]

]

Press fit kit for laser cutter, test and research.

Assignments

- Cut something on the vinylcutter

- Design, lasercut, and document a parametric press-fit construction kit

Research¶

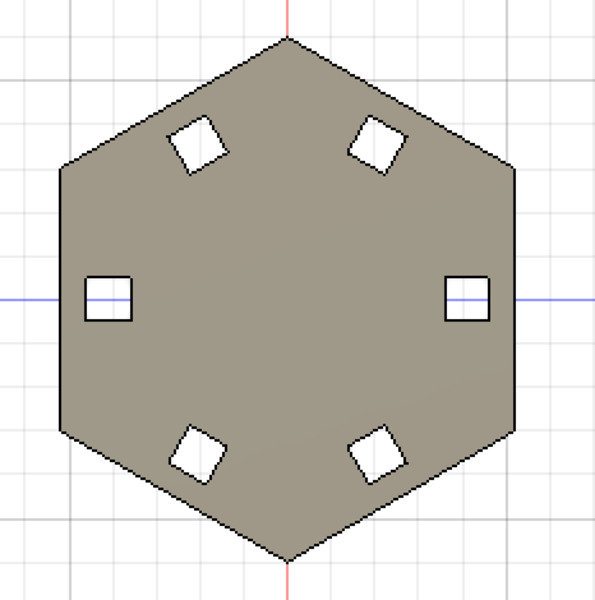

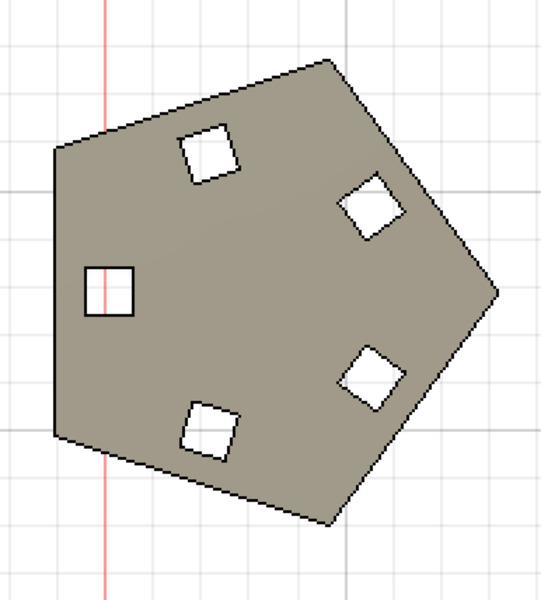

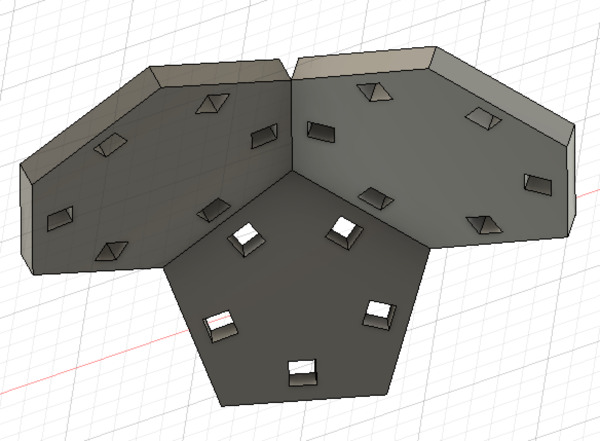

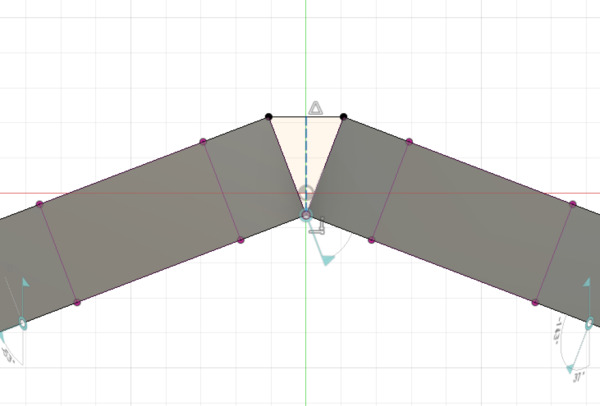

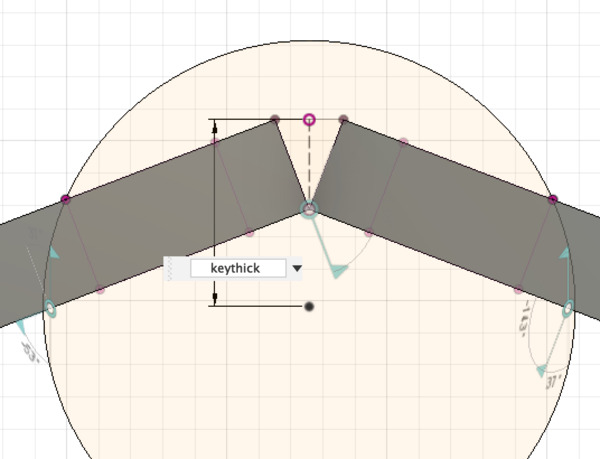

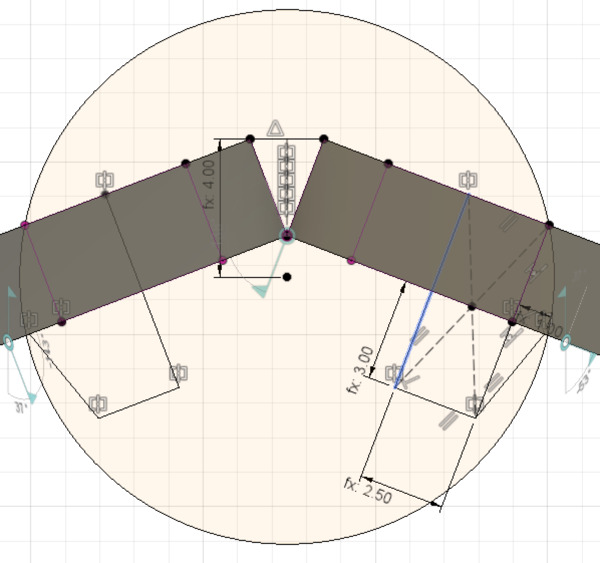

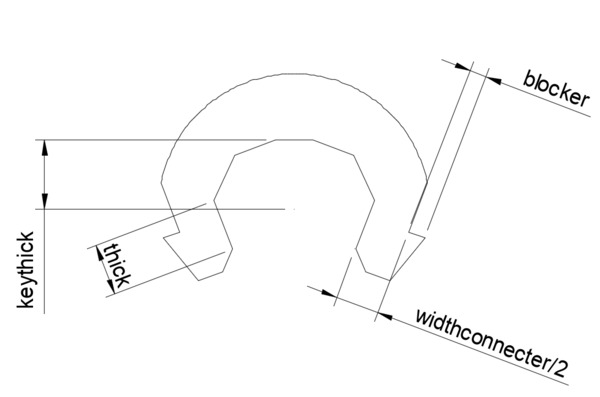

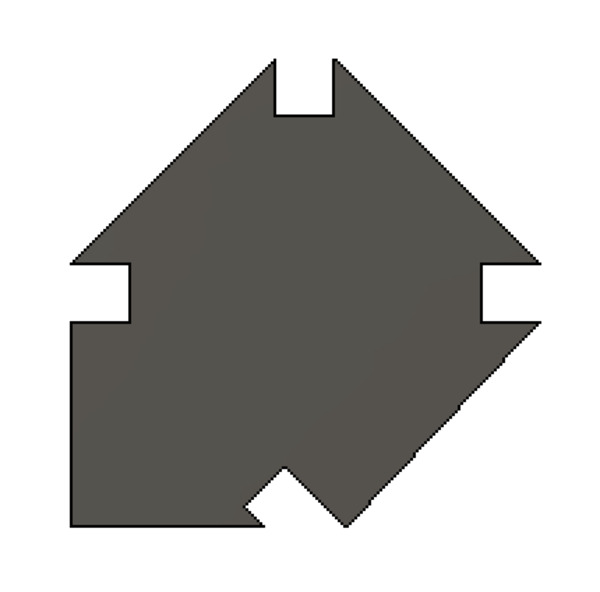

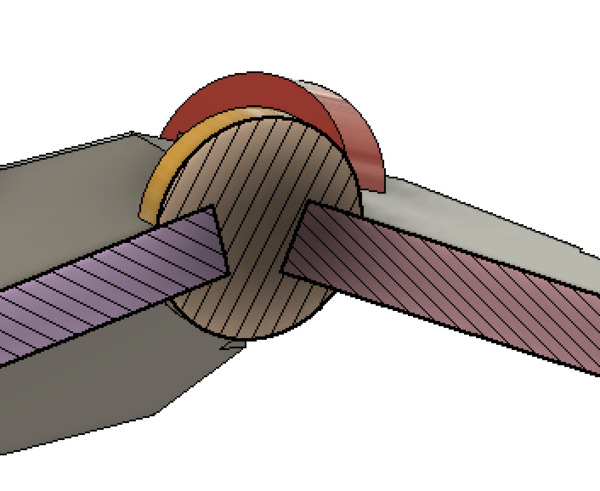

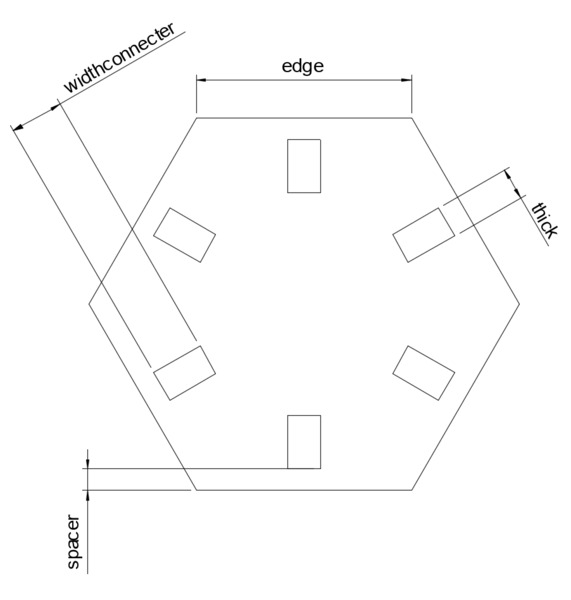

For this exercise, I started by searching and trying some simple forms. For that, I used fusion 360 which makes it possible to assemble components very easily. I used parameters to drive X, Y dimensions (set equal), thickness material and notches (set equal to the material thickness).

|

|

|

|---|---|---|

|

|

Then i looked for examples:

-

I explored the work done by Daniel Asprilla during fabacademy 2015. And i really likes his press fit lamp kit !

-

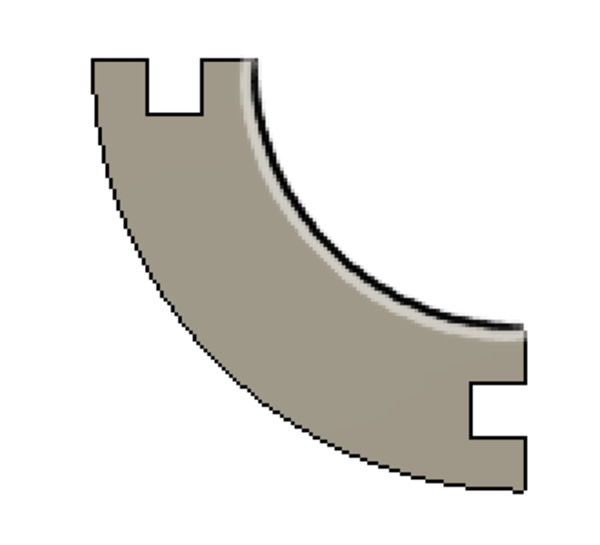

Another nice project of Mechanical Iris made by NNT

Geodesic dome press fit construction Kit¶

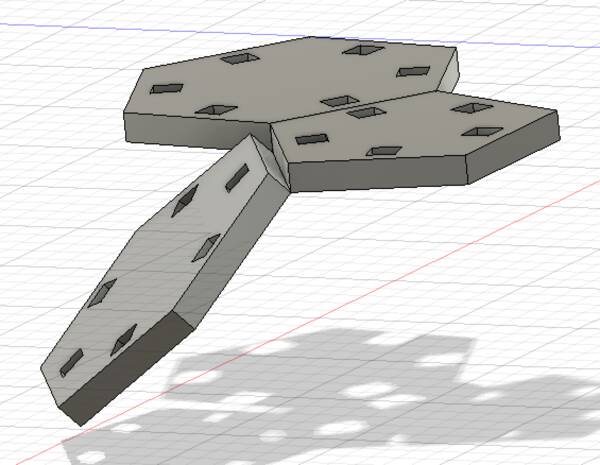

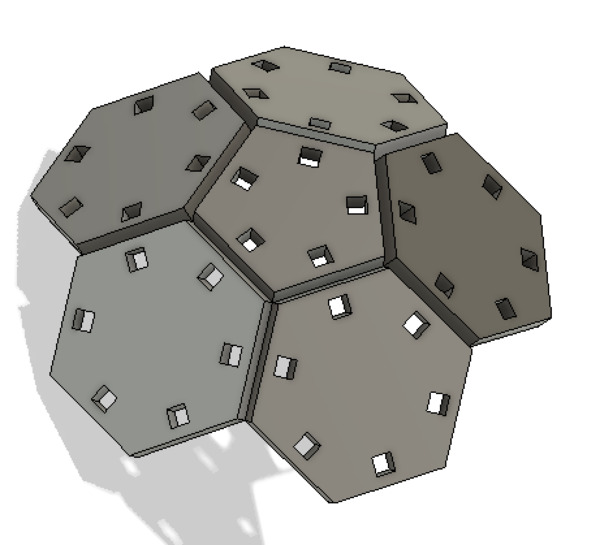

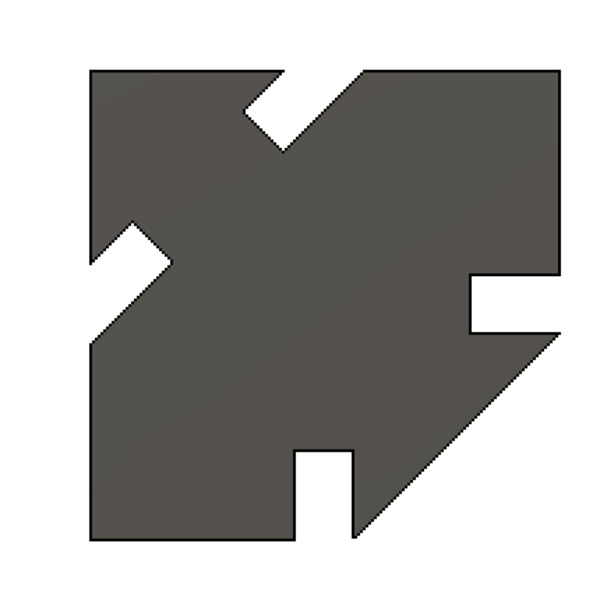

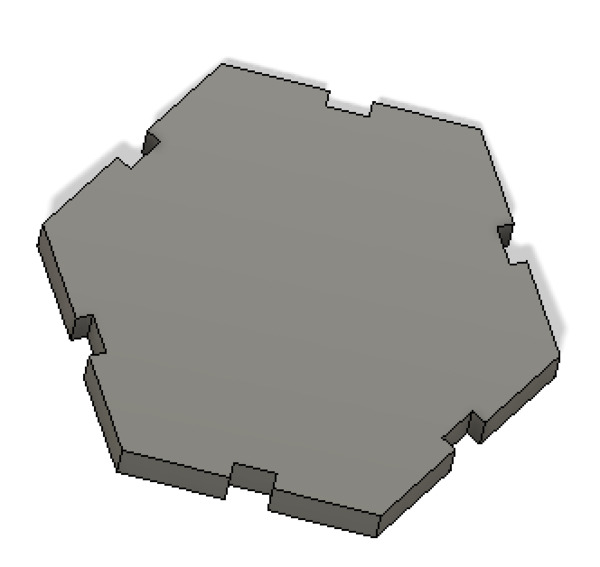

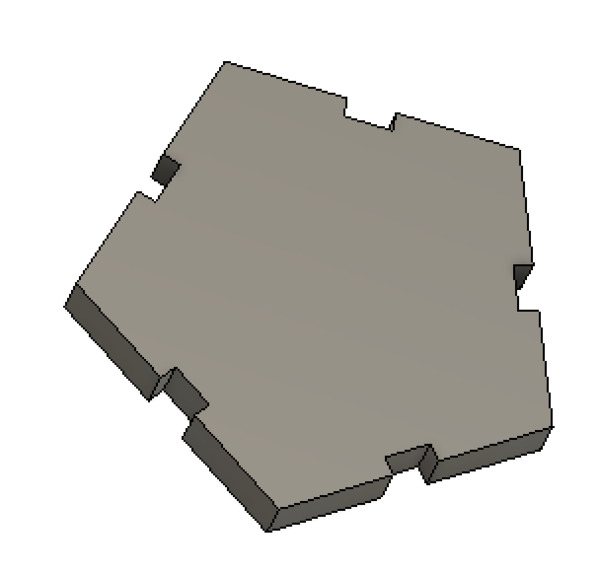

Wishing to work on frameworks to create “closed spaces”, I decided to create a geodesic dome. I was inspired by the Geodesic dome which is build only with 10 hexagons, 5 half-hexagons and 6 pentagons. The construction principle is simple and can be easily implemented with CAD software (I used Fusion 360):

-

create hexagons and pentagons whose edges are equal

-

assemble a pentagon with 6 hexes (one for each edge) taking the middle of the edges as reference and defining a revolute joint

-

continue on this principle until you obtain the desired number of facets

First test¶

| PARTS |  |

|

|---|---|---|

| JOINTS |  |

|

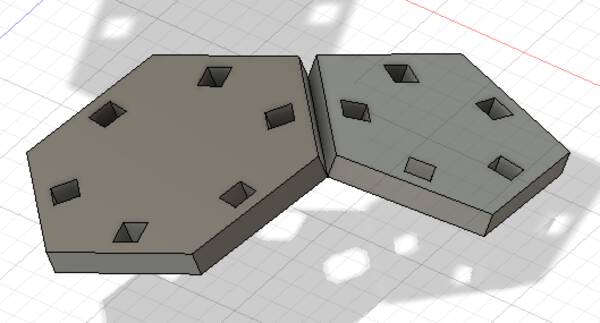

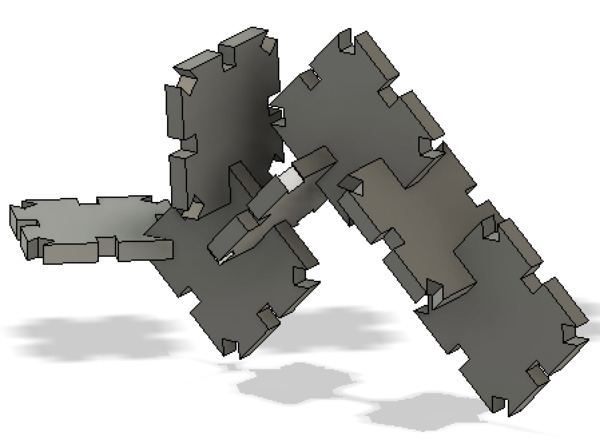

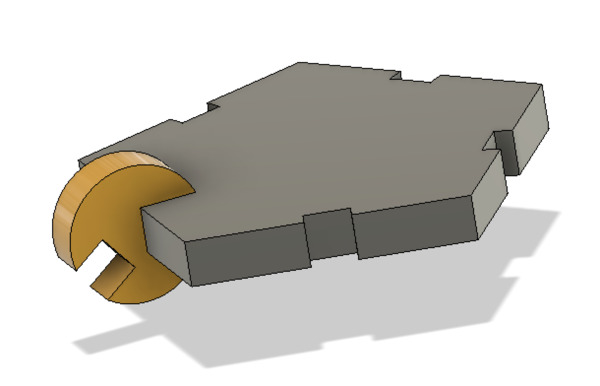

With this technic, the assembly of the parts would be difficult, and I couldn’t put all the connecters.

Final solution¶

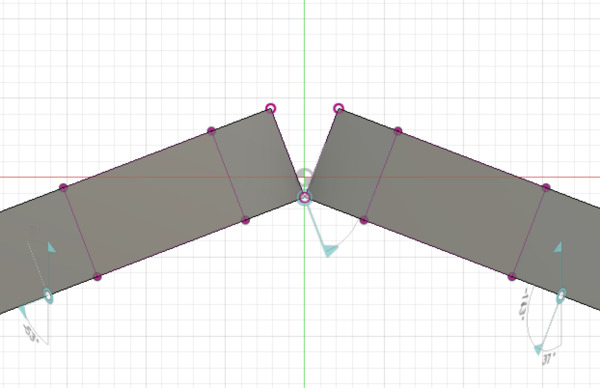

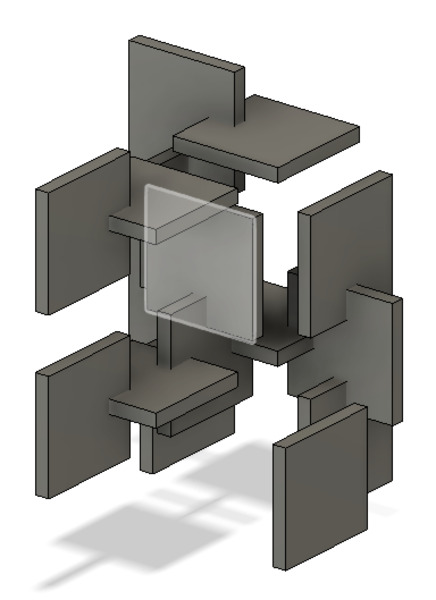

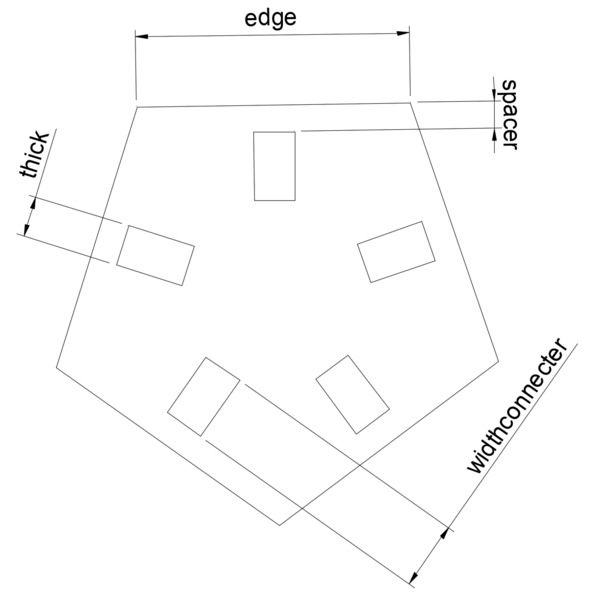

| Parameter definitions | ||

|---|---|---|

| Creation of parameters as on the plan |  |

|

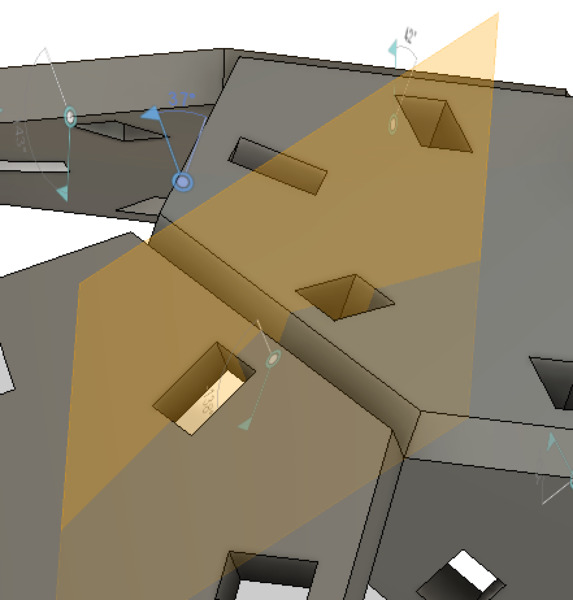

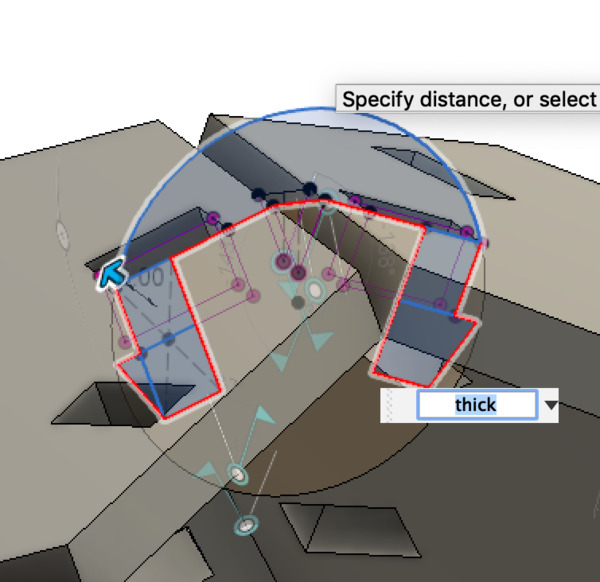

I reproduced the same technique for each of the 2 connecters (one between the hexagons and one between pentagons and hexagons)

Production¶

Parameters used¶

I used 3mm plywood to cut the parts with laser cutter and used this parameters

Machining file preparation¶

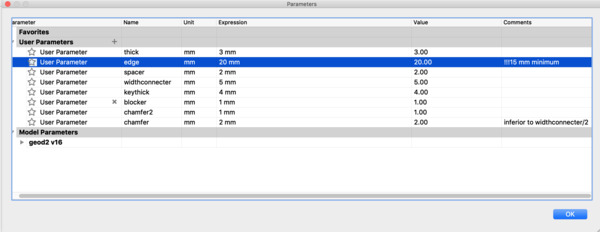

- Creation of the drawing from the fusion 3D model (just to get the paths of the different parts)

- Export from Fusion drawing module to a PDF file

- Importation of the PDF file with Inkscape

- Multiplication of the parts (duplicate tool “ctrl+D”)

- 15 hexagons : 15 parts

- 6 pentagons : 6 parts

- hexapentkey 37,4° : 30 parts

- hexakey 41,8° : 45 parts

Cutting parts¶

-

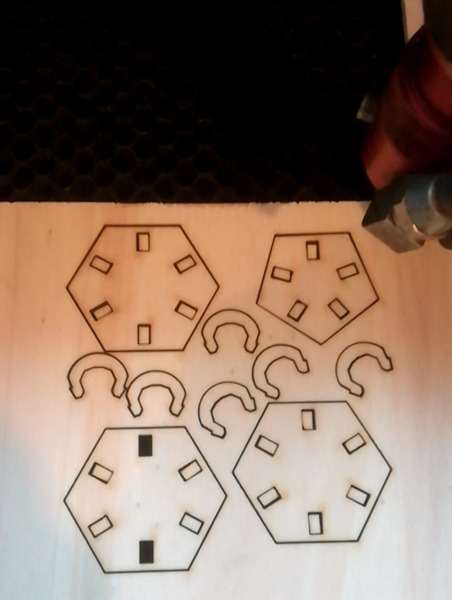

I used our 100W CO2 laser cutter. First i tried with a value of 0,5 mm for the blocker parameters (top of the picture) but it was too small to block the parts. I changed the value to 1mm (bottom of the picture):

-

The width of the kerf is proportional to the power used. The higher the power, the thicker the kerf. To cut plywood 3mm a power of 30% is enough (for our machine).I tried without offset (no compensation of the kerf) and that gave good result. The dimensions of the cut pieces made it possible to obtain a mounting that is both robust and easy to do.

|

|

|---|---|

|

|

Final result¶

Vinyl cutter¶

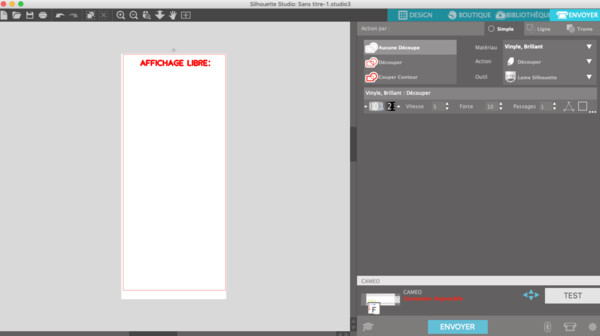

This week, for our reception area we had to create a display. I trained a colleague to use our vinyl cutter.

Our Fab Lab is equipped with a Cameo vinyl cutter

-

I made the design directly with the Silhouette Studio software software because it was only text

-

We didn’t need to compensate the kerf

-

Specifications :

- material: yellow vinyl Silhouette

- Blade high : 2

- Speed : 5

- Force: 10

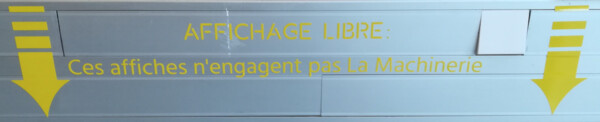

Final result¶

My colleague learned the lesson well, the proof, he added the arrows all alone (with Inkscape i guess)!!