Week 17

Wild card week

Link to the class contentIndividual assignment:

Design and produce something with a digital fabrication process (incorporating computer-aided design and manufacturing) not covered in another assignment, documenting the requirements that your assignment meets, and including everything necessary to reproduce it.

Textiles

GOAL: For this assignment I want to link my final project so I choose to use textiles for the creation of the shelter for my pergola. The family of my friend fabricate sweaters and he very kindly borrow me his flat knitting machine and also explain me the process involved in the fabrication also he helped me in the design process. I am very grateful with Sebastian.

Flat knitting machine

There are two parts of the computerized flat knitting machines, one is the computer controller in the flat knitting machine (hardware), and the other is the computer pattern preparation system (software). The computer pattern preparation system is used to design the knitting data for the computerized flat knitting systems.

I found this link with really good information about Intelligent Computation in the Computerized Flat Knitting Systems also I found this video of Fabricademy 2018 - Week 8 - Open Source Hardware class where they talk about this machines.

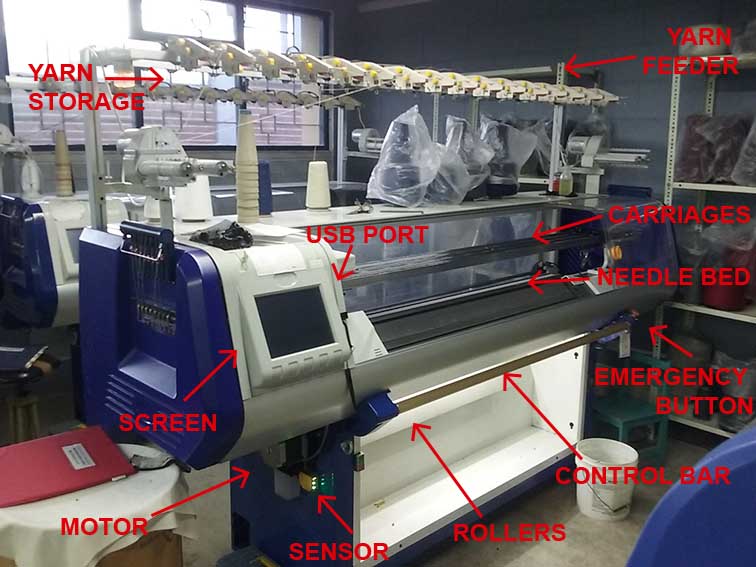

Hardware

Flat knitting machine, a major machine in woolen sweater production, is a kind of V-bed weft knitting machine.

- Company: Qiang sheng

- Product Name: Computerized Flat Knitting Machine

- Function: Knititing

- Place of Origin: China

- Type: Jacquard

- Power: 220V

- Control system: LCD screen

- Input device: USB

- Knitting function: sweater/scarf/hat/placket/carpet.

Quick Details:

- Carriages: system of displacement in one axis.

- Needle bed: had two faces in a V form. We can program the machine to knit in the front or back faces if knit in the middle we are join the knitting of two faces.

- Yarn storage.

- Screen: interface to define the settings for the knitted.

- Yarn feeder.

- rollers: tense the piece one principle of the knitted process and also pull out the final piece is a essential part of the machine.

- Control bar: allow to start and stop the process and also control the speed.

Parts:

The machine had limitations like the type of the yarn we can use cotton, alpaca, wool and acrylic. Another limitation is the size of the piece the widht is 1 meter max and the long could be any.

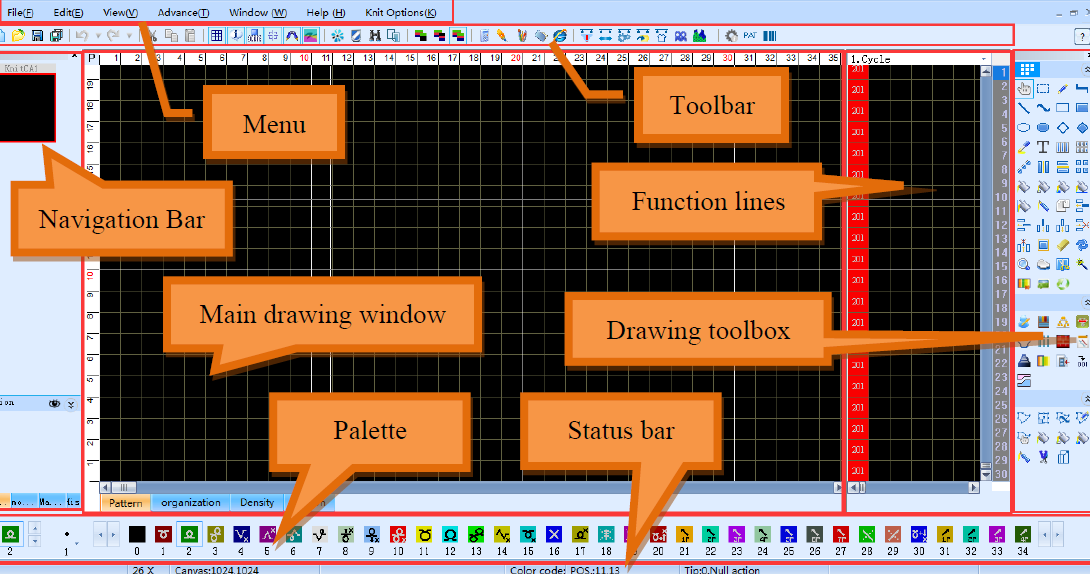

Software

The computer pattern preparation system is used to design the knitting data for the computerized flat knitting systems. All knitting data needed for machine operation are programmed in the keyboard and simultaneously displayed on the monitoring screen. One flaw for the computer pattern preparation system is that a pattern designer needs to spend much time to design a satisfactory pattern.

Raynen QiLi KnitCAD 2018

The software has the automatic programming function and is used for automatically generating control data of the lower computer of the computerized flat knitting machine. Its main functions include pattern design, image analysis, automatic compiling, data transmission, etc.

Design

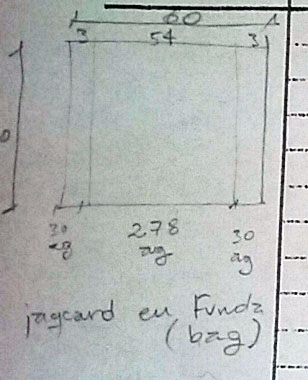

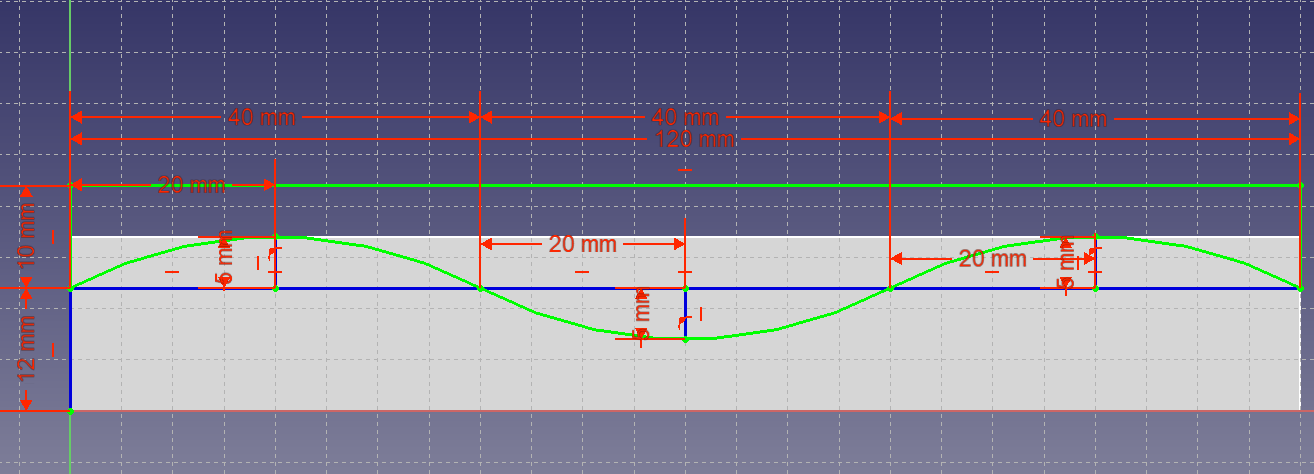

The idea is to create two bags at each side to hang up the textile on the pergola inserting tubes in the bags. The size of the piece is related to the module of 60 cm X 60 cm and to transfer that size to the machine we need to make some test to know how many needles we are going to need and reach the desired size. For one bag we use 30 needles to reach 3 cm and for the pattern 278 needles to reach 54 cm. For the final piece we use 26 needles for each bag.

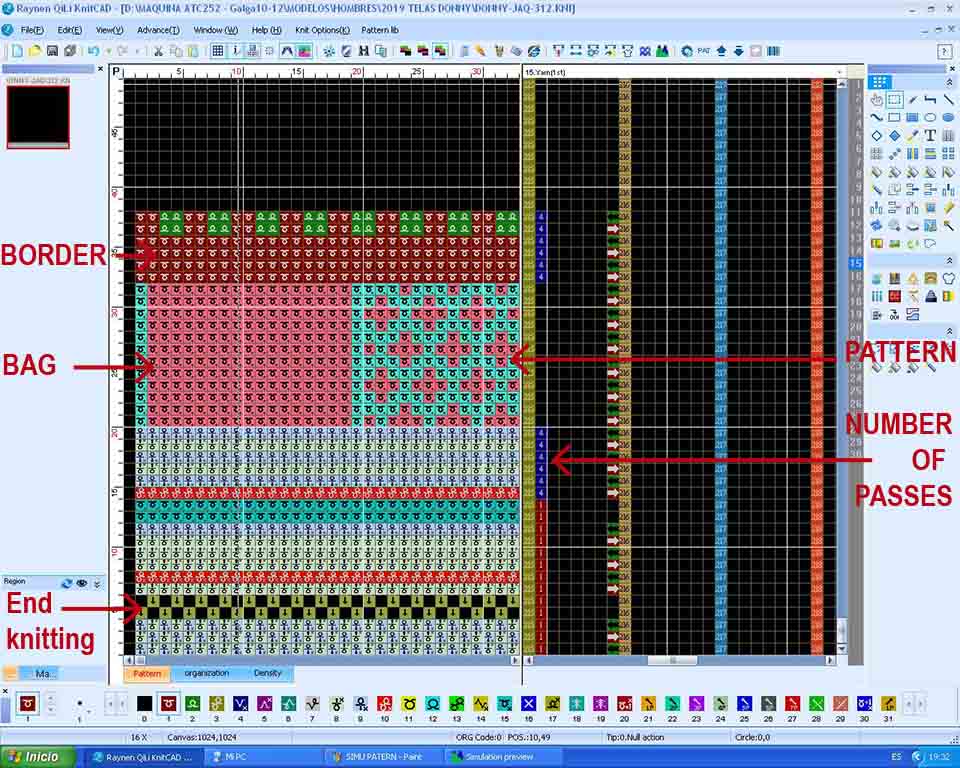

I was a little confused because of the symbols of the program that make a shape like pixels but my friend explained me that there are just 10 principal stitch and the rest are variations of those stitch. Making a pattern from the beginning takes a lot of time even for someone who knows to use the program or an expert depending of the complexity of the design. So I really need help to do this design so with the help of my friend we did the next work flow:

- Border: located at the sides columns we are programming to close the knitting from both sides of the bed.

- Bag: We start from a previous design for the bags and just increase the raw pattern to reach the desired size. We are programming the machine to knit the two sides of the bed creating the top and bottom layers.

- Pattern: After that we make the simplest pattern as a cross shape.

- Number of pases: or cycles are the number of times that the rows are repeating.

- End knitting: or throwing thread has to be done at the beginning until the knitting reach the rollers and is tensed by them and also we programed at the end to be removed from the piece because the machine can't close the knitting or slice as a principle of everything need to be knit so this side should be stitch in another machine to avoid unravel.

- Save the current pattern. The saved file format is KNI.

- Export to the machine file. The “*.001” file achieved by Raynen-Qili KnitCAD compiltion.

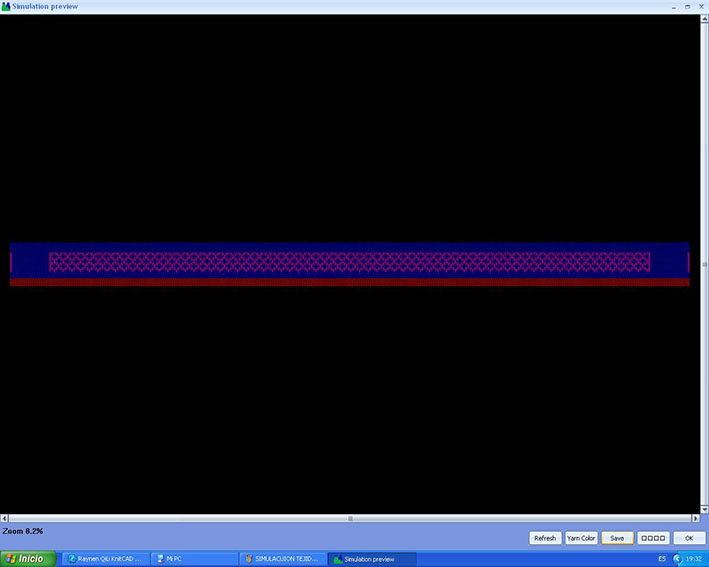

Simulation:

The software allow us to simulate or render the final appearance of the knitting and we can see the top side and the bottom sides as well. What we are looking at the both sides are the bags at the bottom in red is the throwing thread.

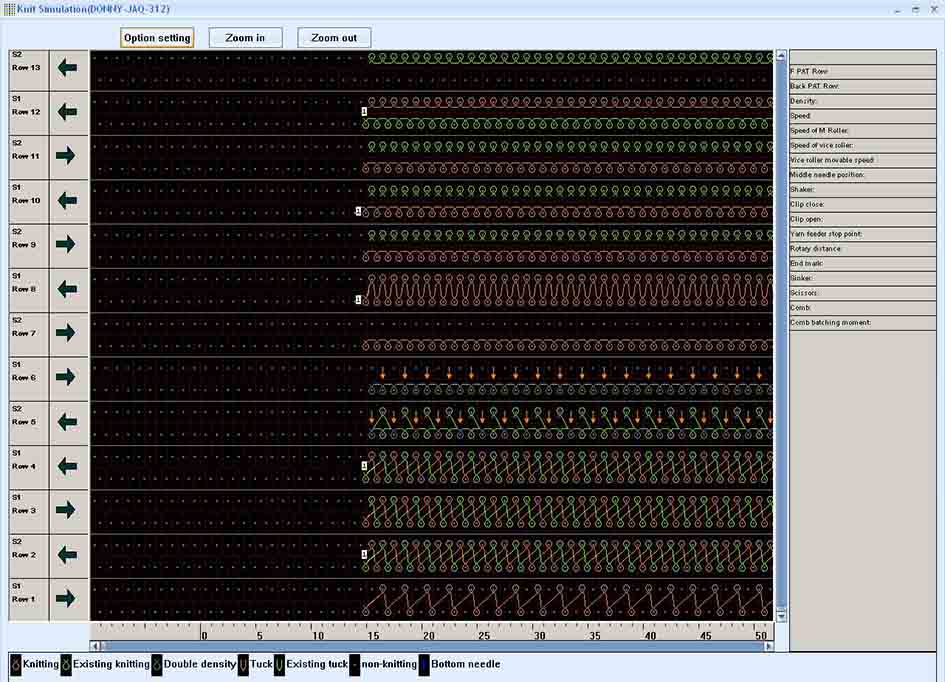

Also allow us to simulate the knitting on the needle bed to see how is the stitch is made per pass in each raw.

You can download the files:

Machining

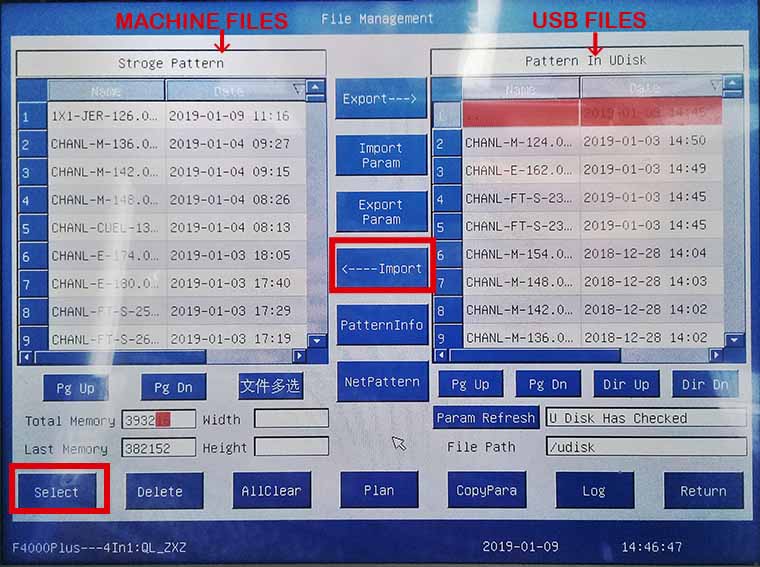

Main menu:

- Connect the USB

- Select file management

File management:

- Select the file from the Udisk

- Import

- Select the file from the machine

- Click Select

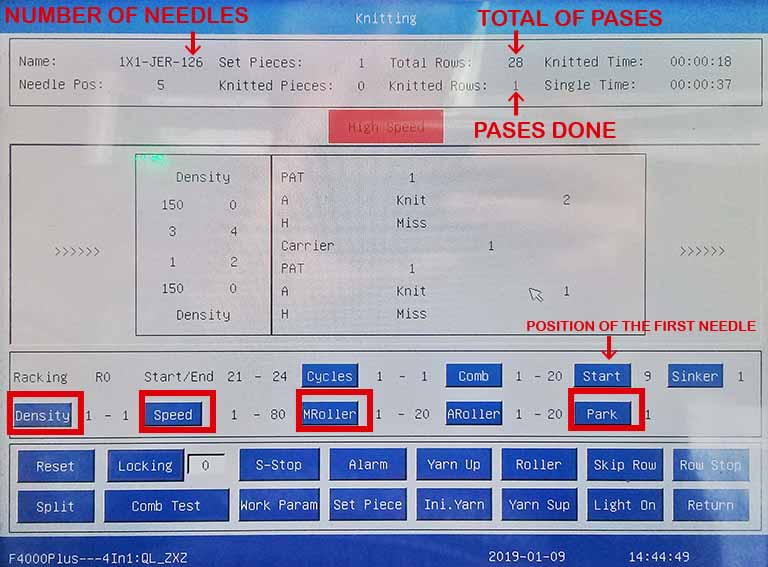

Knitting menu:We can configure this settings:

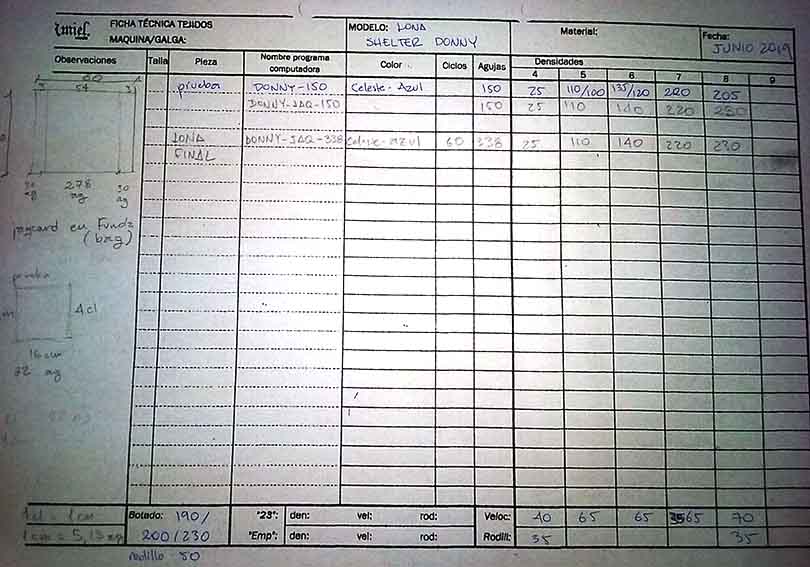

- Density: 230

- Pases Speed: 70

- Roller speed: 35

Parameter sheet: Its necessary to anotate the different parameters used in the test to remember the different seetings.

Final result: One side need to be sewn and also the cuts for the tubes to prevent unravel.

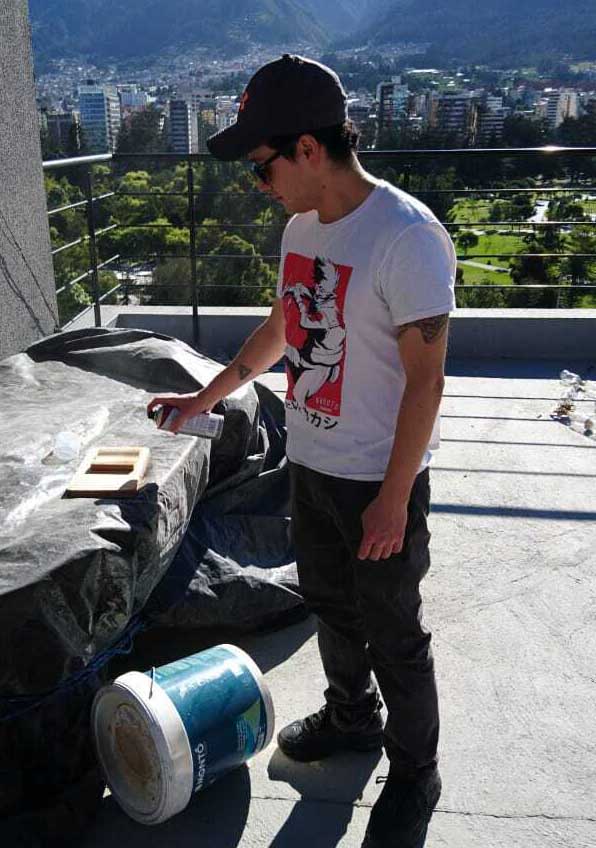

Hero shot: the goal was accomplish the size of the piece was good fits perfectly with the pergola and also the bags for the tubes.

COMPOSITES

Design

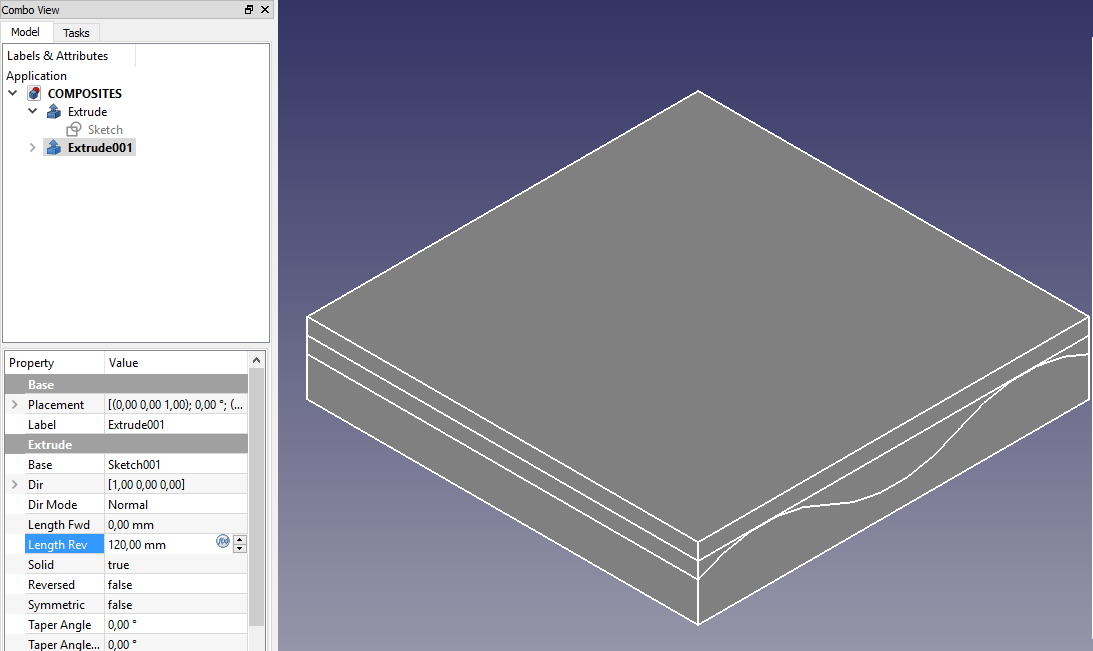

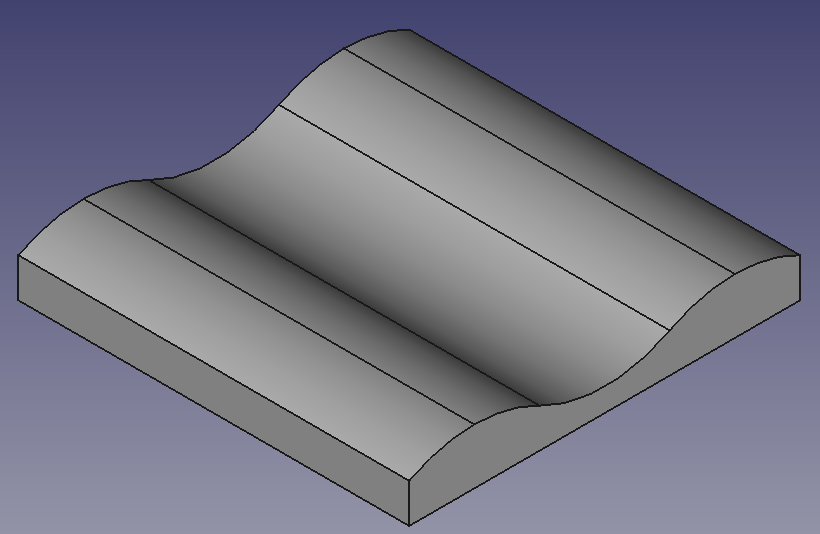

I choose to make a 17 mm MDF mold with a 3d wave shape and make a composite with a textile and a epoxy resin just to test behavior and if it work right the application in a bigger scale could be as a roof tile.

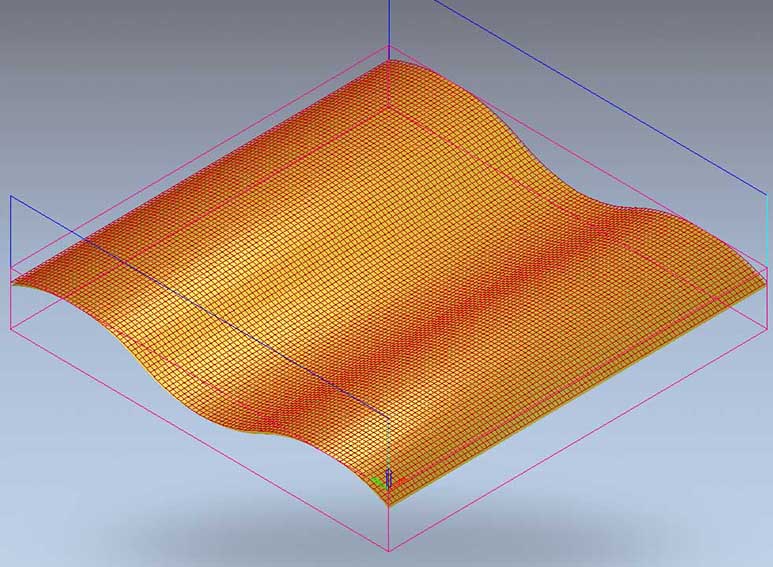

Freecad work flow:

- Create a new sketch with a square shape 12 X 12 cm.

- Extrude it 17 mm.

- Select a lateral face from the extrusion and create a new sketch attached to the flat face.

- Draw the wave profile and extrude it 12 cm.

- In the Part work bench select the two extrusions and make a cut of the two shapes.

- In the mesh design work bench select the cut shape and create a mesh from a shape.

- Export the mesh a STL file.

You can download the files:

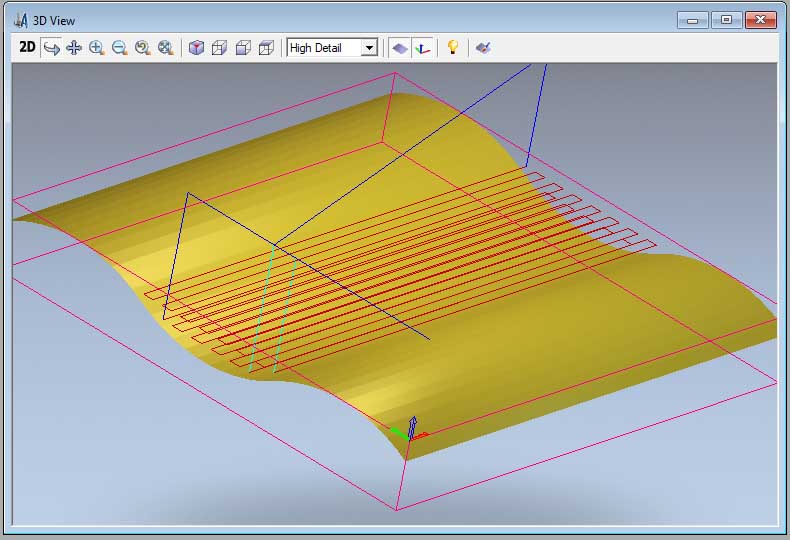

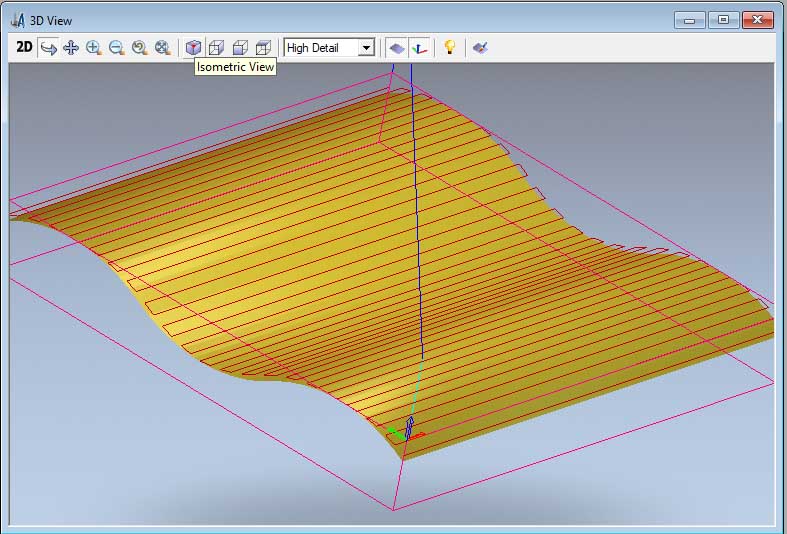

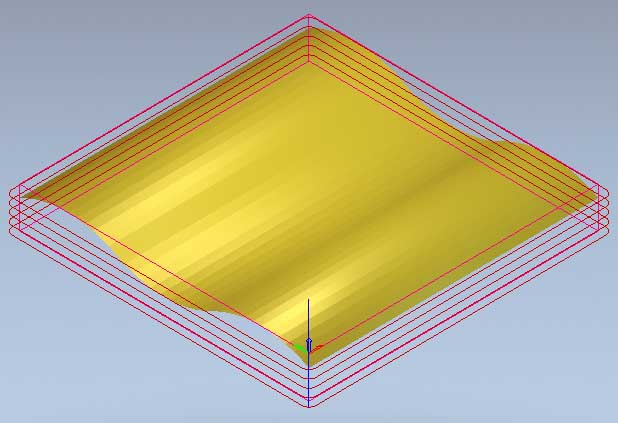

Artcam work flow:

- I followed my documentation from week 10 and use the same seethings for the 6mm and 4mm milling cutters in artcam.

- Roughing 1: 6mm flat milling cutter.

- Roughing 2: 6mm flat milling cutter.

- X and Y Finish: 4mm flat milling cutter.

- Cut: 6mm milling cutter. In freecad I export the 2d shape of the base as DXF to my file in Artcam and the I did a 2d tool path to make the cut.

Machining

The finish make the difference in the final result but also need a little sanding to have a better finish.

Composite

- The MDF mold need a few coats of lacquer and a little sanded until get a smooth surface.

- I choose to use a porous textile so the epoxy could penetrate to the other side of the textile.

- Spread some WD-40 oil to the mold surface.

- Attach the textile to the mold with some screws to expand the textile opening it's porous and attaching it completely to the mold to get the desired shape.

- I'm using XTC-3D that I used in the week 10 and I did the same work flow mixing the component A with the component B in a relation of 2:1 respectively.

- Error: I spread just a little amount of the epoxy and it stick to the wood surface and also I realized about the quantity in the data sheet if the quantity is more it will dry faster so I should put more.

- Debugging: at my second attempt I put much more quantity of the epoxy and also cover the wood with a plastic bag and spread over it some Vaseline and then I attach again the textile with some screws.

- We did this composite exercise with Ale like a group assignment and support each other.

- This time the final result was better than the expected with a smooth surface and it dry in four hours which is very fast.

- This time the unmold process was better because the resin doesn't stink to the wood.

- Final result: The top surface look very well but I had a unexpected result in the bottom surface because of the texture of the plastic bag something really crazy to consider in the design.

Work flow:

Conclusion:

Was very difficult to find information about the specific machine in the Internet.

Each machine company uses its own code and software so it makes difficult to share some codes between different developers.

In this assignment I learn a lot about textiles and now I know there are a lot applications for textiles not only for fashion industry also for architecture, furniture, etc.

The creation of patterns in the software was the most interesting thing for me because allow to create very crazy thing but also need a lot of time and you really need spend time learning about that subject to program and make good design.

Composites was a very funny exercise to experiment and very interesting I still think that in a bigger scale I could make some kind of tile roof.

The combination of the two different materials mix the flexibility of the textile with the hardness of the epoxy giving to the composite a better structure property resistant to the compression and tension.