|

Assignment 10: 3D scanning and printing.

This weeks assignment is to 3D scan an object and print it. I would like to make something in clay first, and then scan and print it. I printed a bracelet with the Ultimaker, and scanned a clay puppet with the Modela which I aim to print as well.

PRINTING

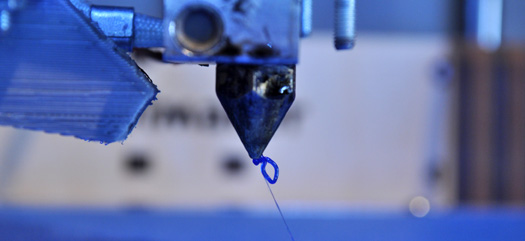

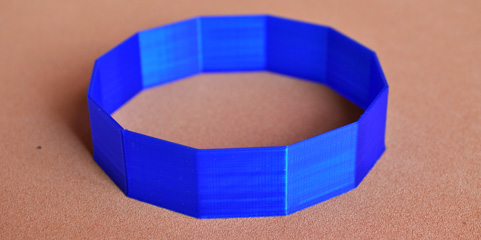

I designed a straight-forward object - a bracelet - in Rhino, and exported it to .stl. Then imported it in Replicator G and generated the gcode that the Ultimaker understands. The platform of the machine needs to be covered with a flat clean layer of heat-resistant tape.

The temperature of the PLA has to be heated up to 220 degrees and then you are ready to go.

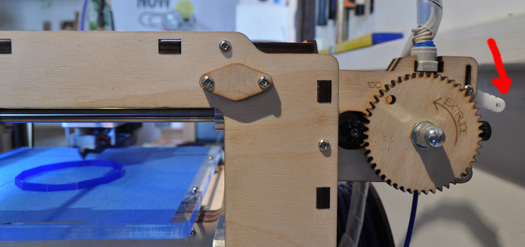

In case you need to pull the PLA thread out, release it with the white little handle at the back of the machine.

SCANNING

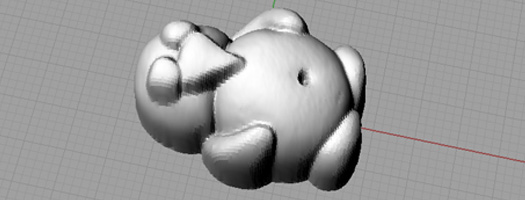

This puppet was made in Fimo clay and hardened in the oven for 30 minutes. Then I glued it on a wooden platform with tape and 2 component glue. The Modela scanner software is very friendly, it guides you nicely through the process of adjusting the scan area and resolution. It took about two hours to scan this little puppet. As you can see the modela only scans from the top downwards, so you can actually only scan objects with one flat side.

I used the 'smoothen' function to round off the edges. I edited the file in Rhino to remove the bottom raft and used a mesh boolean to make it a solid object. I checked the edges with analyze naked edges, and exported it to .stl.

Then I wanted to print it with the ultimaker, but I did not get it to fill the inside of the object, so this was the result:( Still trying to find out how to print it as a solid object.

|

Astrids Fab Academy Projects

Astrids Fab Academy Projects