Moulding and Casting¶

-

review the safety data sheets for each of your molding and casting materials, then make and compare test casts with each of them

Always read data sheet for your material as each one may vary!¶

Reading Data Sheet of the Silicon Oomoo¶

Oomoo 30

- 30 min pot life

- 6 hours cure time

- A:B mix volume 1:1

- A:B mix weight 1:1.3

Oomoo 25

- 15 minutes

- 75 minutes cure time

- A:B mix volume 1:1

- A:B mix weight 1:1.3

Both:

- Cure at room temperature

- They don’t have a great tear strength

- Simple one- or two- piece moulds

- Can use a sealing agent to prevent inhibition

Safety:

- Use in a well ventilated area

- Wear gloves (only vinyl gloves not latex gloves), goggles, long sleeves

Mould max is better for high tear strength¶

Mixing and Measuring:

- Mix together the parts well with tool of your choice

- Make sure to scrape the bottom of the pot

- Keep going until no colour streaks are visible

- Mix for at least 3 minutes

- Mixing container should have straight sides and a flat bottom

Pouring:

- A uniform flow is best to avoid trapped air

- A thin steady flow is best

- Start from the top of your pieces and let the silicon move down the piece

Curing:

- Allow to cure as advised (6hour for Oomoo 30 and 75 minutes for Oomoo 25)

- Post curing an extra 4 hours will prevent any residue moisture or alcohol

- Do not cure rubber where temperature is less than 18oC

Using mould:

- No release agent is needed when casting wax or gypsum

- We advise release agent when using polyurethane, polyester and epoxy resin

Mould performance and storage:

- The moulds life time is dependant on the material used to cast with

- When stored wipe down with soapy water and dry off

- Stored in a cool dry environment on a level surface

- Two part moulds should be stored together

![]()

![]()

![]()

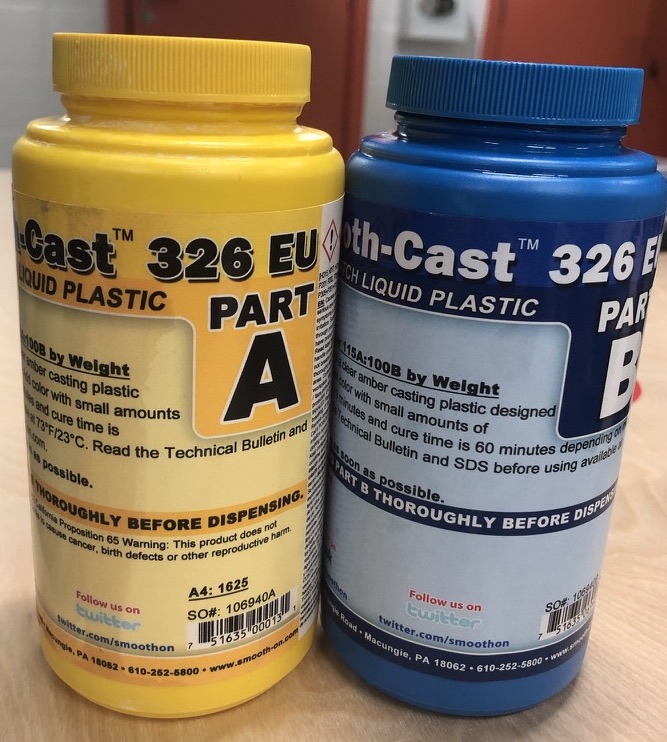

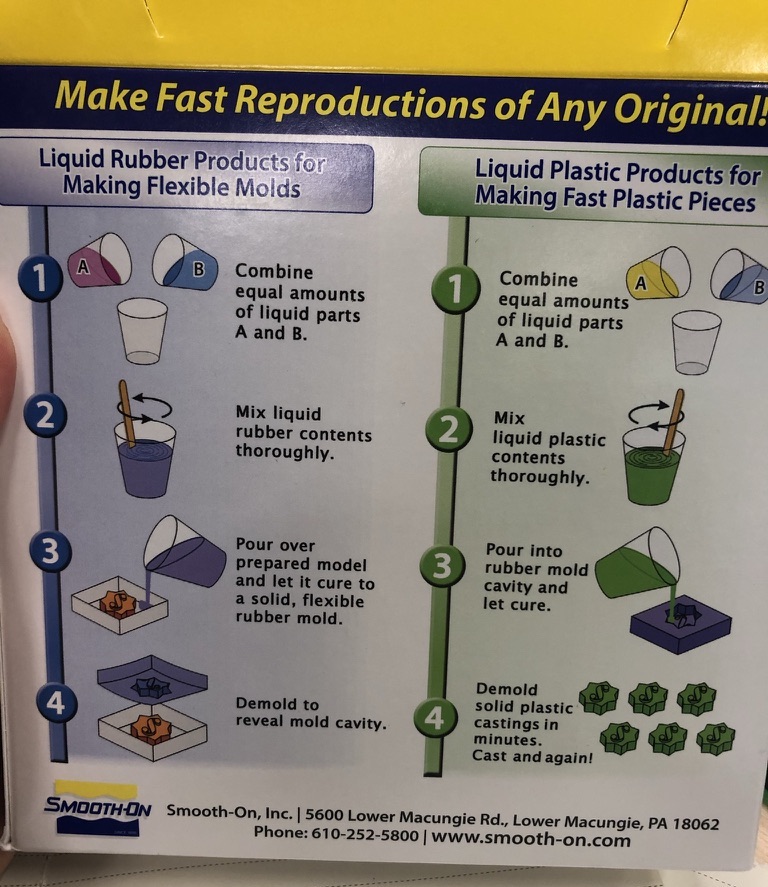

Reading Data Sheet of the Clear Cast 326¶

Oomoo 325

- 2.5 min pot life

- 10 minutes cure time

- A:B mix volume 1:1

- A:B mix weight 115:100

- Shrinkage = 0.01 in/in

Oomoo 326

- 7-9 min pot life

- 60 minutes cure time

- A:B mix volume 1:1

- A:B mix weight 115:100

- Shrinkage = 0.0075 in/in

Oomoo 327

- 10-20 minutes

- 2-4 hours cure time

- A:B mix volume 1:1

- A:B mix weight 115:100

- Shrinkage = 0.0075 in/in

Features:

- developed specifically for adding colour pigments and fillers

Safety:

- Large mass castings will get very hot and shrink more

- Materials should be used in a warm environment

- Materials should be stored in a warm environment

- Limited shelf life and should be used a soon as possible

- All liquid urethanes are moisture sensitive and will absorb atmospheric moisture

- Tools and containers should be clean and made from metal, glass or plastic

- Mixing should be done in a well ventilated area

- Wear safety glasses, long sleeves and rubber gloves

Applying a release agent:

- This will help release your piece when casting into or over most surfaces

- Apply release and brush with a soft sponge over all surfaces

- Follow with a light mist

- Let release agent dry for 30 minutes

- Most silicon mould do not need a release agent unless doing silicon on silicon

- Appalling a release agent prolongs the life of your mould

Mixing and Measuring:

- Stir or shake both parts A and B

- Measure equal volumes (115A:100B by weight)

- Mix thoroughly

- Stir making sure you scrape the sides and bottom of the mixing container several times

- Avoid splashing over container

Pouring:

- Pour your mixture in the lowest point of the container

- Allow the mixture to seek the areas do not push into areas

Curing:

- Leave to cure in a well ventilated room

- Do not inhale or breathe in fumes

- Cast large mass objects may be hot to the touch

- Allow casting to cure completely to room temperature before handling

Post Curing:

- Casting will reach ‘full cast’ faster and reach Maximus physical properties if post cure.

- Allow material to cure for recommended cure time and then left at room temperature for another 4-6 hours

- Allow to come to room temperature before handling

Performance:

- Cured casts are rigid and durable

- They resist moisture, moderate heat, solvents, dilute acid and can be machined primed/ painted or bonded to other surfaces

- If machining cured material wear a dust mask

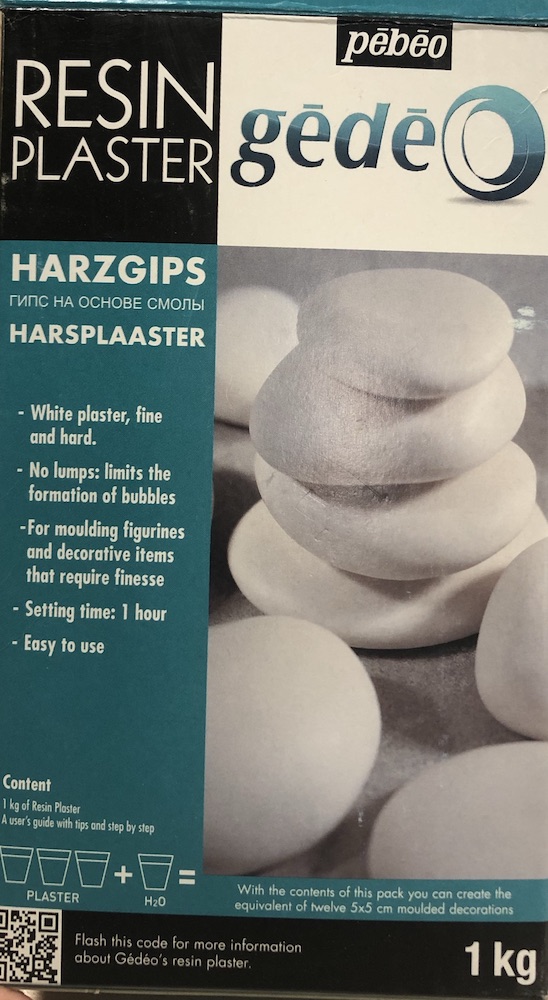

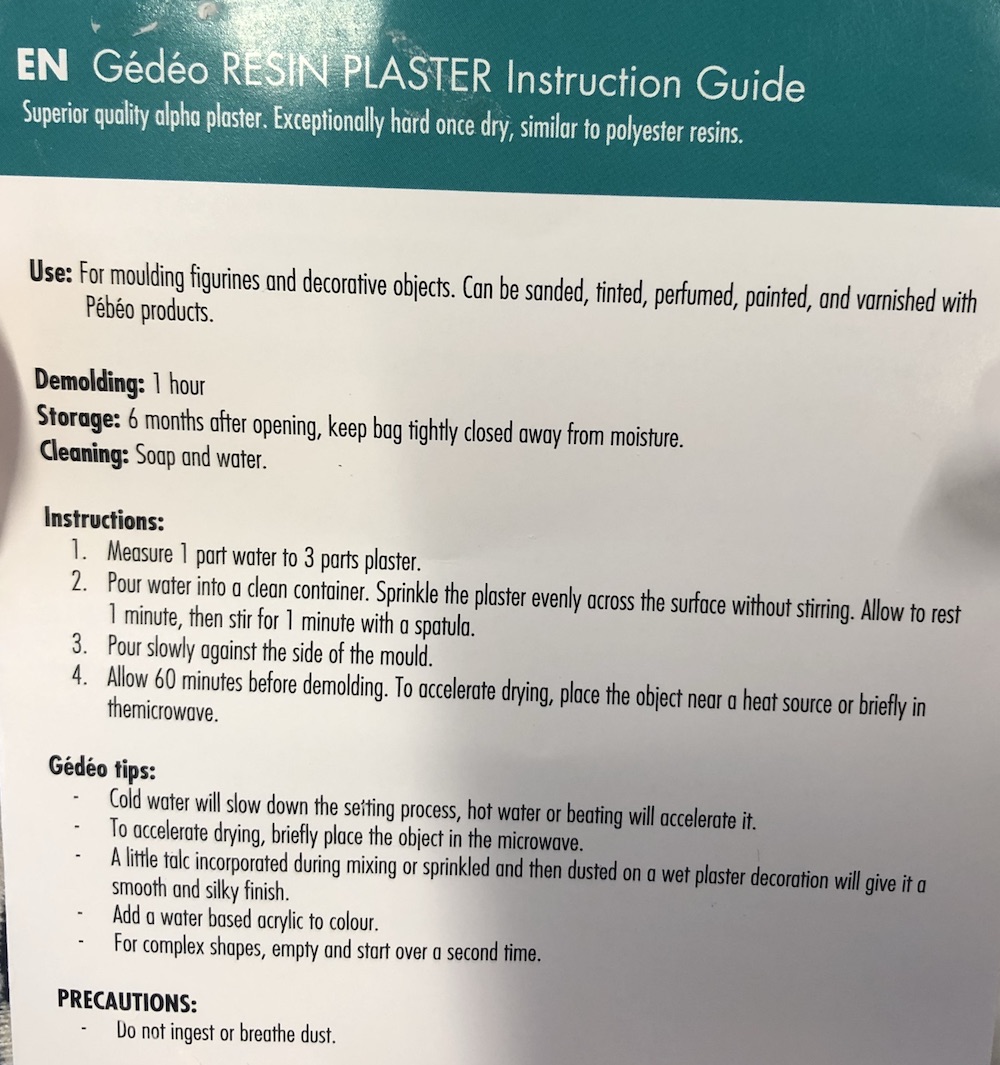

Plaster Data Sheet¶

Use:

- For moulding figurines and decorative objects. Can be sanded, tinted, perfumed, painted and varnished with Pebeo products

Demoulding:

- 1 Hour

Storage:

- 6 months after opening, keep bag tightly closed away from moisture

Cleaning:

- Soap and water

Instructions:

- Measure 1 part water to 3 parts plaster

- Pour water into a clean container

- Sprinkle the plaster evenly across the surface without stirring. Allow to rest for 1 minutes, then stir for 1 mine with a spatula

- Pour slowly against the side of the mould

- Allow 60 minutes before remoulding

- To accelerate drying, place object near a heat source or briefly in the microwave

Gedeo tips:

- Cold water will slow down the setting process, hot water or beating will accelerate it

- To accelerate drying, briefly place the object in the microwave

- A little talc incorporated during mixing or sprinkled and then dusted on a wet plaster decoration will give a smooth and silky finish

- Add water based acrylic to colour

- For complex shapes, empty and start over a second time

Precautions:

- Do not ingest or breathe dust

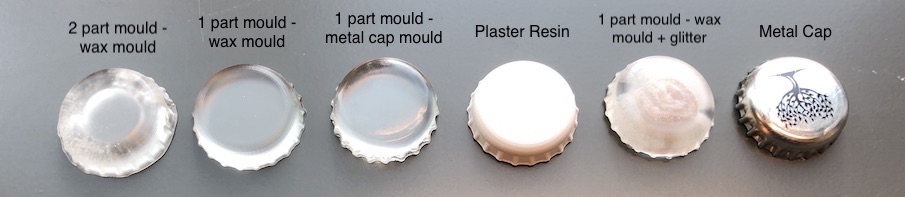

Comparing Test smaples with eachother¶

Katie's Tests

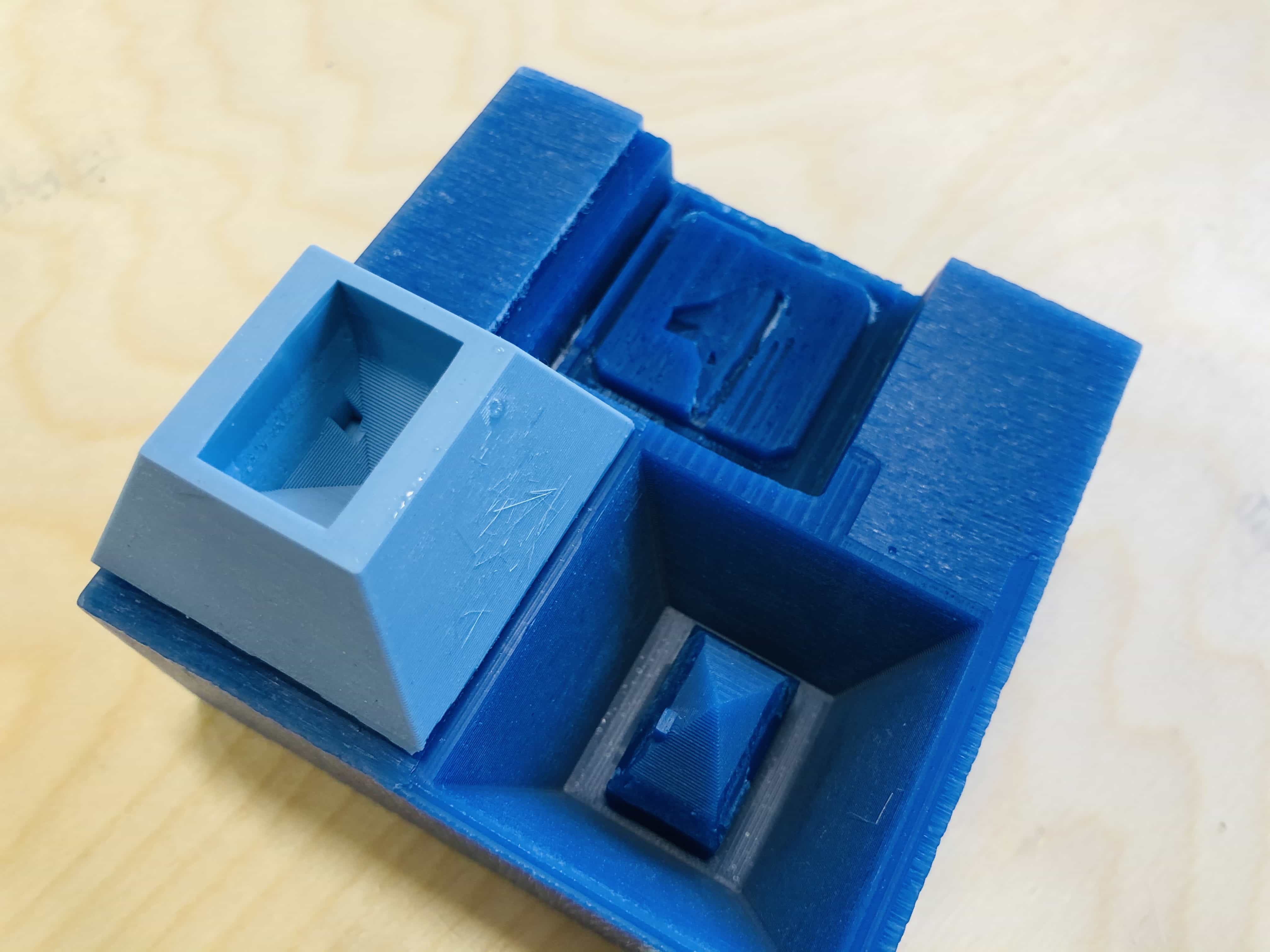

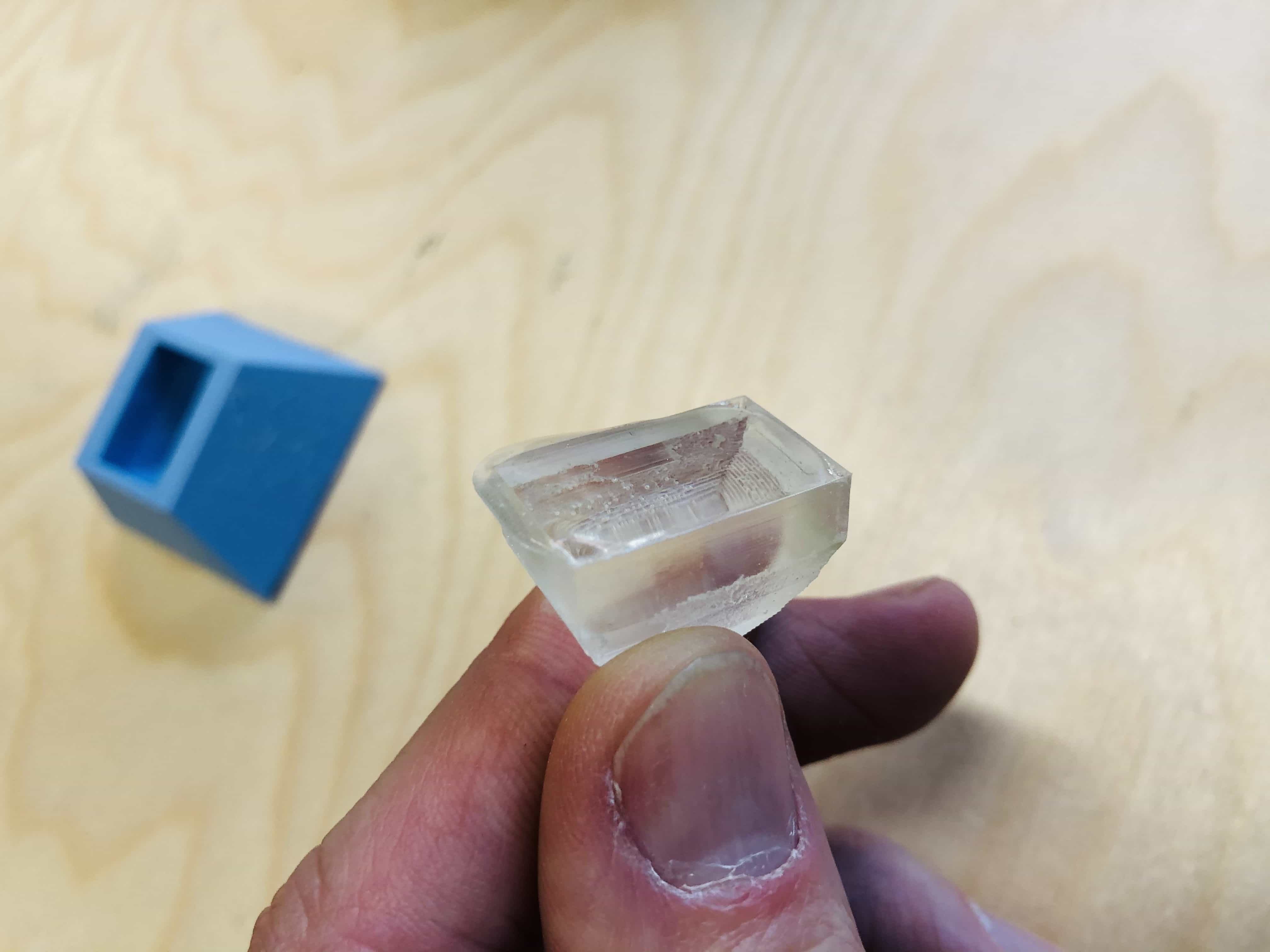

Jonny's Tests

- Silicone dog pre-mould

- Silicone house pre- mould

- Resin house

Last update: May 18, 2021