11. Output Devices¶

Assignment¶

Individual assignment:¶

● Add an output device to a microcontroller board you’ve designed, and program it to do something

Group assignment:¶

● Measure the power consumption of an output device

Group assignment¶

Group:

● - Xinhui Hu

● - Zhengya Gong

● - Yazan Barhoush

● - Noora Nyberg

More details click Group assignment

Individual assignment:¶

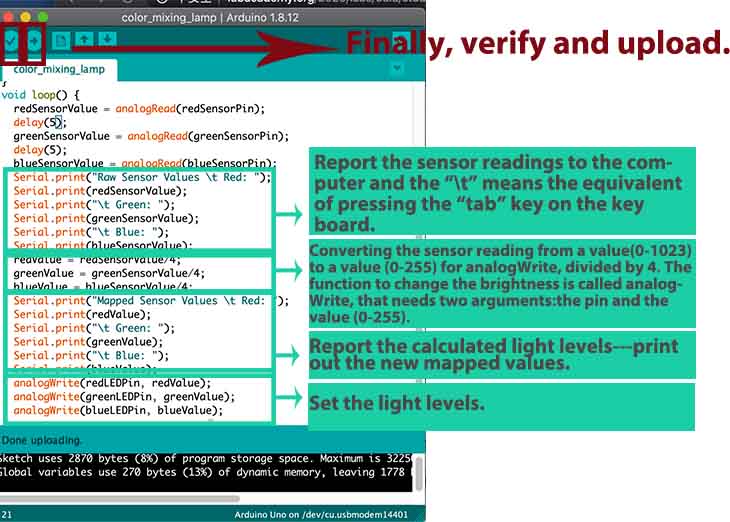

This week I used a tri-color Led and three photoresistors and created a lamp that smoothly changes colors according to lighting conditions.

Because of the virus, the fab lab closed two weeks ago; everyone stays home working remotely, so I need to design something independently. It is not easy for me to add a sensor to a microcontroller board, but fortunately, Ari sent me Arduino Projects Book, which helps me follow the book to design the lamp.

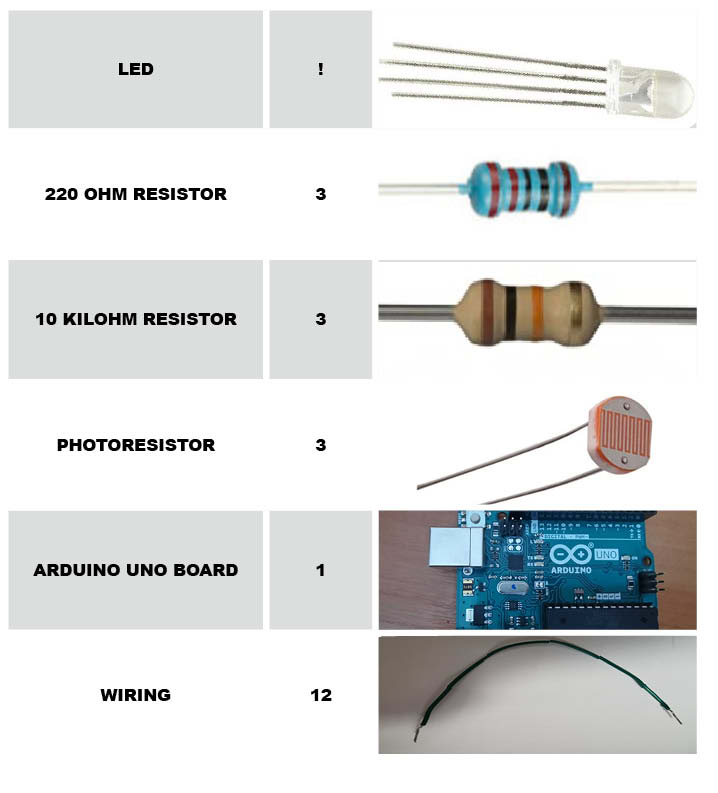

● Step 1. Find out the components. Maybe it is easy for individuals who are familiar with electronics; however, for me, I even can not identify the different resistors. Therefore, I googled the keywords, and watch some video.

Figure 1. The components

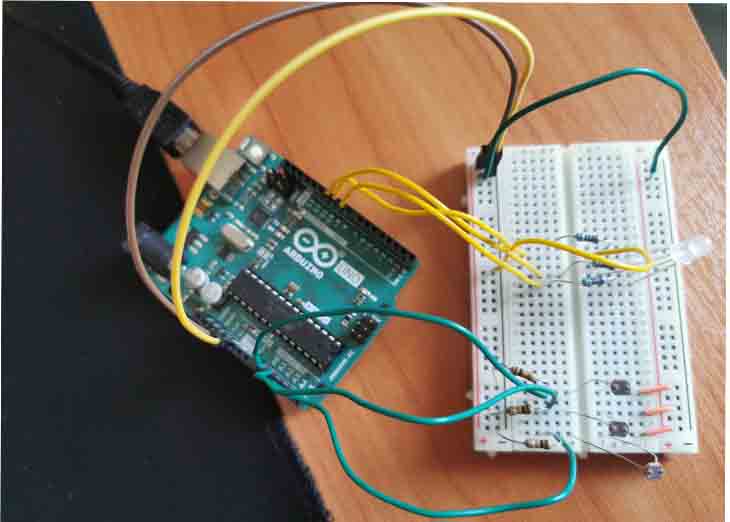

● Step 2. Build the circuit.

Figure 2. The circuit

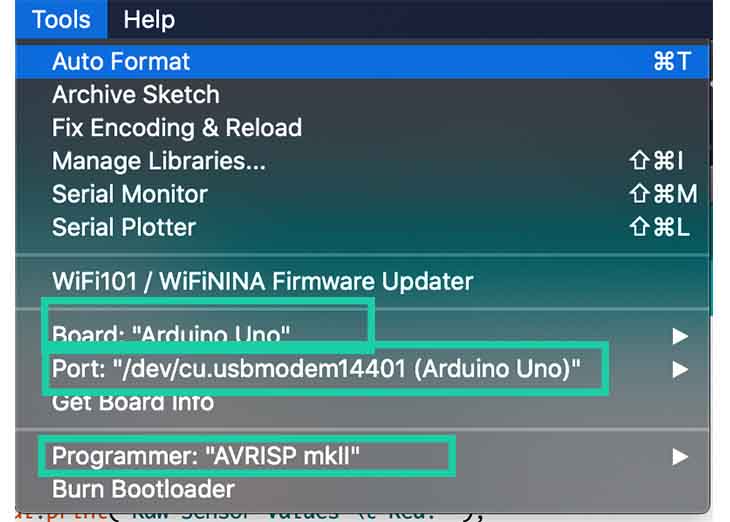

● Step 3. Connect to my laptop. I used the USB cable to connect the Arduino board to my laptop. I opened the Arduino IDE and set all settings as shown in the tool.

Figure 3. The tool setting

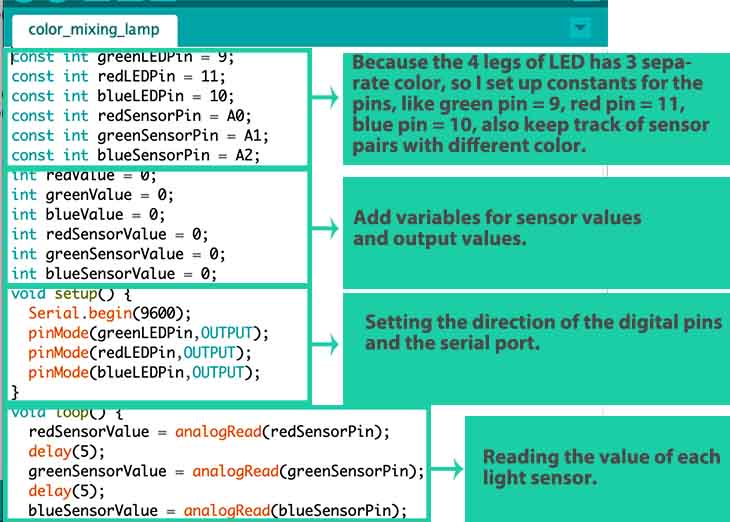

● Step 4. Programming.

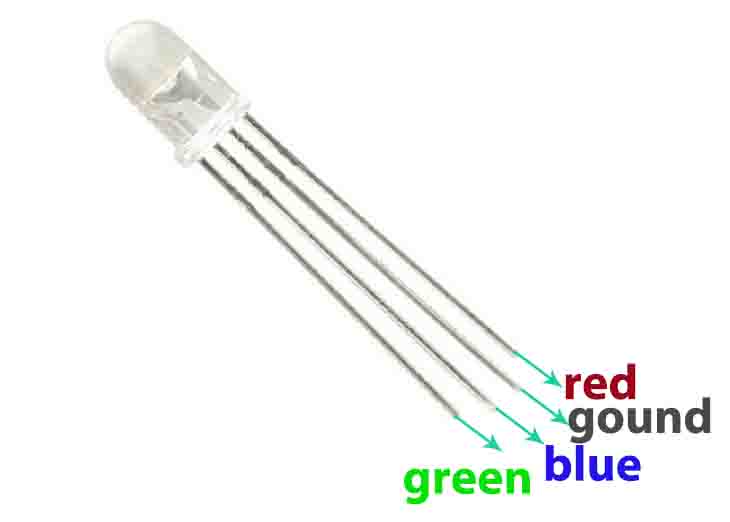

Because the 4 legs of LED has 3 separate color, so I set up constants for the pins, like green pin = 9, red pin = 11, blue pin = 10, also keep track of sensor pairs with different color.

Code Example¶

const int greenLEDPin = 9;

const int redLEDPin = 11;

const int blueLEDPin = 10;

const int redSensorPin = A0;

const int greenSensorPin = A1;

const int blueSensorPin = A2;

int redValue = 0;

int greenValue = 0;

int blueValue = 0;

int redSensorValue = 0;

int greenSensorValue = 0;

int blueSensorValue = 0;

void setup() {

Serial.begin(9600);

pinMode(greenLEDPin,OUTPUT);

pinMode(redLEDPin,OUTPUT);

pinMode(blueLEDPin,OUTPUT);

}

void loop() {

redSensorValue = analogRead(redSensorPin);

delay(5);

greenSensorValue = analogRead(greenSensorPin);

delay(5);

blueSensorValue = analogRead(blueSensorPin);

Serial.print("Raw Sensor Values \t Red: ");

Serial.print(redSensorValue);

Serial.print("\t Green: ");

Serial.print(greenSensorValue);

Serial.print("\t Blue: ");

Serial.print(blueSensorValue);

redValue = redSensorValue/4;

greenValue = greenSensorValue/4;

blueValue = blueSensorValue/4;

Serial.print("Mapped Sensor Values \t Red: ");

Serial.print(redValue);

Serial.print("\t Green: ");

Serial.print(greenValue);

Serial.print("\t Blue: ");

Serial.print(blueValue);

analogWrite(redLEDPin, redValue);

analogWrite(greenLEDPin, greenValue);

analogWrite(blueLEDPin, blueValue);

}

The function to change the LED’s brightness via PWM is called analogWrite(). It needs two arguments: the pin to write to, and a value between 0 - 255. This second number represents the duty cycle the Arduino will output on the specified pin. A value of 255 will set the pin HIGH all the time, making the attached LED as bright as it can be. A value of 127 will set the pin HIGH half the time of the period, making the LED dimmer. 0 would set the pin LOW all the time, turning the LED off. To convert the sensor reading from a value between 0 - 1023 to a value between 0 - 255 for analogWrite(), divide the sensor reading by 4.

● Step 5. Testing.

Individual assignment 2(for final project):¶

For my final project, in input device week I created a circle (integrated with input, output device and networking and communication)and designed my PCB board. So for this week, I tested my board and did programming. Also, the networking and communication in networking and communication.

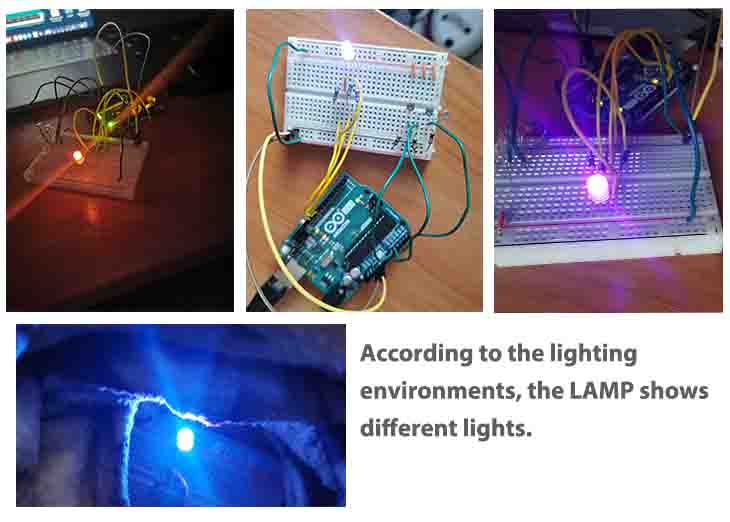

It is a challenge for me. I used the Keil (download link)to write the code and STC-ISP (download link to program. The reason because the Keil is easy for new one to program, and many people recommended to use it. The another reason because I found various codes related to my project online. I downloaded the codes and edited it.

write the code¶

● 1. Download the Keil (download link), and create a new project.

● 2. Choose the target, then click the device to choose M6032.

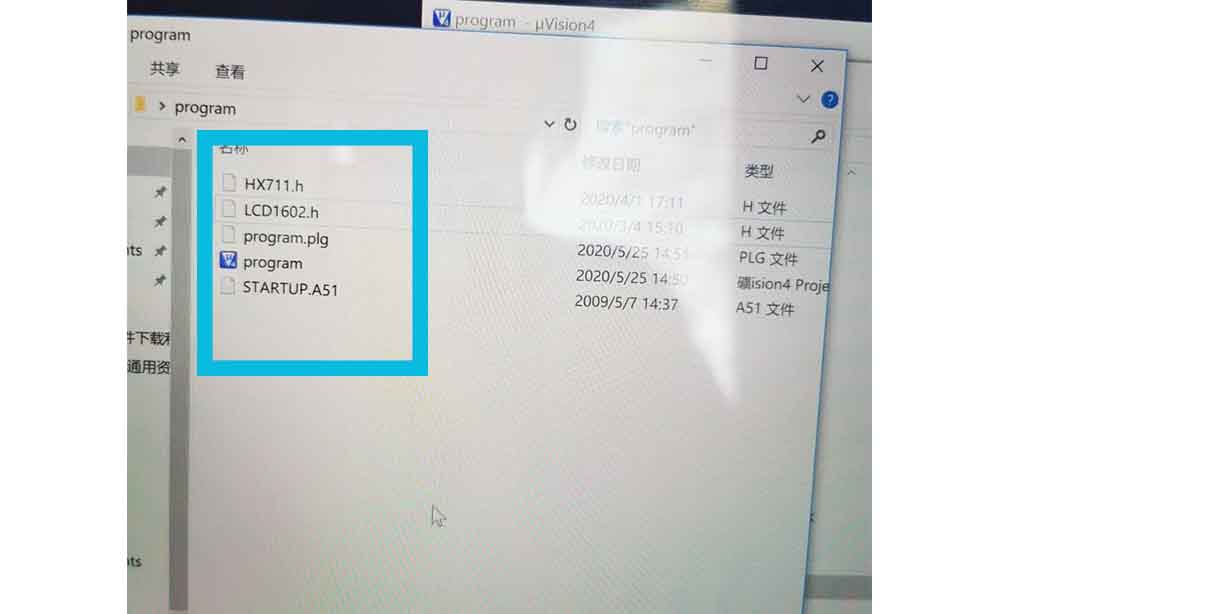

● 3. Store the project in a folder, it will automatically create another files, named .plg and startedup.A51 and added the HXL711.h and LEC1602.h. in the folder.

● 4.Write program in C using Keil.

I just copied some code from open source1, and according my project to edit it.

To control the weight sensor using HX711, code from some forums.

#ifndef __HX711_H__

#define __HX711_H__

#include <intrins.h>

#include <string.h>

unsigned long HX711_Buffer = 0;

unsigned long Weight_Maopi = 50;

unsigned long Weight_Maopi_0 = 0;

unsigned long Weight_Shiji = 0;

unsigned long Weight_Shiwu = 0;

#define GapValue 379

//=================================//IO set

sbit HX711_DOUT=P1^2;

sbit HX711_SCK=P1^3;

//Function or variable declarations

extern void Delay__hx711_us(void);

extern unsigned long HX711_Read(void);

//****************************************************

//The time delay function

//****************************************************

void Delay__hx711_us(void)

{

_nop_();

_nop_();

}

//****************************************************

//Read HX711

//****************************************************

unsigned long HX711_Read(void)

{

unsigned long count;

unsigned char i;

HX711_DOUT=1;

Delay__hx711_us();

HX711_SCK=0;

count=0;

while(HX711_DOUT);

for(i=0;i<24;i++)

{

HX711_SCK=1;

count=count<<1;

HX711_SCK=0;

if(HX711_DOUT)

count++;

}

HX711_SCK=1;

count=count^0x800000;//When the 25th pulse comes down the edge, convert the data

Delay__hx711_us();

HX711_SCK=0;

return(count);

}

//****************************************************

//MS delay function (test under 12M crystal vibration)

//****************************************************

void Delay_ms(unsigned int n)

{

unsigned int i,j;

for(i=0;i<n;i++)

for(j=0;j<123;j++);

}

//****************************************************

//Measuring weight

//****************************************************

uint jilu;

uint zhongliangcha;

void Get_Weight()

{

static bit maopi=1;

Weight_Maopi_0 = HX711_Read()/GapValue;

Weight_Maopi_0 = Weight_Maopi_0%10000;

if(maopi)

{

if(Weight_Maopi_0==Weight_Maopi)

maopi=0;

Delay_ms(200);

Weight_Maopi = Weight_Maopi_0 ;

}else

{

Weight_Shiji = Weight_Maopi_0 - Weight_Maopi; //get net weight

// Weight_Shiwu = Weight_Shiji; //ce shi yong

if(Weight_Shiji>5&&Weight_Shiji<90000 )

{

if(Weight_Shiji%10==0)

{

Weight_Shiwu = Weight_Shiji ;

}

else

To control the LCD1602 Screen, the code from

#ifndef _LCD1602_H_

#define _LCD1602_H_

#define uchar unsigned char

#define uint unsigned int

#define LCD1602_dat P0 //Data parallel port macro definition

sbit LCD1602_rs=P2^5;//IO definition

sbit LCD1602_rw=P2^6;

sbit LCD1602_e=P2^7;

void LCD1602_delay(uint T) //The time delay function

{

while(T--);

}

/********************************************************************

* name: LCD1602_write(uchar order,dat)

* function: 1602 write as data function

* input: order is the data/command switch variable //0 is the command 1 is the data

* : dat is the data/command sending data

* output: none

***********************************************************************/

void LCD1602_write(uchar order,dat) //1602 One byte processing

{

LCD1602_e=0;

LCD1602_rs=order;

LCD1602_dat=dat;

LCD1602_rw=0;

LCD1602_e=1;

LCD1602_delay(1);

LCD1602_e=0;

}

/********************************************************************

* name: LCD1602_writebye(uchar *prointer)

* function: 1602 write data function pointer

* input: enter what needs to be displayed

* output: none

***********************************************************************/

void LCD1602_writebyte(uchar *prointer) //1602 String processing

{

while(*prointer!='\0')

{

LCD1602_write(1,*prointer);

prointer++;

}

}

/********************************************************************

* name: LCD1602_cls()

* function: initialize 1602 liquid crystal

* input: none

* output: none

***********************************************************************/

void LCD1602_cls() //1602 initialization

{

LCD1602_write(0,0x01); //1602 clearing instructions

LCD1602_delay(1500);

LCD1602_write(0,0x38); // Function Settings: 8-bit, 5*7 lattice

LCD1602_delay(1500);

LCD1602_write(0,0x0c); //Set the cursor not to show the switch, not to show the cursor, the character does not flicker

LCD1602_write(0,0x06);

LCD1602_write(0,0xd0);

LCD1602_delay(1500);

}

● 4. Write the codes, that included the HXL711.h and LEC1602.h.

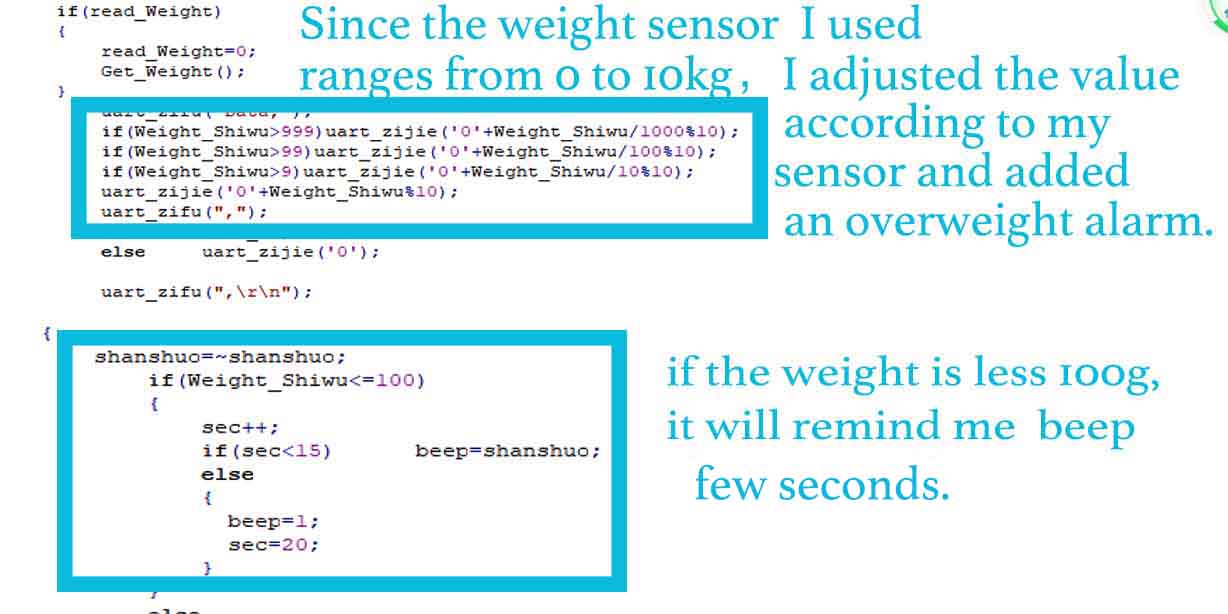

Actually, I downloaded the codes online and edited, the main different is following.

#include <reg52.h>

#include"LCD1602.h" //LCD1602 display

#include"HX711.h"//read weight

#define uchar unsigned char

#define uint unsigned int

//---------------------------------->T0

bit read_Weight=0;//Read the weight marker bit

sbit Led=P1^1;

sbit beep=P2^0;

//----------------------------------->Function declaration

void display();//display function

void T0init();//T0 initialization

void AnJian();// key

void uart_zijie(uchar zijie);

void uart_zifu(uchar *zifu);

//********Main function *****************************

void main()

{

T0init();//T0 initialization

LCD1602_cls(); //LCD1602 initialization

//==========major cycle==============================

while(1)

{

display();

if(read_Weight)

{

read_Weight=0;

Get_Weight(); //As the variable Weight_Shiwu is generally 10 kilograms, an overweight alarm should be added }

uart_zifu("Data,");

if(Weight_Shiwu>999)uart_zijie('0'+Weight_Shiwu/1000%10);

if(Weight_Shiwu>99)uart_zijie('0'+Weight_Shiwu/100%10);

if(Weight_Shiwu>9)uart_zijie('0'+Weight_Shiwu/10%10);

uart_zijie('0'+Weight_Shiwu%10);

uart_zifu(",");

if(Led) uart_zijie('1');

else uart_zijie('0');

uart_zifu(",\r\n");

}

}

//========T0 initialization==========================

void T0init()//T0 initialization

{

TMOD=0x01;

TL0 = 0x00; //Set the initial timing value of 50ms

TH0 = 0x4C; //Set the timing initial value

ET0=1;

TR0=1;

EA=1;

SCON = 0X50;

T2CON = 0X34;

RCAP2H = 0XFF;

RCAP2L = 0XDC;

}

//-=======================================

void uart_zijie(uchar zijie)

{

SBUF = zijie;

while(!TI);

TI=0;

}

void uart_zifu(uchar *zifu)

{

while(*zifu)

{

uart_zijie(*zifu++);

}

}

uchar sec=0;

bit shanshuo=1;

//======Display function==============================

void display()//Display function

{

//The first line shows the weight data with the Settings of the overweight bar

LCD1602_write(0,0x80);

LCD1602_writebyte(" Hello ");

LCD1602_write(0,0xC0);

LCD1602_writebyte(" Weight:");

if(Weight_Shiwu<10000)

{

if(Weight_Shiwu>999)LCD1602_write(1,0x30+Weight_Shiwu/1000%10);

else LCD1602_write(1,' ') ;

if(Weight_Shiwu>99)LCD1602_write(1,0x30+Weight_Shiwu/100%10);

else LCD1602_write(1,' ') ;

if(Weight_Shiwu>9)LCD1602_write(1,0x30+Weight_Shiwu/10%10);

else LCD1602_write(1,' ') ;

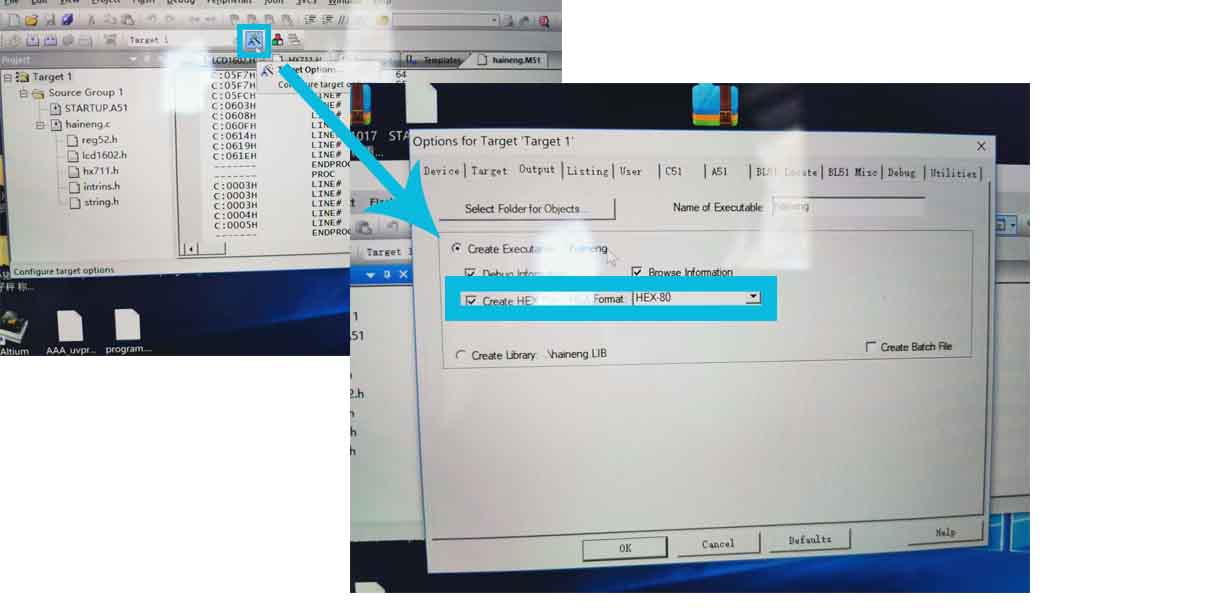

● 5. Automatically create a hex file for programming. Click the target, and create HEX file.

programming¶

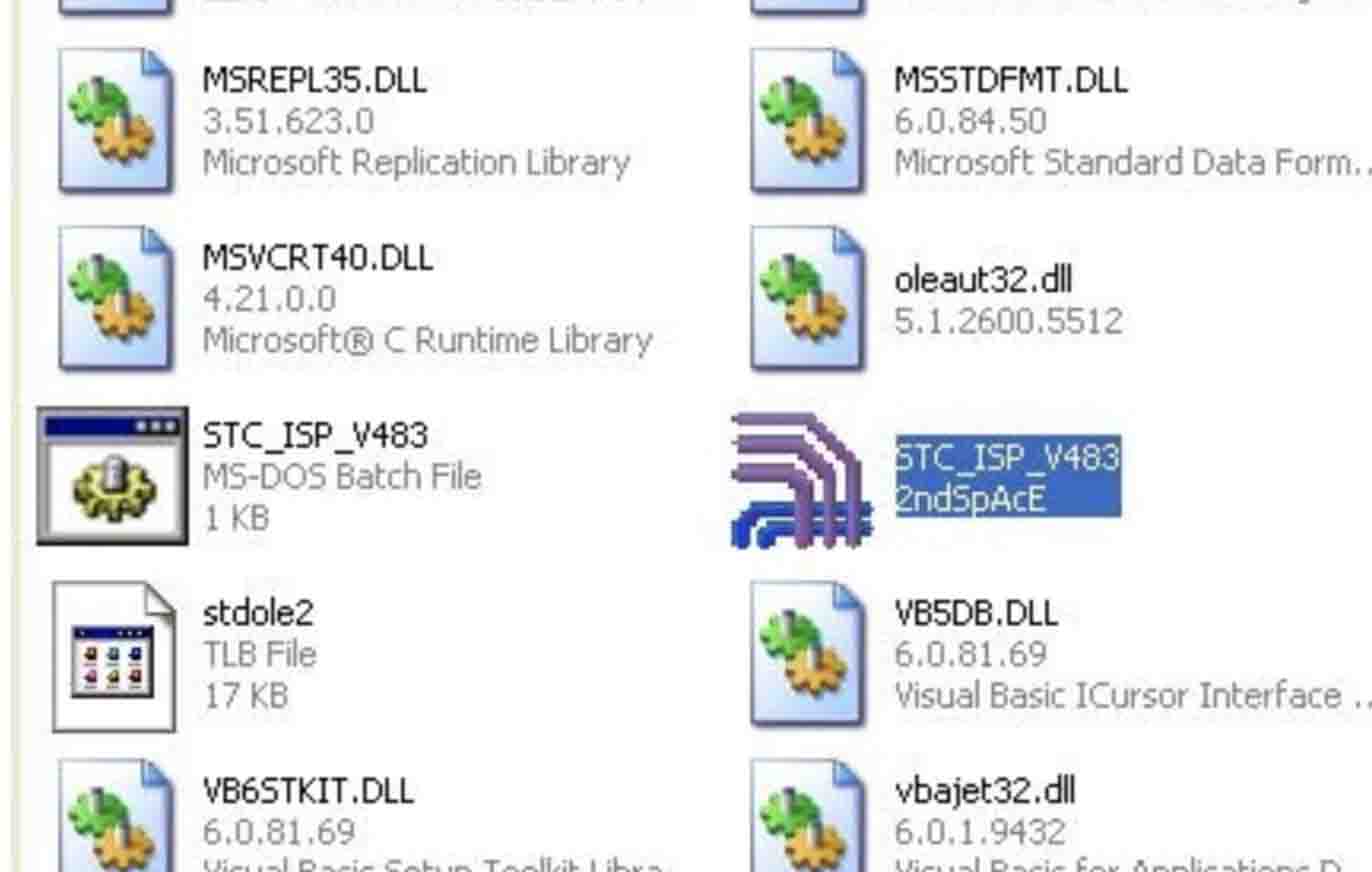

I used STC-ISP (download link to program.

● 1. I downloaded a later version from stcmcu.com and installed it.

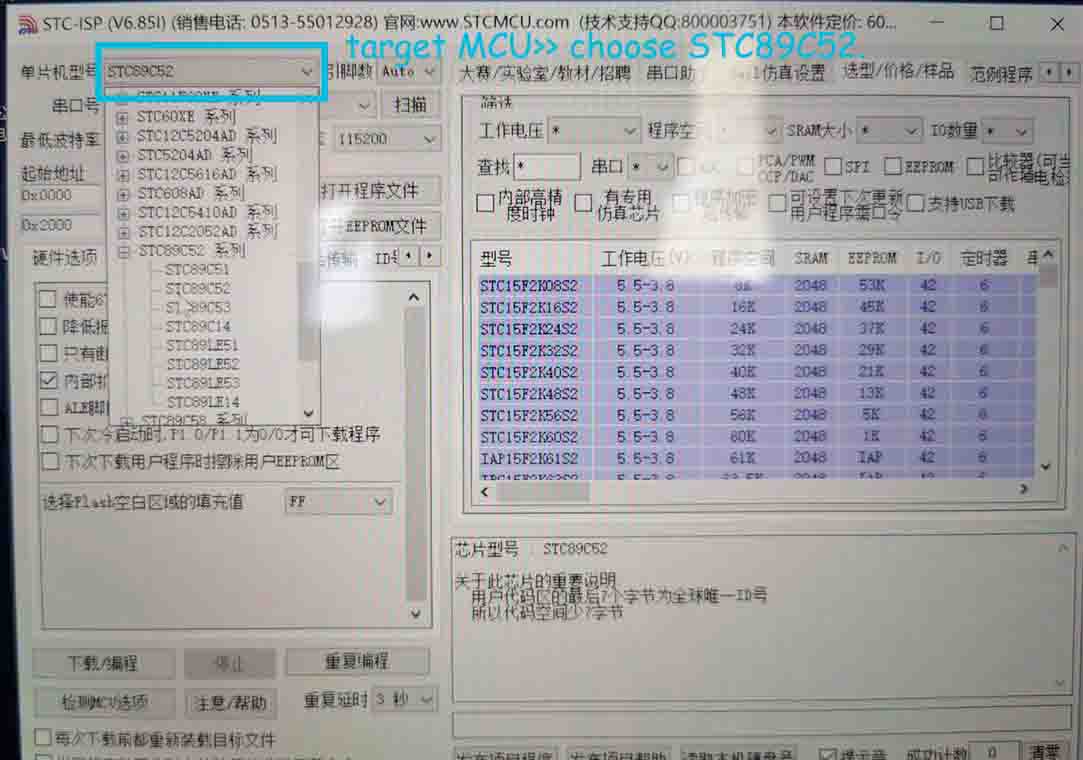

● 2.Start the STC-ISP software(double click STC-ISP) Select the target MCU>> choose STC89C52.

● 3. Connect the board to my laptop.

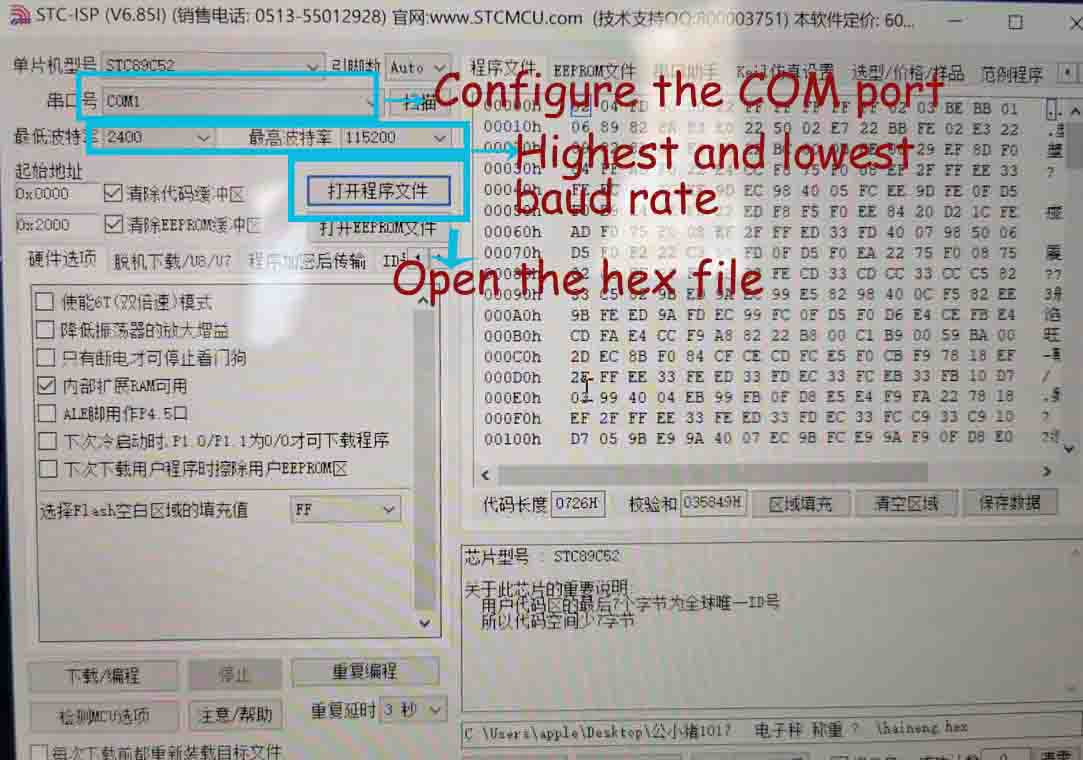

● 4. Open the hex file, Configure the COM port, and set up the Highest baud rate and lowest baud rate.

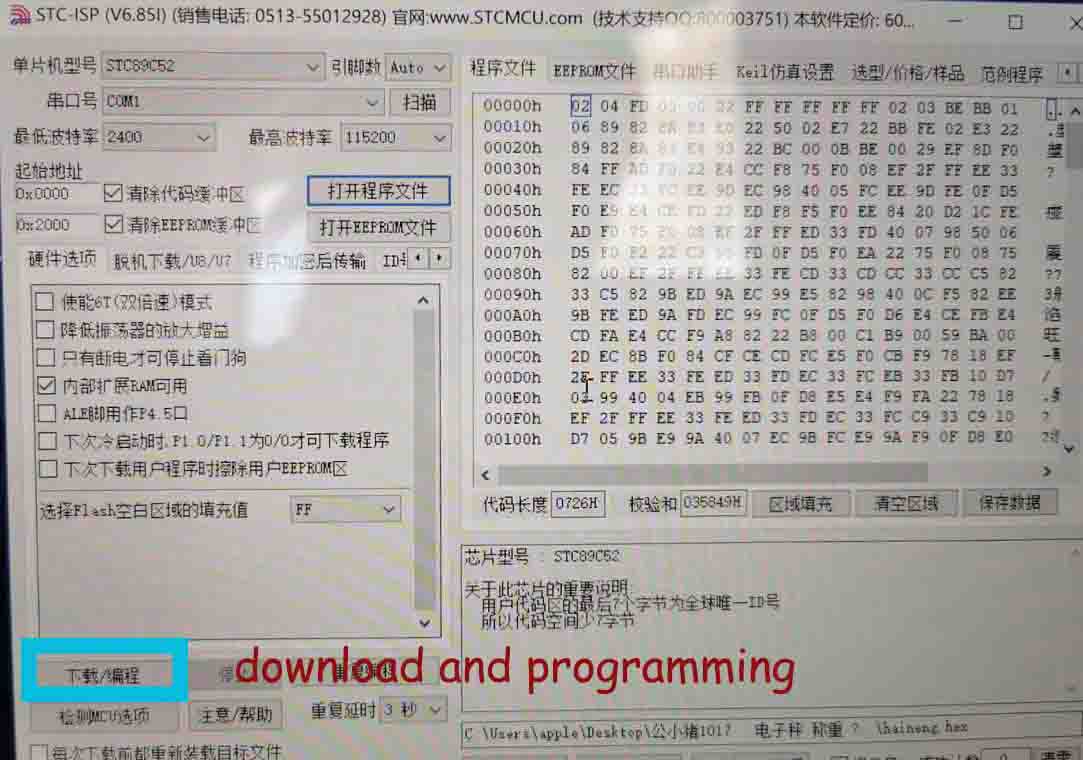

● 5. Press download and programming.

● 6. Switch on the power on my board. (That is important, although I do not know the reason, everyone mentioned that, before pressing the download, the power switch should turn off. )

After....

Finally.....my board is working, when I pressed the power switch, it measured the weight, the LCD shown the measured weight is 0g, and beep few seconds. When I put something on the surface, it measured the weight again. Because the item weight is more than setting(100g), it would not beep, just shown the weight.