Molding, Casting and Composites

March 9th, 2011

The Puffin

This was a fun assignment. I had never casted anything before, let alone something I had designed myself.

To keep the assignment in the spirit of Vestmannaeyjar I made a Puffin!

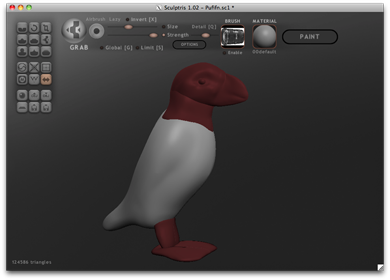

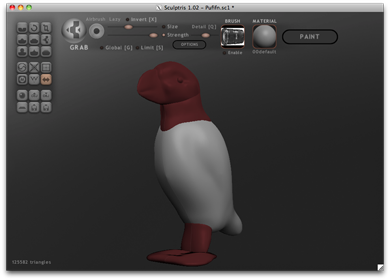

I recently discovered a program called Sculptris that allows you to sculpt a very detailled 3D model out of virtual clay. The program allows you to export .OBJ files which you can then import in other 3D modelling software such as Blender. I was wondering if this could be used to create a mold and deciced to try it out.

First, I modelled a very simple Puffin in Sculptris

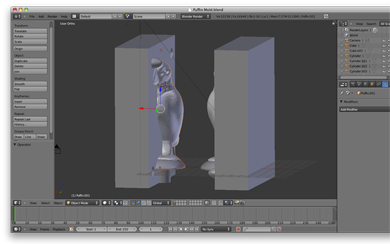

Then, I imported the .OBJ file into Blender. It looked just as good as the Sculptris version but it contained too many polygons. The program would crash when I tryed to export the model and had trouble calculating the graphics when I moved and edited the objects.

I fixed that by using the "Decimate" Modifier on the model. This decreases the amount of vertices, faces and lines and made the model a lot smaller and easier to work with at the cost of some detail.

Imported .OBJ file in Blender. ---------------------- The Low-Poly version of my Puffin.

Imported .OBJ file in Blender. ---------------------- The Low-Poly version of my Puffin.

My Puffin model with the mold design.

Then, after a long, long night at the FabLab, the milling machine finished milling out the modelling wax. I was pleased with the result.

The molds themselves turned out fine although I used some Ducttape on one of the ends because the base of the puffin was very close to the surface and I didn't want it to tear when I removed the cast (plus, everything is better with Ducttape). I also had to cut some parts of the mold away with a knife and scissors to make them fit correctly.

After finishing the mold, I made a plastic cast. I chose plastic because we where, again, low on time and the plastic only takes about 30 minutes to dry. Although the beak is pretty much absent in the casting, the rest turned out way better than I expected. I already knew that the beak was very small, but decided to risk it because of the time limit.

Extra

We also experimented with other molding and casting materials and using cloth to improve the strenght of the casts. You can see these pictures here: LINK.

Use the arrows to navigate through all the photo's.