18. Project development¶

Assignments¶

Complete your final project, tracking your progress:

-

what tasks have been completed, and what tasks remain?

-

what’s working? what’s not?

-

what questions need to be resolved?

-

what will happen when?

-

what have you learned?

What tasks have been completed, and what tasks remain?¶

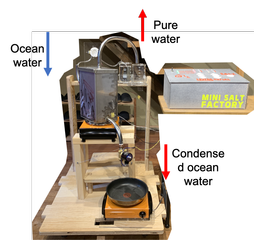

Since I’m documenting this after my final presentation, here are the tasks that I have completed:

-

Fabricate the distillation tower.

-

Fabricate a peristaltic pump.

-

Fabricate a control panel.

-

Figure out the power supply since DC motor and solenoid pump requires 6V and 12V power.

-

Produce a PCB that controls the whole system.

-

Program the system.

-

Integrate all the parts to ensure safety, and neat wiring.

What worked? What didn’t?¶

On a more general manner:

-

Salt & pure water was generated.

-

Large buttons and shiny LEDs were used in the control panel, which ensures a more interesting experience for children. Maybe it can be more simplified but I’m happy with the result.

-

I wanted to make salinity sensor to test the salinity of condensed ocean water coming out. But that was triaged.

-

It works as a continuous process, but each cycle takes too long(it takes around 15 minutes to make 1 batch of salt). In chemical engineering, the amount of inlet particles need to be the same as the outlet to make sure a continuous process. Therefore, to make sure this process is continuous, the amount of ocean water inlet should be the same as the sum of pure water and condensed ocean water coming out. Ocean water inlet can be controlled by DC motor’s speed and time span turned on. Pure water outlet can be controlled by the heating temperature and time of condense tower. Condensed ocean water outlet can be controlled by the solenoid valve’s time span turned on. I would love to figure out the relationship of those in equations and implement that into the program.

I tried a program to simulate chemical engineering processes called DWSIM. You can see my documentation here.

In a more specific manner:

-

My peristaltic pump worked during testing, but didn’t pump liquid properly when integrated into the system.

-

I successfully welded a condense tower that does not leak.

-

I was able to heat the tower and control it under a centain temperature using a thermistor as temp. sensor, and an SSR.

-

I was able to control the outlet of the tower using solenoid valve.

-

I was able to mold and cast button caps that fit on tactile switches for the control panel.

-

I wired the tact switches and LEDs by soldering them onto nichrome wire on the other side of control panel.

What questions need to be resolved?¶

As listed in the previous question, 2 main questions remained are:

-

How to make a continuous chemical engineering process?

-

How to design and fabricate a peristaltic pump that works everytime?

What will happen when?¶

All responses are based on the operation using control panel.

When the toggle switch is flipped on, 100V is supplied to the system.

In Tower heating temperature section, when nothing is done, the heating temperature for distillation tower is set to be 100 degrees, and the LED column on the right that indicates the set temperature would have 1 light on.

Each time when the up button is pressed, the set temperature is increased by 10, and 2 lights on the set temperature column lights up.

And when the down button is pressed, the set temperature is increased by 10, and 2 lights on the set temperature column lights up.

In this way, the temperature can be set to 100, 110, 120 degrees.

When the round button is pressed, the heater is turned on and the heat control system programmed starts.

And the right column in Tower heating temperature section indicates the actual temperature. Thus when the temperature reaches 100, 1 LED lights up. When reached 110, 2 light up; when reached 120, 3 light up.

The outlet time span section works similarly.

The buttons change the ON time of solenoid valve, thus the time outleting condensed ocean water.

When nothing is pressed, the time span is set to be 0.5s, the other 2 stages are 0.7s and 0.9s. The up and down buttons switch time span among that, and the left column LEDs indicate that.

When the round button is pressed, peristaltic pump that inlets ocean water is on. And after 30s, solenoid valve is turned on to the time span set. Pressing round button again stops it.

The round button at salt production section turns the heater for pan on and off to control the heating of condensed ocean water.

What have I learned?¶

Besides all the fabrication skills I learned through each week’s assignment, I especially learned how to

-

Design an UI that is children friendly - adding bigger buttons, shiny panel, etc.

-

How to arrange wires to make the installation more neat.

-

How to manage my time. I did make sure to make as many parts that go into the final projects in each weeks assignment as much as possible. I would say since we had more time than previous years, I was able to pursue most of the things I wanted to fulfill. But I did triage by setting my priorities and decided not to do salinity sensor. I also learned a lot about time management with each week’s assignment. There are so many things to explore, yet I learned about setting my goals for that week based on my time, the requirement for assignment, and what I want to achieve through FabAcademy.

-

A most important learning outcome is my understanding towards chemical engineering has evolved so much during this process. I did learn about the conditions to create a continuous process, but this is the first time that I really thought about how to make it happen. I found out that the process of reproducing a process helps me learn so much more than just reading about it on books.