4. Computer controlled cutting¶

This assignment is about:

Group assignment

- characterize your lasercutter’s focus, power, speed, rate, kerf, joint clearance and types

Individual assignment

- cut something on the vinylcutter

- design, lasercut, and document a parametric construction kit, accounting for the lasercutter kerf, which can be assembled in multiple ways, and for extra credit include elements that aren’t flat

Group assignment¶

Since we are all remote students, I characterize the lasercutter at my lab

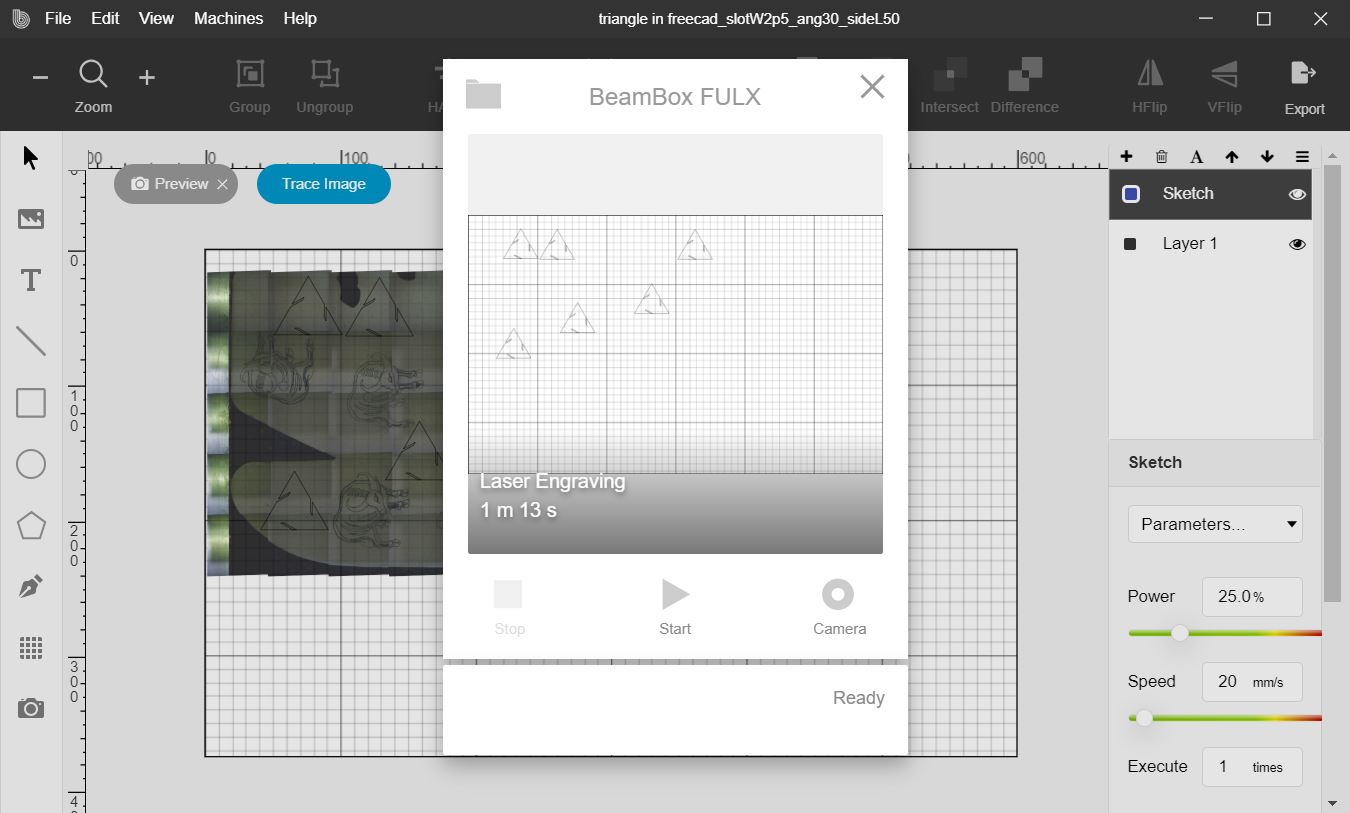

- Brand: Flux Beambox Pro

- Power: 50W

- Work area: 600 x 375 x 80 mm

- Type: CO2

- Focus depth: 13mm

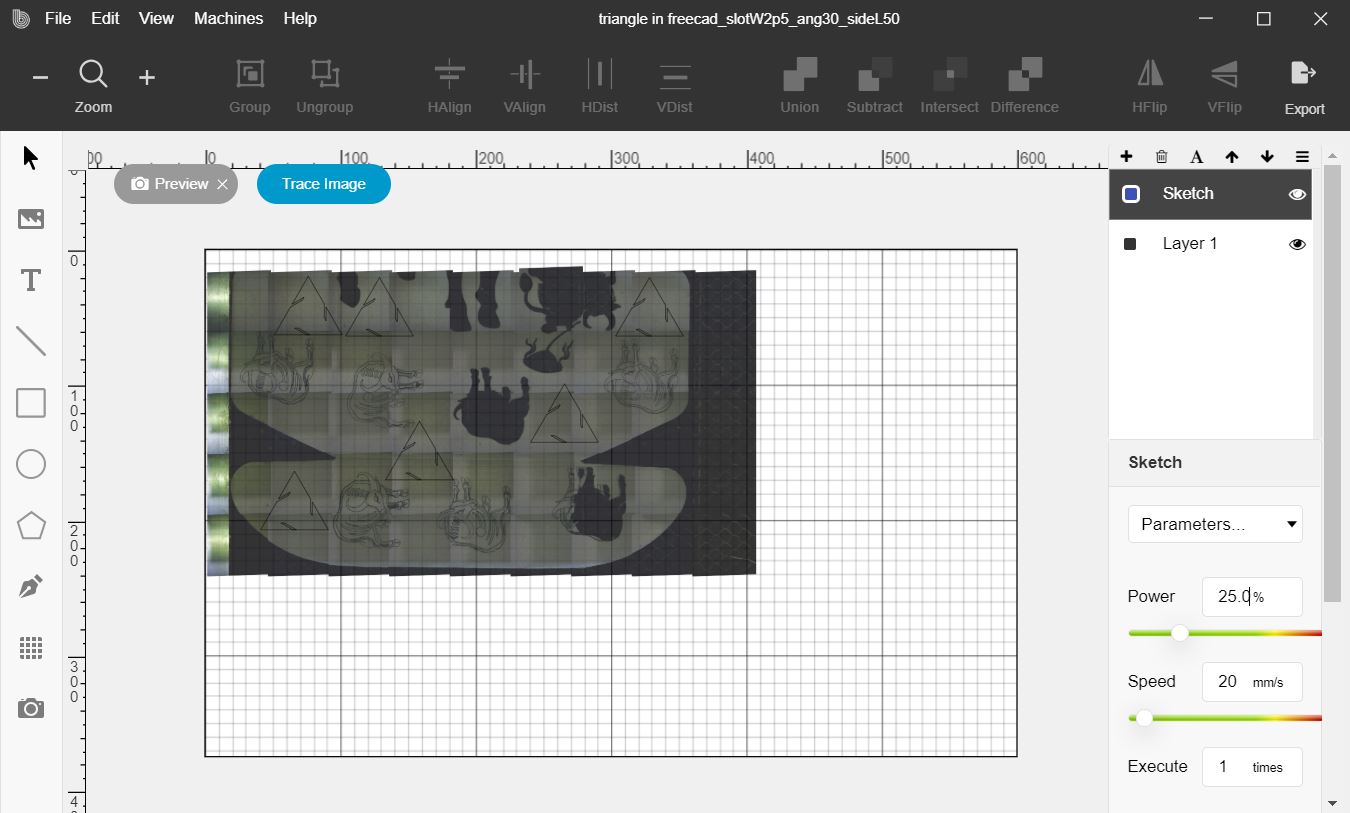

A bunch of 2mm cardboard is available in the lab, and I just used that for testing the kerf. Power and speed settings used are 30% and 17mm/s respectively. I first drew a parametric triangle cutting pattern using FreeCAD, gradually decreasing the kerf value from 2mm down to 1.6mm in increments of 0.1mm. At 1.6mm two pieces of cardboard snuggly fit together. I can shake them without things falling apart.

Individual assignment¶

My initial idea for this assignment is to make a geodesic dome, but it seems that many previous students already did that, so I decided to play with the basic shapes and see what there might take.

Parametric triangle experiment¶

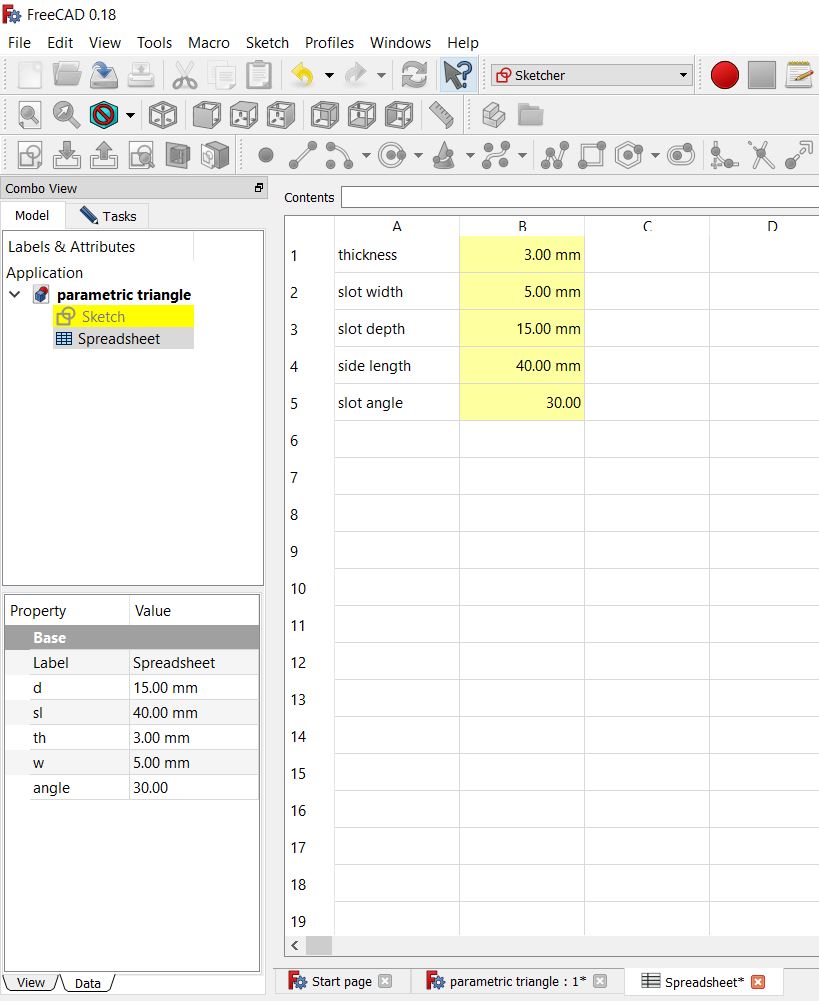

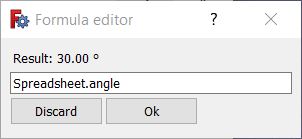

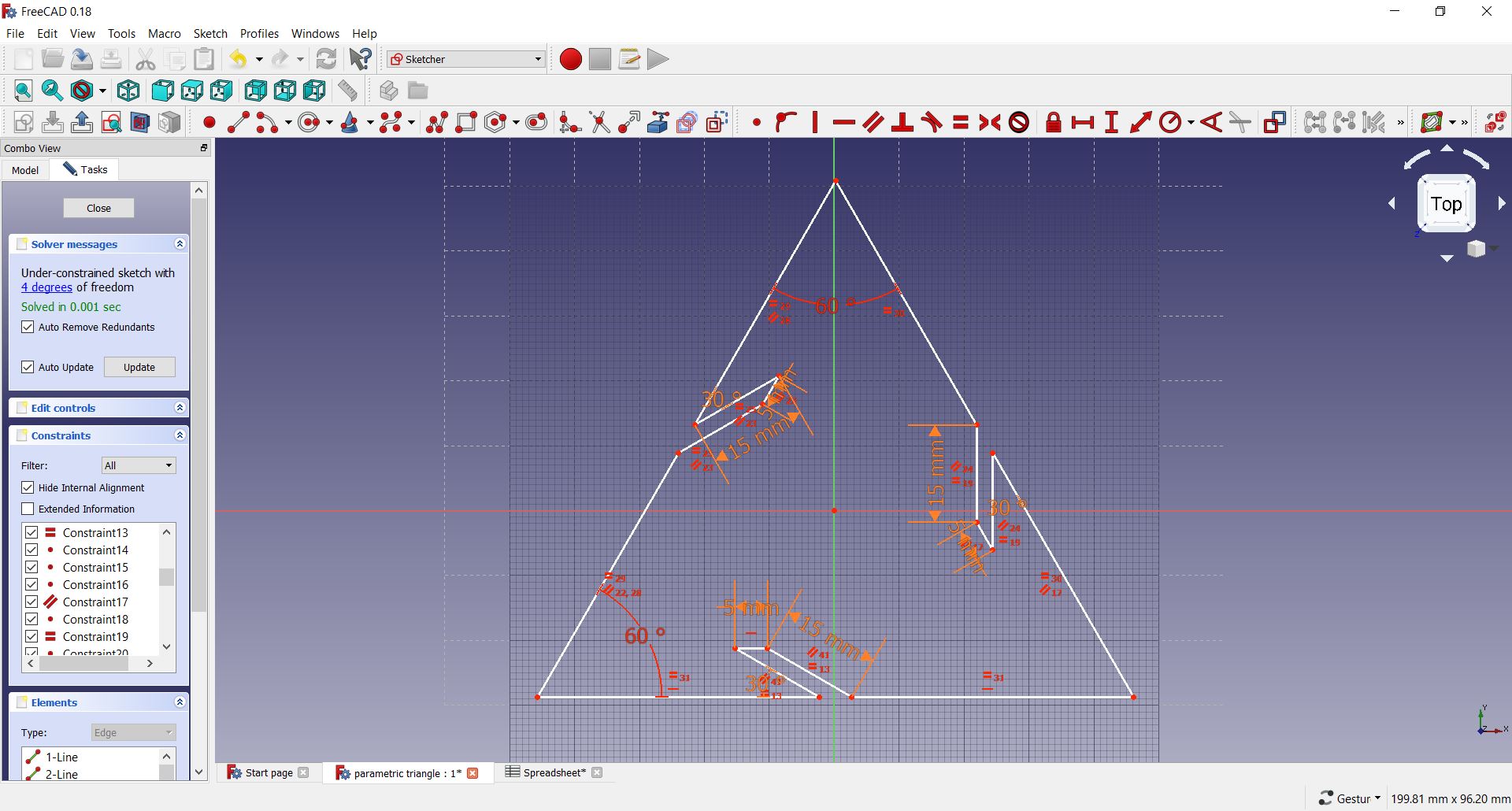

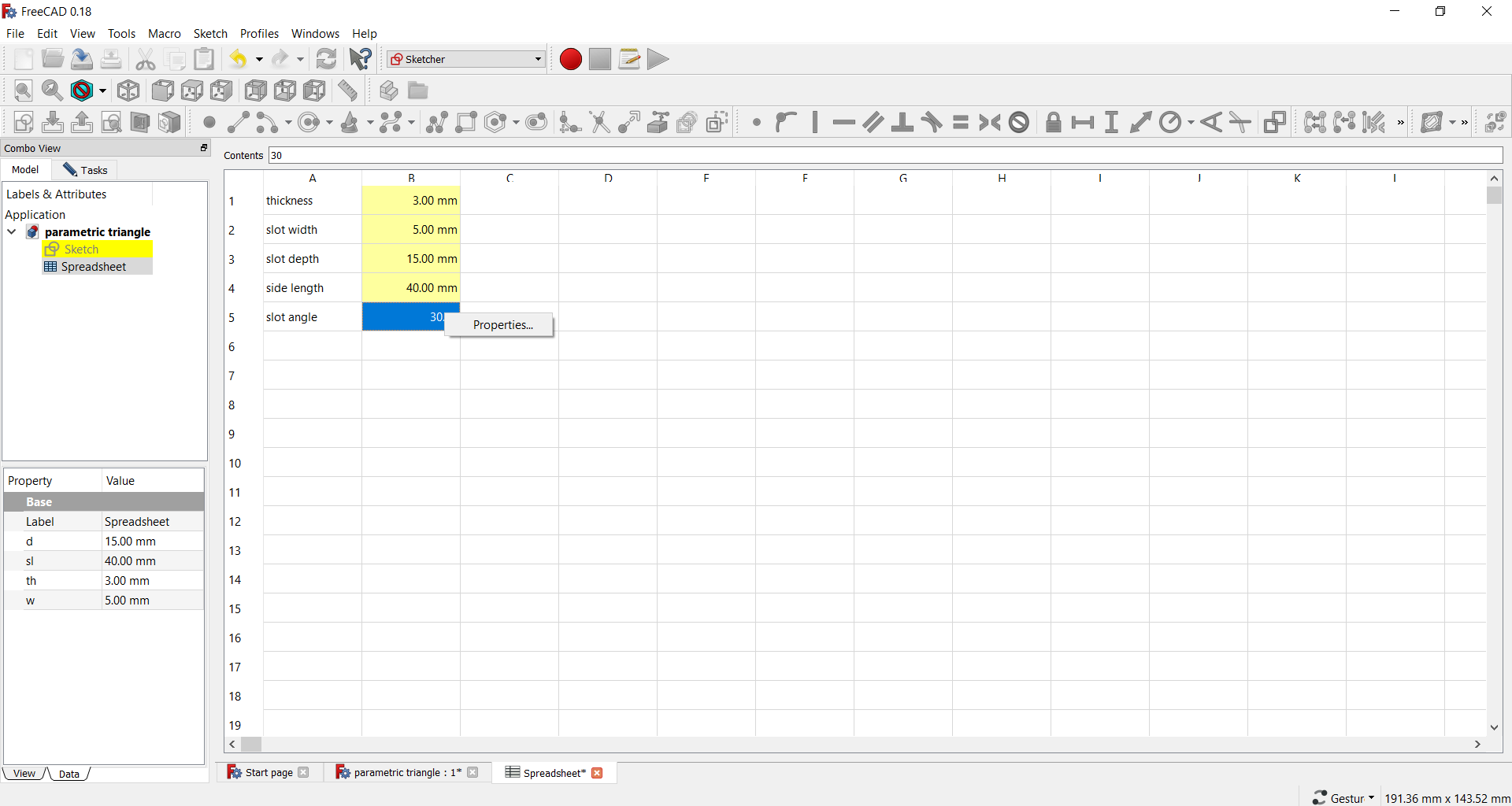

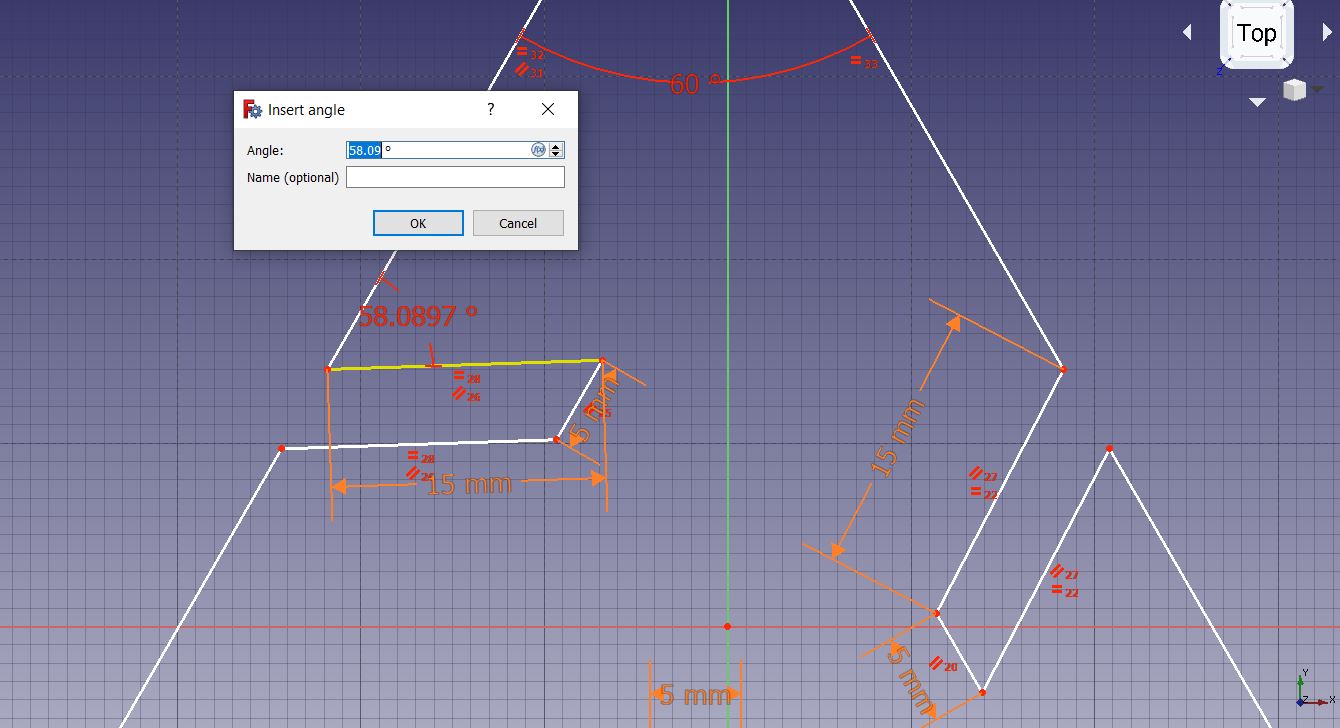

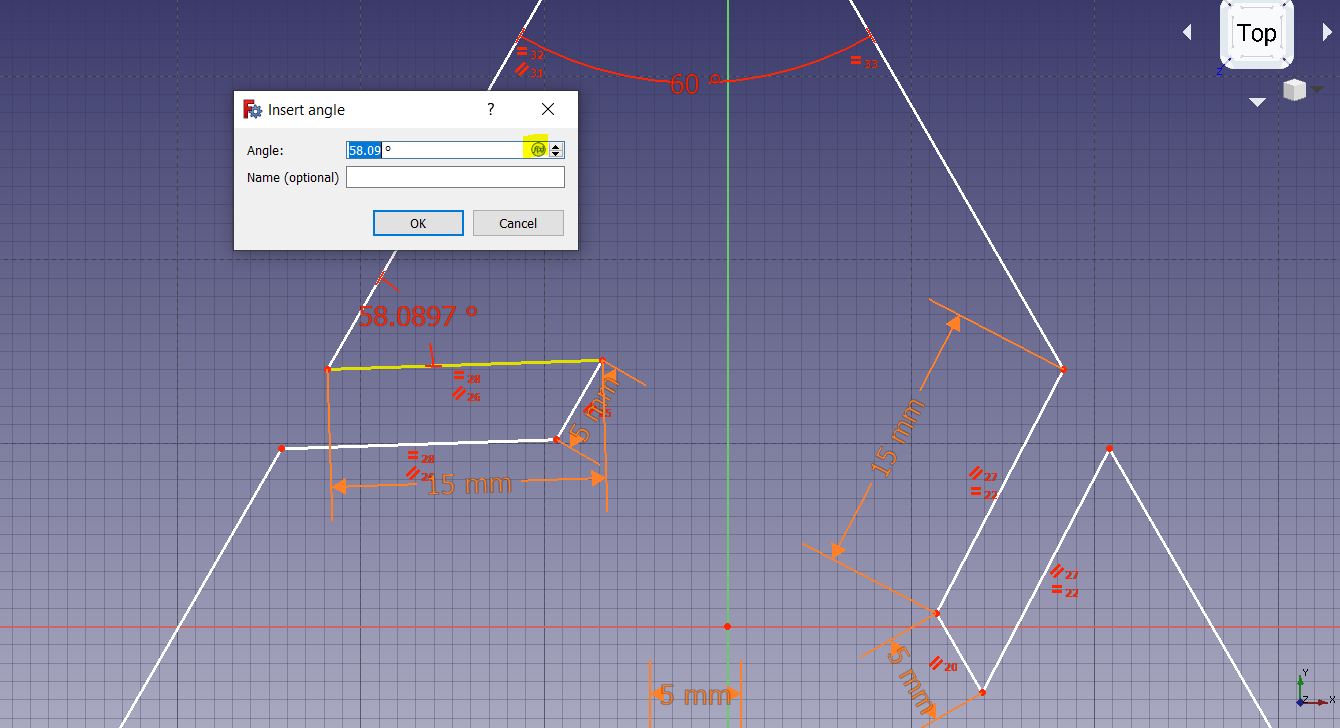

In the Sketchers workbench, I created a sketch of a triangle. To make the design parametric, I opened the Spreadsheet workbench, started a spreadsheet and defined the parameters.

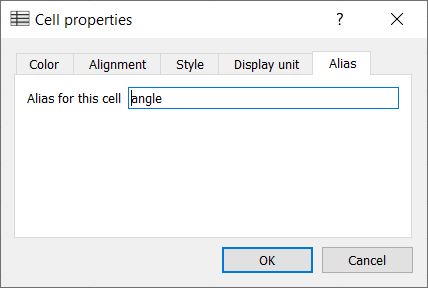

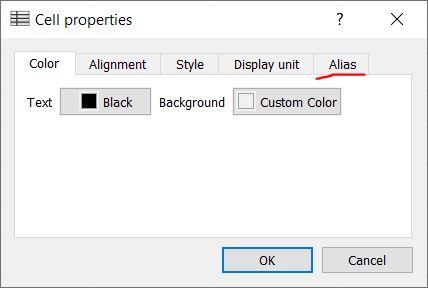

Next, I right clicked on each dimension cell, select Cell properties and typed in a short name as alias for each dimesion.

All cells with aliases became highlighted in yellow.

Once all parameters are applied, the kerf dimensions become uniform and look great.

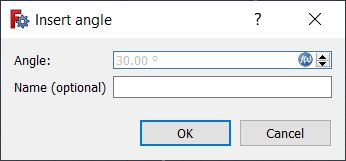

I then exported it to .svg file and passed to the lasercutter software called Beam Studio.

Initially my slot angle was 30 degrees. In the end, for ease of assembly, I changed the slot angle to 90 degrees.

Assembly take 1¶

Make a module and expand vertically. It looks like a flower growing day by day.

Assembly take 2¶

Make a structure and expand horizontally. This could be a pavillion. Lots of shade underneath.

Parametric cloud experiment¶

The idea was making a ceiling hanging in the shape of a cloud which people can assemble by themselves.

This looks quite random and fun. I would like to design a better shape when I have more time.

Vinyl Cutting¶

For this exercise, I would like to make a sticker inspired by Vietnamese filtered coffee.

Photograph by Mark Prince & CoffeeGeek.com

Using Inkscape, I prepared a vector file for vinyl cutting. It is modified from a Vietnamese filtered coffee icon made by Anh Nguyen for The noun project.

My vector looks like this

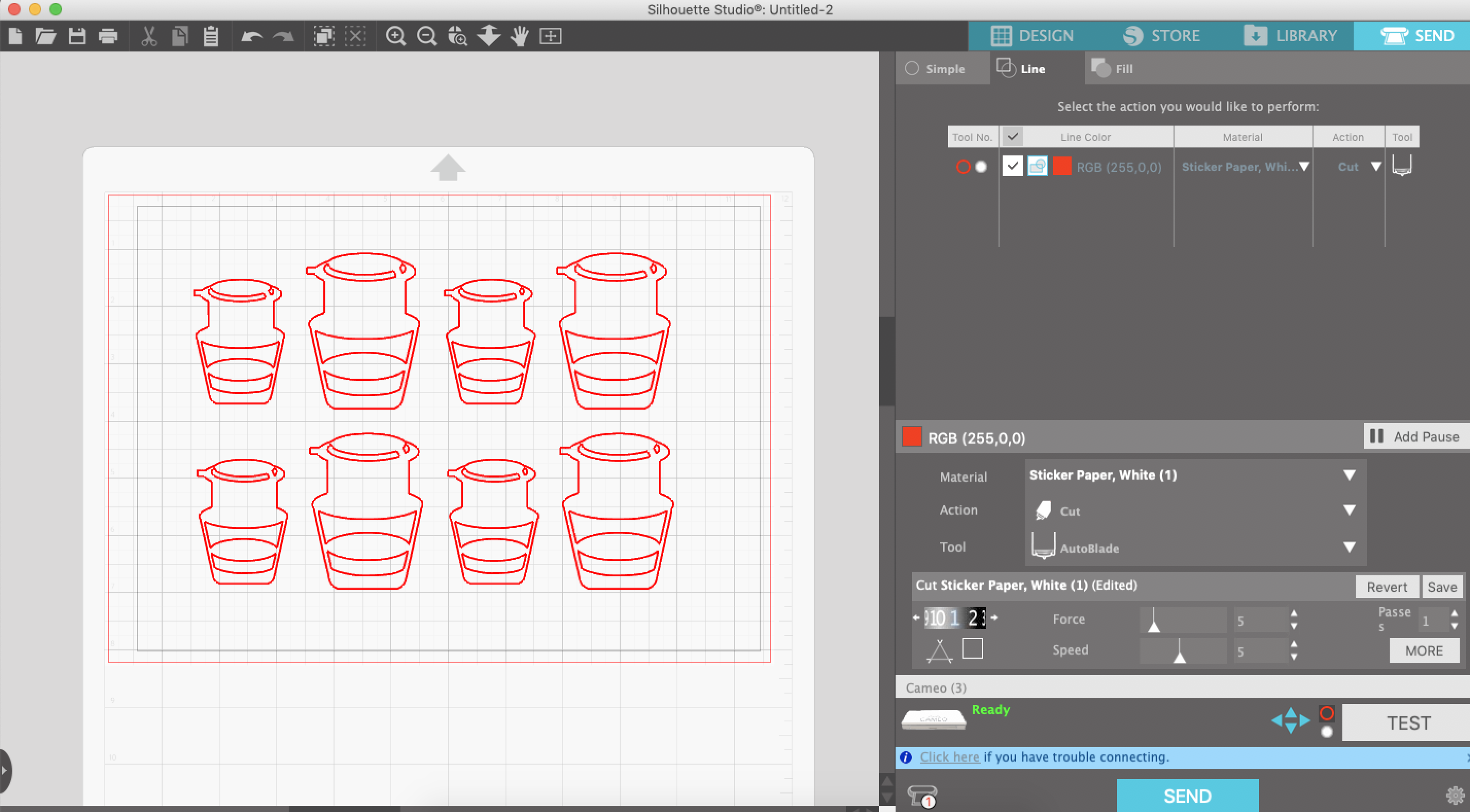

The vinyl cutter used is Silhouette Cameo 3.

As the machine can only read raster images, the vector file was exported to .png format and opened in Silhouette Studio software

Selected settings:

- Material: Sticker Paper

- Action: Cutting

- Blade: AutoBlade

- Force: 5

- Speed: 5

The resulting sticker looks pretty cute. I plan to decorate it with colour markers and make it look nicer.

Useful links¶

Files¶

- Parametric triangle in .svg format

- Planet design for vinyl-cutting in .svg format

- Vietnamese coffee design for vinyl-cutting in .svg format