Week 17 : Wildcard Week

This weeks group assignment is to make and compare differnt test coupons using composites

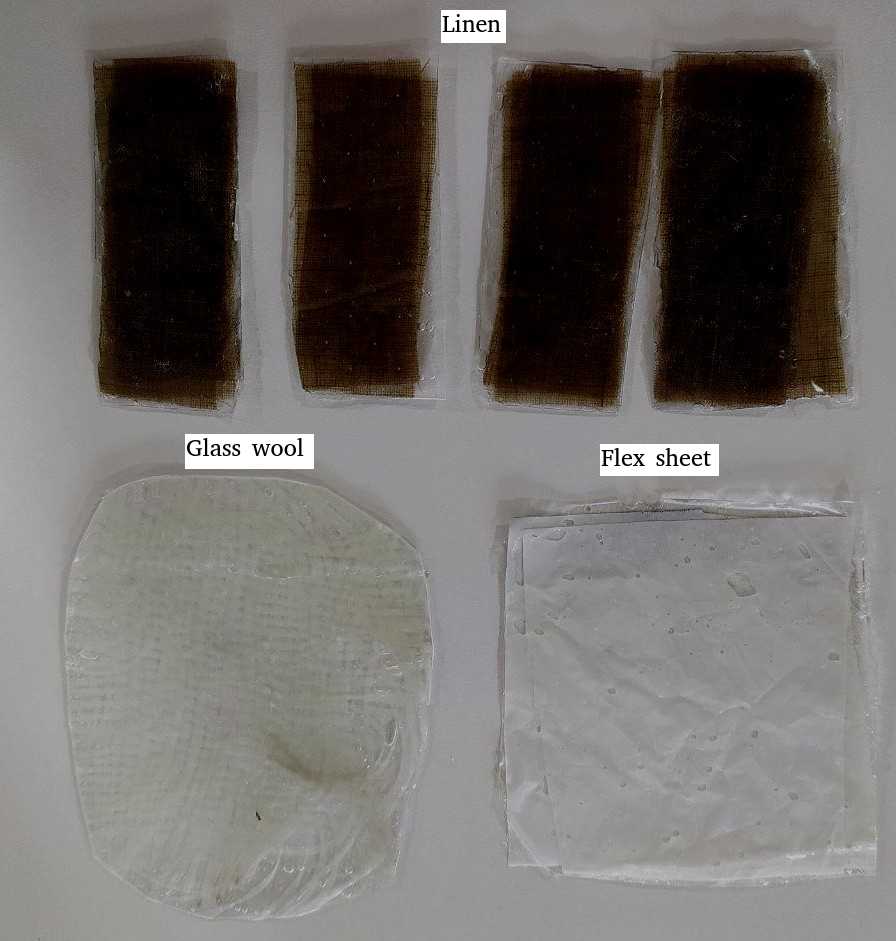

We are going to make sample pieces of composites of epoxy. You can vary with combining different textiles, the number of layers, the amount of epoxy you use, etc. After they are finished we will describe the difference between the different example pieces: Are they flexible, hard, nice to look at, etc.

First we tried to cut the linen cloth into equal sized pieces using laser cutter.

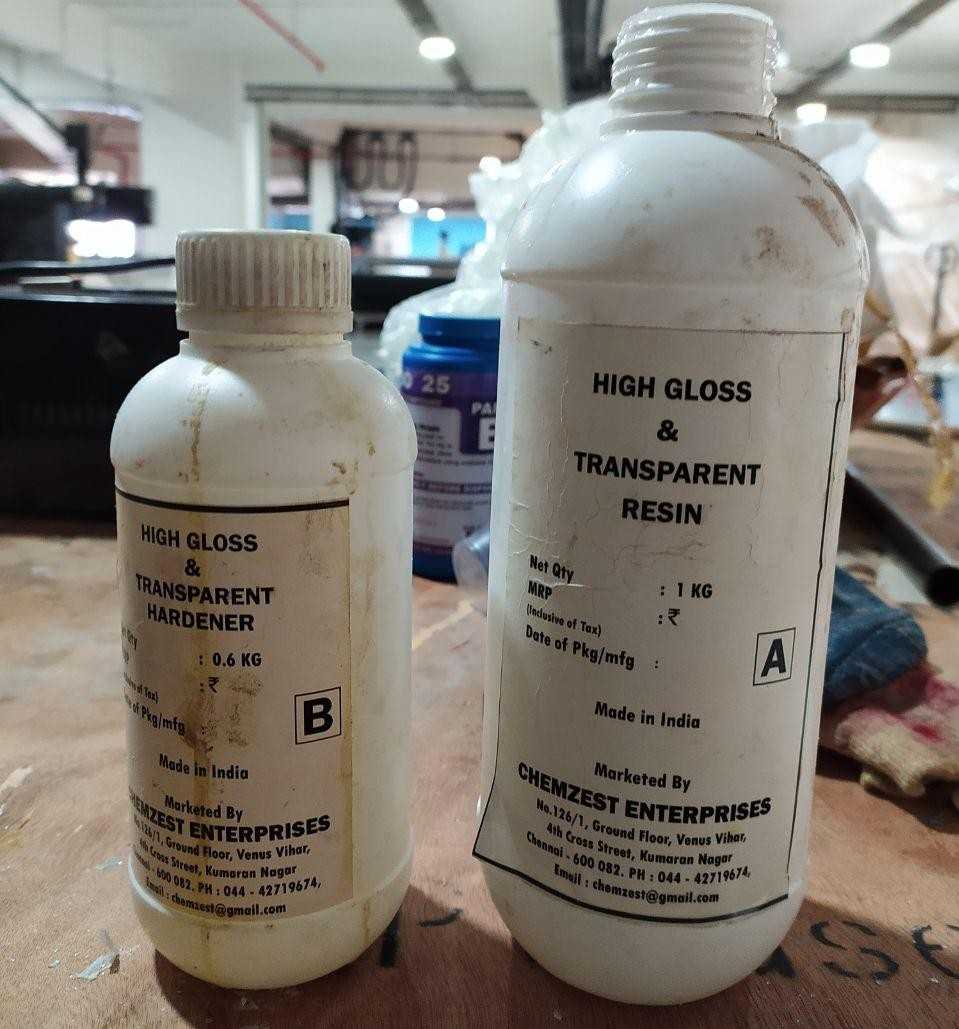

The resin made is regionally available made by chemzest enterprices but datasheet is not available in the internet.So we are planing to keep the resin for 24 hours to set perfectly after mixing A and B

As planed we mixed the resin A and B in the ratio 2:1 respectievly.And test pieces where dipped into the resin. 2 layer of glass fiber, 2 layer of flex material, 2 layers of linen till 5 layers as shown in the pic

After 24 hours of setting time the epoxy was set and it looked good.

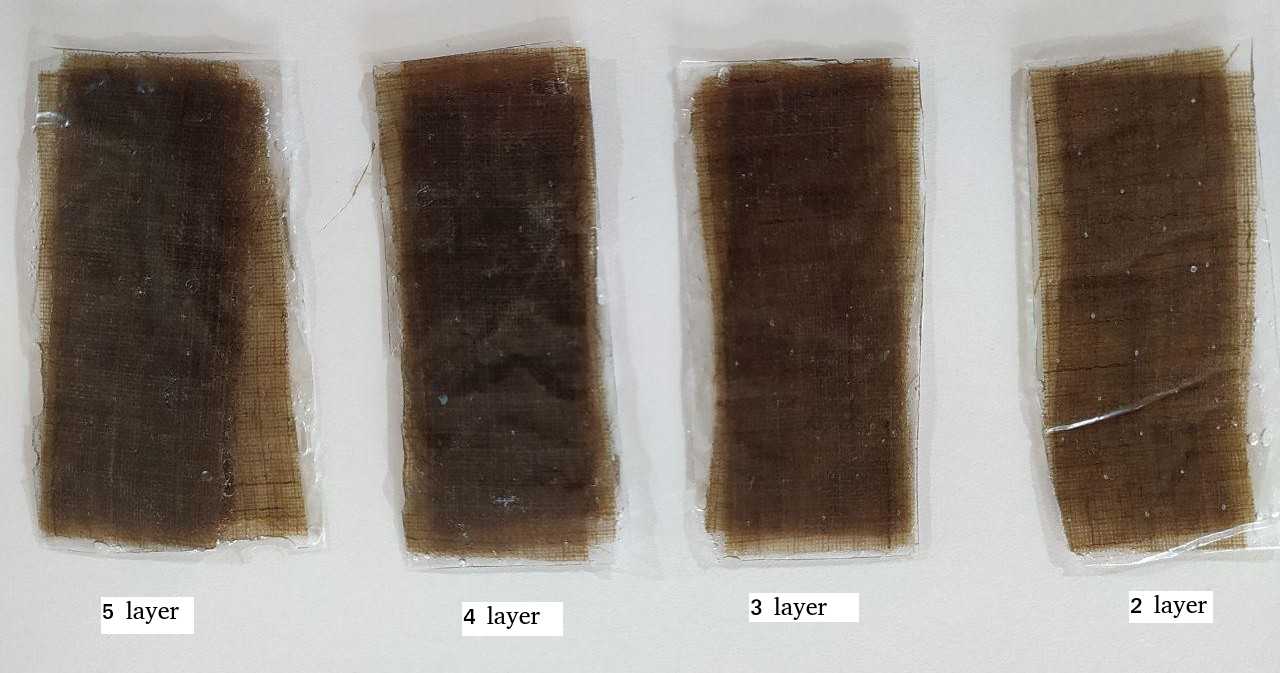

Increasing layers of linen.

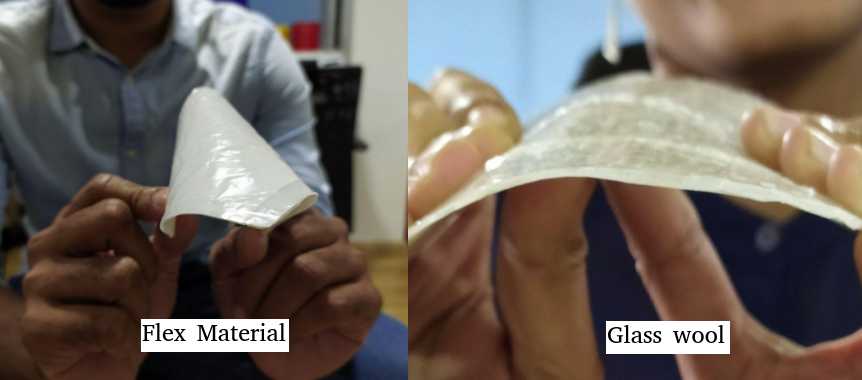

As it can be seen the flex material bend to maximum degree. glass fibre was hard to bend

2 layers of linen was relatievly easy to bend with increasing difficulty with each layer. 5 layers where pretty hard to bend.

We are planing to use linen for our desired purpose and from the above experiments maximum 3 layers of linen is apt for a strong composite anything more than that is waste of material and cloth.

Powered by w3.css