Composites

This week I will create something really strong from a polystyrene mold using fibre and resin.

Part One 2D to 3D- Design of the MoldPart Two Using Rhino CAM

Part Three CNC Milling of Polystyrene Mold

Part Four The Composite: Fibre and Resin

Part Five The Files

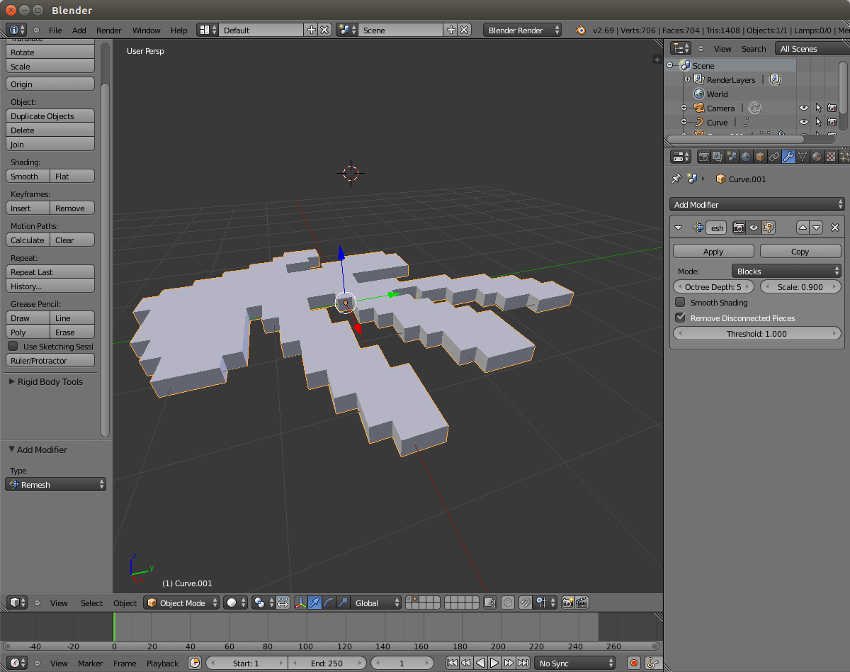

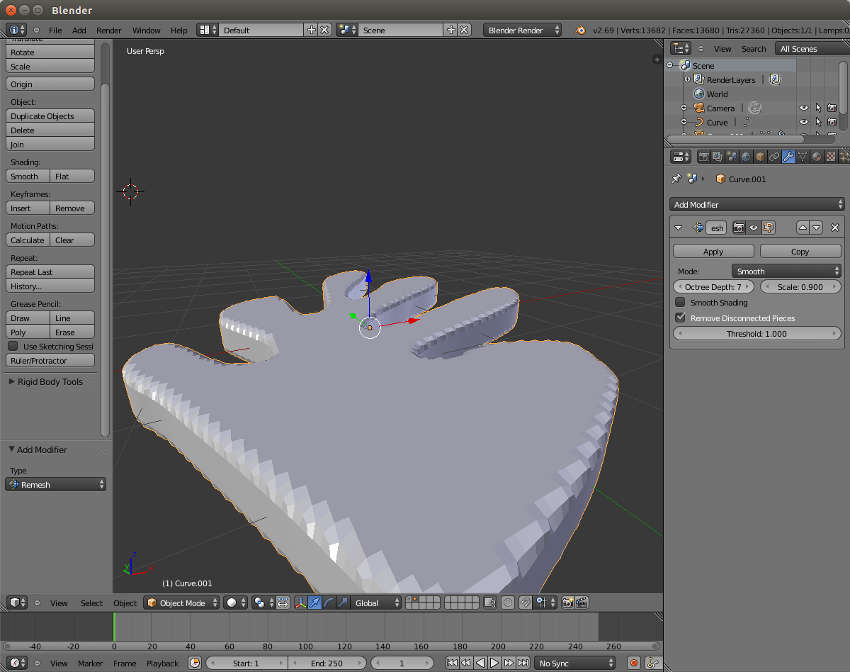

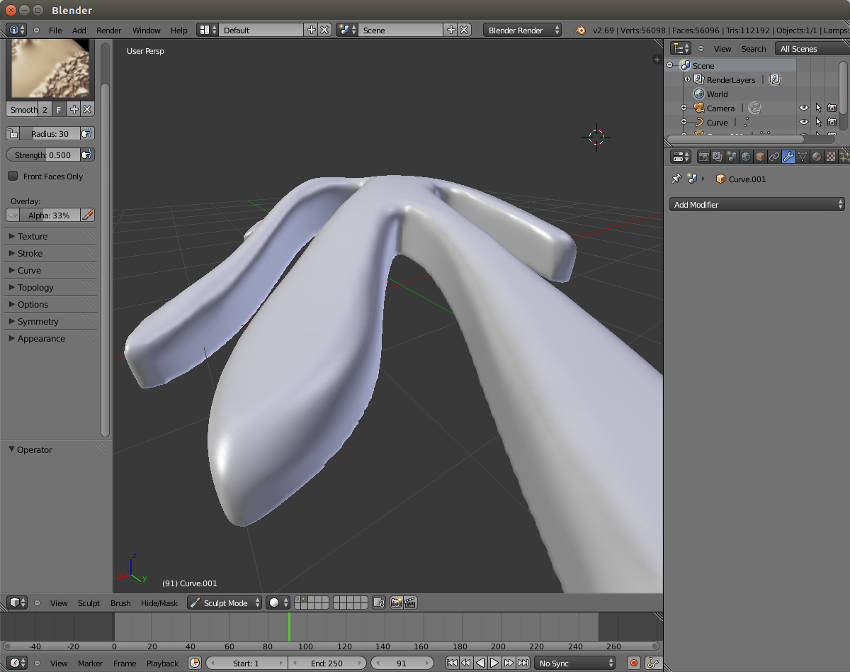

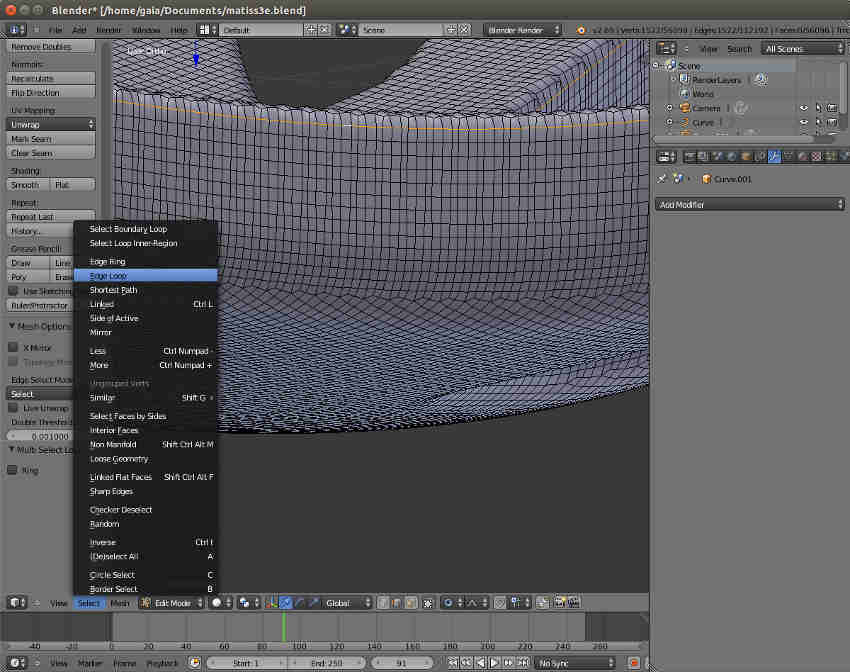

2D to 3D Design

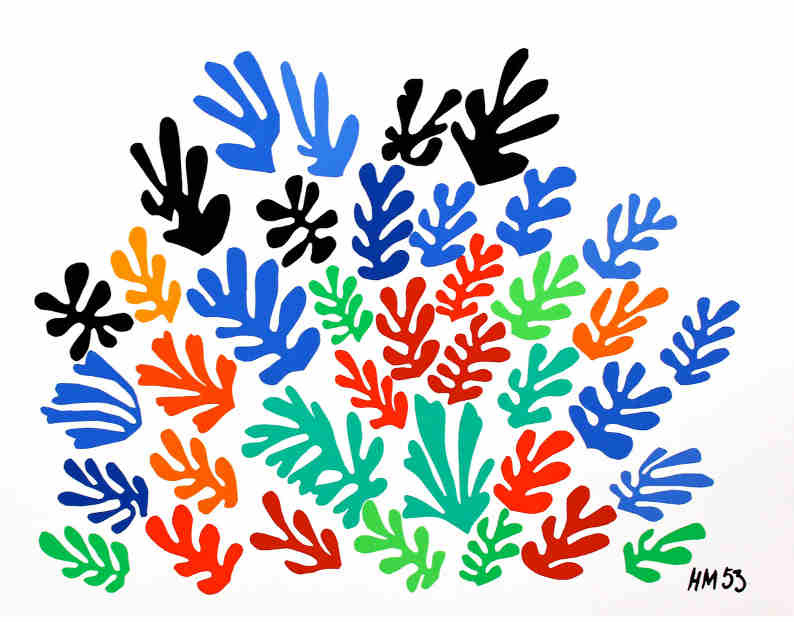

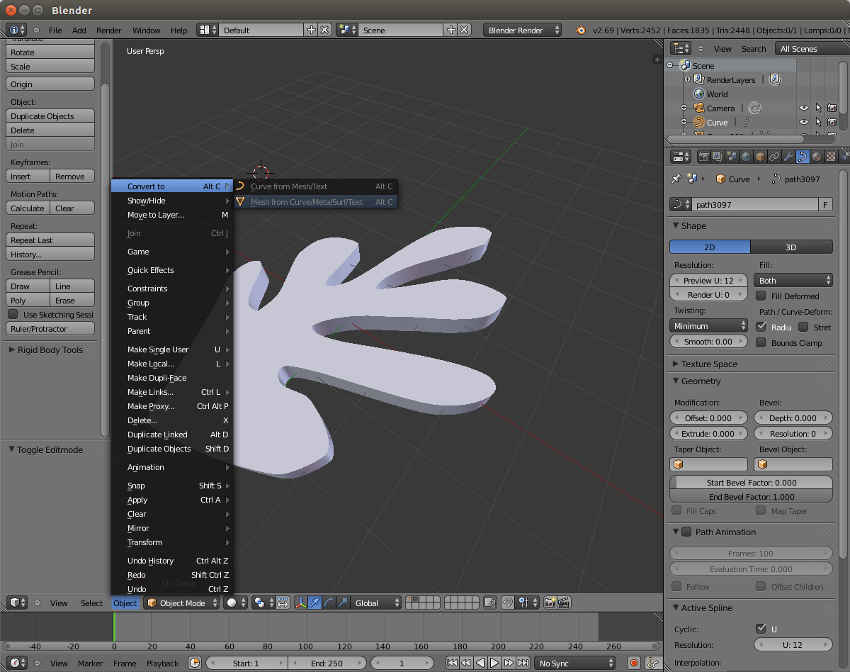

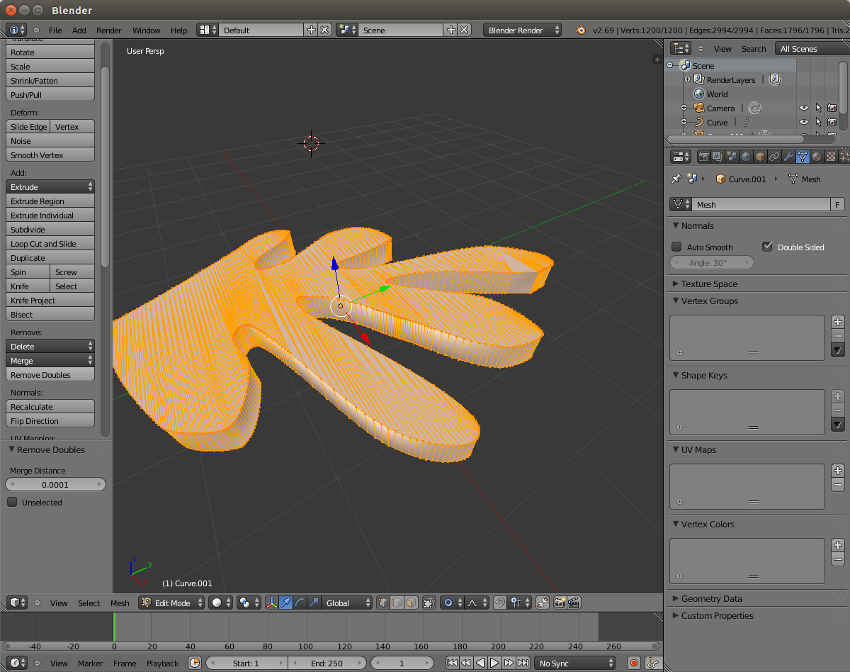

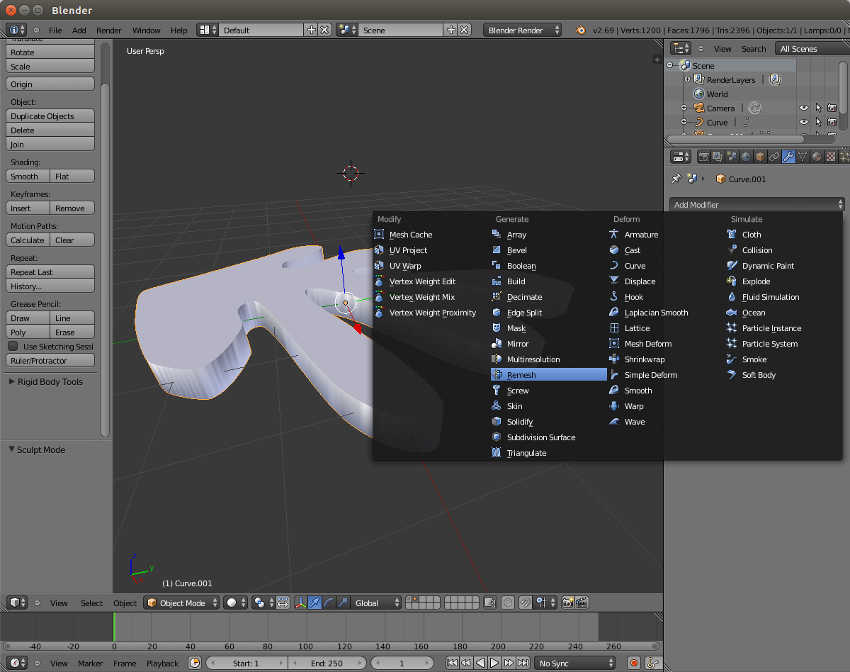

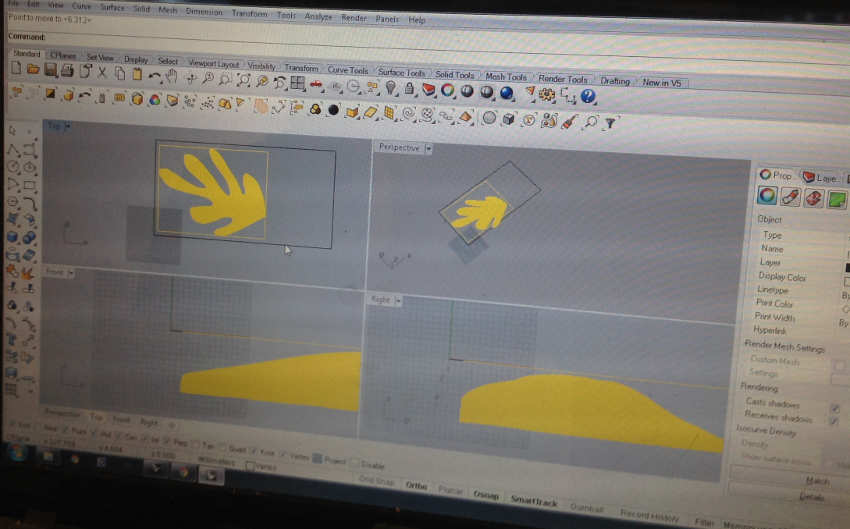

This week my inspiration was Henri Matisse. I took one of his cut out forms converted it to an indexed image in Gimp, vectorized it in Inkscape and sculpted it into a 3D model using Blender.

A purely open source program workflow!

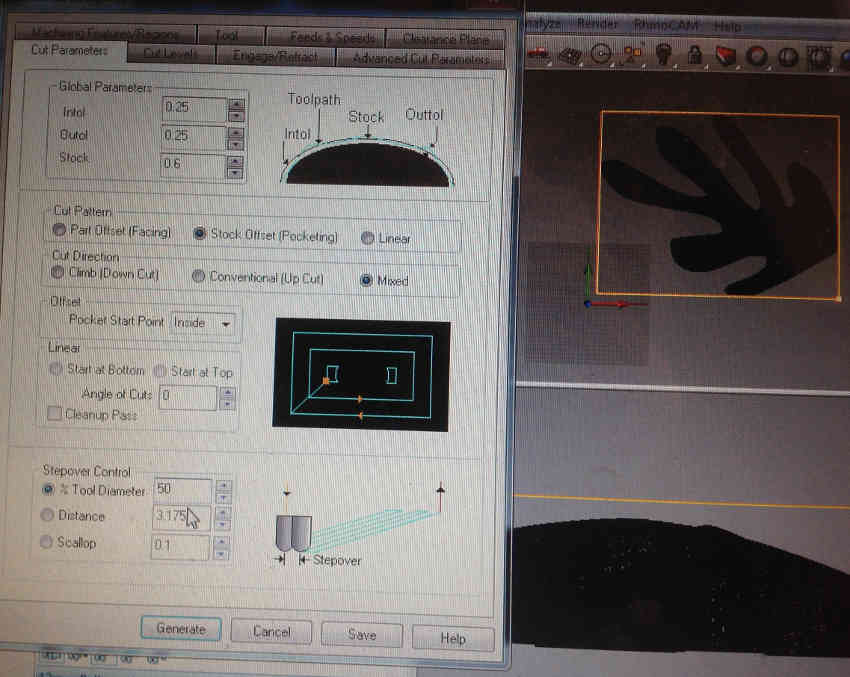

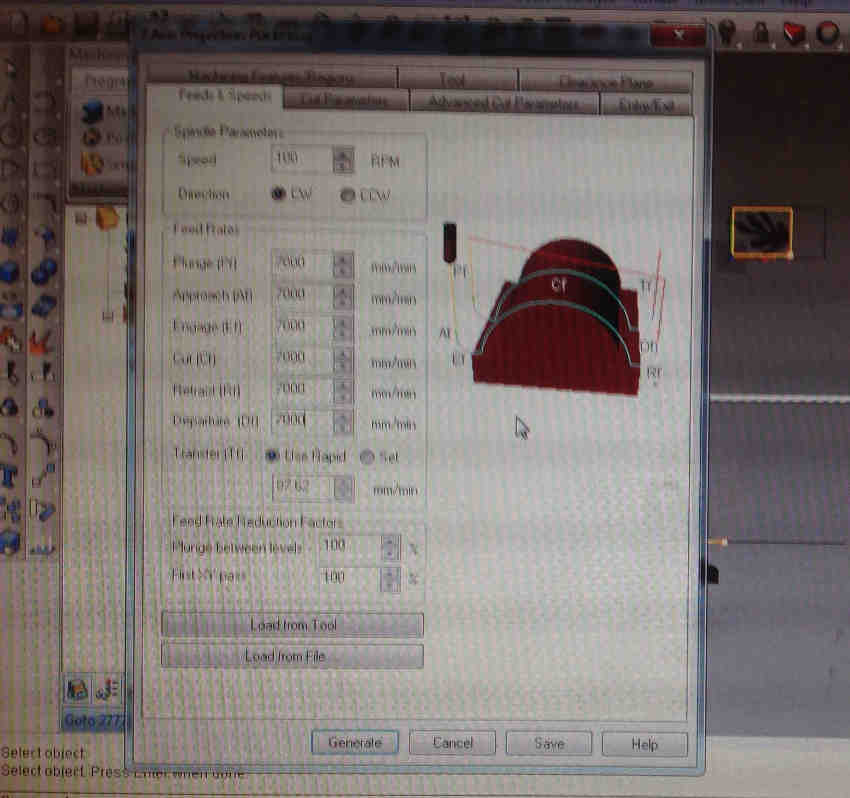

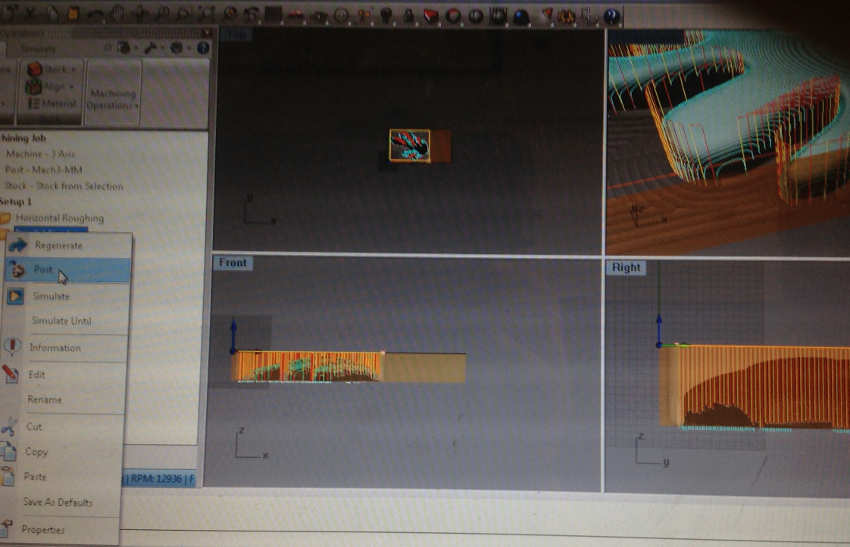

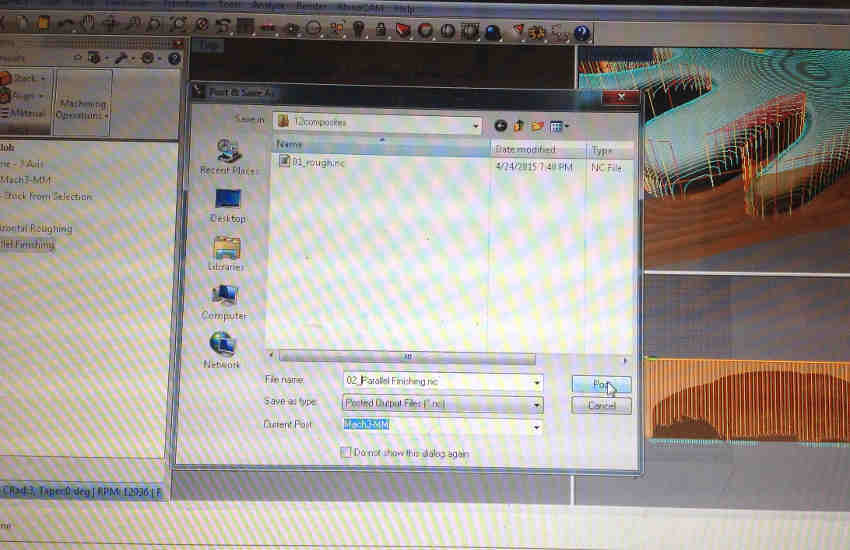

Using Rhino CAM

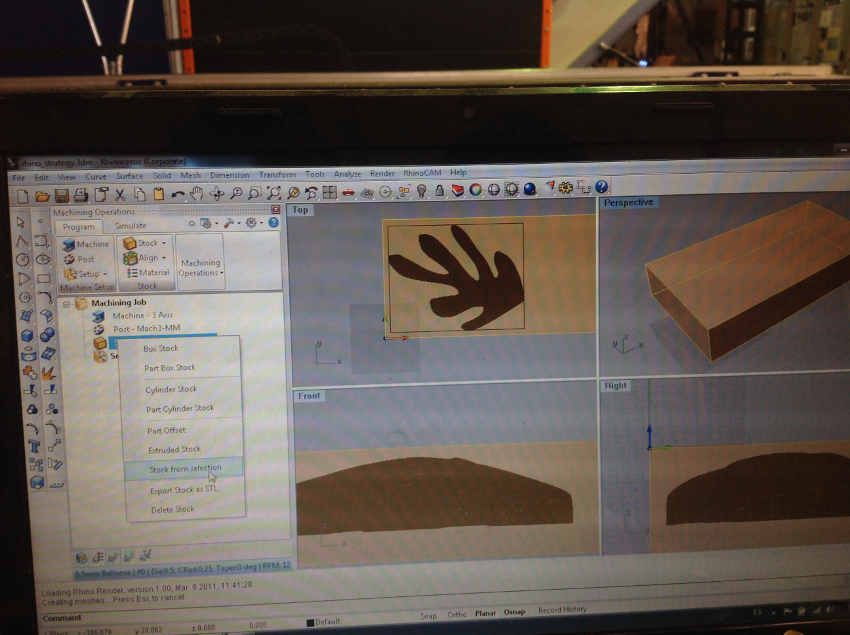

I measured my polystyrene block and created a block in RhinoCam. I selected the block as my Stock Material using the option Stock from selection . Then I deleted the block.

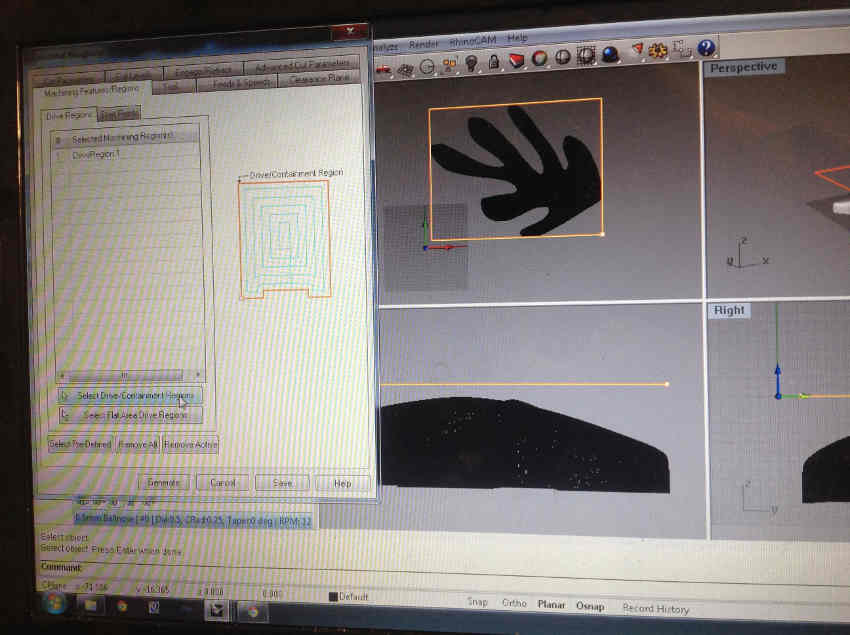

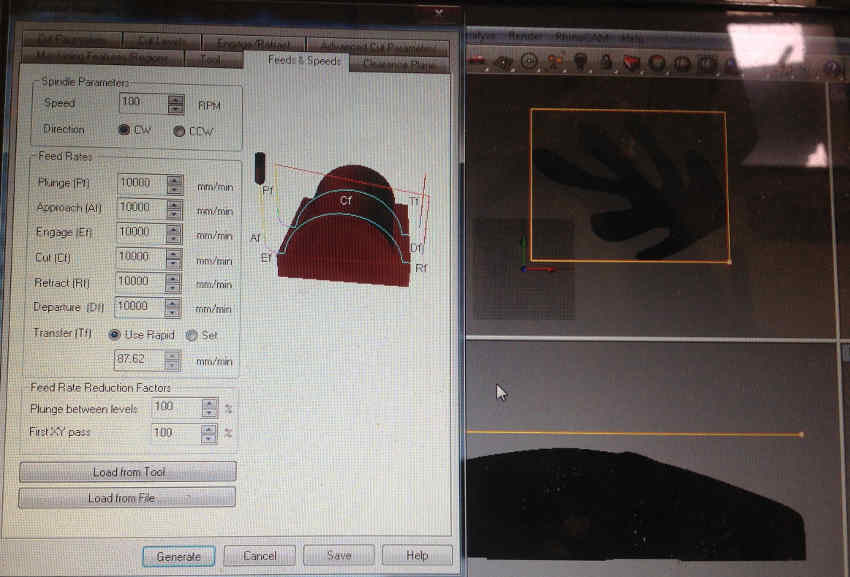

CNC will mill the shape in two stages:

- Horizontal Roughing- roughly cuts out the form

- Parallel Finishing- the finishing pass

<

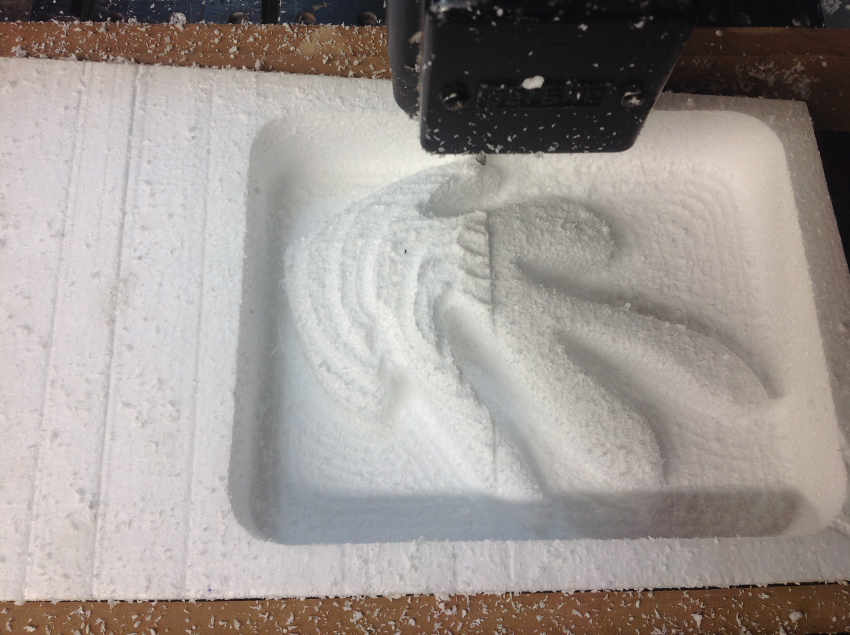

CNC Milling of Polystyrene

Initially I got the X and Y axis mixed up on the machine. Thankfully milling in the air first meant the problem could be identified.

Between the Horizotal Roughing and Parallel Finishing Stages

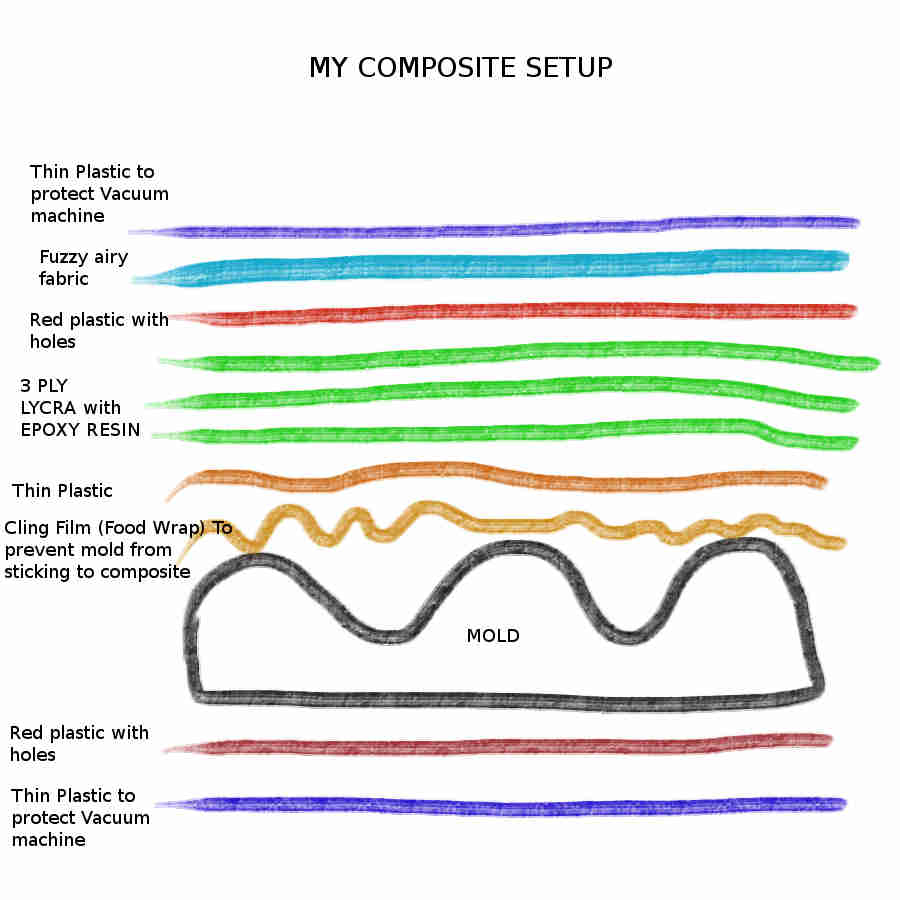

The Composite: Fibre and Resin

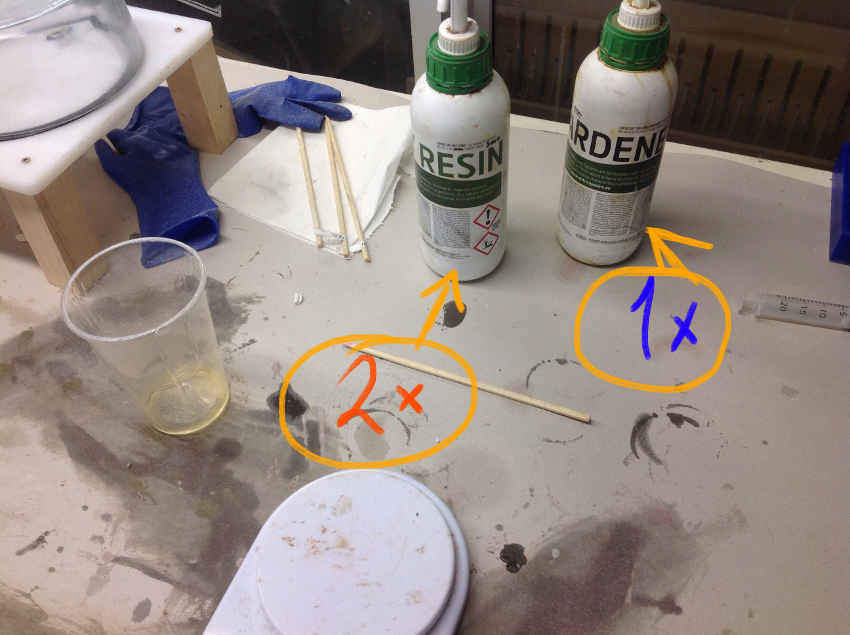

On recommendation by Anastasia from the Fab Lab Barcelona I used Lycra as my fibre. The resin was Epoxy Resin.

2 part Epoxy Resin to 1 part Hardener ( Supersap brand)

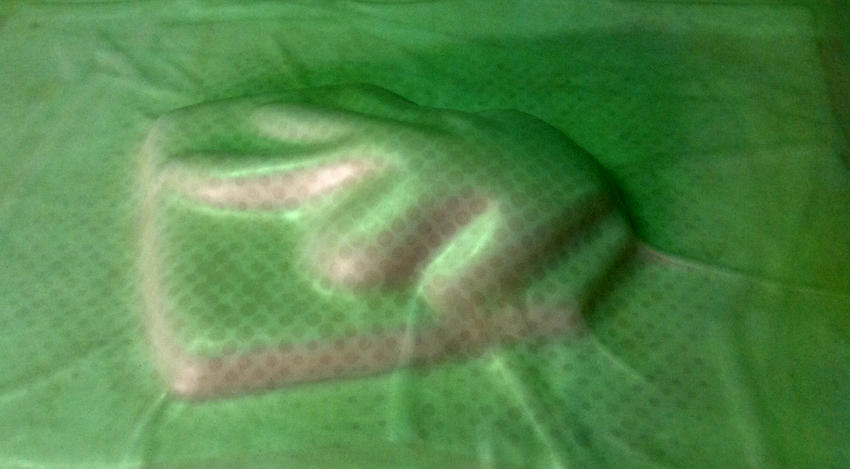

Into the Vacuum Machine for 6 hours...

Out of the Vacuum Machine

The CAD file of the Matisse form can be downloaded here