18. Project Development¶

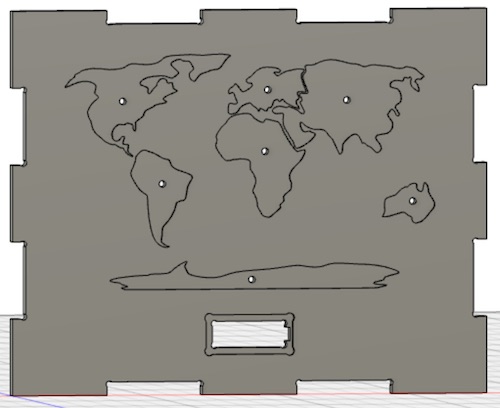

I worked on developing my final project, an interactive, continent-naming touch map that showed images and the continent name when a continent is touched. The idea, at this point, had changed from the original plan I had. The original design, as I mentioned in week 1 was a large-scale project for our school’s global studies program. However, I decided for this final project to make a prototype of that final project. Much of my final project documentation is on the final project page

Here is a summary of all the parts I have that covers different skills:

| Skill | Project Implementation |

|---|---|

| CAD | Project design in Fusion360 / Inkscape |

| Laser/Vinyl Cutting | N/A, maybe accessories and a Latin sticker |

| Electronics Production | Boards for sensors / communication |

| 3D Printing | Hooks |

| Electronics Design | Designing the electronics/boards for the project |

| CNC | Frame |

| Embedded Programming | Programs for the boards |

| Molding and Casting | frame for around the LCD display |

| Input Device | Capacative sensors (pcb copper map) |

| Output Device | LCD Display |

| Networking and Communication | Software serial communication between communication board and sensor boards |

| Interface and Application Programming | Processing interface to show images |

What tasks have been completed, and what tasks remain?¶

I have finished a lot of the design, electronic, interface, and CNC work this week. In terms of CAD work, I have:

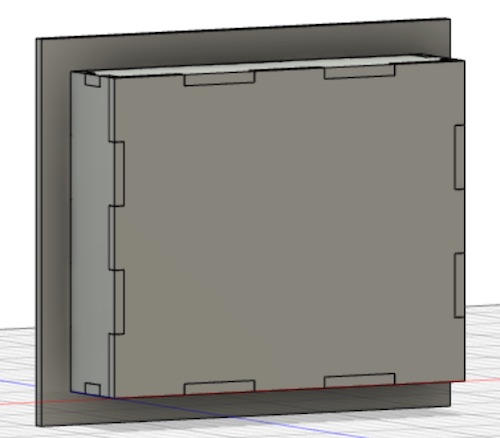

- Chosen the type of map design and determined the size of the project (continents only, Robinson projection, size 1.5ft x 1.2ft)

- Designed the map, imported into Fusion. I worked in Fusion to design continent pcb shapes and parts of the frame.

- Designed hooks that I 3D printed (to stick my project onto the wall)

For electronic work, I have:

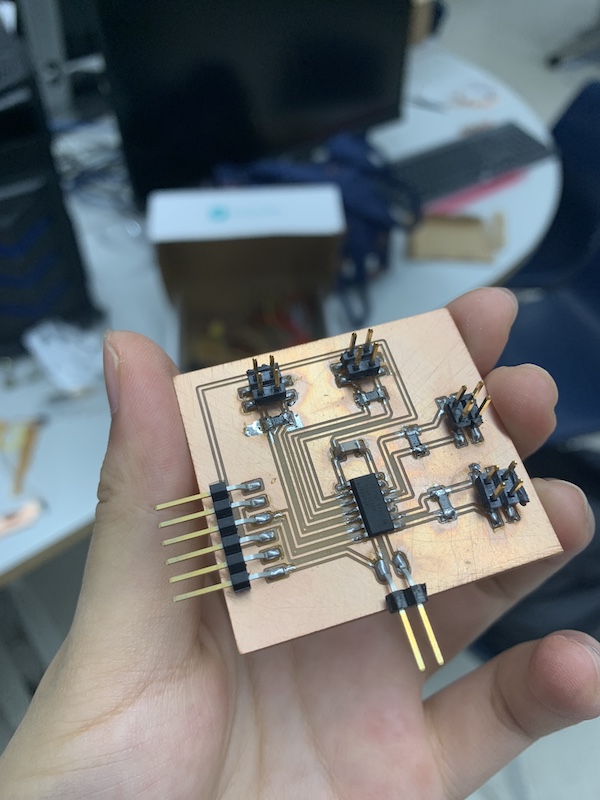

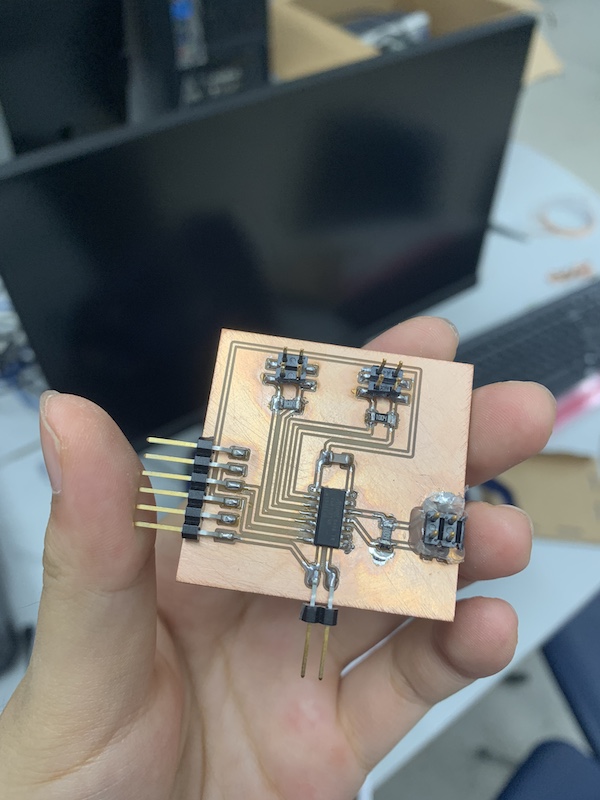

- Made test boards to test the concept of individual sensor boards

- Design final boards for the project, including two sensor/target boards and one communication/lcd board. For now, I have to work on testing and programming them.

For interface work, I have:

- Written up a code for my Processing interface (it hasn’t worked yet, so it’s still a work in progress)

For CNC/Othermill work, I have:

- Used the Othermill to mill out the continent pcb sensors.

- Used the CNC to mill out all parts of the frame except for the front piece.

All I have to do left is to finalize the programming and ensure that my boards work, remill them to fit the wires of the new sensors, integrate them into the frame, and mill out the front piece of the frame. I also have to make sure that my interface works well. Furthermore, I need to calibrate my sensor threshold values in the code with the continent shaped sensors before I assemble everything.

What has worked? what hasn’t?¶

Fortunately, most of my designs have come out the way I wanted them too the first time. Things like tab fittings and dimension issues haven’t been too much of a problem for me. My frame has so far come out alright, and so have my boards.

However, there are still problems I have to solve. Currently, my software serial with pins 2 and 3 does not work the way I want it to. Each individual sensor board works well, but I need to integrate them into one system correctly. It also took a lot of time to get the sensor boards working, and the process involved a LOT of trial and error. I also need to try out my Processing code and fix it once my electronics are in line. The bulk of the work I have left to do consists of getting electronics concepts down, getting the boards to work, remilling them, and integrating them into the system, as mentioned in the answer to the previous question.

What questions need to be resolved?¶

- How will I get the software serial working?

- Will I have to make major adjustments to the threshold values given the varying sizes of the continent shaped sensors?

- How will I get the Processing interface code working?

What will happen when?¶

I made this semi-janky Gantt chart to manage everything I will do within the next 10 days.

I will first get my electronics working this weekend. I will mainly make sure that all three boards can work well together. Then I will work on completing the interface. On Monday, I will mill out the front piece of my frame, check that the 3D printed hooks fit well, and finish sanding the frame. If I have time, I will remill and reprogram my sensor boards with holes instead of pin headers and test that the sensor boards work with the electronics. On Tuesday, I will make sure all the electronics are working properly and put everything together. Throughout the rest of the week, I will work on completing documentation, my video, and my slide.

What have you learned?¶

I have learned a lot. First and foremost, I have learned about time management. It’s imperative that I not only plan out how and when I will do things, but that I also do them as planned. Secondly, I learned that capactive sensors are a pain. They are extremely interesting and satisfying when they work, but their instability makes it often frustrating to work with. I also learned that getting things to work, a lot of the time, just takes patience and more time.