WILDCARD WEEK| WEEK 17

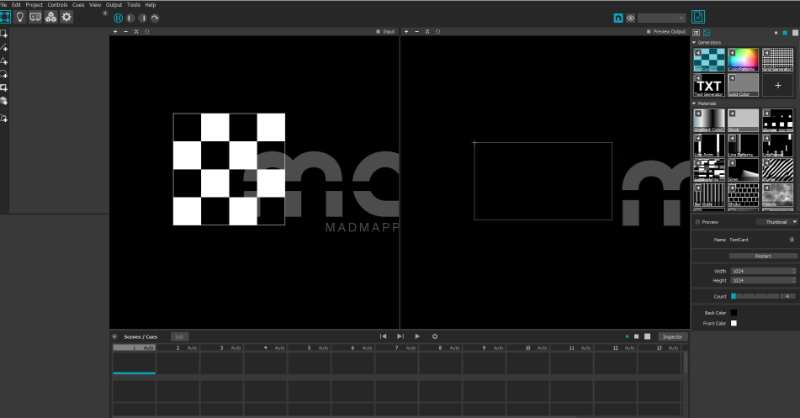

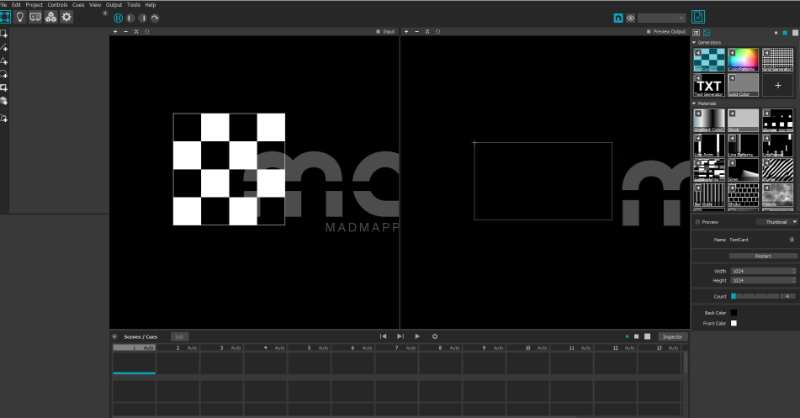

After the interface week playing with processing and with the backfground of our instructor in visual arts I wanted to try Mapping. It's an interesting technique to play effects in surfaces. I used Madmapper a software recommmend by Marta. The basic interface is easy, with two windows, one for the effects and the other to create the surfaces where the effects are going to be projected. But first...

Pepakura.

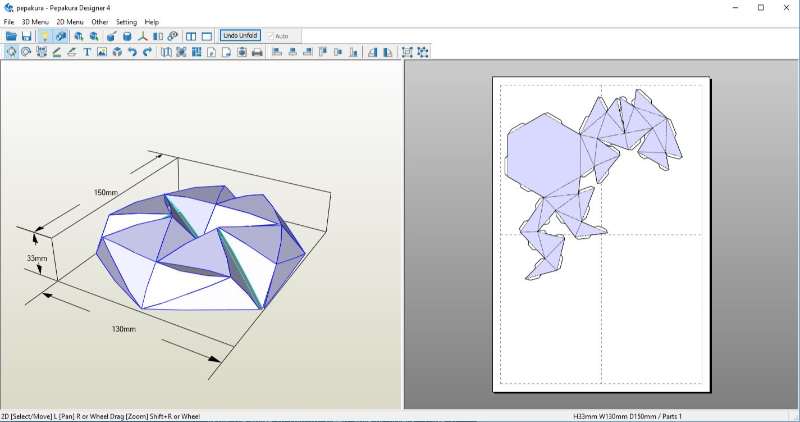

Obviously the first thing that you need to try mapping is something to map. I used the same 3d model from the week of molding and casting a origami model made by me. This time i'm going to use the the kirigami technique to create a 3d from a laser cutted piece of paper.

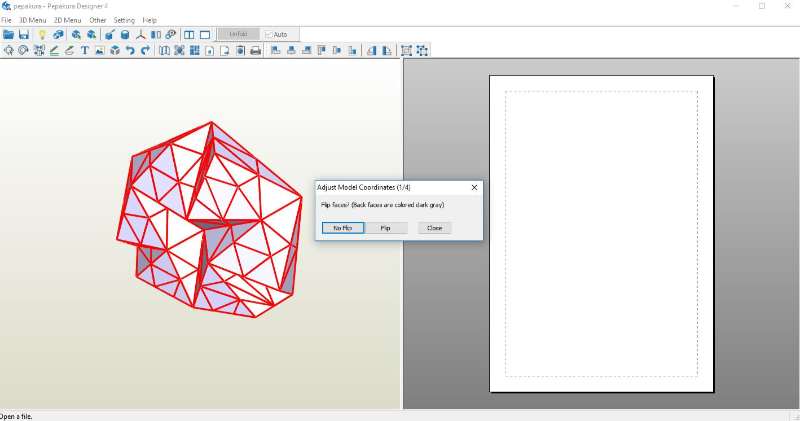

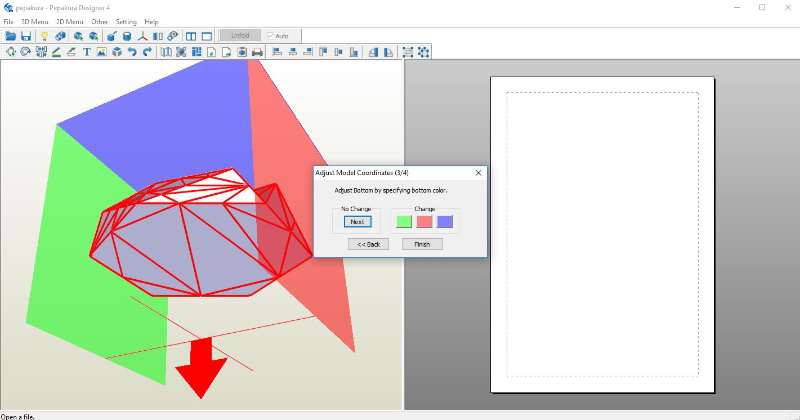

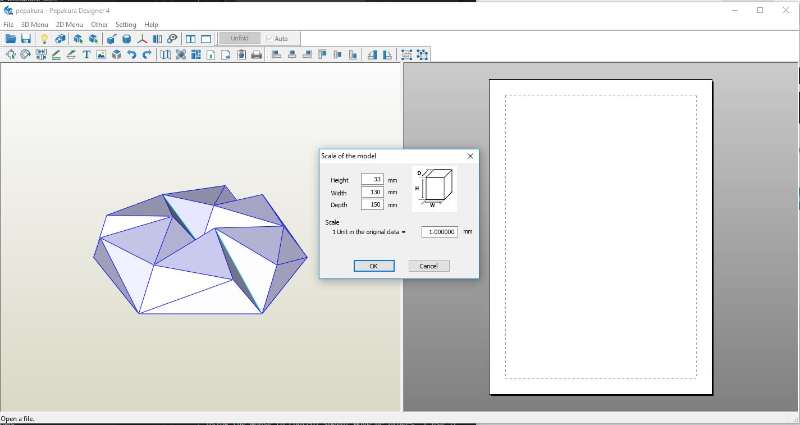

I have never used Pepakura but the explanations in the web are easy to folllow, just three steps and a stl can be transformed a flat diagram ready to print and fold.

The first part is to upload the model correctly. The program ask simple question as position and size.

When the model is ready. The only thing that it necessary is to click unfold and the program shows a unfold version of the 3d file.

Now the file can be exported as JPEG, or PDF free, for other formats is necessary to pay, but PDFs works as a vector file.

Cutting, gluing and folding

With the diagram cutted in the laser cutting machine I used double face tape in the flaps and mount everything. A good thing to say is that pepakura creates all the fold lines to go down, which is good because is not possible to cut the paper in the other side.

Here is one module finished.

After the first one I cut and fold three more to create a more complex piece. The module is modular so I have any problem putting all of them togheter.

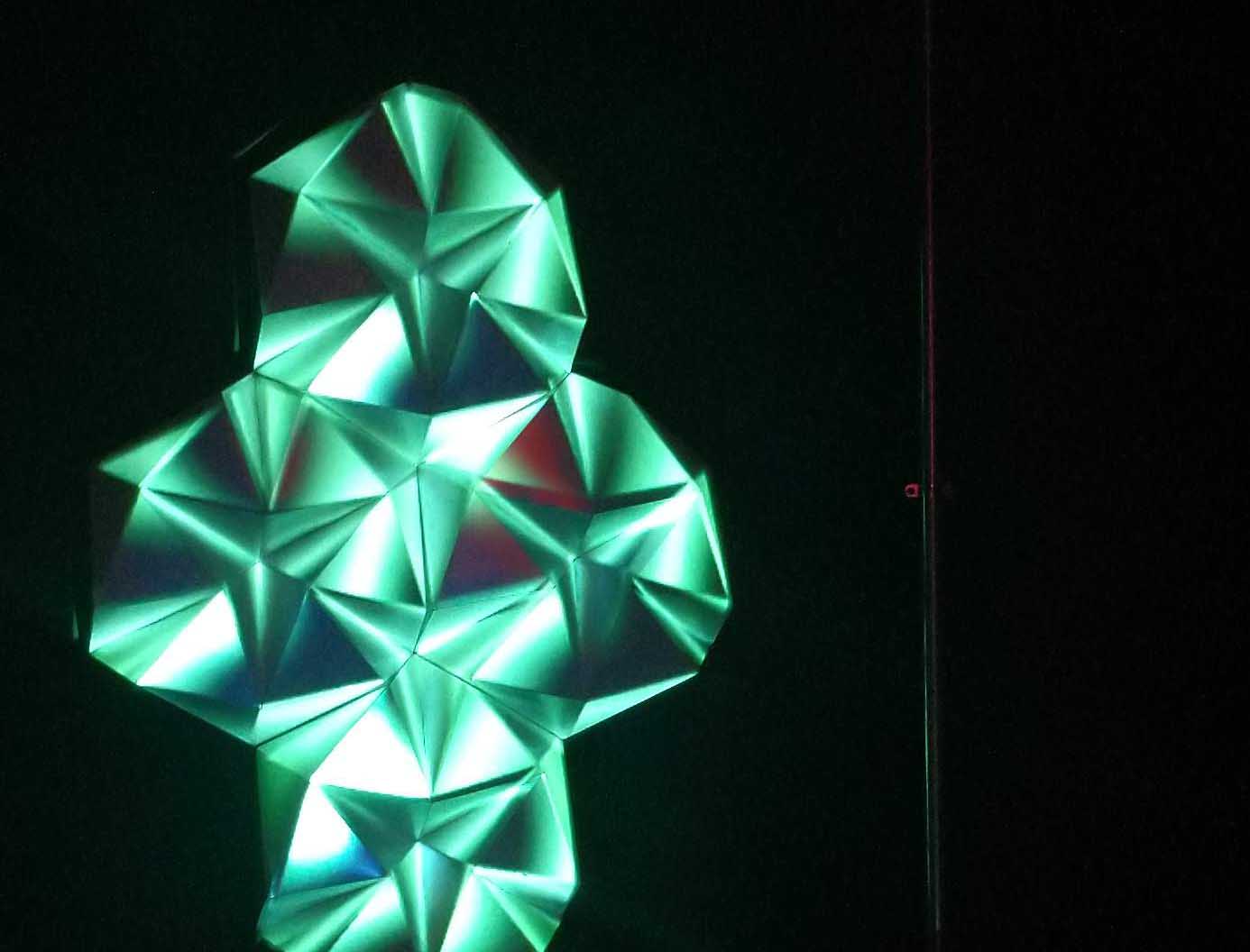

This is the result ready to be map in the wall of a small dark room of the lab.

Mapping with madmapper.

To map something it's necessary to have a computer with the program and a proyector, it's important that a good contrast but any one can work.

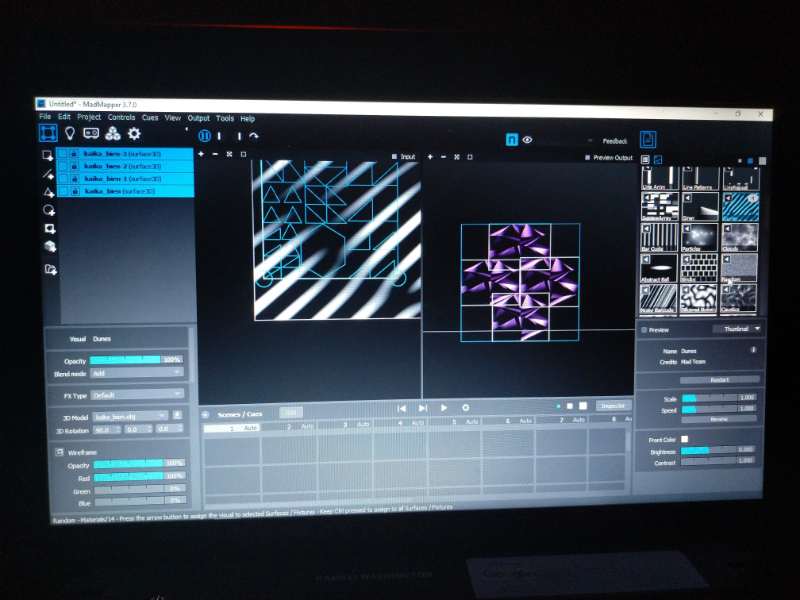

Here is the interface of madmapper. Now I have to put the 3d version of the object that I create by folding. The first thing that you can see is that the object is not exactly like the one in the wall. Well, this is normal, but it can be easy to fix using calibrate option, they deform the virtual model based on the projection.

When the model is calibrated it time to have some fun. I tried different predefined options: Change color, apply different materials and speeds.

This are some videos showing the different effects.

Conclusion

Video mapping is something very interesting that I want to investigate more in the future. The basic technique is easy to learn but you need good ideas to make it look good.

The object in the picture above is called "push", is a lasercutted steel piece designed and sell by Fundamental.Berlin. I wanted to replicate using Mirror vinyl because I plan to use it in my final project.

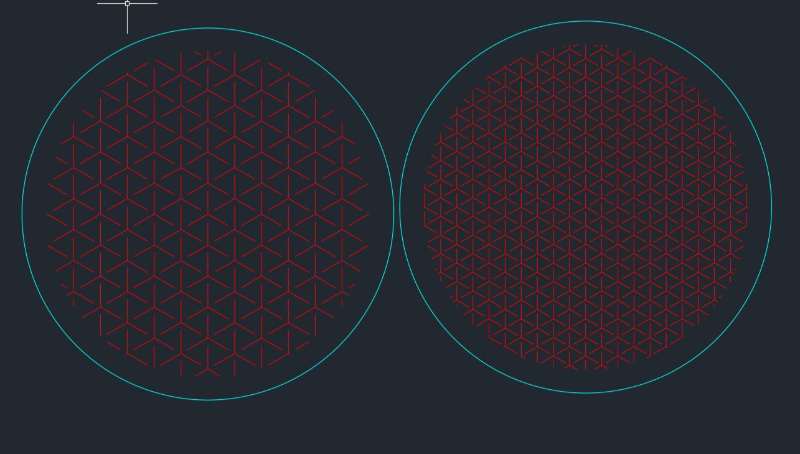

First, I draw the pattern in autocad, my idea is to cut the vinyl in the vinyl cutting machine. But first I need to paste create a double face material with mirror in both sizes.

.jpg)

My first try, by "brute force" was a real disaster. Then I made some research and project water in the glued face before paste both of them and use a smooth scraper to take of the water and the bubbles of air. It worked.

.jpg)

.jpg)

Then I tried to cut the double vynil but the knife got stuck all the time. Here are some pictures.

.jpg)

The second part of the experiment it was to deform the cutted piece with the heat gun. But it didn't work.

.jpg)

.jpg)

Conclusions

There are two more things that I want to try: Another material called metalon, which I'm trying to find, and use something to fix the vinyl while the vinyl machine is cutting.

After the first days playing with mapping I didn't have the program and I wanted to experiment with something different. In the lab we have a instructor called Luis. Cool guy. We knows a lot about origami, clay and molds. So I talk with him to make my origami piece with vacuum forming. This idea started a long process. Because, well Vacuum forming is easy but you need the correct piece to do it well.

The piece, to create the piece that I need for the vacuum formed piece

I need a piece made with plaster because paper is not strong enough for the pressure of the vacuum machine. Also, paper is not good enough for the plaster and I did it with flaps inside so I have two reason to make it the part again. I had board from the first assignment with the laser and I thought that it was a good option... it wasn't.

I cut some rectangles to calculate the correct speed of the laser before cut the real diagram. finally th evalues were: 28 of power and 5 od speed. Close to cut but not enough.

.jpg)

Here is the final parts cut. This time without flaps, I'm going to use tape instead to avoid any marks in my mold.

.jpg)

After I put all mount the piece I discover some issues: The board is too thick and it's not looking good, and even more Luis is not very happy with my selection.

.jpg)

.jpg)

We suggest me to try again with polipropilene, a plastic that can be cut with laser and with a thickness of 0.8mm, not bad for folding.

.jpg)

.jpg)

Finally, my third mold, made with plastic is good for the next step. Time for the plaster.

Plaster

I prepare put the mold over a board of wood to make it easy when I have to move it. Then I mixed the plaster with water and put it inside the mold. We had a problem that I didn't expect but it was not a big one. The polipropilene deformed got deformed with the weight of the the piece was ok without it.

.jpg)

.jpg)

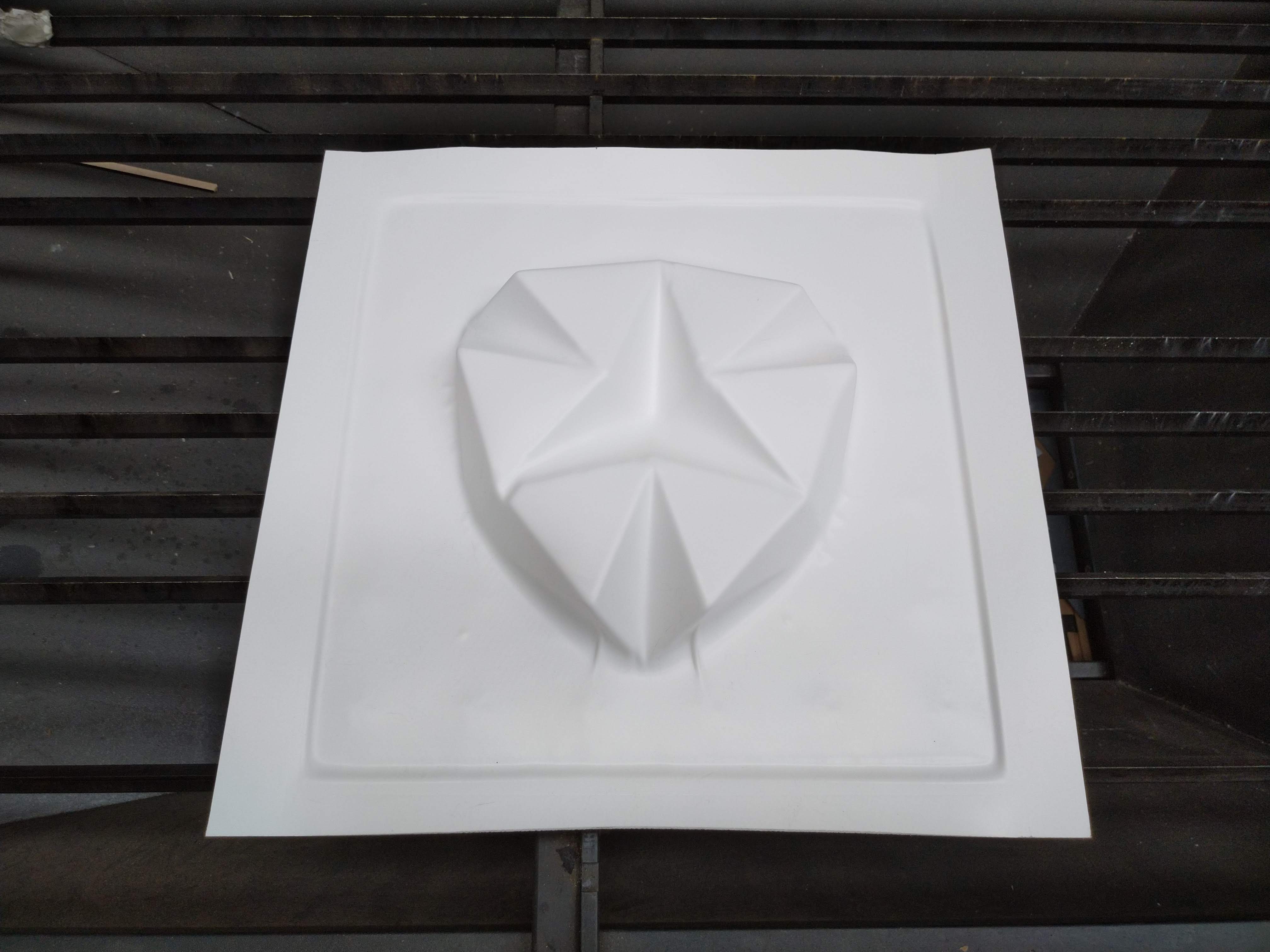

The plaster gets hard in about 20-30 minutes and it's possible to take it off the mold but it's necessary more time (one day or even more) for the plaster to get really dry. Here is a picture after take the mold off.

.jpg)

The piece has some errors that could be fixed in the next mold but I preferred to fix them with putty.

Vacuum forming

Finally I can use the the vacuum machine. To use it I need to turn on the machine 30 minutes before. Then I have to fix the piece in the top let the heat do the job for one minute and then move the bed to the top and connect the vacuum. The result is marvelous!

I made to tries, one with 0.8mm PVC and other with 3mm Forex. The difference is visible in the amount of detail. The red one is the thinnest and as you can see it very precise and the result has almost all the details from the model (specially the errors)

Then I tried with a 3mm forex that looks very good, I got less details but the curves are very interesting. It gaves me ideas for future pieces and the king of molds that it's possible to do.

It was so fun that I did a third one with some tools to create an "artistic piece".

Here you have some videos of the machine working it's hypnotic!

Luis has a very cool machine, a gyroscope designed by him to rotate a mold while is drying. The advance is that centripetal force push the plaster to the wall and leaves the interior clean. Letting us to have a hollow piece.

I wasn't thinking to use this machine so I did not have time to fabricate something but I wanted to try the effect of the centripetal force with the plater. So I used a bottle of water.

.jpg)

.jpg)

.jpg)

Here I am moving the machine until the plaster is dry enough to get stick in the walls.

.jpg)

Time for results

Two hours ago the plaster was dry enough to try to get of the bottle. I cutted in two parts using the lines of the union in the real mold.

.jpeg)

.jpeg)

The aspect is great and has all the details of the bottle. Sadly, I broke the neck of the bottle while I was trying to take off the plastic. But I think this is a good opportunity to take practice some japanese Kintsugi. If I have time...

.jpeg)