Group assignment

2D stacked Cardboard CNC

In the workflow, part of my contribution was on the beginning (and the other part was in assembling and 3d print some parts of the machine)...

Individual assignment

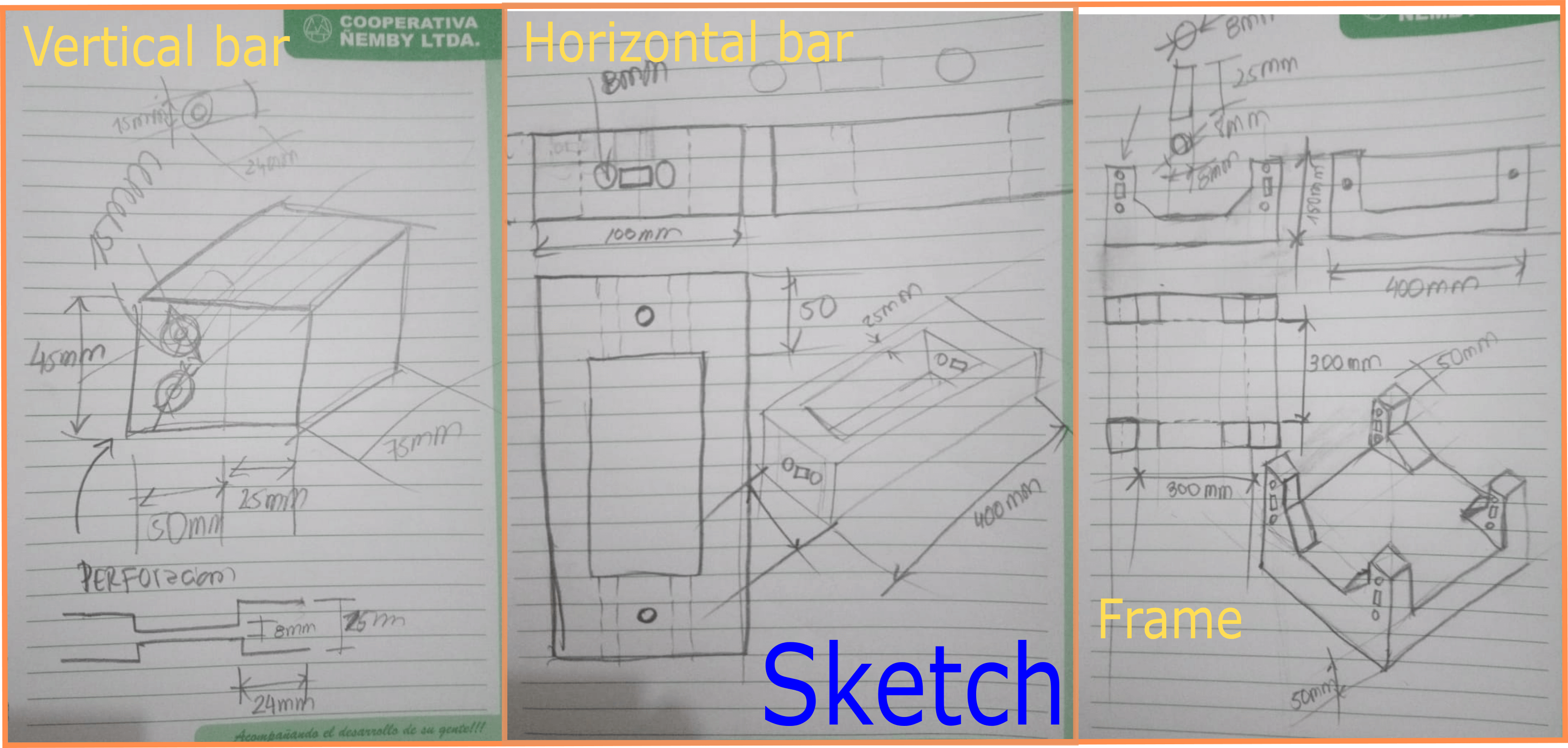

For this week I design a XY mechanism based on XY Core.

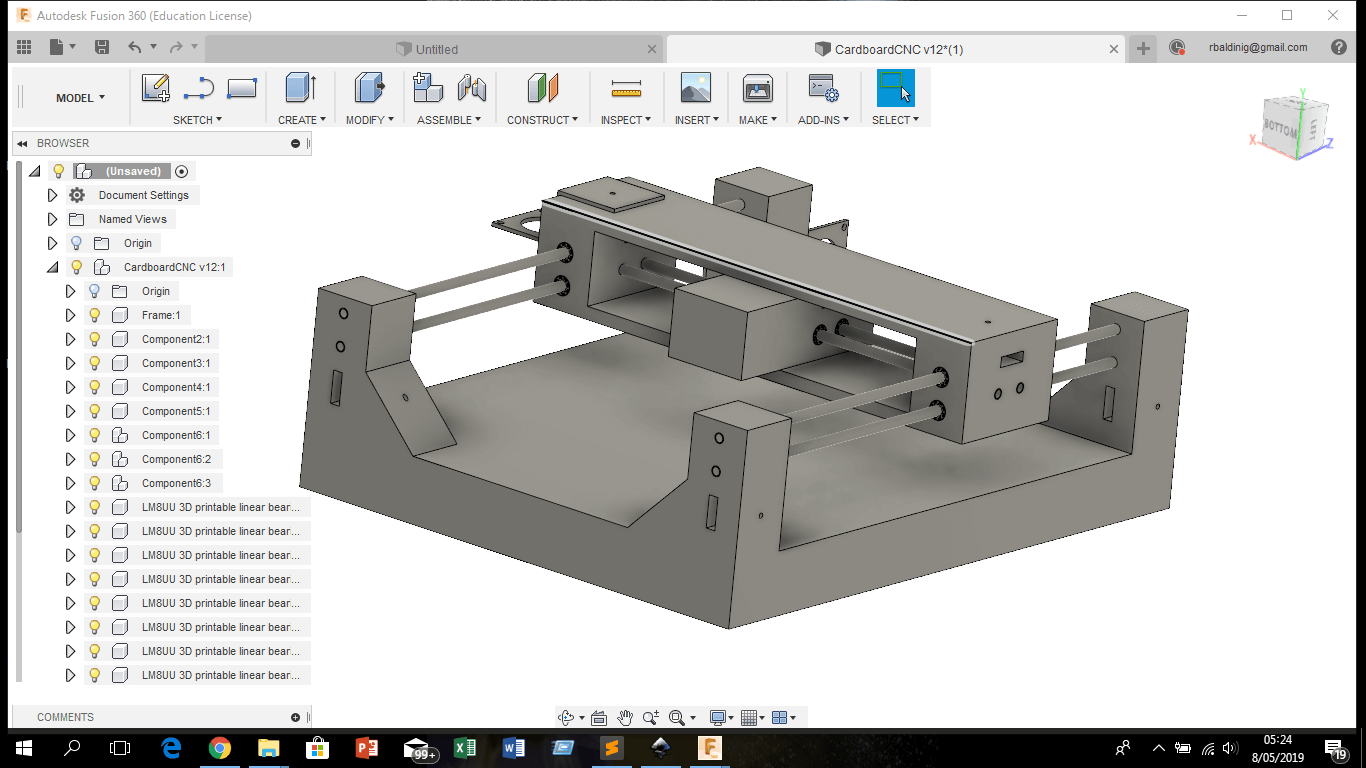

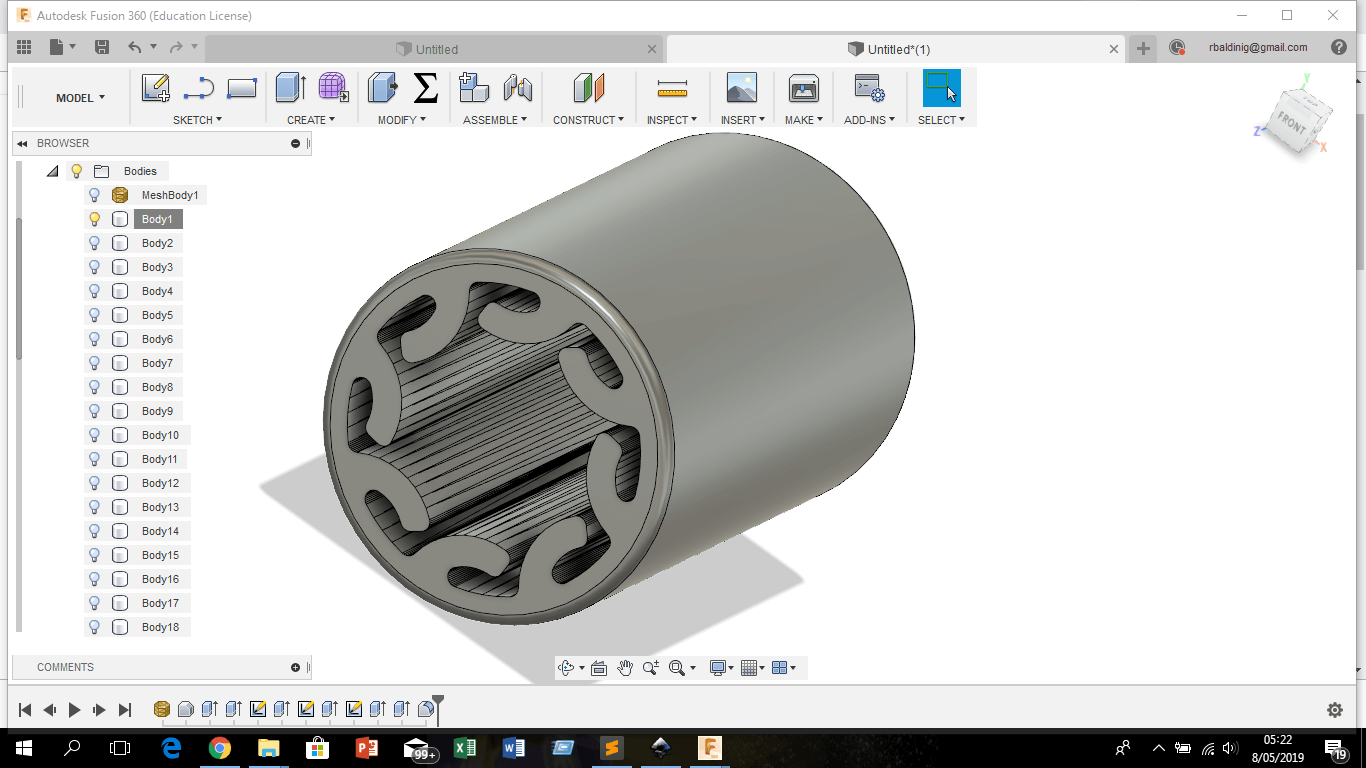

I design the frame, horizontal and vertical bar in Fusion 360, and add a linear bearing from thingiverse.

Fusion 360 Frame file

Then a colleague, was responsible for entering the model to Slicer for Fusion 360 to make the frame (link to Abdon's page).

Assembly (Groupal)

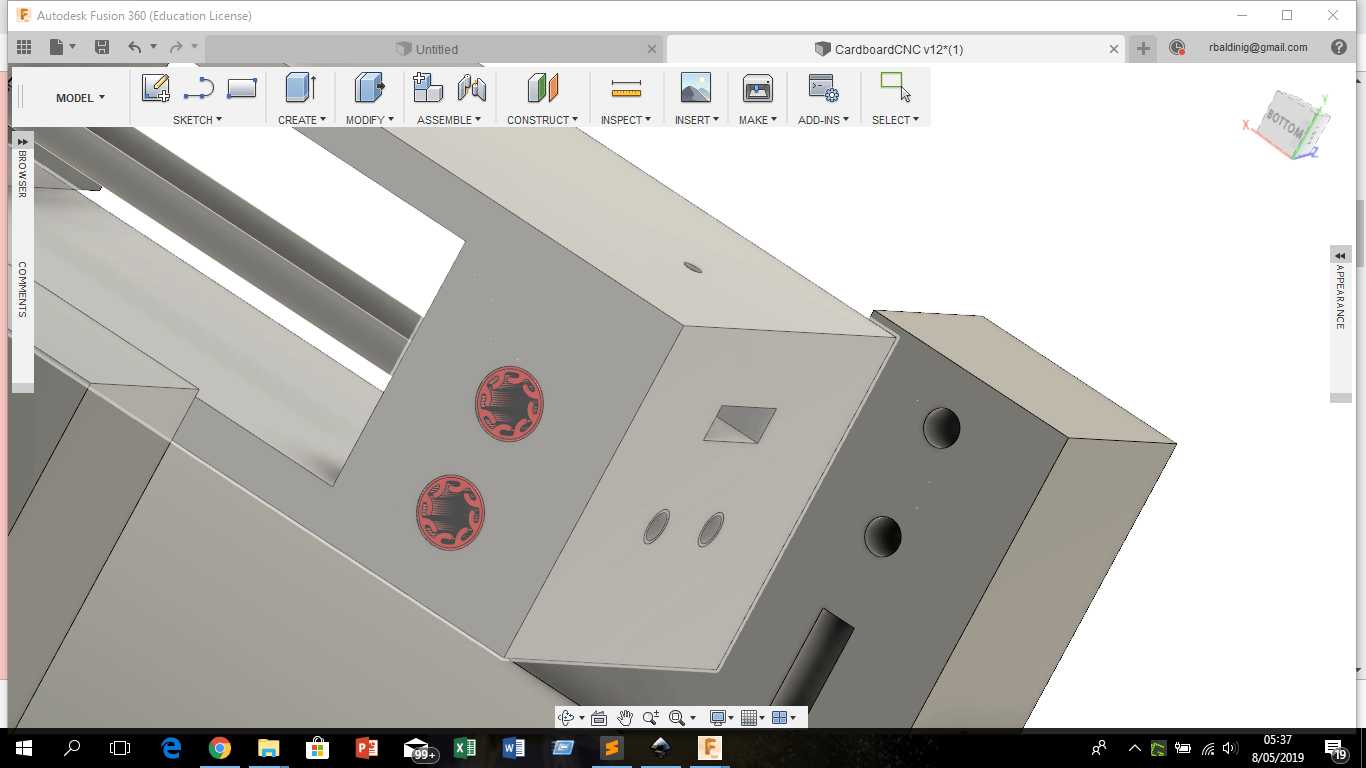

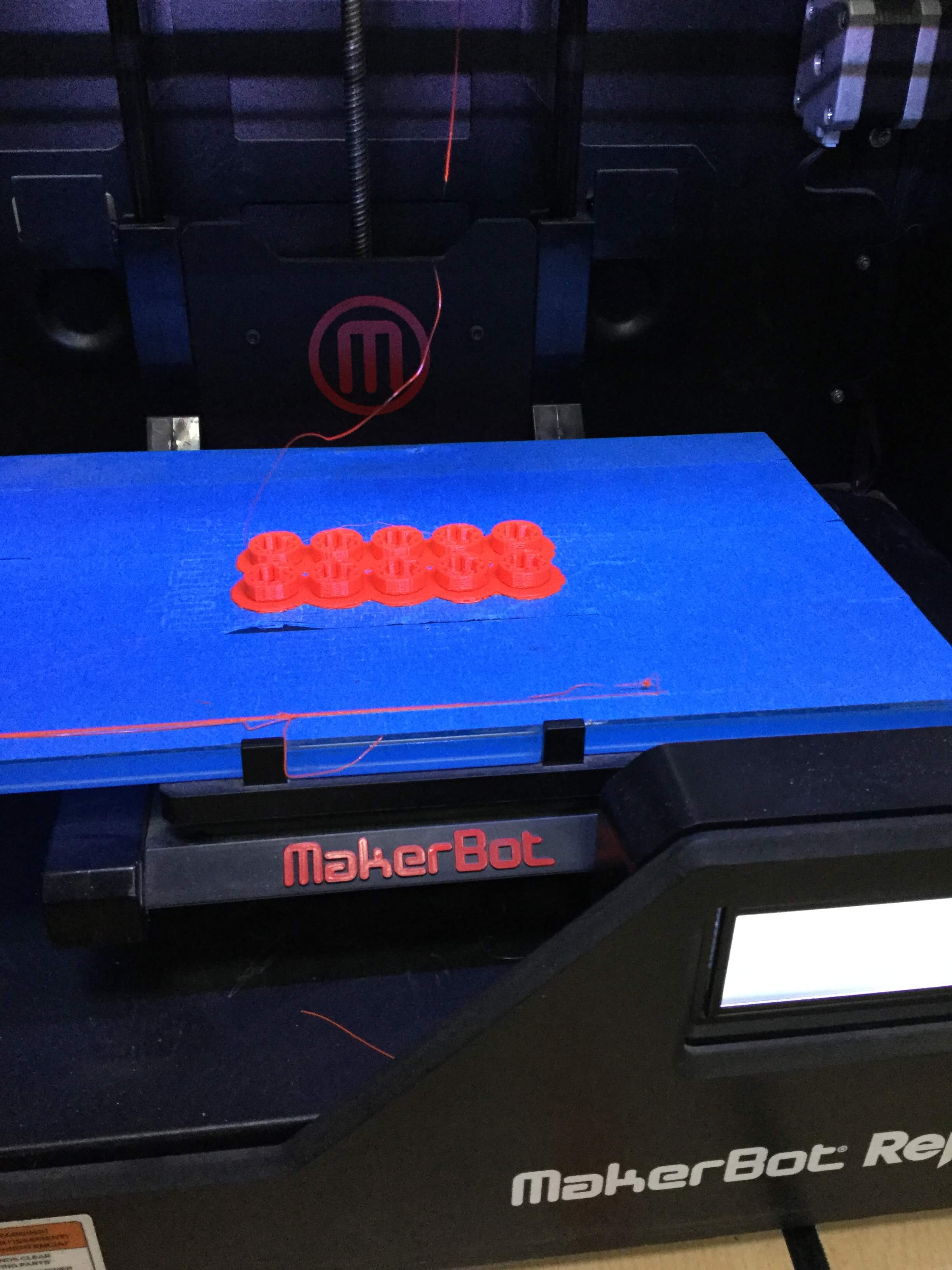

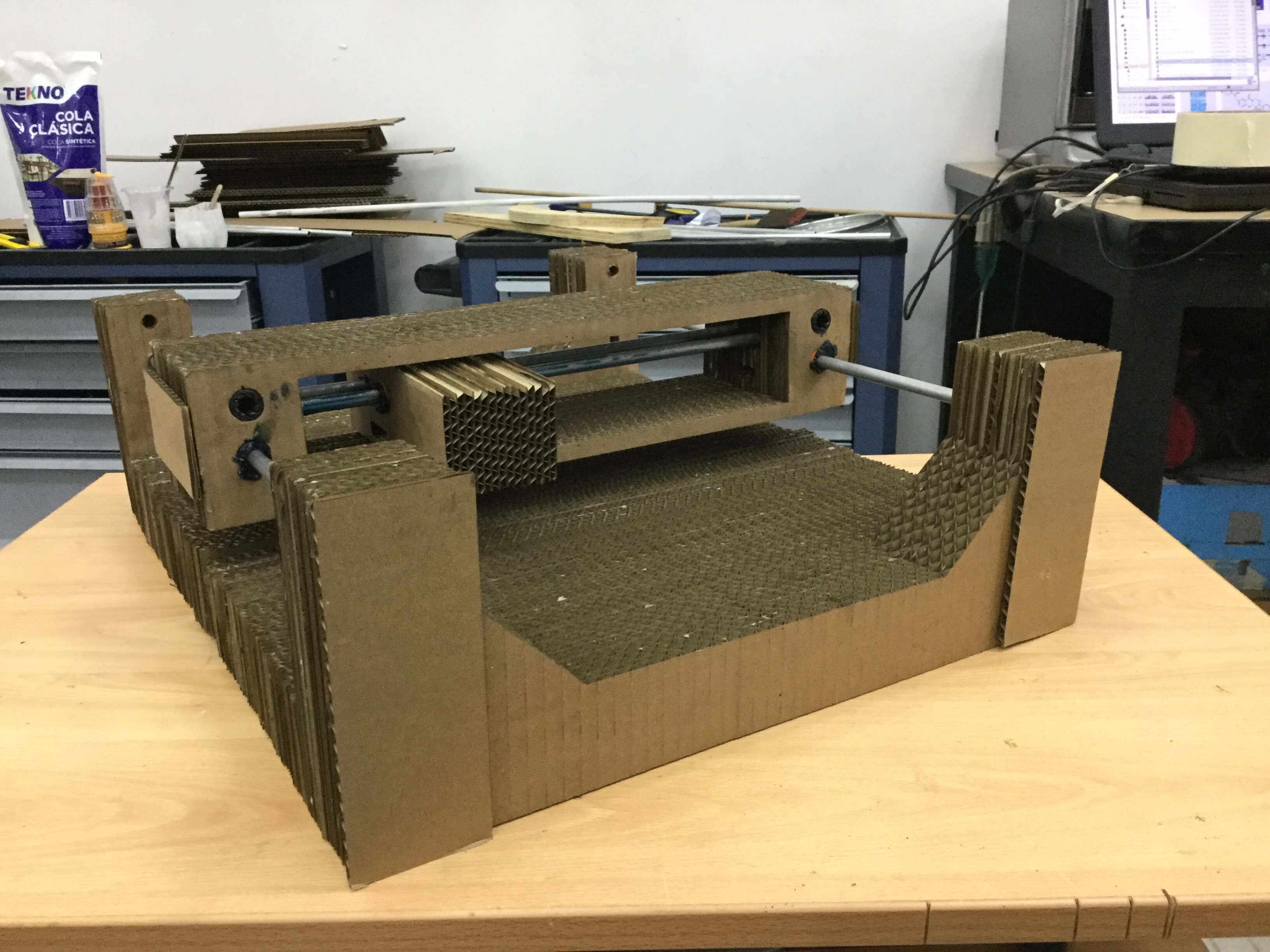

After generate de DXF file produced by Slicer for Fusion 360, the cardboard was laser cutting, the linear bearing was 3d printed, and we use six 8 mm of diameter aluminium bars as guidelines. For stack the cardboard, woodworking glue was used:

One of the problems was that the linear bearing doesn't fit well in the aluminum bars because the bars weren´t homogeneous at all, so we warm up the linear bearing with a heat gun, and due the internal shape of the linear bearing was easy to fit after that.

Another problem was generated by the misalignment of the staked carbboard, in the moment for insert the aluminum bars in the movil parts, I think that generate a shear strees along the bar due the sum of the staked boards (it needs to be a perfect align), this was solved put car grease to reduce the friction.

Asignment goals

- Design a machine (mechanism + actuation + automation), build the mechanical parts and operate it manually, document the group project (group assignment).

- Document your individual contribution.

Learning outcomes

- Work and communicate effectively in a team and independently.

- Design, plan and build a system.

- Analyse and solve technical problems.

- Recognise opportunities for improvements in the design.

Have you?

- Explained your individual contribution to this project on your own website.