times original volume and develop a uniform cell structure. It is tack-free in about 4 - 6.5 minutes, developing handling strength in 20 minutes and full cure in 2 hours.

Time needed: Approx 3 hours for prep, pouring and curing.

Work Hand

Depending on how bio-mechanically correct we wish to make this hand, will determine how many joints I will have to cut the foam hand into. The structure of the foam and material can be easily worked with basic DIY tools and sand paper.

Time needed: undetermined so far.

UPDATE

I was persuaded to change the material/techniques to use when creating the hand to be that of laser cut 3mm thick cardboard. The main reason being that even though i have casting experience I should use things I know from the FabLab.

I searched for free 3D objects on CGtrader for a royalty free 3D model of an arm.

Importing it into Fusion360 and trying to cut the ‘hand portion’ off the model for me to prepare for cutting on the laser cutter. Preparing the model consisted mainly of checking the measurement units of the and scaling it up to a ‘life size’ proportion (factor of 1000).

As the object was a Mesh I had to use slightly different tools in Fusion360. Like creating solids I had to create an ‘Offset’ plane and position it at the wrist joint. I made note of this so Paula could use the same model and cut at the same point, but keep the other half of the model for the arm. I then used the [Plane cut] tool from [Mesh] > [Modify] menu. Selecting the offset plane as the cutting plane across the model, leaving just the hand portion.

A handy tip from Michelle (Henk’s magical assistant) was to install a now ‘unsupported’ addon (‘Slicer for Fusion’) to Fusion360. This addon application allowed you (from within Fusion360 or as a standalone app) to slice the mesh object in various ways and automatically arrange the pieces on an area of material you specify. (it even adds numbering for easy combining).

Letter [S] shortcut for ‘Design shortcuts’ ;) and search for ‘Slicer’.

Here I change the direction of the cuts to be longitudinal, mainly to give strength and stability to the piece as it will be attached to the arm. Horizontally slicing will put stress on just the layer/area that its attached to the arm.

Choose from the presets of standard material dimensions, or add one to the presets yourself. Choose the construction technique you wish to use and arrange the plane on the model if needed. This should show you what the cut layout will be like and any issues.

Once happy with the slices, ‘Get Plan’ is the way to export the cut layout. The numbering and helpful positioning marks for construction are also exported as a separate layer from the cut lines.

For operating instructions for the Laser Cutter see Week 4

Then it was over to the laser cutter computer as a .DWF file. The slicer had pretty much packed the pieces onto the cardboard sheet edge to edge (very efficient). I was worried that the cuts were so close to the edge of the material that any mistake placing the origin of laser would end up off the edge. So I used the move tool in the LightBurn software to re-arrange some pieces away from one side of the material’s boundary. I also added different settings to the ‘edge cutting’ and ‘scribing’ layers, changing the layer order so that the ‘scribing’ layer played out first.

Upon seeing the hand in it’s fully stuck together form he remarked that its size looked like a gorilla’s hand. It won’t be until the machine is finished that he will see who’s likeness we have based the aesthetics of our machine on.

Design Hinges

Depending on the amount of joints wanted and how we attach the moving parts will determine how much design time is needed. Phalangeal joints (those in the fingers) can all use the same hinge, where as the wrist and other joints will need specific hinge shapes being modified forms of the finger hinges.

Designed in Fusion360, the main features of the wrist joint included:

- Holes to attach controlling wires and springs.

- The main body would consist of flat plates angled so that they would act as a mechanical form of constraining the angels the hinge could bend.

- A central ‘Rod’ of a diameter that matches the inside of the ‘arm bone’ pipe.

- Further ‘Rods’ that would be pushed into the material (cardboard) of the hand and arm. Chamfered ends to ease insertion.

We decided only to use a joint at the wrist. I designed it to include some structural pins that would attach to the inside of the arm ‘bone’ pipe, and on the hand side, pins that i could physically push into the solid cardboard hand.

In the end some ‘adjusting; was needed, on the hand side i needed to cut the end of the wrist into the same planes as the hinge used to fit properly. On the arm side, the extra smaller pins weren’t needed, and got in the way of the arm cardboard pieces. It was decided later on that the wires for the sensors needed to go through the centre of the structural pin, so I ‘fashioned’ a hole through the centre with a soldering iron, as the melted plastic would help to keep the structural strength rather than remove material from the infill inside the pin with a drill.

Print Hinges

I estimate the small hinges to take between 10-15 minutes printing time, while others will be longer. Knowing how i need to make will give a more accurate approximation of time.

UPDATE Due to the amount of time we have, the only joint to be made will be that of the wrist. 3D printing will take 3+ hours for each side of the hinge. Longer depending on how much infill is needed in the object to provide enough strength in the rods that will attach to the cardboard hand and arms.

Attach Hinges

After testing ‘glues’ on a small piece of foam to see it’s effect, it shouldn’t take long to apply the ‘glue’. I shall design extensions to the hinges that will travel into the centre of the foam joints for extra stability, surface area for the glue to act upon and structural strength (like partial bones).

Drying / curing time will be determined by the glue that is eventually chosen not to have a detrimental effect on the foam.

Attaching the hinges to each side to a lot of ‘adjusting’. The solid nature of the cardboard allowed for easy cutting and removing material. I used epoxy to give a firm attachment to the end of the wrist and the pins. Any places that had too much material removed i filled in with the waste cardboard material and PVA glue - just to give it a good aesthetic.

Attaching to the arm side was more tricky; cables had to be threaded through the hinges and ‘bone’. Only the main pin was used and the others were removed. The stop sensor wire was threaded through and hot glue ‘smeared’ on the pin and inserted into the pipe, without squashing the wires at the same time.

Attach Wrist to Arm + attach wires.

The design of the wrist and the end for the arm should be well thought out enough to allow easy attachment.

Once the hinges were attached and a bolt (in place of the printed joining pin) placed through the joint, we glued in the servo and measured the fishing wire needed to attach to the hand.

This fishing wire was secured on the underside of the palm by tying a the end onto a nut (from a bolt) and hot glueing the nut. The wire ran through the hand, coming out of the top of the hand and running down to the wrist hinge which has a hole to direct / constrain / direct its movement.

The free end of the fishing wire was attached to the servo’s armature, knotted and smeared with some of our favourite hot glue.

We tested the servo to see if it could bring the hand up to its stop point, and return to its original position, allowing gravity to help.

Create the Video

For speed and convenience i offered to edit the video we need to produce for the group assignment due to my professional background. The others offered to contribute their (un)professional skills and enthusiasm as actors in the production.

To maximize time efficiency, and prepare as much as I can before the only time we can get together to film, I used the following workflow. Leaving as little as possible to do the night before the Global presentations.

- Write script.

- Create Storyboard to pre-vizualize shots, timing and actions.

- Prepare an animatic edit from the storyboard, including as many effects and online editing elements as possible.

- Film

- Import footage and replace animatic shots.

The concept I had was to replicate a 1980’s American 2nd hand car sales / Shopping channel advert. With Bad acting (set the bar high for us), bad filming, bad visuals, bad framing, jump cuts, old effects. So bad it’s good!

I created a story board with a free web-based app called Storyboarder. It was the first time I used it and with a bit of experimenting came up with a rough visualisation of the script. The great thing about this way of working is that i could try out different types of shots and ideas, including ready made characters who didn’t need any drawing skills to create.

I found a free website that converted Text to speech in an .mp3 format as we as a group lacked the ability to get even close to an American 2nd hand car salesman’s voice. To customize the interpretation of the voice, it is possible to use Amazon SSML Tags for Amazon Polly. ttsmp3.com - Input limit: 3,000 characters free per day.

So I created all the elements sufficiently badly enough to fit the style of the video and placed them in an edit. Audio, graphics and special effects etc, have been organised so that all that needs to happen is swapping the real footage for the placer images form the animatic.

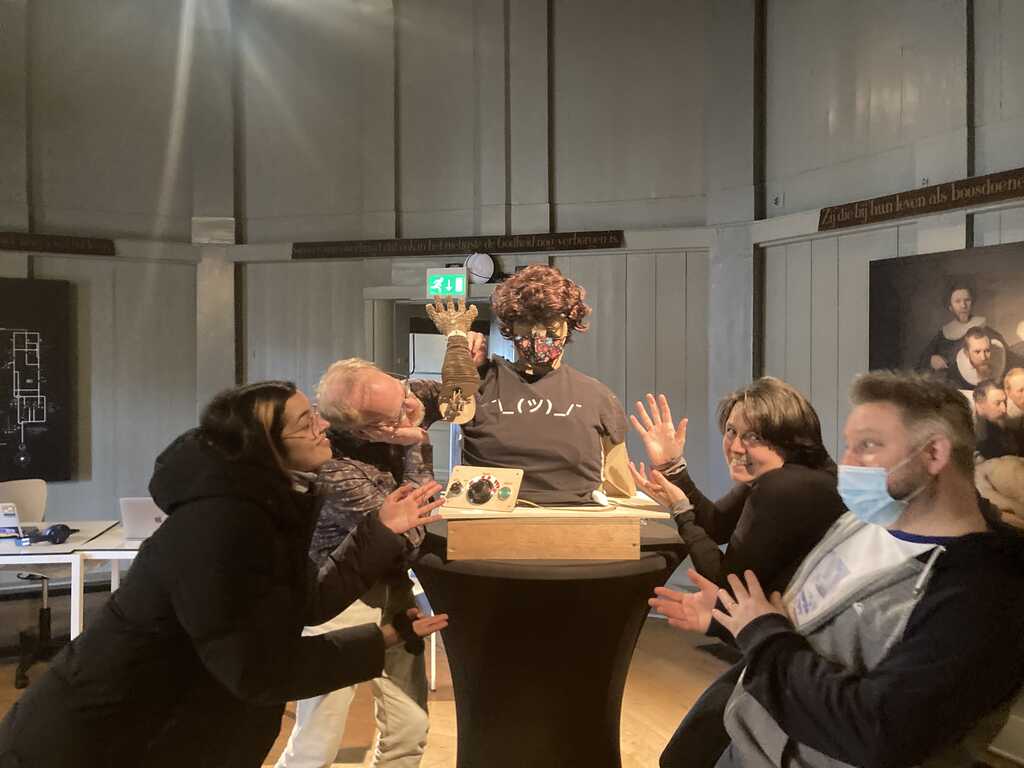

Filming was done as late as possible due to the machine taking time to get finished. All the preparation helped it go smoothly and none of my stars wanted to hog the limelight ;). I think it was a nice little bit of relief for them from the stress of working on the machine as they enjoyed it very much.

We were filming and replacing the real footage for the prepared up until the last minute before the regional meeting. In my tests on preparing a workflow for this edit, i estimated about 90 minutes to render all the edit and effects.

Three quarters of the way through the render in Adobe Media Encode it suddenly wanted me to confirm that i wanted to quit the application. And it wouldn’t take no for an answer. It seemed to be still working in the background so I left it and went away to have a small heart attack quietly.

Luckily it finished the render and we could upload with 30 minutes to relax until the Global meeting.

It was a HUGE success and Neil really laughed!

What I would’ve liked to have done

Had more time.

Time to really test how the joint fitted together and make adjustments to the design based on those findings. Been more involved in the other areas of the assignment as they all looked fun and I could’ve learnt more.

Made all the parts of the whole system as a group

All the parts of the system were interesting and I could’ve learnt something from all of them.

Mistakes & Issues

Turning a Mesh into a solid in Fusion360:

The scanned hand from the free 3D object website came as an .OBJ file. Fusion360 saw the model as a MESH, or a set of polygons, as opposed to creating solids from sketches that i’m used to. I had to watch a few tutorials on working with Meshes in Fusion360 to understand the process in case i needed to modify the hand at any point.

Amount of Infill needed in the model when printing.

The design looks so big on the screen, however in reality this is misleading and the ‘rods’ that will pierce the cardboard material of the hand and arm are in fact quite thin. The standard setting for 15% infill inside the model didn’t provide enough strength and many broke off at the slightest application of stress. The second attempt the setting was 50%, to give the best chance of having lightness and strength.

Difficulty animating joints in ANIMATION mode.

Upon creating ‘As-builtin’ and normal ‘Joints’ and specifying their constraints, I wanted to make an animation of them moving. Just like Fusion360 previews your joint with an animation. I though this would be the same as animating parts in the Animation mode like I had done before. However i tried moving the components in Animation mode, the joints weren’t properly constrained and moved from it’s constraints. To rectify this i found a tutorial that suggested making a ‘Motion Study’ in the ' Design mode’ and ‘Assemble’ menu (with all the other joint tools).

This saves the ‘study’ as an ‘object’ in the ‘Browser’ like other things such as sketched and bodies etc. This can be opened / selected in the ‘Render mode’ and rendered as movie or image that way.

Resolution of 3D print.

When printing an objects with fine tolerances that need to fit together as a joint, its best to print the objects in the finest resolution possible. The tolerances i had made in the design weren’t enough (0.5mm) and had to work the object for it to function properly.

3D printed plastic is probably not the best material as a joint pin.

Even at a fine resolution the material is difficult to get perfectly circular and has a builtin resistance factor if it comes into contact with other moving plastic parts.

Lack of time to work together.

I believe a lot of the small design problems that we found (even though it is a prototype) would’ve been found and corrected had we been able to work together more closely and more often. Certain things only come to light once you all come together with your individual work. I would think that in a professional setting, there would be closer links and more collaborative designing more often to minimise mistakes.

CONCLUSION

I think these tasks were more about working as a group and understanding what you must think about when working on one part of a multipart system. How they will have to attach or be combined with other parts. It was a little disappointing just making the one part as all the parts of the system would’ve been fun to make / learn about together.