Week 4 : Computer-Controlled Cutting

This week Group Assignments is to understand lasercutter's focus, power, speed, rate, kerf and joint clearance.

The Lasercutting machine in our lab is TROTEC SPEEDY 400 FLEXX. It has got a bed size of 1016x610mm. This machine also allows combine application of Co2 and fiber laser.

Controlling and operating the machine is very easy, the interface is simple and can be easly used by a beginer.

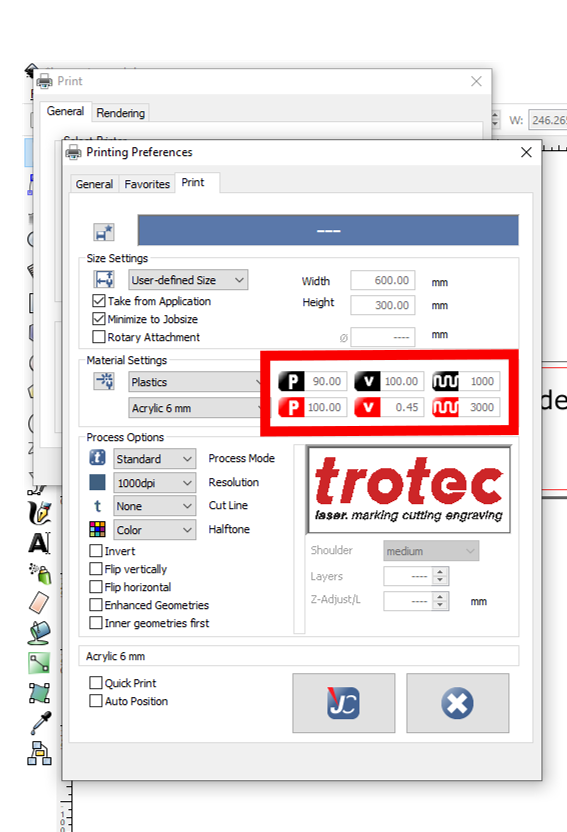

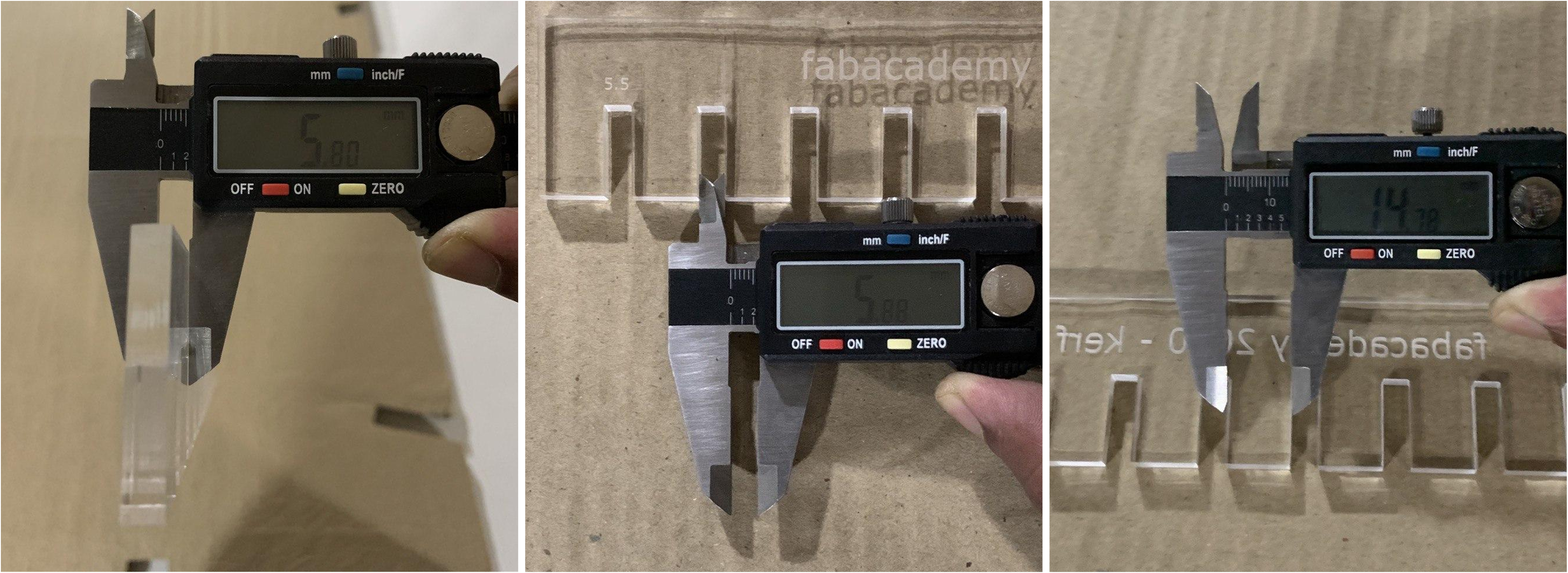

First we tried cutting a 6mm acrilyc sheet to understand the machine parameters and to determine the kerf and joint clearance. For that we did a test cut by varying the values of power, speed and rate.

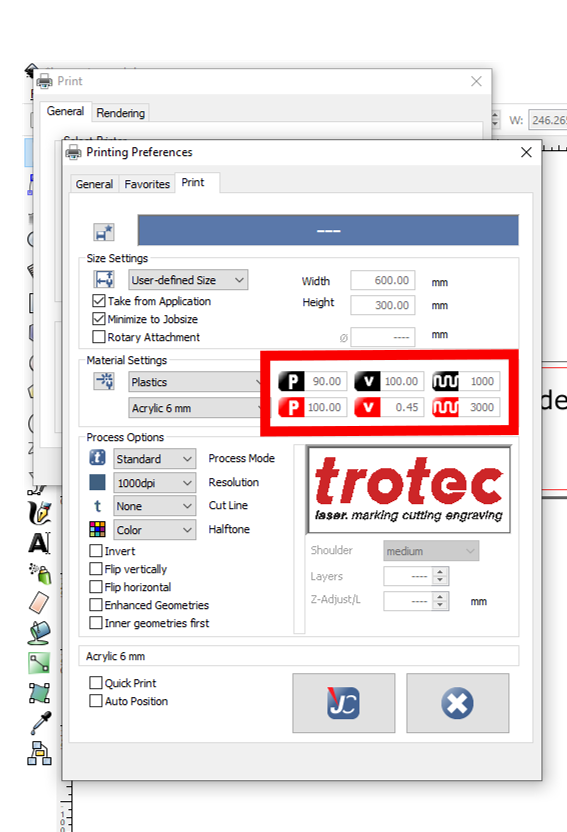

After multiple trials, we got a perfect cut when the parameters where set to Power=100%, Speed=0.45, Rate=3000Hz and Passes=2. And for engraving, the parameters where set to Power=90%, Speed=100, Rate=1000Hz and Passes=1.

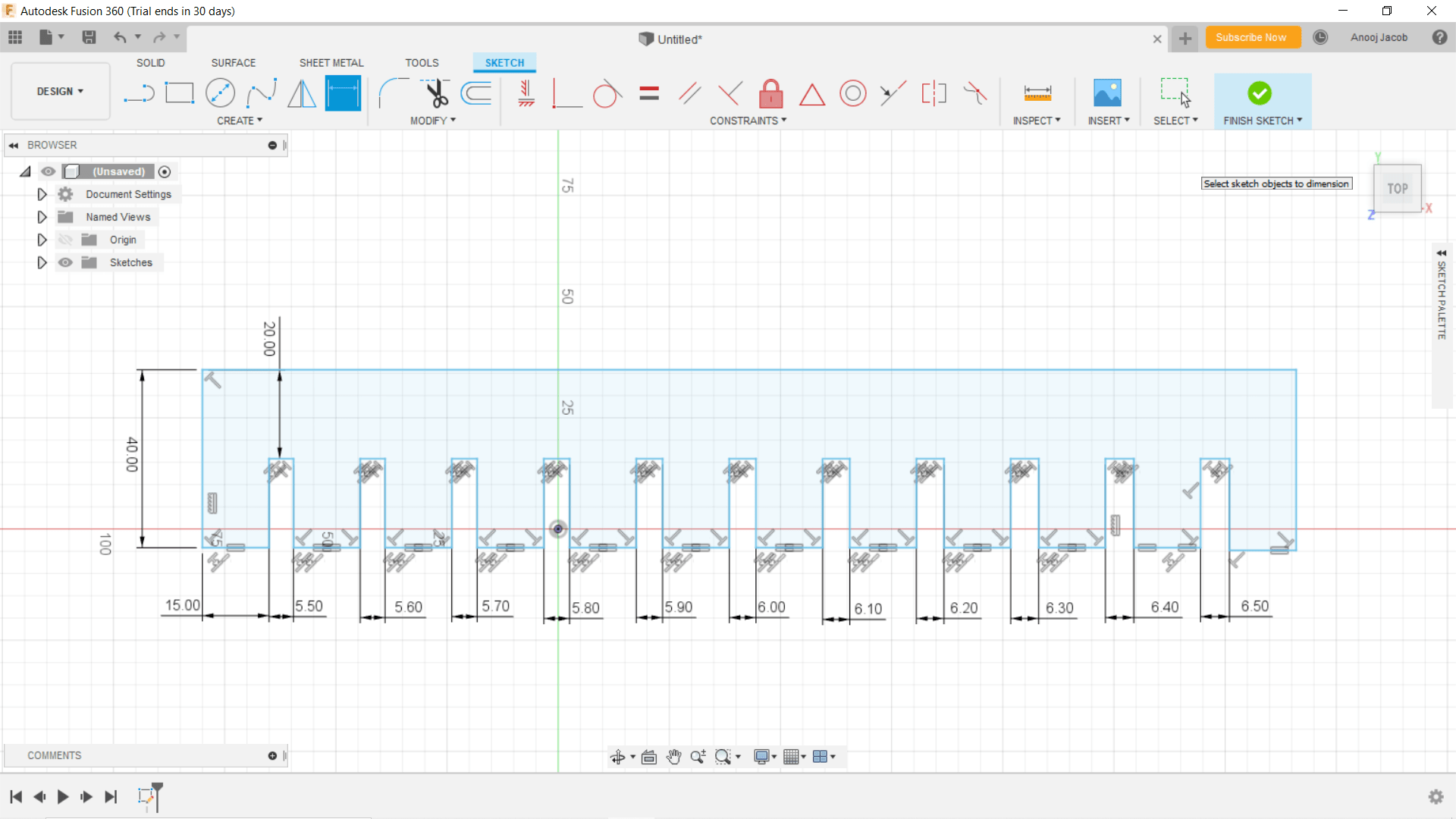

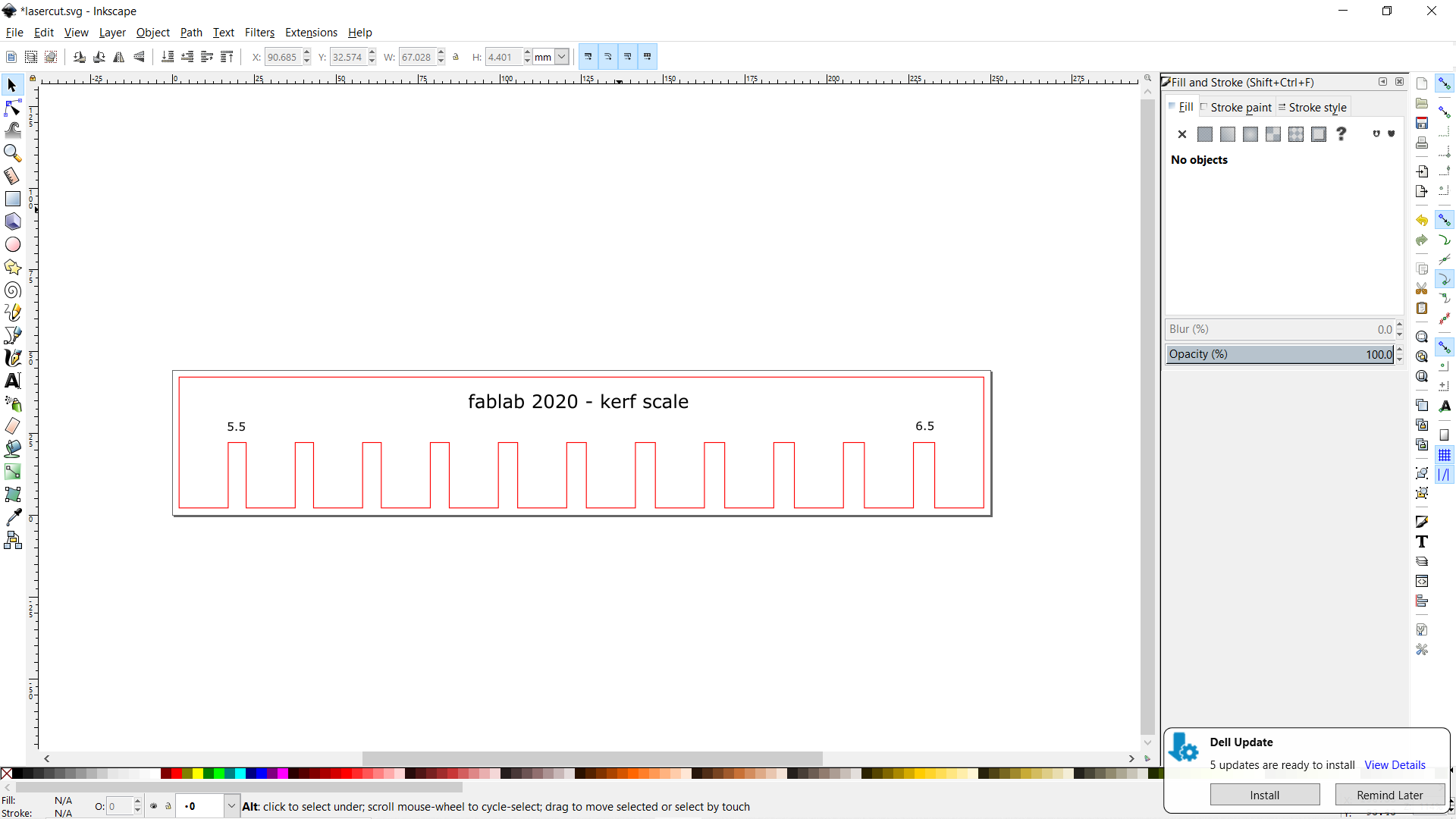

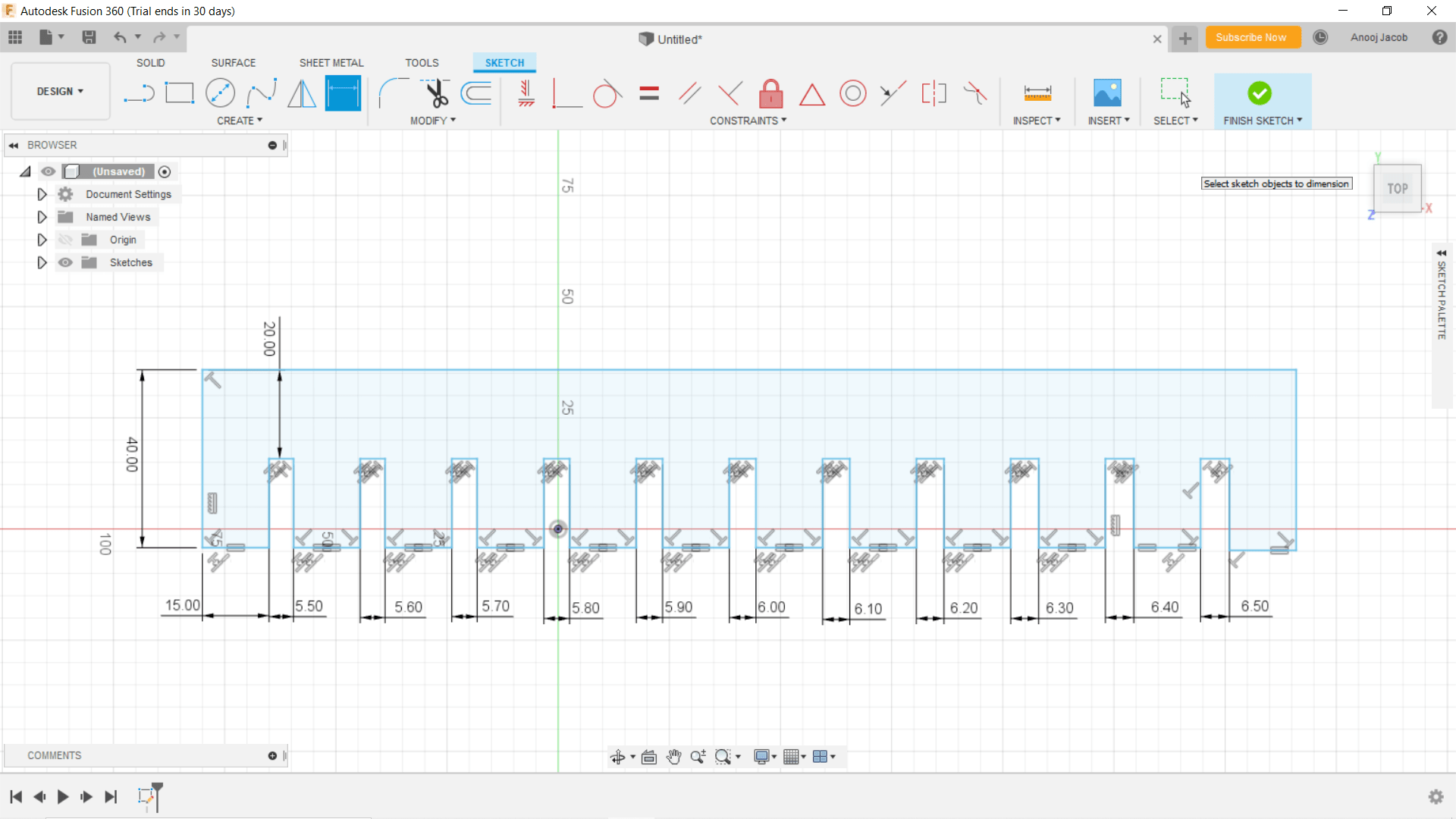

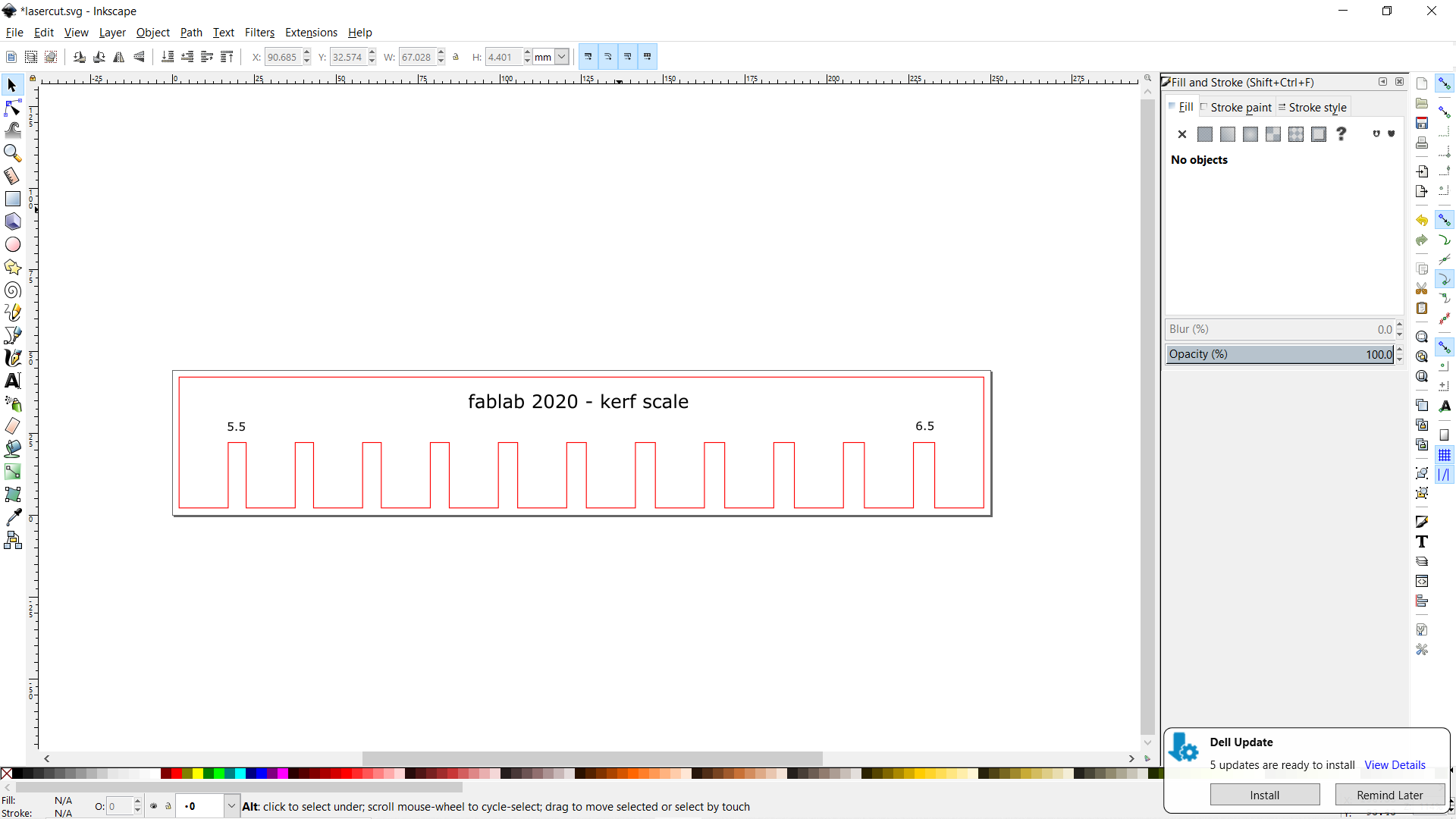

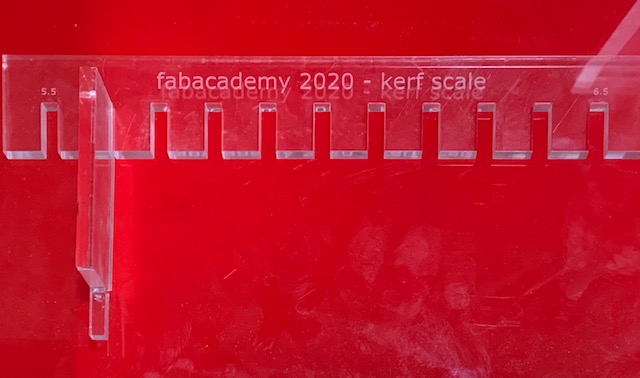

After setting the parameters, we designed a Kerf Scale using Fusion 360, the scale have slots with the slot widths ranging from 5.5mm to 6.5mm. And then we exported the dxf file to Inkscape for cutting.

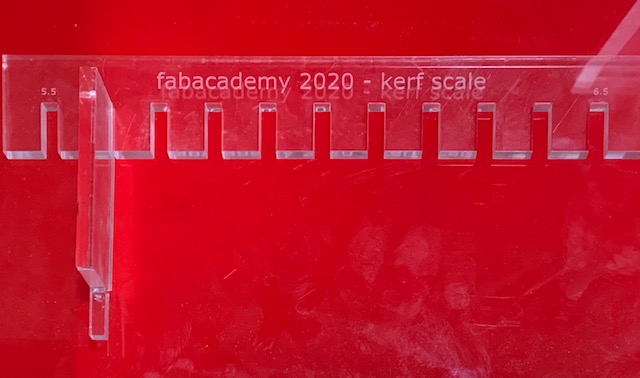

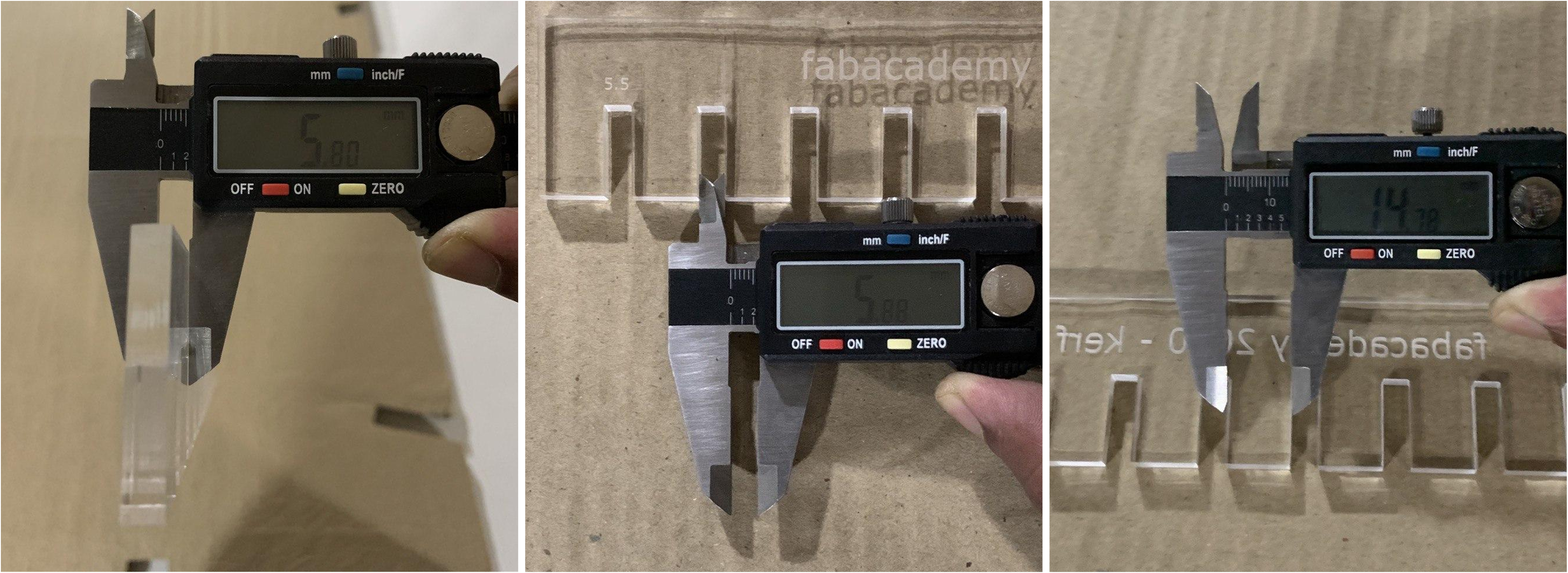

After laser cutting, we got a pefect fit in the 5.6mm slot.

Conclusion:

1) The thickness of the acrilyc sheet was below 6mm, around 5.8mm.

2) Kerf = 0.2mm

3) Joint clearance = 0.1mm

Powered by w3.css