Fight against COVID-19

Here is my little contribution to the fight against the pandemy.

Unfortunately I'm stuck at home at the moment, and all our 3D printers are still in our Fablab where we're not allowed to go.

But as I have a personal printer I could start printing. The printer is running 24 hours a day and the first shields will be sent to hospitals on next Monday (April 2nd).

The printed shields are looking great and should be efficients. So far so good.

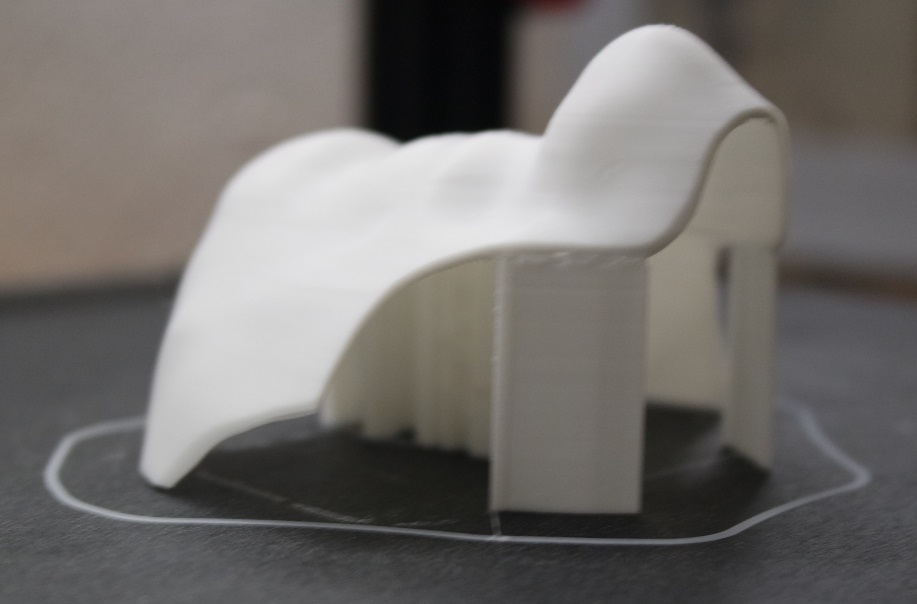

Here is a photo of the first printed ones:

I've been asking my school if I could go back to our Fablab to bring back home the printers we have to be able to produce even more and faster.

I hope they will give me their agreement. I think they will...

As I was running out of filament rolls, I also contacted a french manufacturer to order a few more and explained what it was intended for. The company was closed but did answer me and was kind enough to offer 2 rolls for free. I really appreciate that and can only say a BIG thank you!

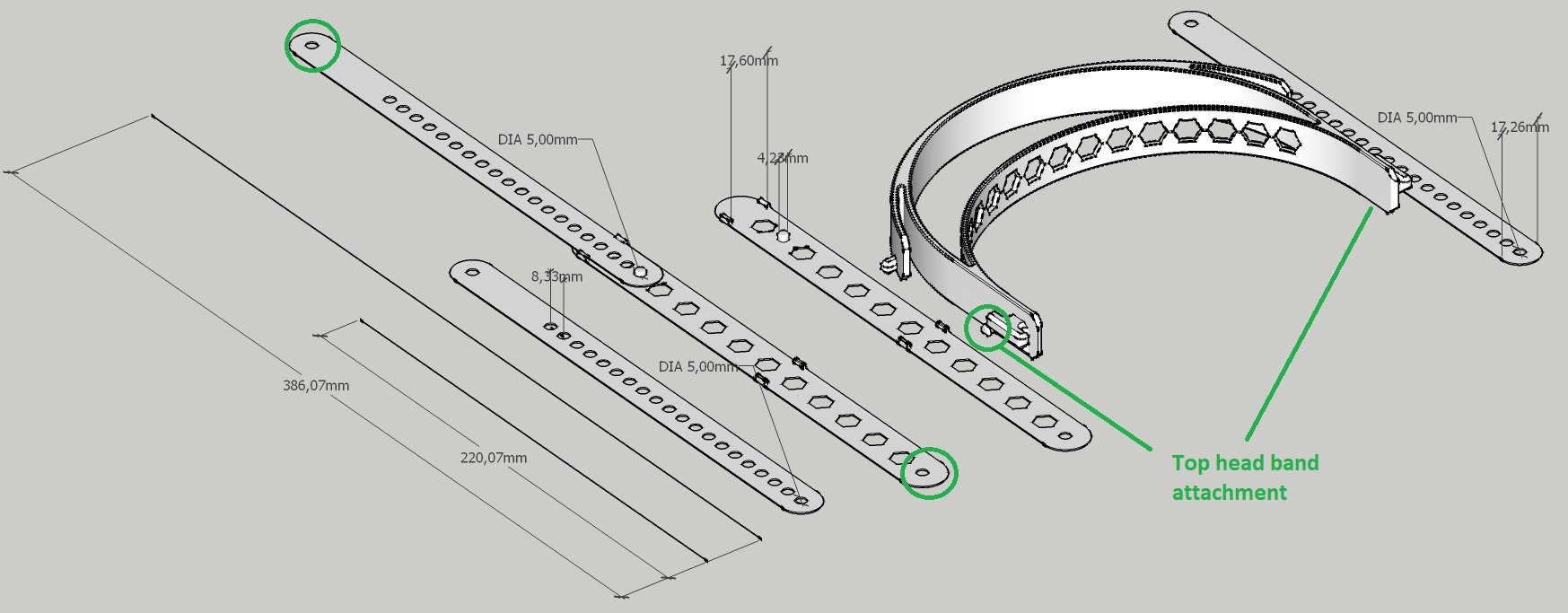

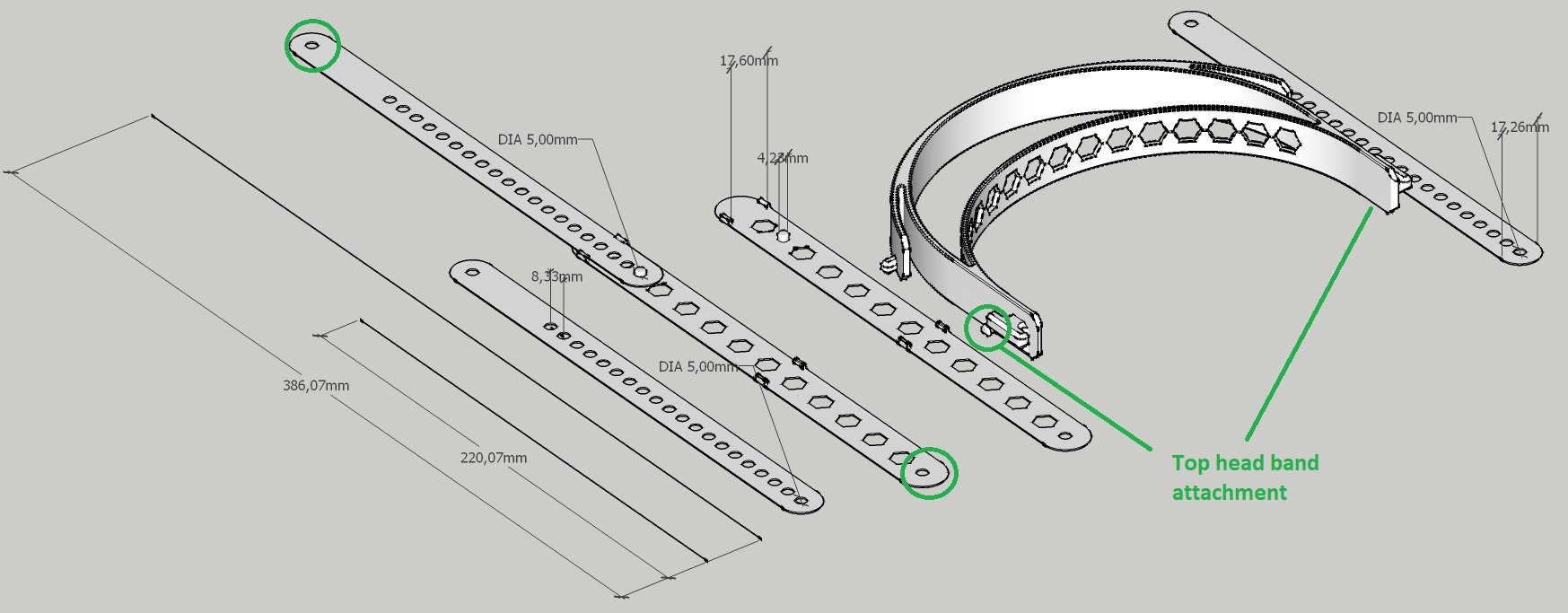

The other thing I did is to try to improve the comfort of these face shields by adding an adjustable top head band. It can be extended from 220 to 386mm by 8.33mm increments. I don't know if the comfort will really improve because I'm not the one wearing them all day long.

Here is my Prusa's face shield fork in case someone would like to try it (all engraved text was also removed for shorter print time):

Download STL files: Prusa_fork.zip

A friend of mine asked me why I don't print the 3DVerkstan version instead. So I gave it a try...

While it can print twice faster as the Prusa, it's unusable because it twists as soon as you wear it.

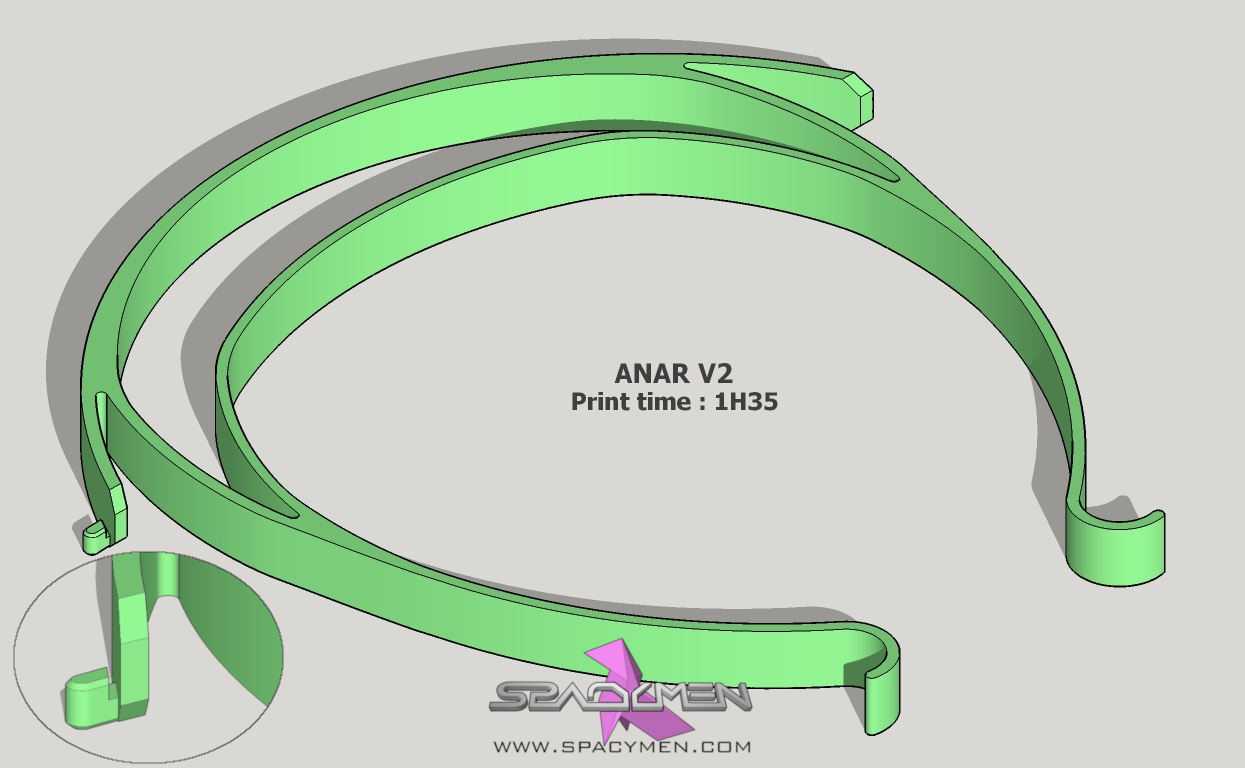

I then decided to make my own design with the advantages of both versions and came up with a version that can print as fast as the 3DVerkstan with the comfort of the Prusa.

It doesn't need a rubber band and doesn't twist.

You may download it here.

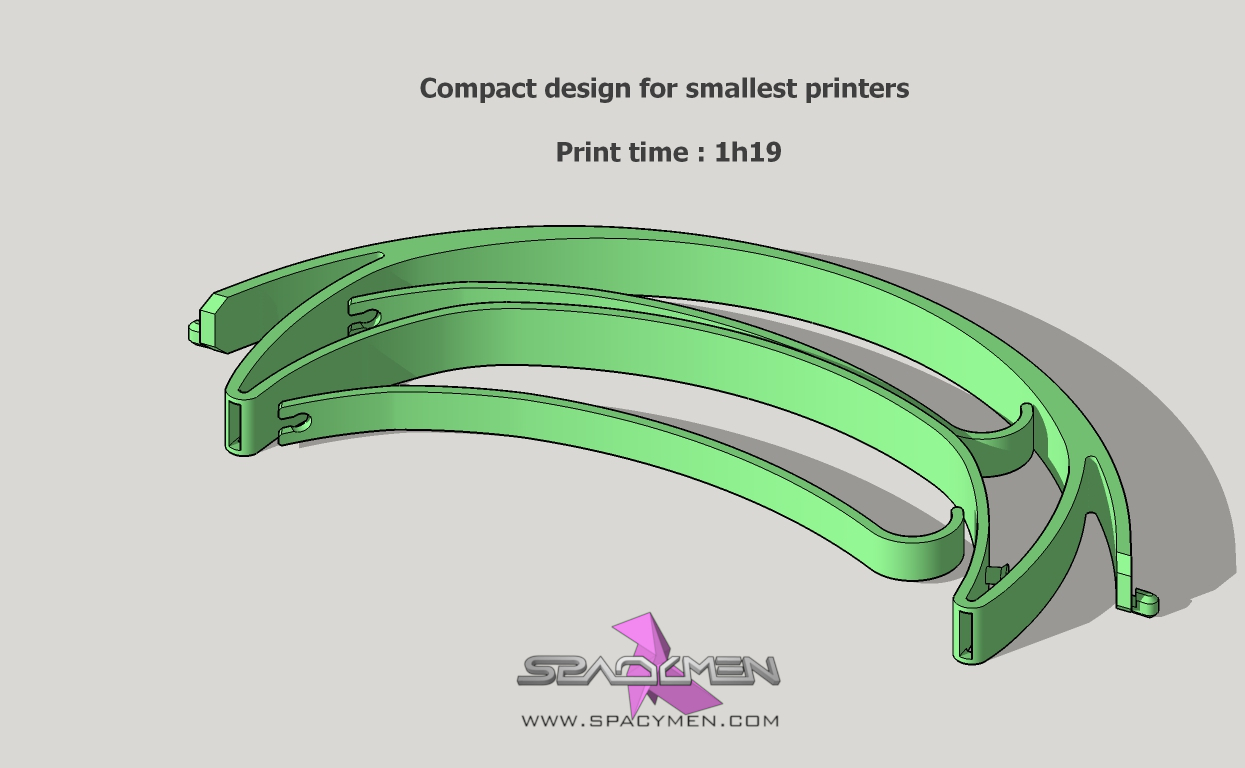

And a "maker" told me he couldn't print my face shield because his printer's platform was too small.

So I also made a compact version. In fact this version works so well that I decided to print it instead of my previous version (V2).

It let me pack and print much more pieces at once.

You may download it here.

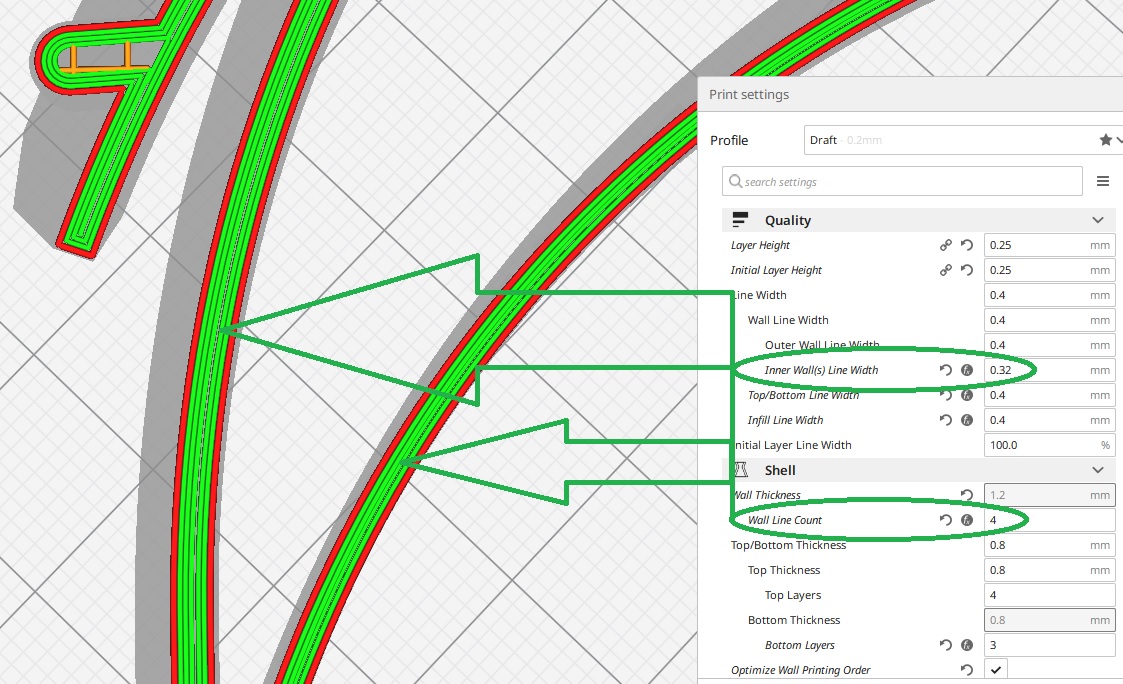

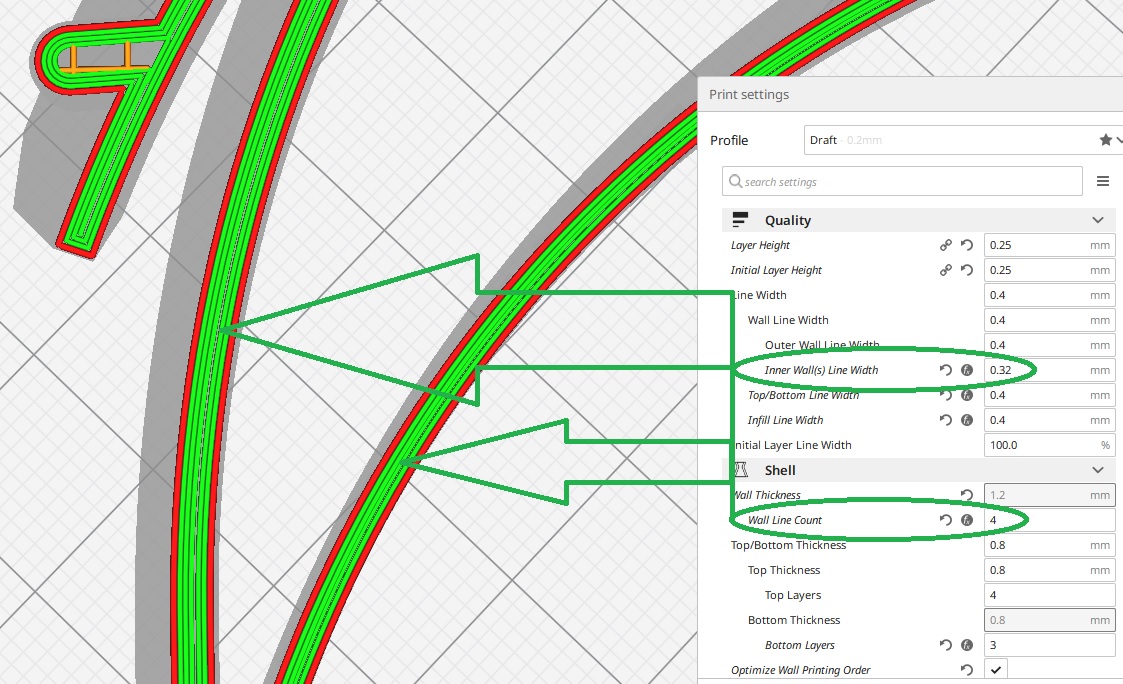

But more important is to set the inner wall width correctly to have a nice toolpath in the center of the walls instead of a regular infill to avoid "shaking" and "stress" on the machine:

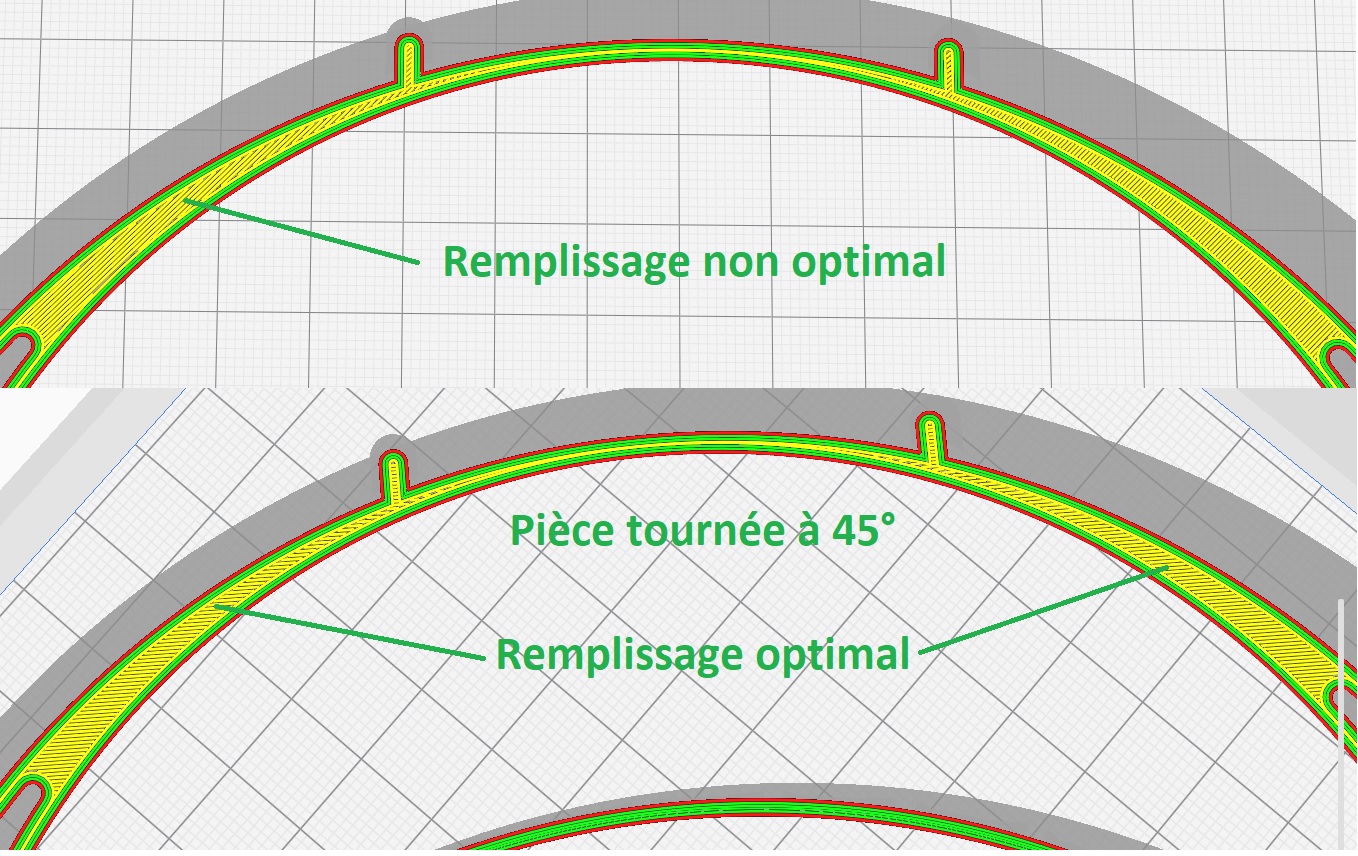

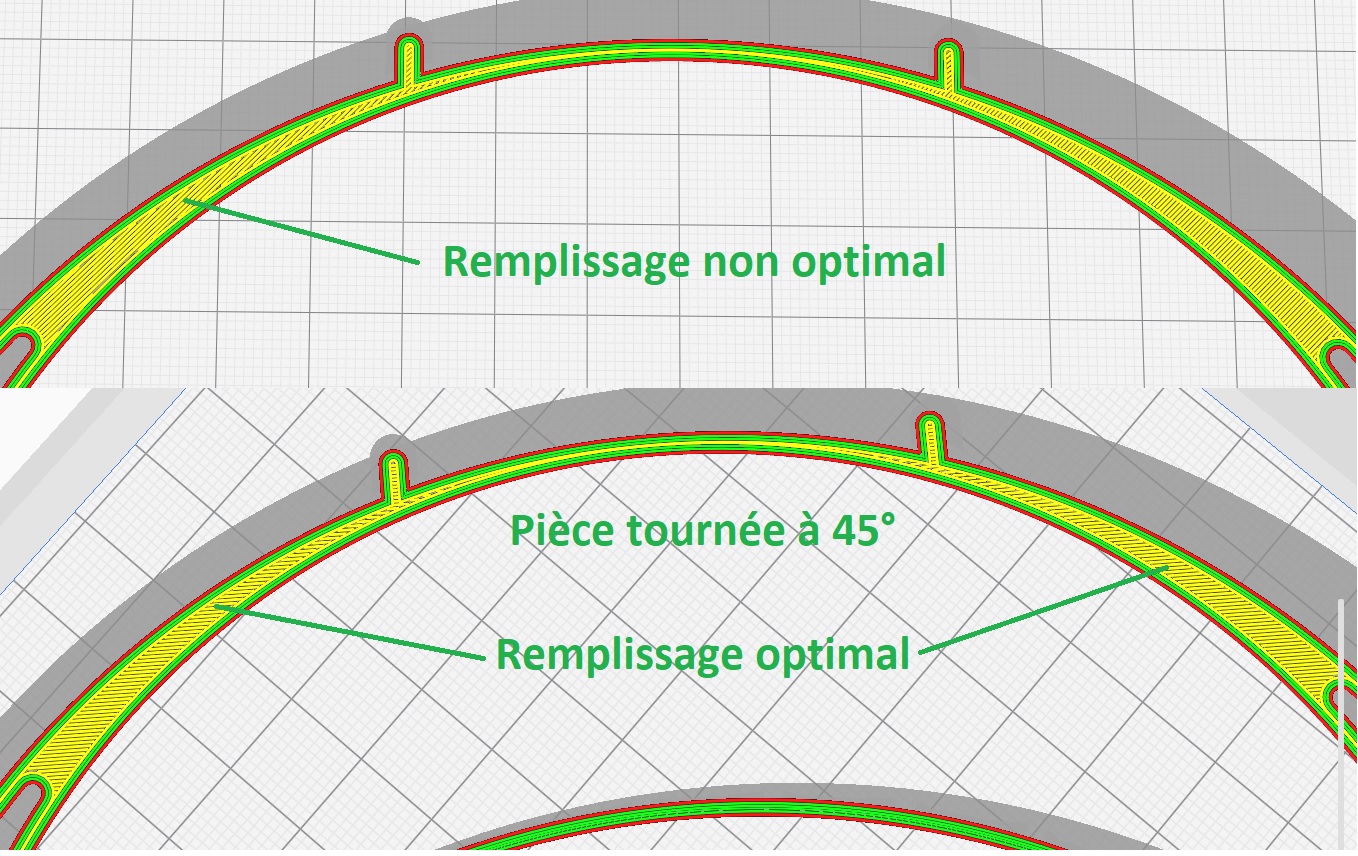

The other thing I noticed is that with the default orientation of the mesh on the platform with the default infill pattern for tops and bottoms (45°/135°) is not ideal.

By turning the mesh 45° you can get a much better and elegant one which lead in a stronger part. There's a Cura setting to modify the default 45°/135° but it doesn't produce what I expected.

You will notice Cura won't let you turn the mesh 45° pretending it's too big which isn't true.

It's because Cura's estimate of volume is based on the mesh's bounding box. By turning it 45° in an external app solves the problem:

Here's an optimised version of the original Prusa face shield (defeatured and 45° oriented):

RC2_optimized.zip

RC3_optimized.zip

I've seen a project to produce customized masks based on a photogrammetry of the patient's face.

While being a good idea, I think this method is too long and needs the patient to be able to take several good photos. If he is alone at home it might even become a more difficult task.

I then remembered a demo web application I had seen some time ago that can produce a 3D face based on a single photo.

I was sceptical about the quality of the result but decided to give it a try for custom mask production.

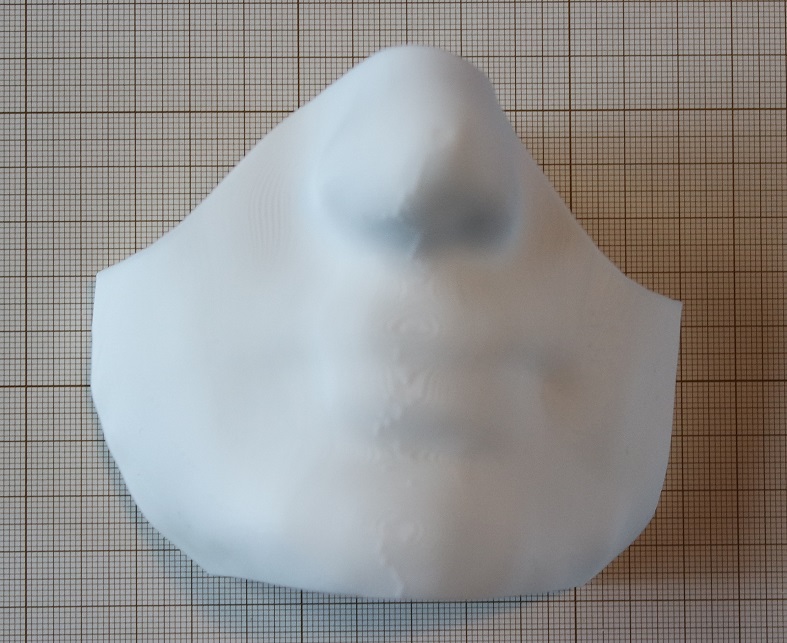

My 1st tests are showing that the result isn't that bad and the printed test part I've made is fitting my face quiet well.

But one of the problems is that the resulting mesh from that web application is not up to scale. But it can be corrected by taking a few measurements of your own face and calculate a scale factor.

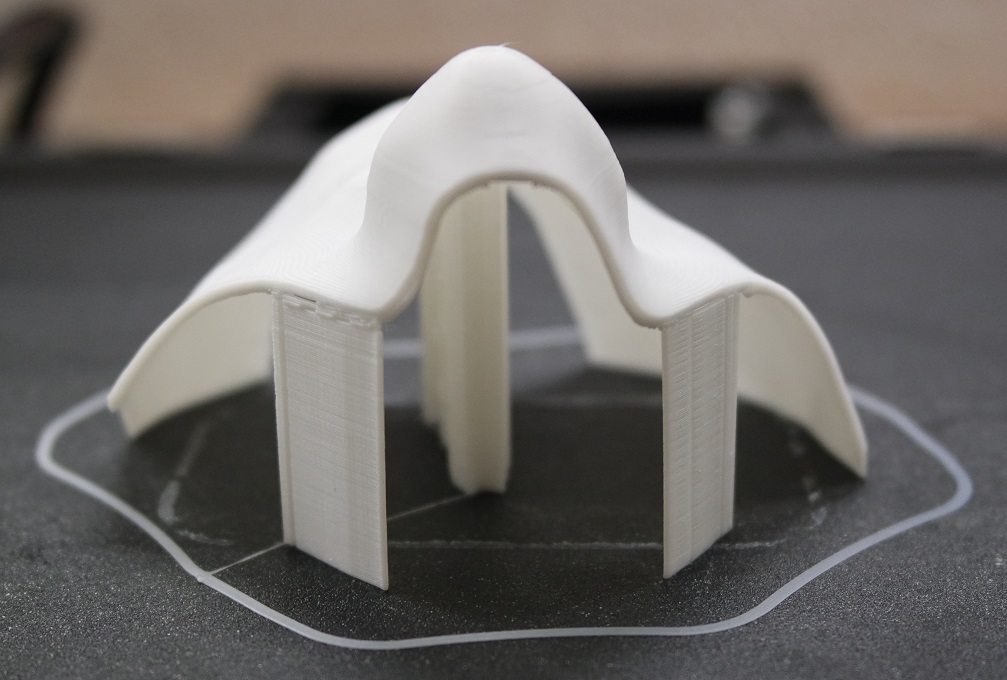

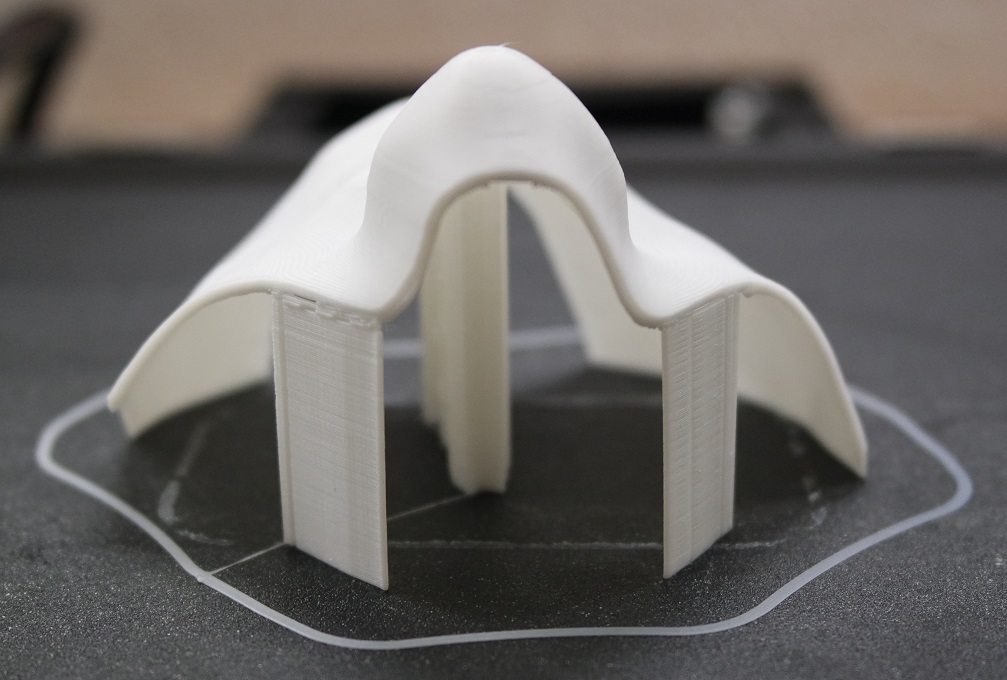

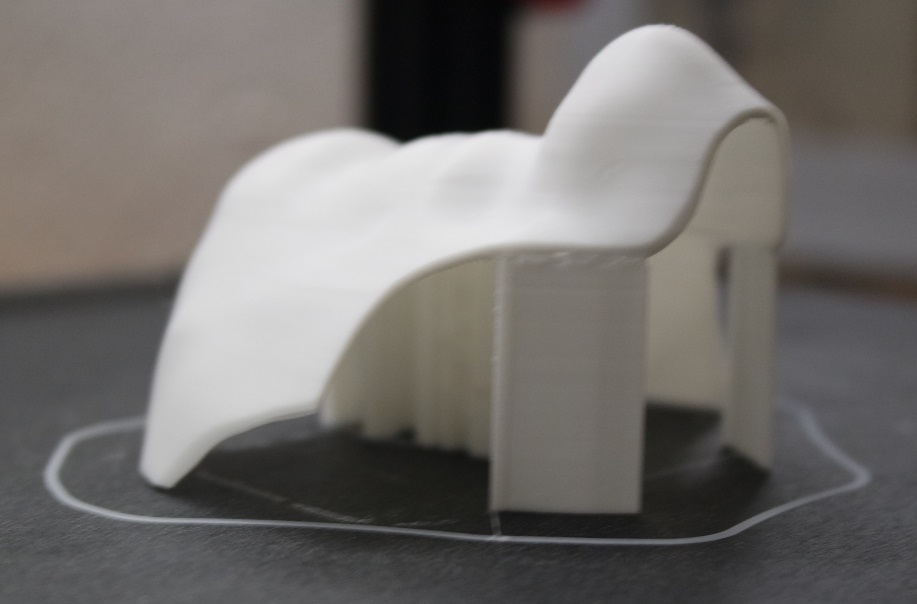

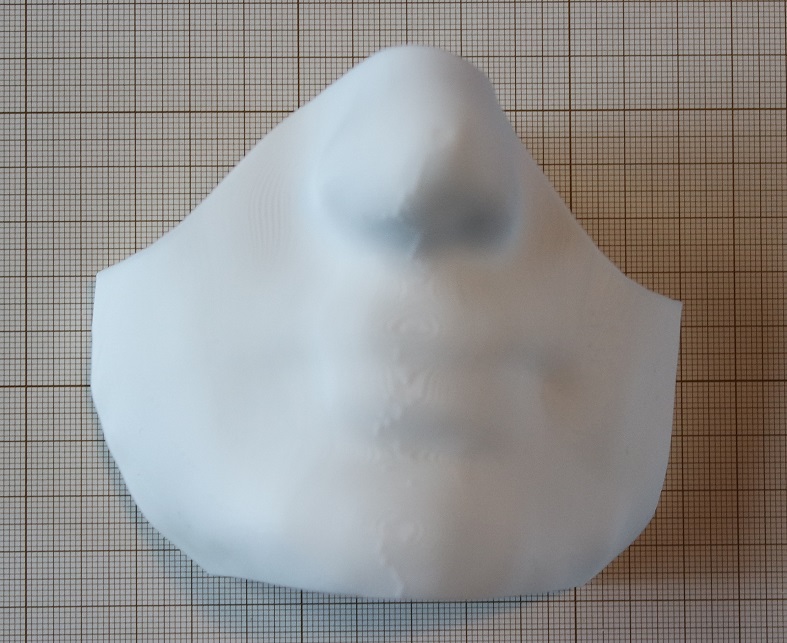

Here are photos of my test mesh scaled, offseted and printed:

In order for this method to be easier for the patient, it would be better if we could avoid him taking measurements. It would also avoid the scaling up step in the design process.

So I contacted the programmer of this web app but didn't receive any answer so far.

The source code is on Github but I don't have neither the time nor the competence to understand and modify the code. Maybe someone could catch on that.

One more thing...

I'm not quiet sure that it's a good idea to print 3D masks. They will probably be very uncomfortable unless printed with soft material. And I'm also not quiet sure about the safety of such materials...

Maybe using PLACTIVE material ?

Or Polycaprolactone that could be soften and better adapted to the patient's face ?

Protective face shields

Our school Fablab, in coordination with other university Fablabs of the Paris-sud campus, has decided to bring its small contribution by providing protective face shields to nearby hospitals because there's a huge demand.Unfortunately I'm stuck at home at the moment, and all our 3D printers are still in our Fablab where we're not allowed to go.

But as I have a personal printer I could start printing. The printer is running 24 hours a day and the first shields will be sent to hospitals on next Monday (April 2nd).

The printed shields are looking great and should be efficients. So far so good.

Here is a photo of the first printed ones:

I've been asking my school if I could go back to our Fablab to bring back home the printers we have to be able to produce even more and faster.

I hope they will give me their agreement. I think they will...

As I was running out of filament rolls, I also contacted a french manufacturer to order a few more and explained what it was intended for. The company was closed but did answer me and was kind enough to offer 2 rolls for free. I really appreciate that and can only say a BIG thank you!

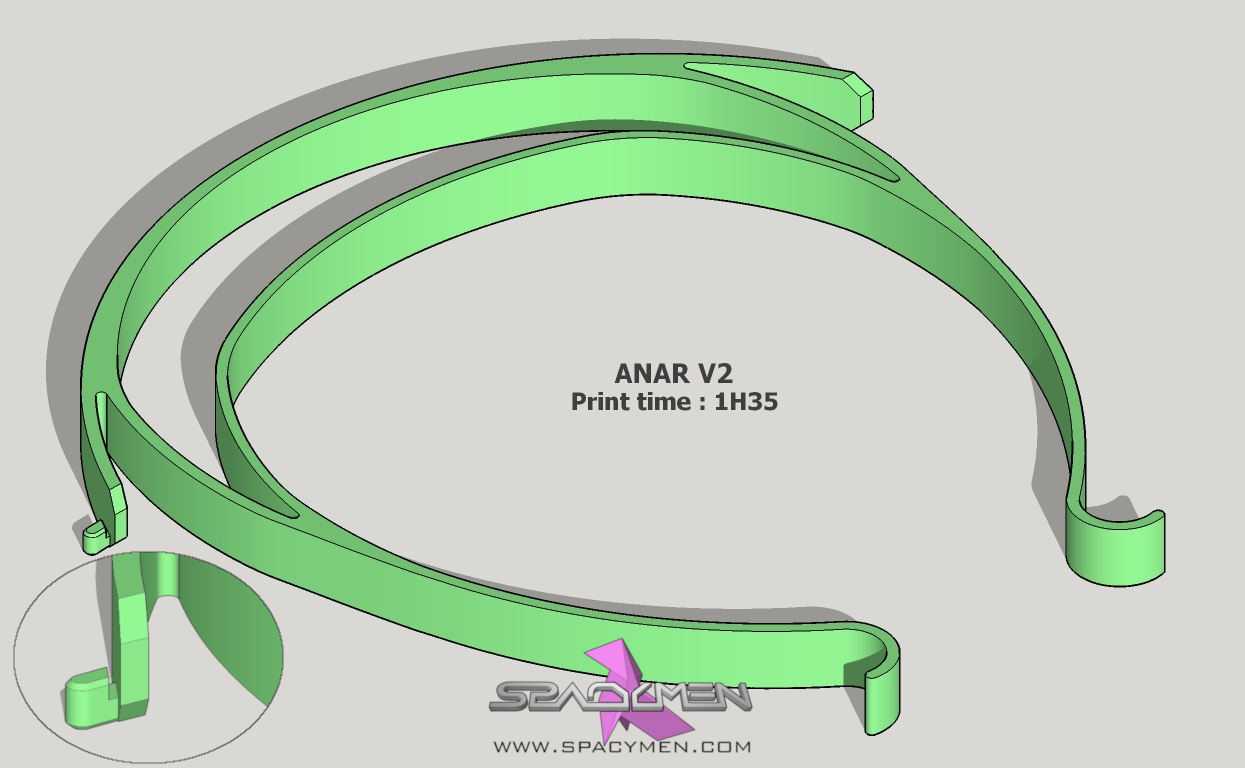

The other thing I did is to try to improve the comfort of these face shields by adding an adjustable top head band. It can be extended from 220 to 386mm by 8.33mm increments. I don't know if the comfort will really improve because I'm not the one wearing them all day long.

Here is my Prusa's face shield fork in case someone would like to try it (all engraved text was also removed for shorter print time):

Download STL files: Prusa_fork.zip

A friend of mine asked me why I don't print the 3DVerkstan version instead. So I gave it a try...

While it can print twice faster as the Prusa, it's unusable because it twists as soon as you wear it.

I then decided to make my own design with the advantages of both versions and came up with a version that can print as fast as the 3DVerkstan with the comfort of the Prusa.

It doesn't need a rubber band and doesn't twist.

You may download it here.

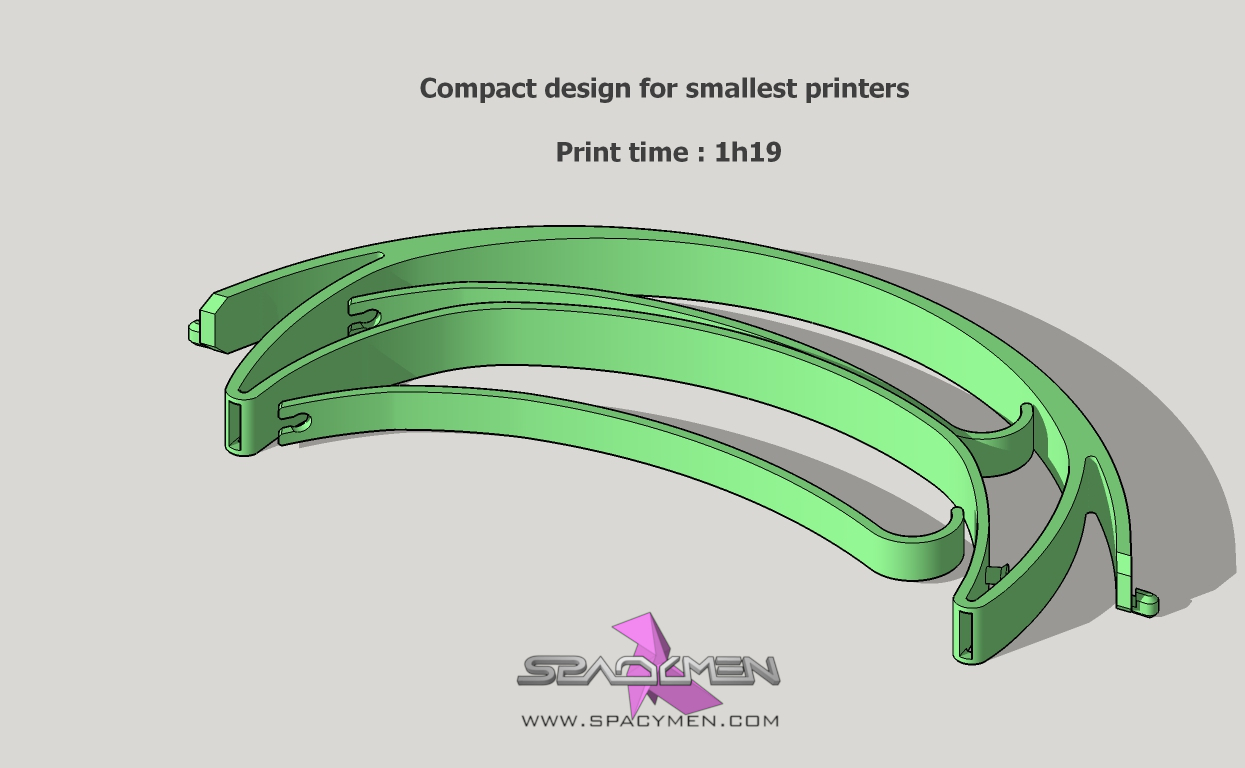

And a "maker" told me he couldn't print my face shield because his printer's platform was too small.

So I also made a compact version. In fact this version works so well that I decided to print it instead of my previous version (V2).

It let me pack and print much more pieces at once.

You may download it here.

Optimised Cura settings

After a lot of settings and trials I could lower print time down to 2h57mn on an old Ultimaker 2. But for a better quality/speed ratio I finally slowered it and am now printing it in 3h47mn.But more important is to set the inner wall width correctly to have a nice toolpath in the center of the walls instead of a regular infill to avoid "shaking" and "stress" on the machine:

The other thing I noticed is that with the default orientation of the mesh on the platform with the default infill pattern for tops and bottoms (45°/135°) is not ideal.

By turning the mesh 45° you can get a much better and elegant one which lead in a stronger part. There's a Cura setting to modify the default 45°/135° but it doesn't produce what I expected.

You will notice Cura won't let you turn the mesh 45° pretending it's too big which isn't true.

It's because Cura's estimate of volume is based on the mesh's bounding box. By turning it 45° in an external app solves the problem:

Here's an optimised version of the original Prusa face shield (defeatured and 45° oriented):

RC2_optimized.zip

RC3_optimized.zip

Test for customized face masks

Nearly everyday I keep an eye on new designs that could help in the COVID-19 fight.I've seen a project to produce customized masks based on a photogrammetry of the patient's face.

While being a good idea, I think this method is too long and needs the patient to be able to take several good photos. If he is alone at home it might even become a more difficult task.

I then remembered a demo web application I had seen some time ago that can produce a 3D face based on a single photo.

I was sceptical about the quality of the result but decided to give it a try for custom mask production.

My 1st tests are showing that the result isn't that bad and the printed test part I've made is fitting my face quiet well.

But one of the problems is that the resulting mesh from that web application is not up to scale. But it can be corrected by taking a few measurements of your own face and calculate a scale factor.

Here are photos of my test mesh scaled, offseted and printed:

In order for this method to be easier for the patient, it would be better if we could avoid him taking measurements. It would also avoid the scaling up step in the design process.

So I contacted the programmer of this web app but didn't receive any answer so far.

The source code is on Github but I don't have neither the time nor the competence to understand and modify the code. Maybe someone could catch on that.

One more thing...

I'm not quiet sure that it's a good idea to print 3D masks. They will probably be very uncomfortable unless printed with soft material. And I'm also not quiet sure about the safety of such materials...

Maybe using PLACTIVE material ?

Or Polycaprolactone that could be soften and better adapted to the patient's face ?