Week 8 : Computer-Controlled Machining

This weeks group assignment is find out the design rules of the machine in our lab.

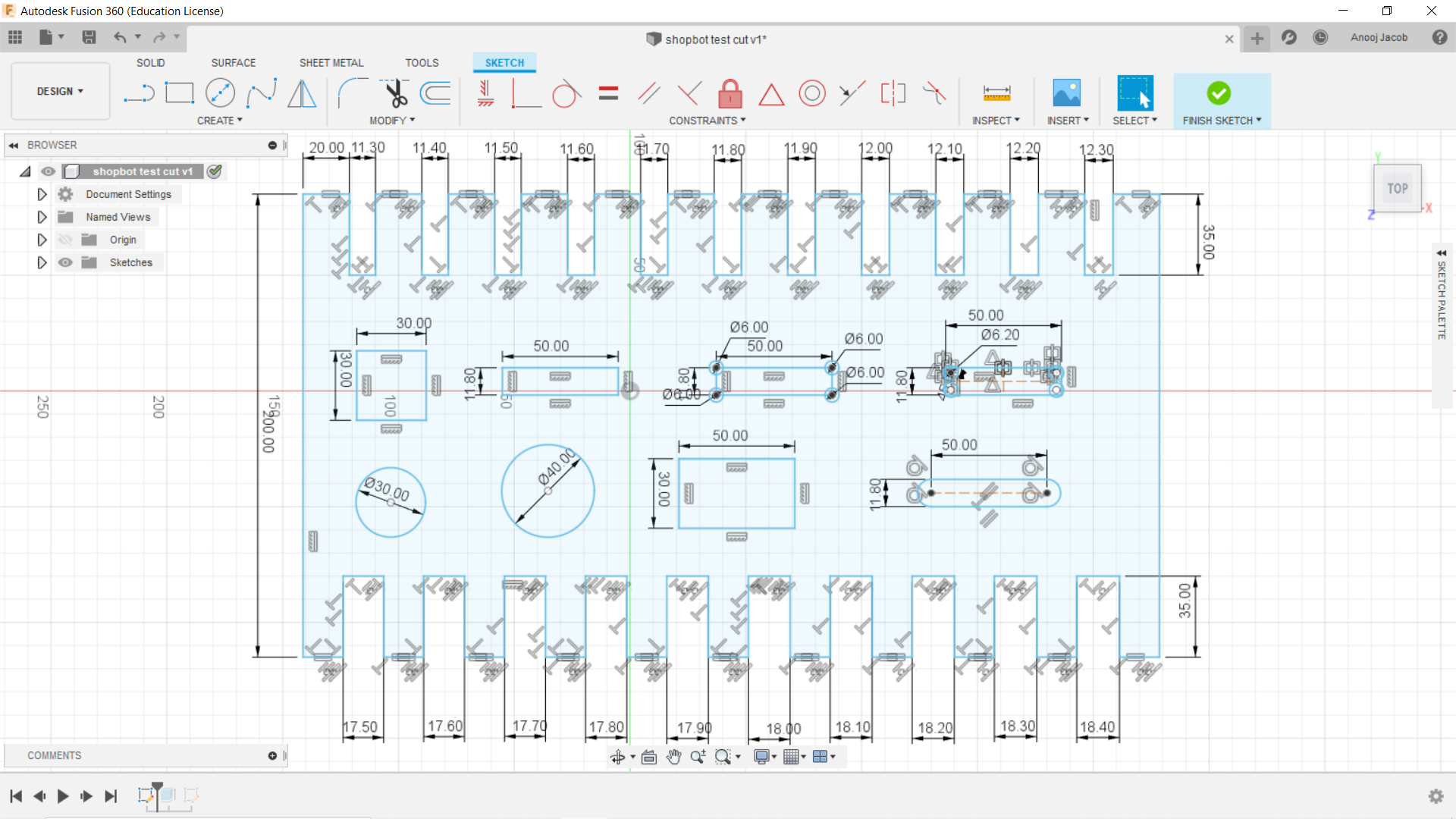

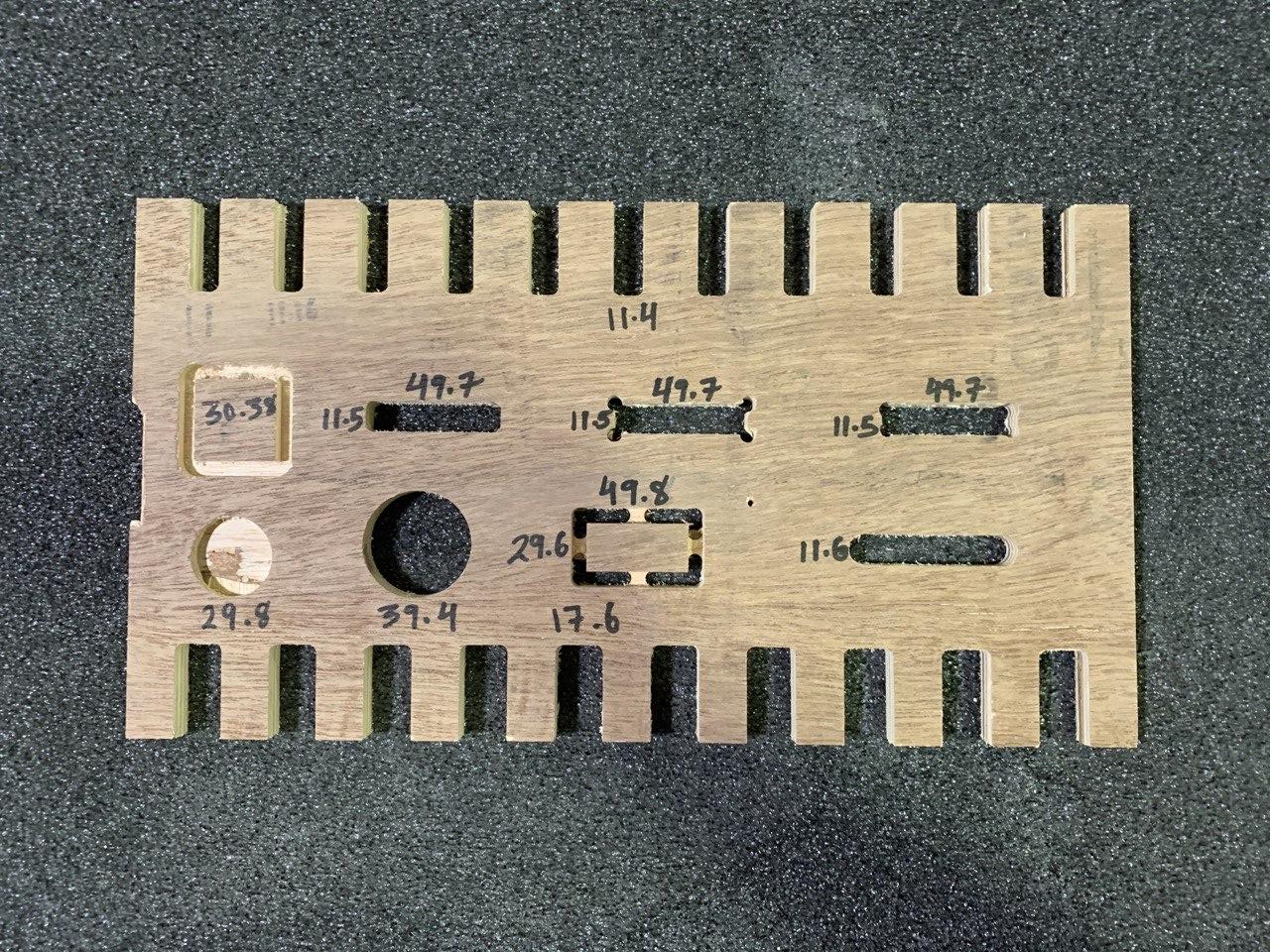

We conducted a test on 12mm plywood board available in our lab. We made a Test File using Fusion 360 with operations involving slot cutting, outline milling, pocket milling and dogbones

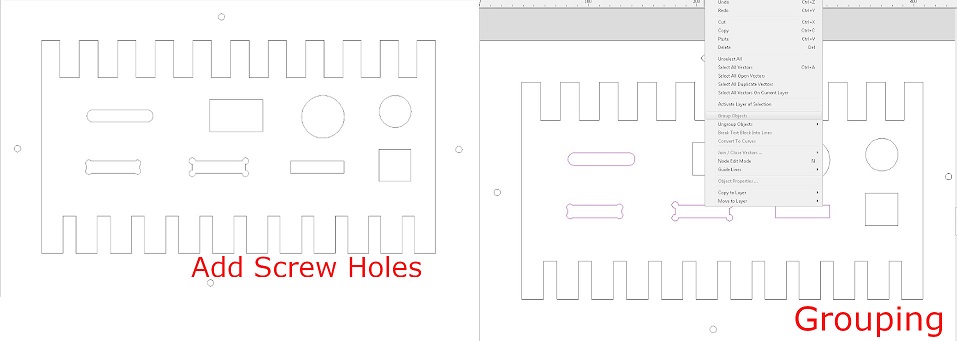

To complete the group assignment for the week, we created models of joint parts that will be used for some of the individual projects for tests. 1. Press-fit Kit Type 2. Pocket Type 3. Dog Bone

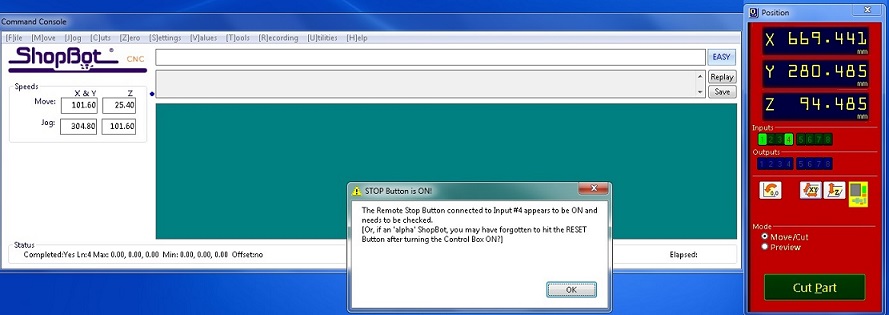

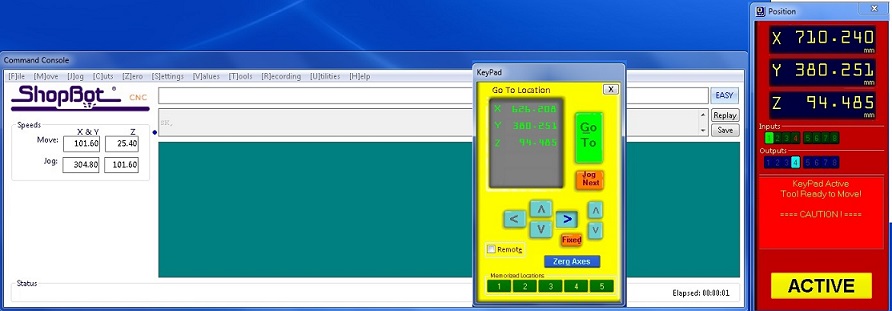

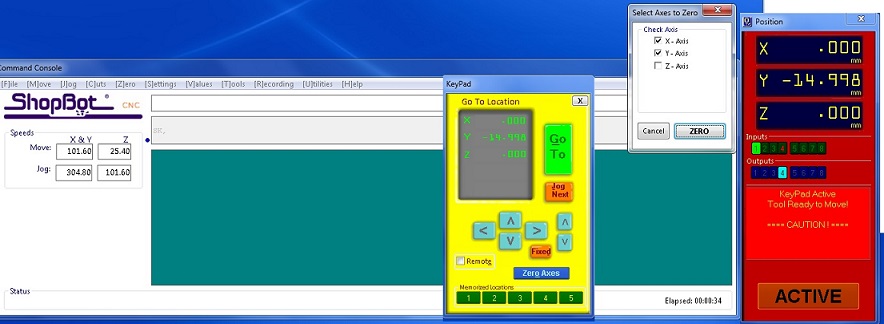

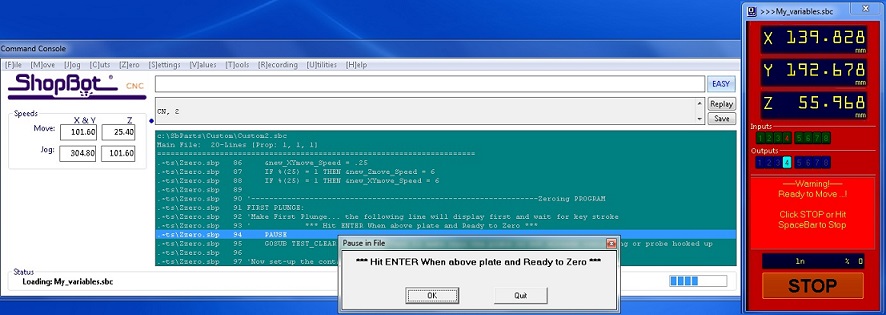

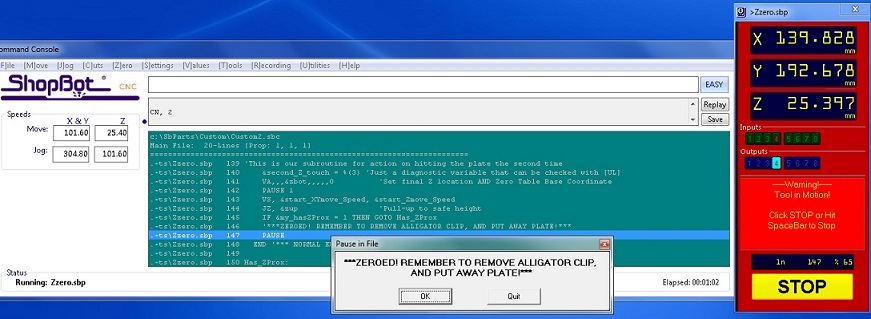

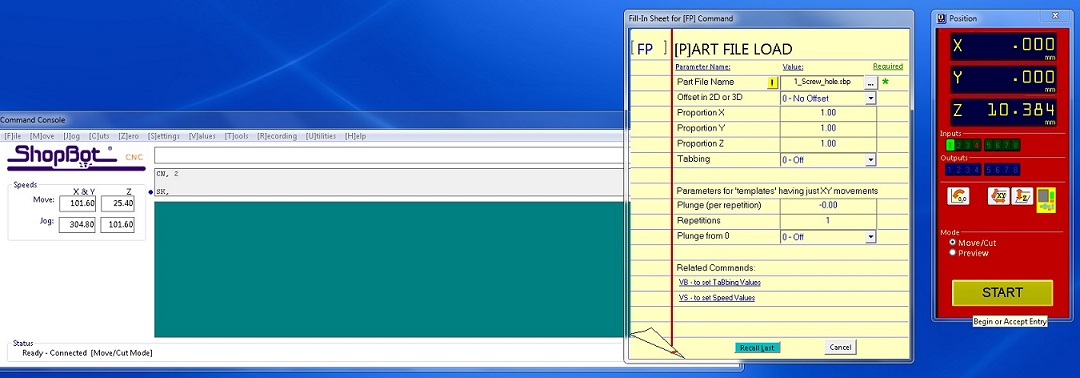

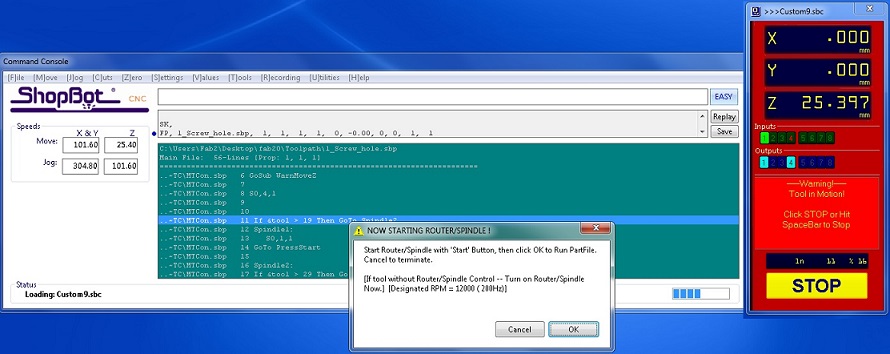

We designed the file in Fusion 360 and exported it in .dtf format. Via a USB we uploaded it to the Computer attached to the ShopBot.

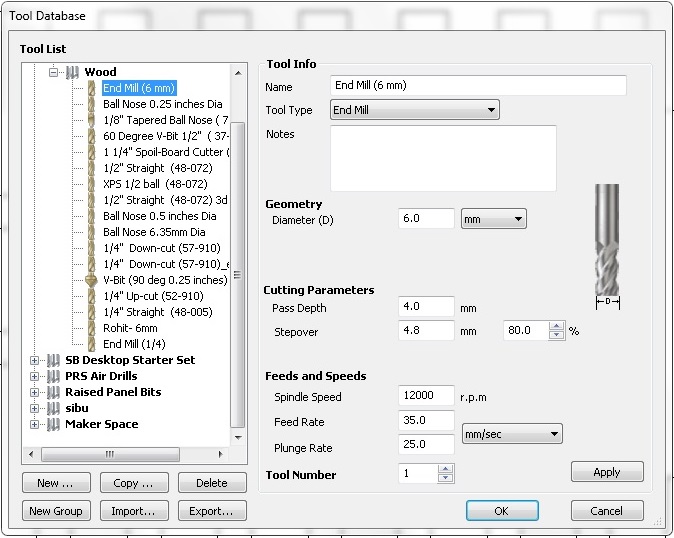

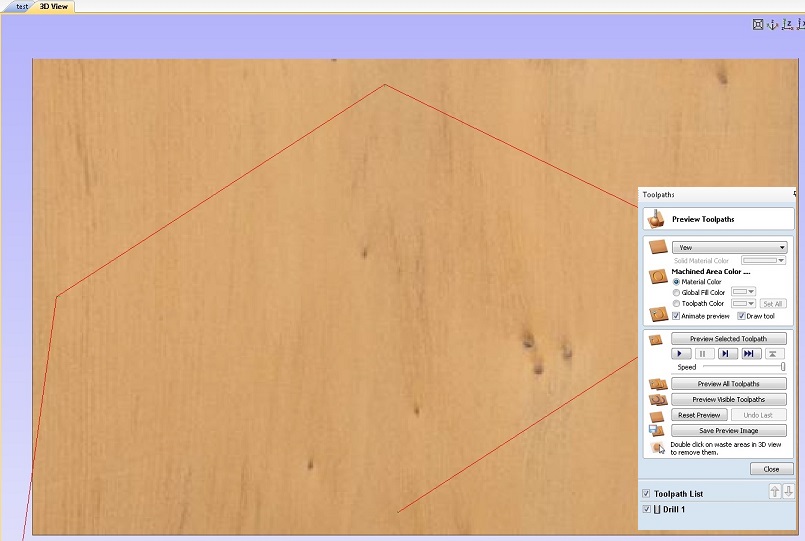

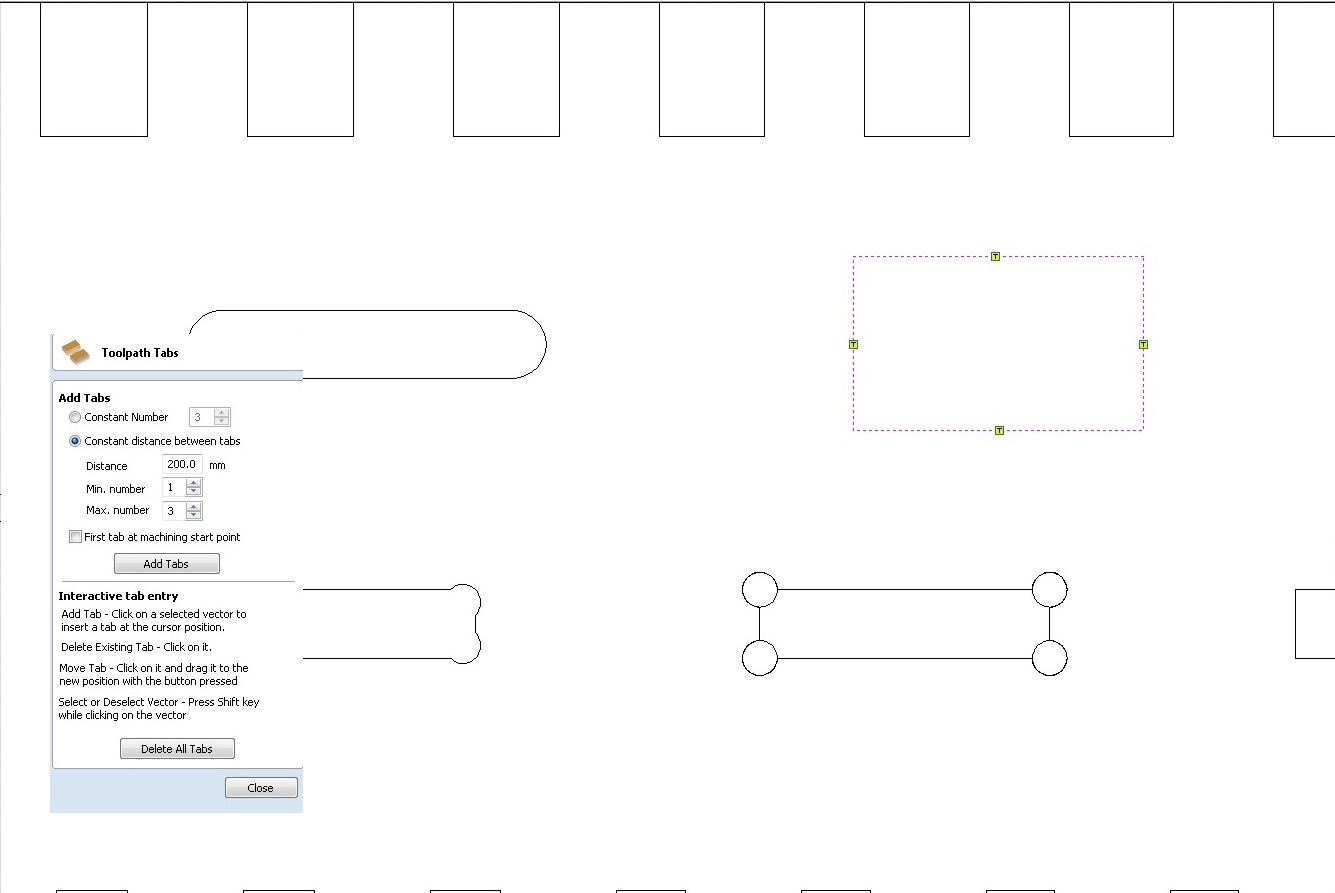

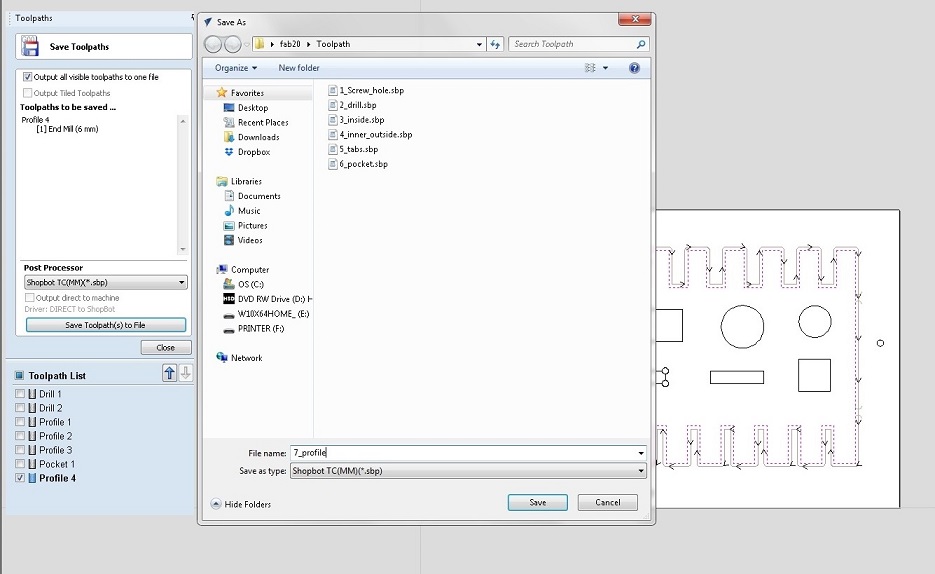

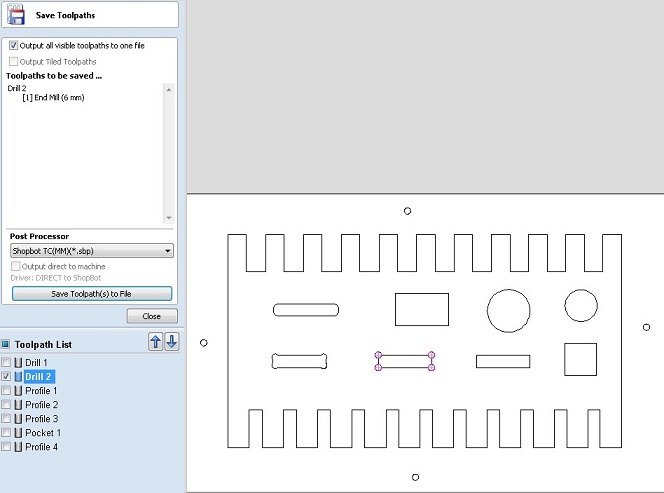

Adding toolpath

Open the file in VCarve

Sanding seems to be a necessary evil. Our Plywood piece was especially prone to fuzzy edges and chipped veneer both making our job take longer. After the CNC work was done we had to do lots and lots of sanding to get those edges looking nice.

The dogbone and edges came out alright.

We measured the milled out design using vernier caliper and found that there is a differnce of 0.4mm between the actual design and the real design

The material thickness does vary a bit with temperature, moisture etc.

Powered by w3.css