3D Scanning and Printing

March 23th, 2011

3D Scanning

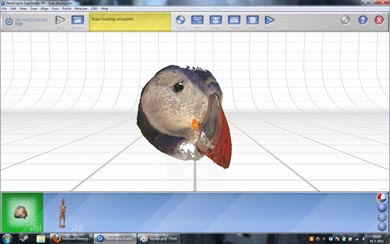

For this assignment we decided that it would be fun to try and get the NextEngine 3D scanner working again (it had problems with Windows 7 some time ago) and scan and print the head of a stuffed Puffin.

The 3D scanning intself was surprisingly easy. The NextEngine 3D scanner did it's job rather quick (30minutes on the HD setting) and the results looked great!

Soon after the scanning however, I found out why Neil told us that the scanner had a downside.

Although the results looked fantastic in the scanning program, they where full of holes as you can see in the images below.

3D Printing

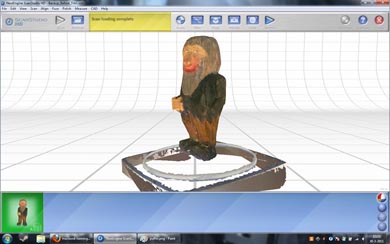

This is where I encountered some problems. The first one was that the 3D scans I made where full of holes. And even though the program has a function to fill those holes, it could not fill the majority of them for whatever reason. I tried to fill up the holes in Blender, but this would mean that I had to select every single line surrounding the hole by hand and fill it up later. Since there where some very big holes in my model and the selection alone would have taken over an hour, I decided to use the model I made for the Casting and Molding lessons to speed the process up a little.

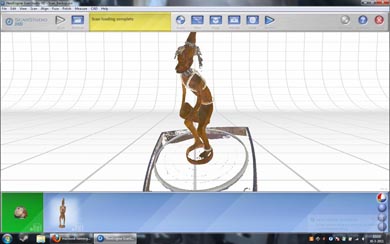

Since Blender is still pretty new to me, I had difficulty finding an option that would give the object an 2mm thick wall while remaining hollow. After some research, I figured out that the "Solidify" modifier would be perfect for this, but I was mistaken.

After using the Solidify modifier, the model showed up as having a thick wall while remaining hollow but it where really just two infinitely thin walls of faces without any mass between them.

Since we don't have a 3D printer on Vestmannaeyjar, Dr. Eddie Kirkby from Manchester offered to print our models. Unfortunatly, because of the aforementioned problems with my design, the printer gave an error and could not print my design.

Eddie was the one that figured out that my model consisted of two thin walls of faces instead of one solid wall, but unfortunately I did not have the time to find another fix and send it to him for printing.