Electrictronics Production

Februari 16th, 2011

Although I have some experience in soldering, it has been quite a few years since I last did it. The milling of the chip itself was entirely new to me and caused some confusion when I was starting out.

The troubles began when I was learning how to switch the bits and one of them slipped through my fingers. Luckily for me it was a thick one, so it did not break.

After installing the 0.156 bit and preparing the machine the bit got stuck in the board and the tip broke off. After Frosti tried it with a new bit and board, it broke again.

We decided to lower the speed on the Y-axis to 0.5 instead of 4. This made the production a little slower, but at least the bit did not break.

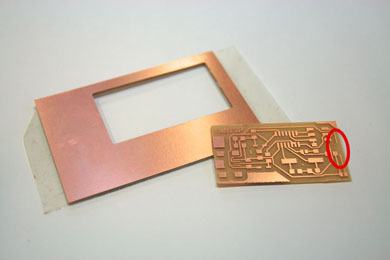

After creating my first board I found out that there was a piece missing.

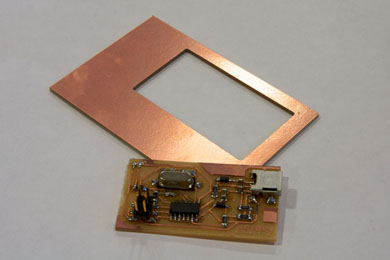

This meant that I needed to create another board. It went very well, nothing broke and the board turned out fine.

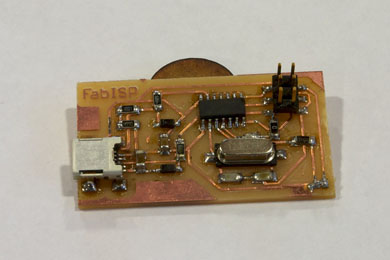

After that it was time to break out the soldering iron! While soldering the first chip I was confronted with my less then steady hands and I made myself a promise that, for everyone's sake, I should never become a surgeon.

Nevertheless, I was pleased with the results.

I have not gotten around to programming and testing the chip yet so I don't know if it will work. Sammi, well known for bending the awesome power of electricity to his will, did take a look at it and said the soldering looked fine.

Hopefully I can give the programming a shot soon.