15. Mechanical design¶

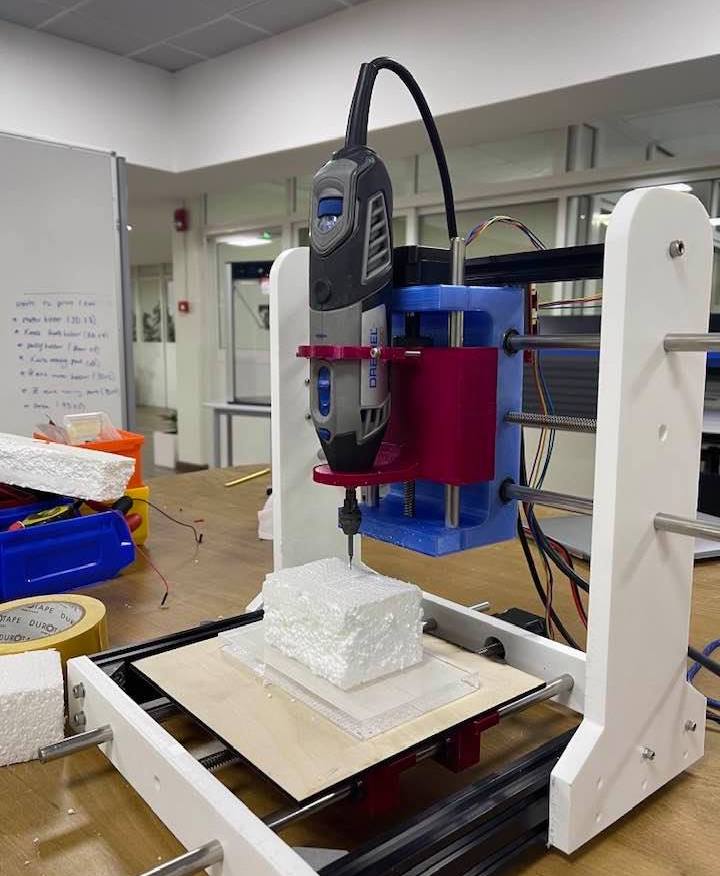

This week my group and I worked on building our own CNC machine. My responsibilities included designing and assembling the Y-axis, and designing and calibrating the machine’s software.

For this week, we split into three groups based on the three pillars of design: Mecahnical, Electronics, and Software Design. I was in charge and leading the Software design team that consisted of me and Mona, a colleague of mine. However, we were also assigned to assist those in charge of the mechanical design as alot of work was needed in that pillar.

Mechanical Design: Y-Axis¶

Overall, we all helped design the different components needed to produce the machine off a list we prepared earlier. I took charge of designing the step motor, some joints, the aluminium profile, and other components to ease the process of designing later.

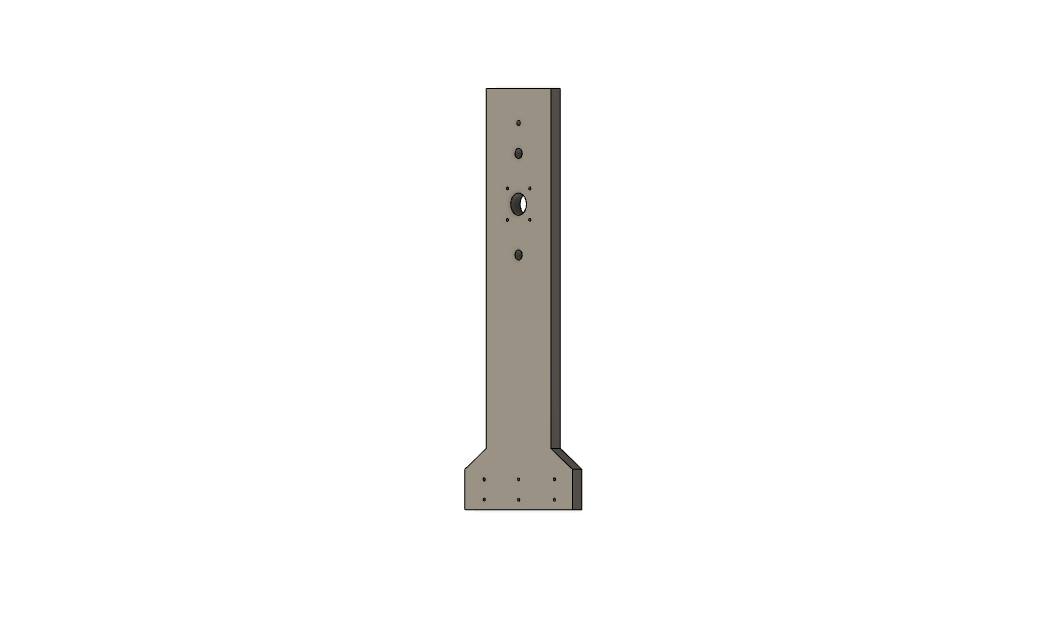

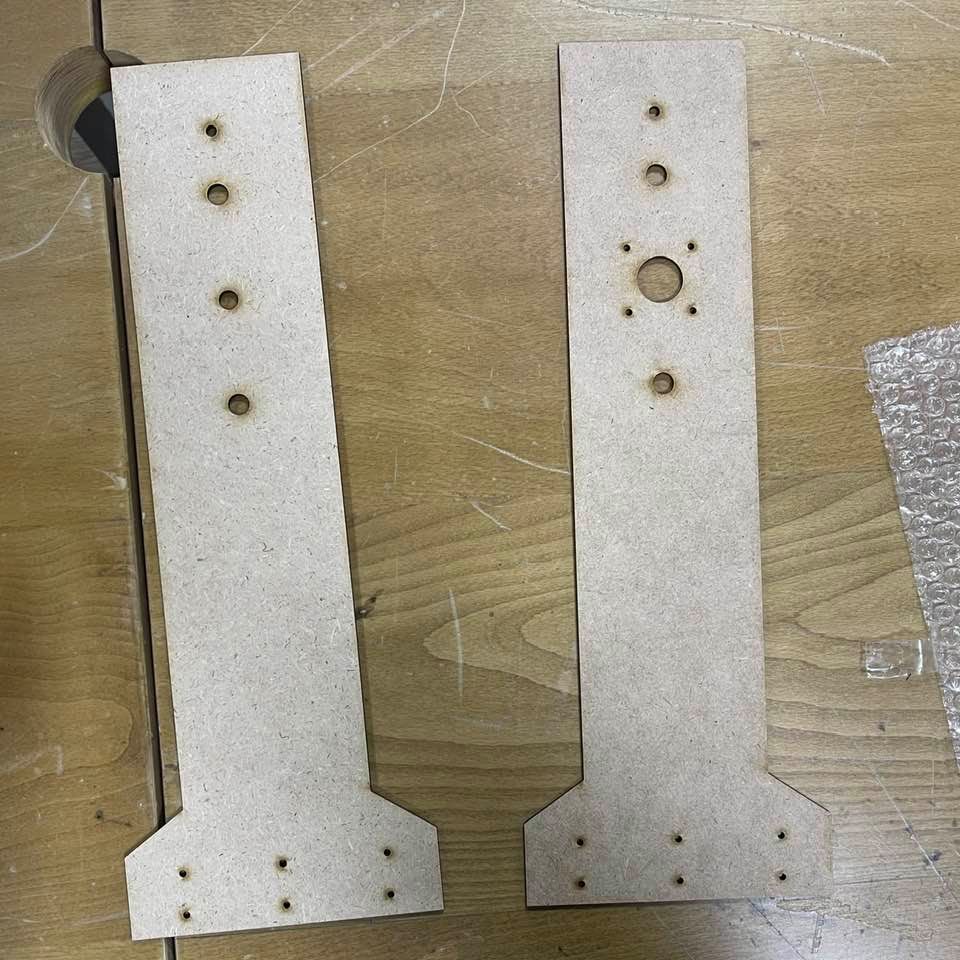

Working with Sara Ali, we designed the seperate pieces on Fusion 360. We started by designing the side pieces which were to be screwed to the sides of the Y-axis and hold the Z-axis component. Although Sara Ali took charge of the design, I helped with testing the length between the holes we made for the screws, the diameters of the screws, and the length of the side piece itself.

After the side pieces were done being designed, using the joints tool on Fusion 360, I connected the rods, the screw, and the aluminium profile to better visualize the final look.

We also did various tests using the laser cutter to verify what measurments fit best for the side pieces.

After all designing was done, we screwed the side pieces onto the x-axis’ aluminium profile.