Wildcar week

Using 3D Printing for Welding Fixtures

This idea is not mine, I was looking for some interesting innovation on traditional welding and I found a company (markforged) that uses 3D printing to generate support pieces to weld parts at complex or custom angles. I found it a very interesting idea and easy to apply.

Another example of aditive manufacturing used in industrial processes is Volvo: “It’s especially good for older machines where the parts that have worn out are no longer made efficiently in traditional production methods. Producing new parts by 3D printing cuts down on time and costs, so it’s an efficient way of helping customers.”

The original idea taken of "Markforged 3D Printers"

Workflow Summary

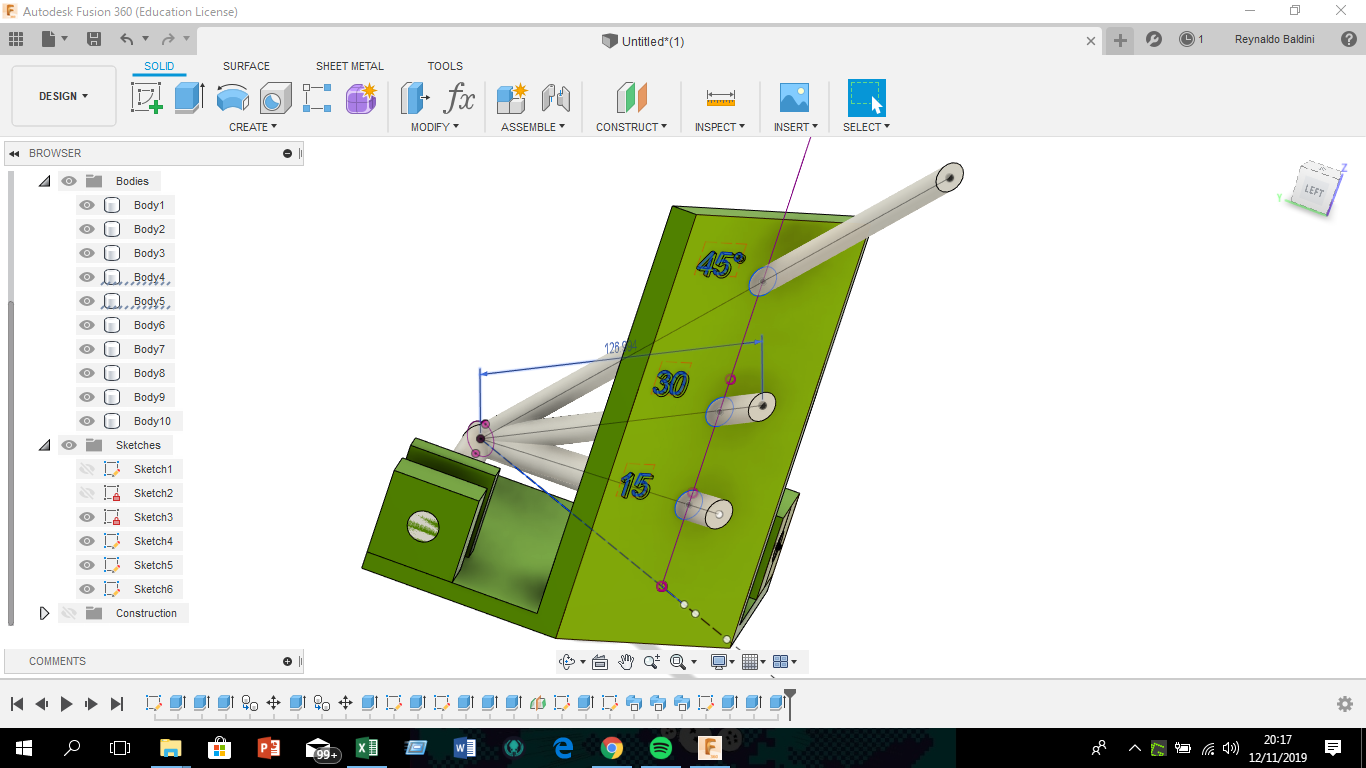

Design the frame usign Fusion 360 (STL Fusion Files). The design of the piece allows welding of 8 mm diameter iron rods, forming an angle of 90 ° in the XY plane, and allows the possibility of adding an additional rod from the vertex of the XY weld to form angles of 15, 30 or 45 ° between the XY plane and the Z axis.

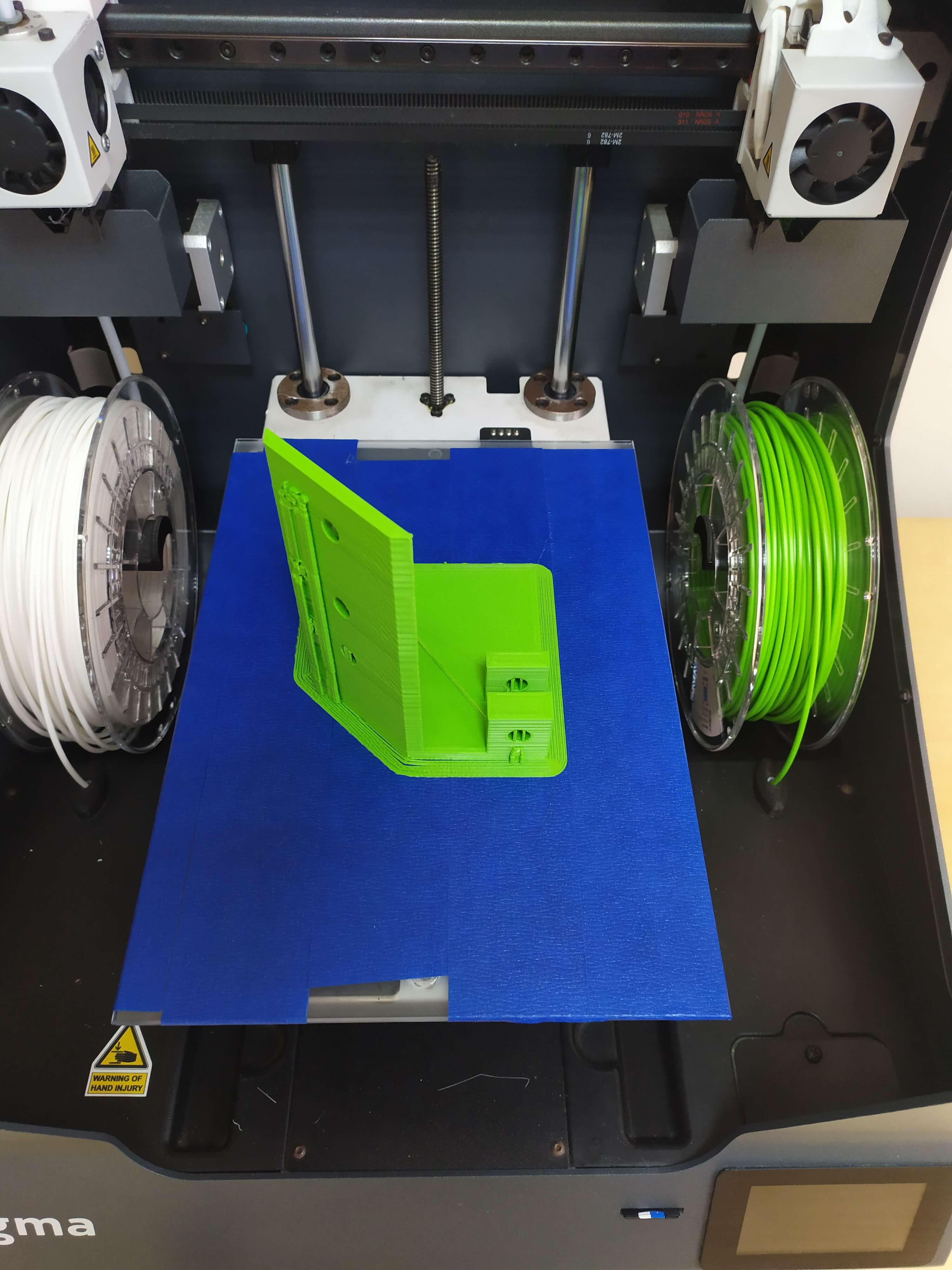

Then I 3D print the component

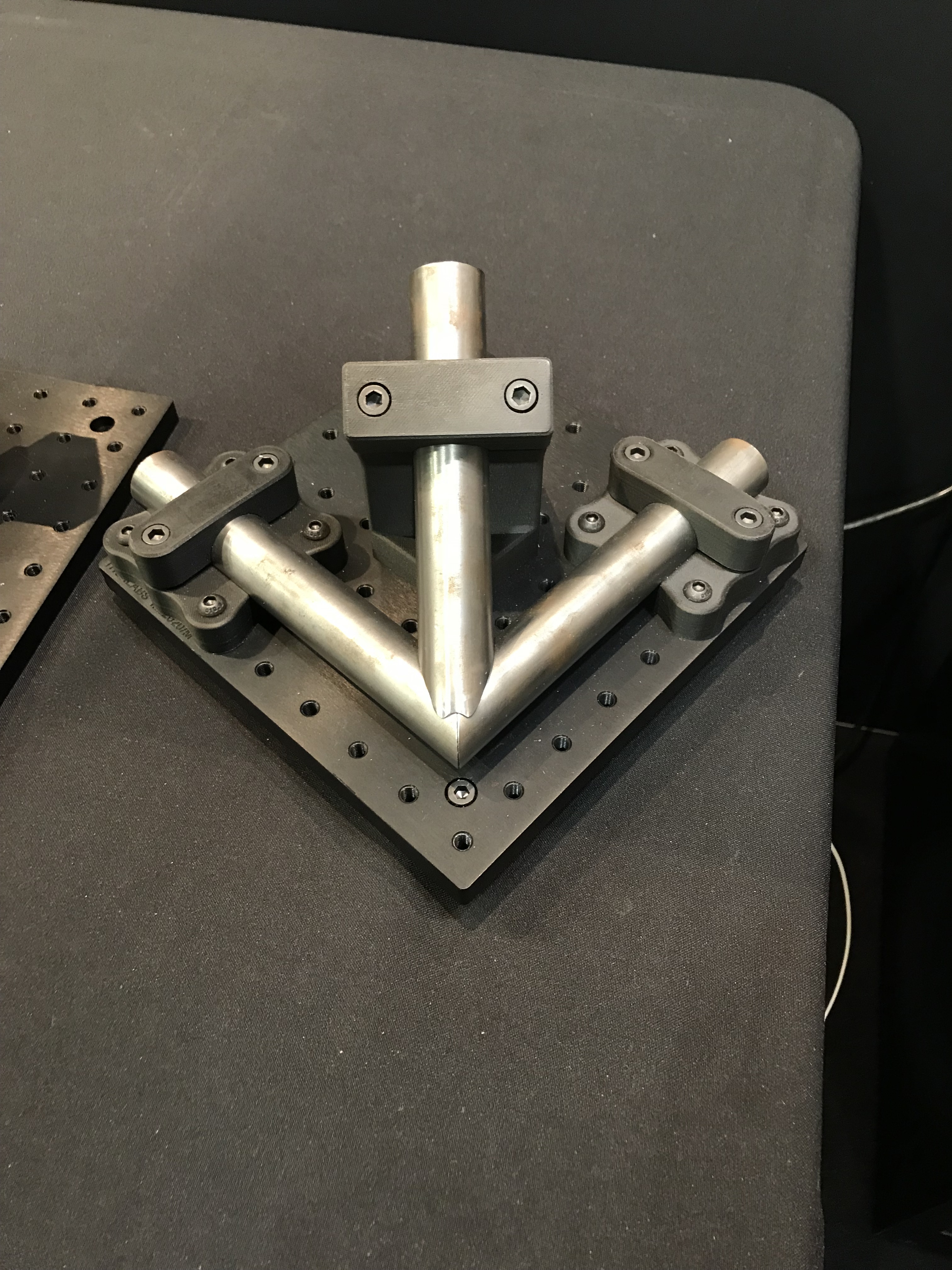

The I presente the metal rods, especially to check the functionality of the component

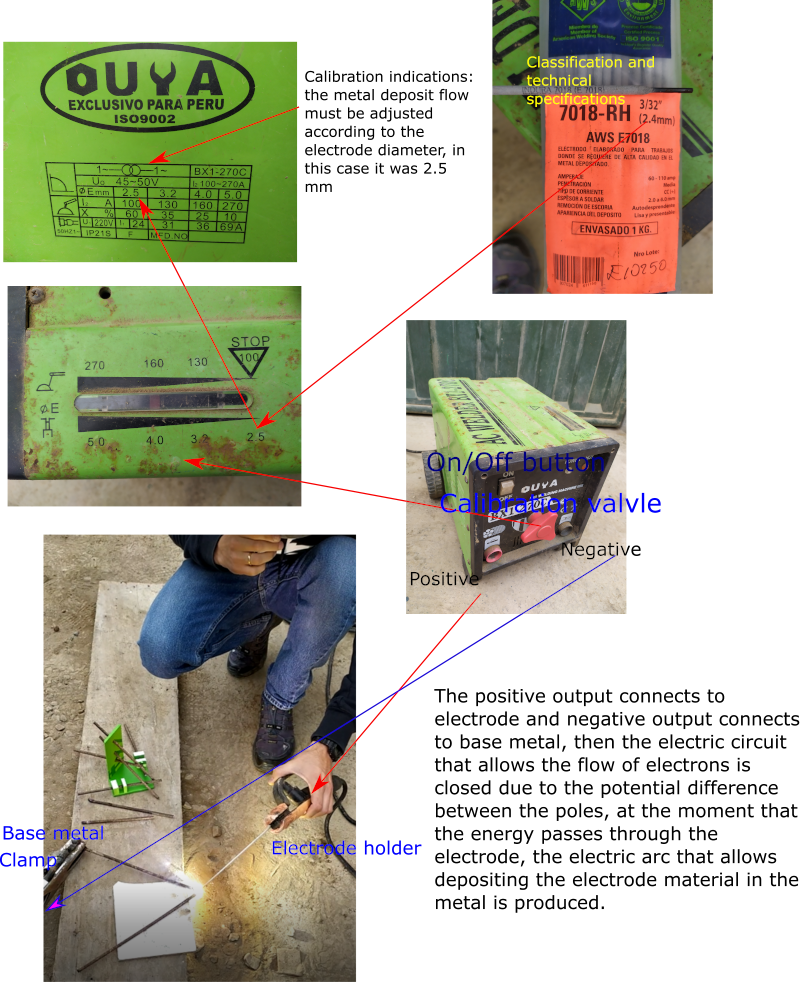

Then, I started wellding the pieces.

Finally, a good result was obtained, getting the rods joined precisely at complicated angles.

Welding process

Safety measures:

at least wear welding mask and leather gloves