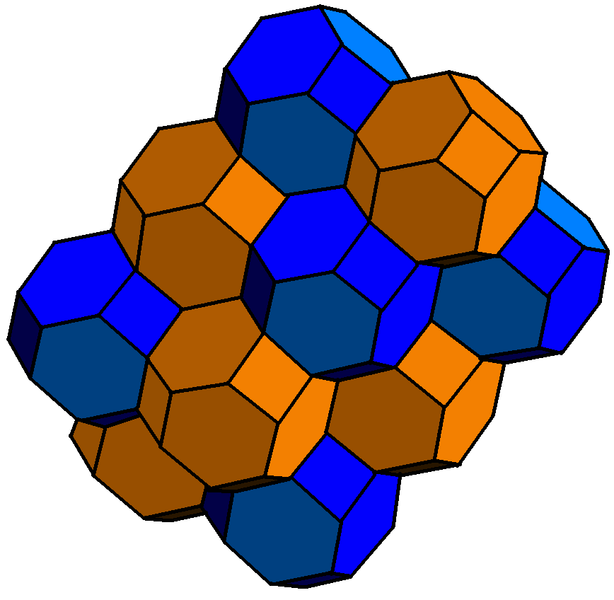

Space tesselation¶

In this case I was interested in some space tesellation. You can see the full project in the project tab (Space tesellation) but here it is as well.

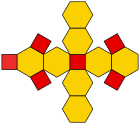

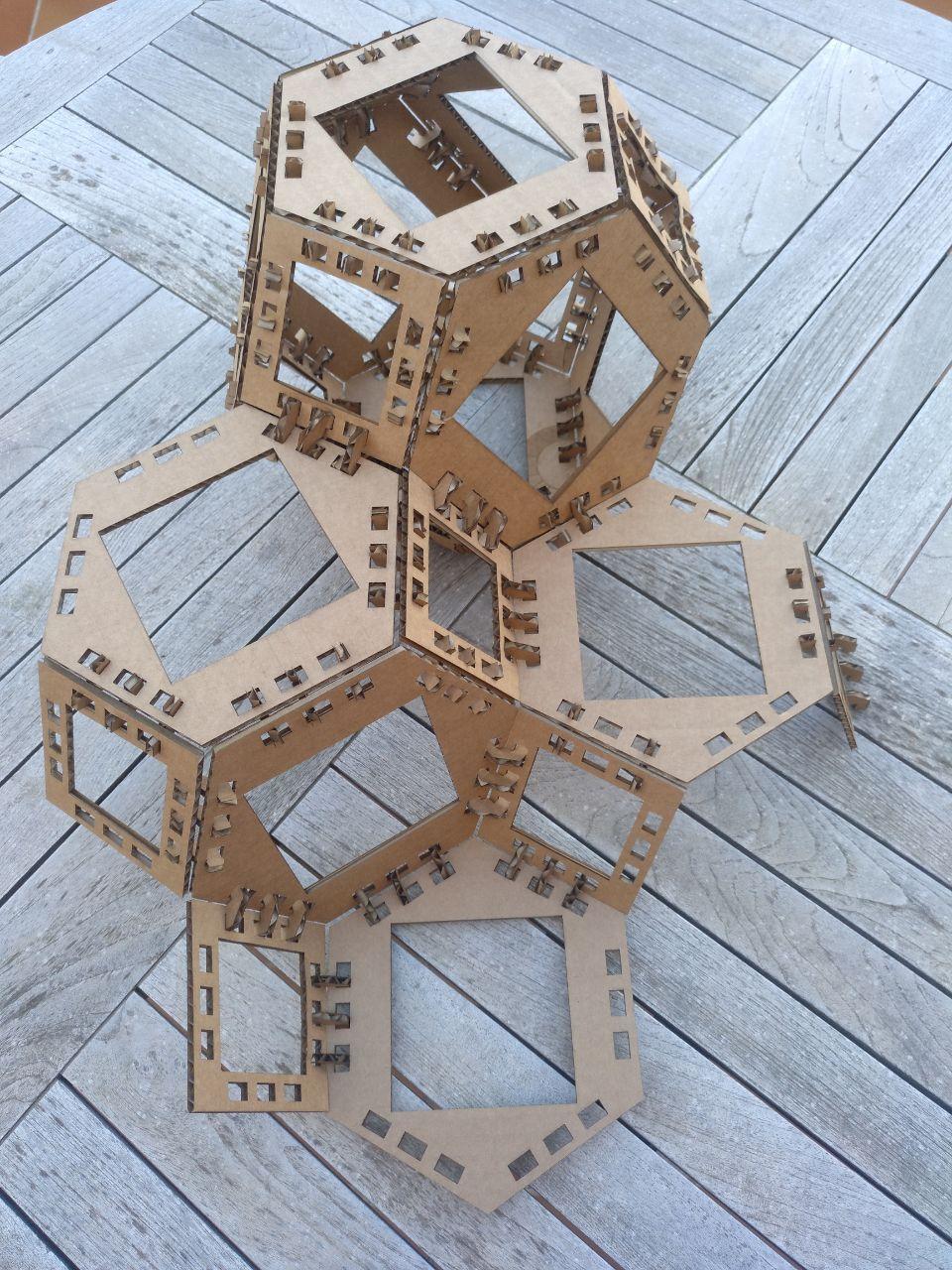

I wanted to copy the tesellation of the plane you can do with hexagons in a honeycomb or with several paterns of polygons. I wanted to make it the next level and avoid using cubes or prismatic shapes (that are the solutions of the 2d plane but extruded) so I stumbled upon the truncated octaedra. This poliedric shape consist on 6 squares and 8 hexagons with the same side. And putting next to each other you can fill the space in several dimensions.

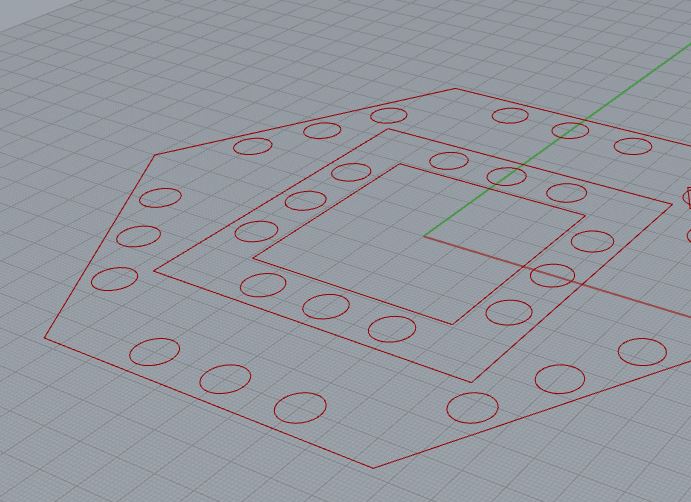

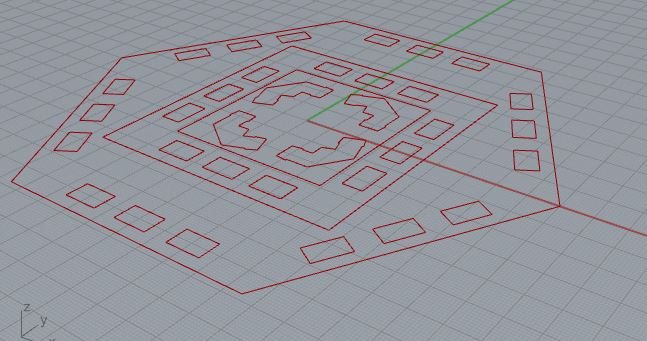

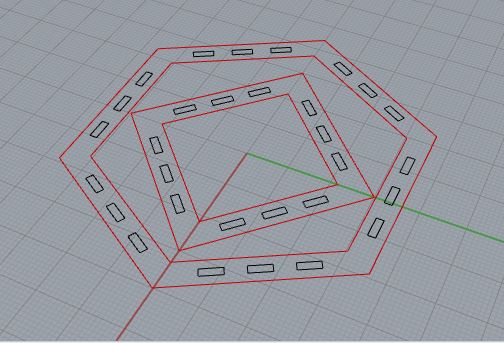

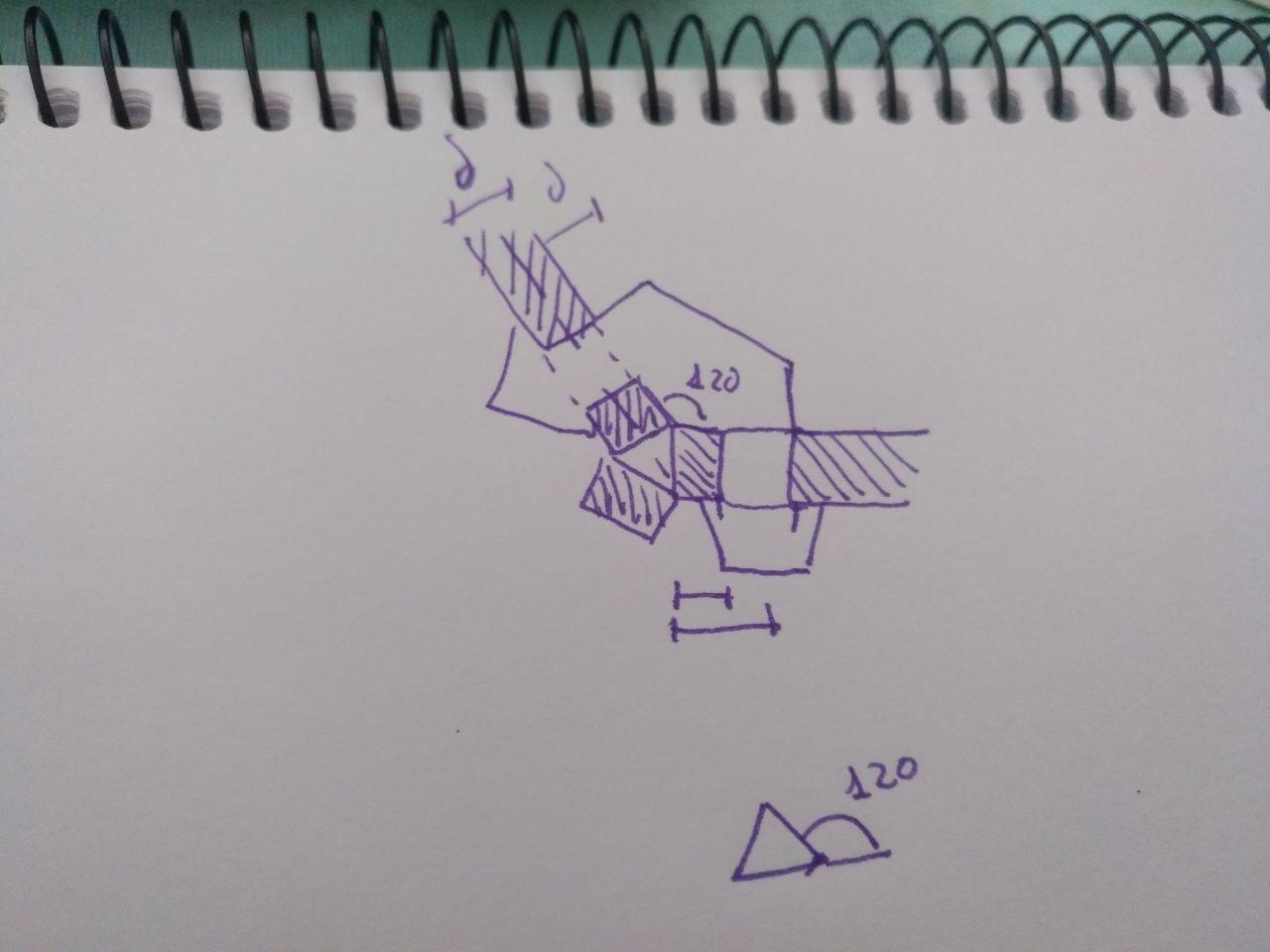

Skeches and first drafts undestanding the geometry:

Result¶

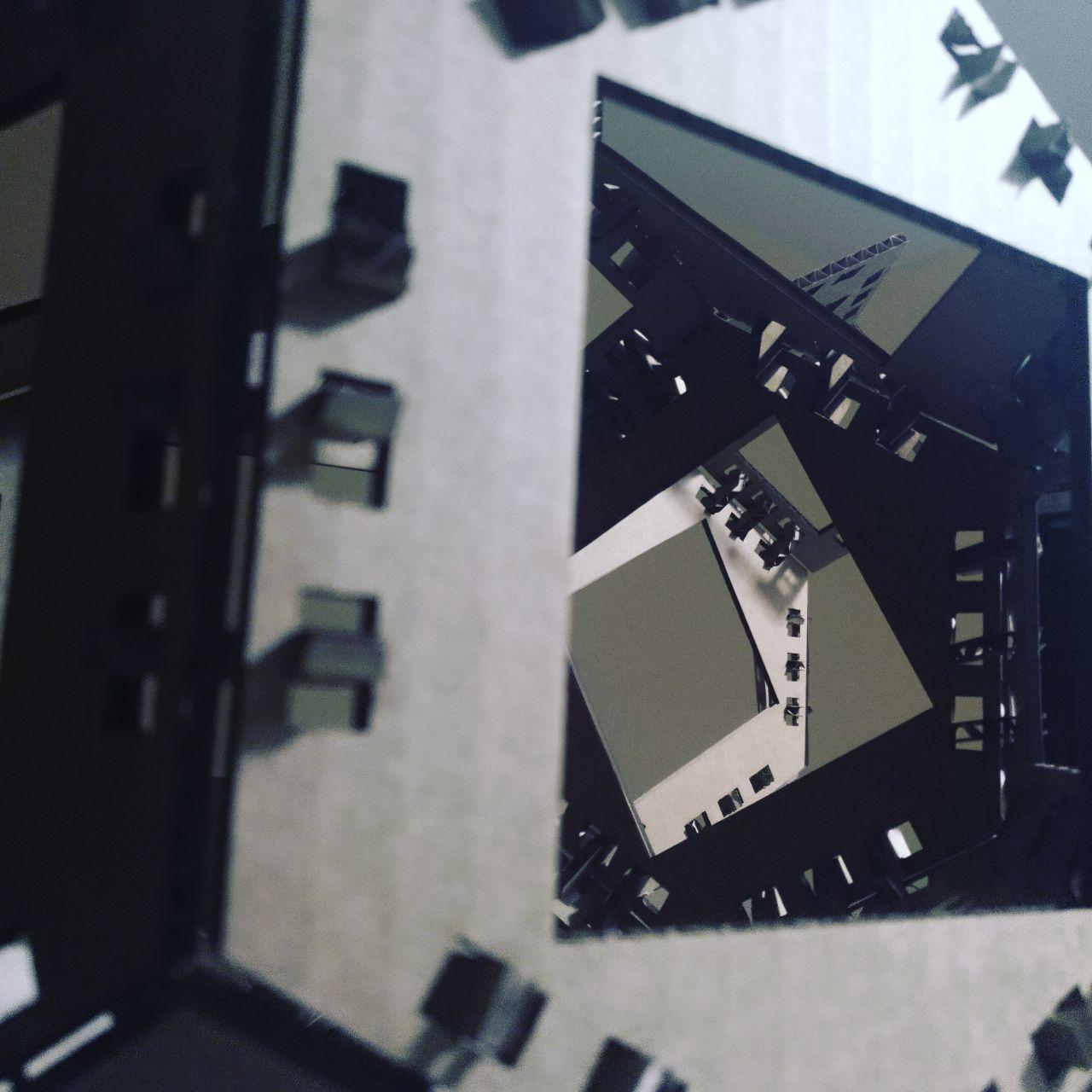

Some final abstract images:

Process¶

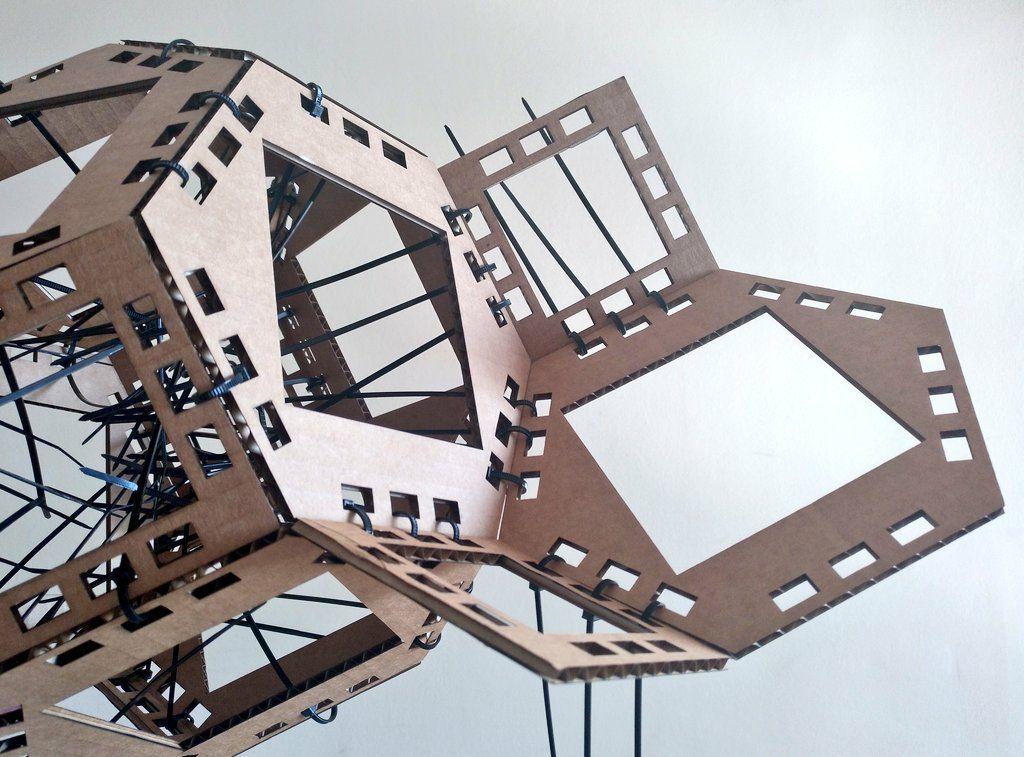

I wanted to do some spacial prototipe and go away from the Usual H-shaped joints. So I imagined some hexagons and sqares joint with plastic brackets. So they will be lasered cutted with some holes to fit the plastic brackets that will join the edges.

So to make the parametric design I thought of faces interconected side by side with auxiliary plastic connectors. And I made the grasshopper to make these shapes n-sided with n holes to interconect the brackets.

As soon as I told this to the instructors they told me that this doesn’t fit the assigment.

Going after something that fits the assigment!¶

After coping with it. I went back to grasshopper to change and improve my design. I could keep good part of the design and build on that. Instead of doing some circular holes, I can draw rectangles and afterwards design the joints that could be clicked.

(make those rectangles align to the sides was tricky)

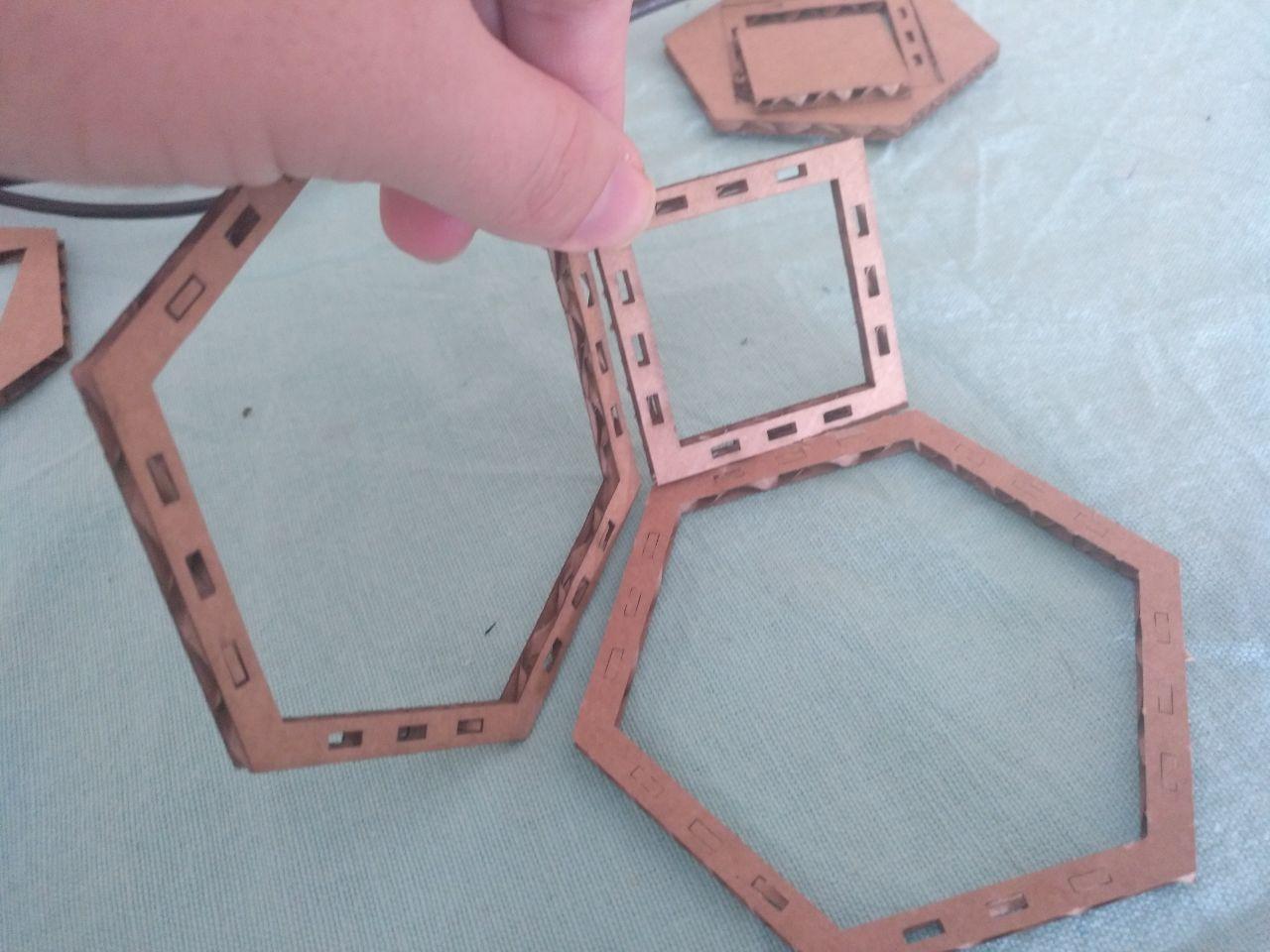

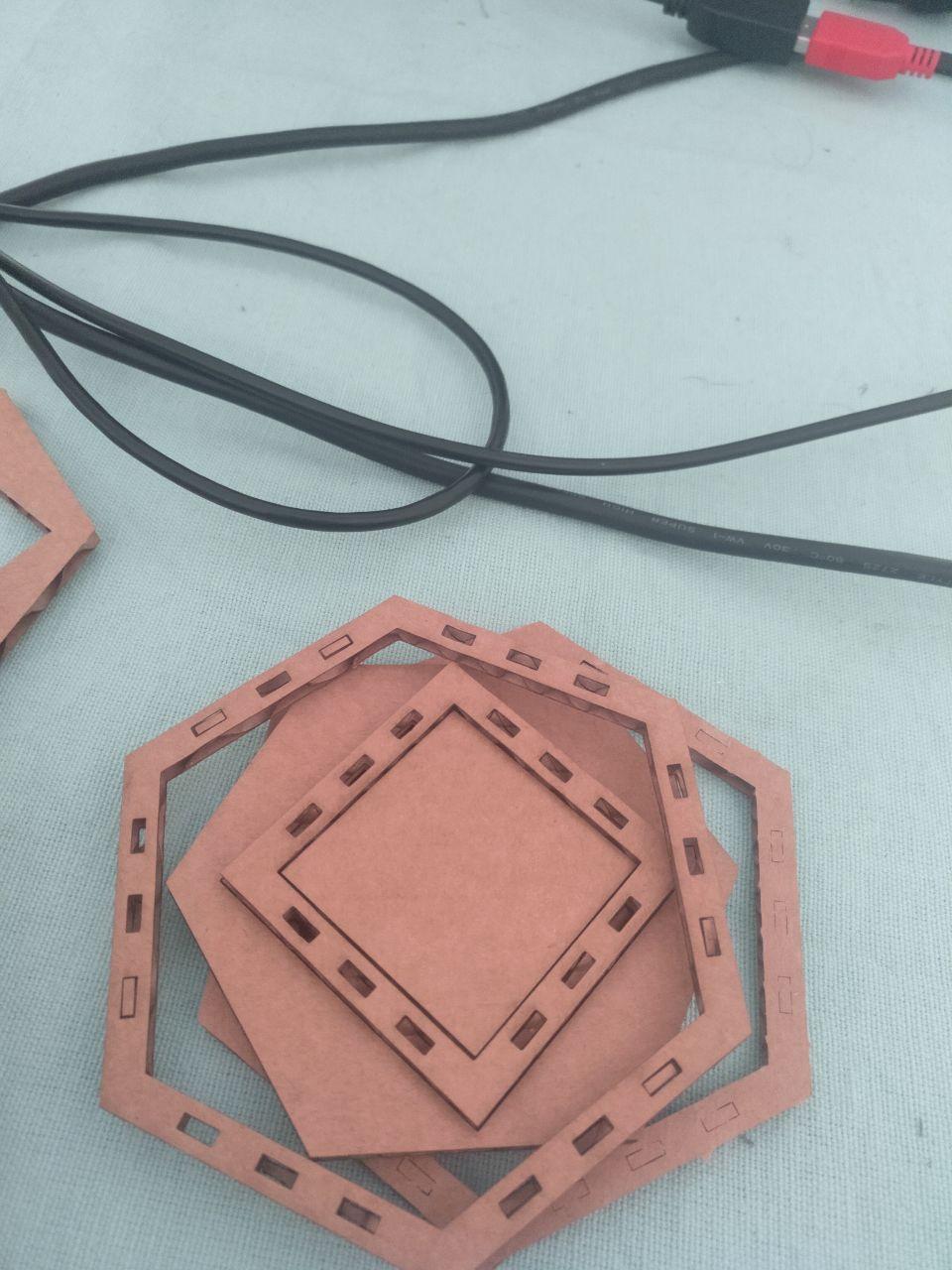

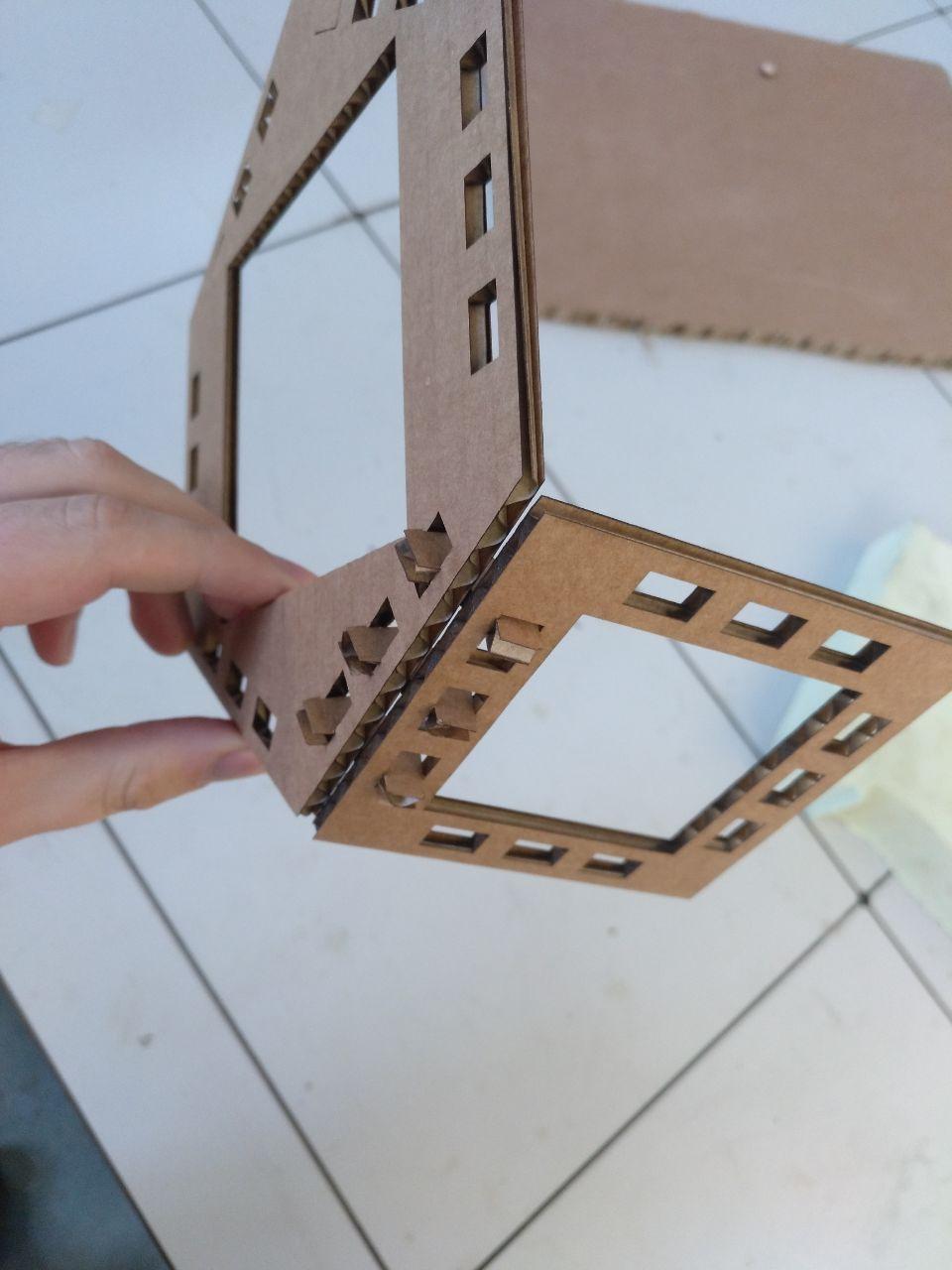

So first I made the faces and tested them. They were too small so thanks to grasshpper I could make the design bigger in no time.

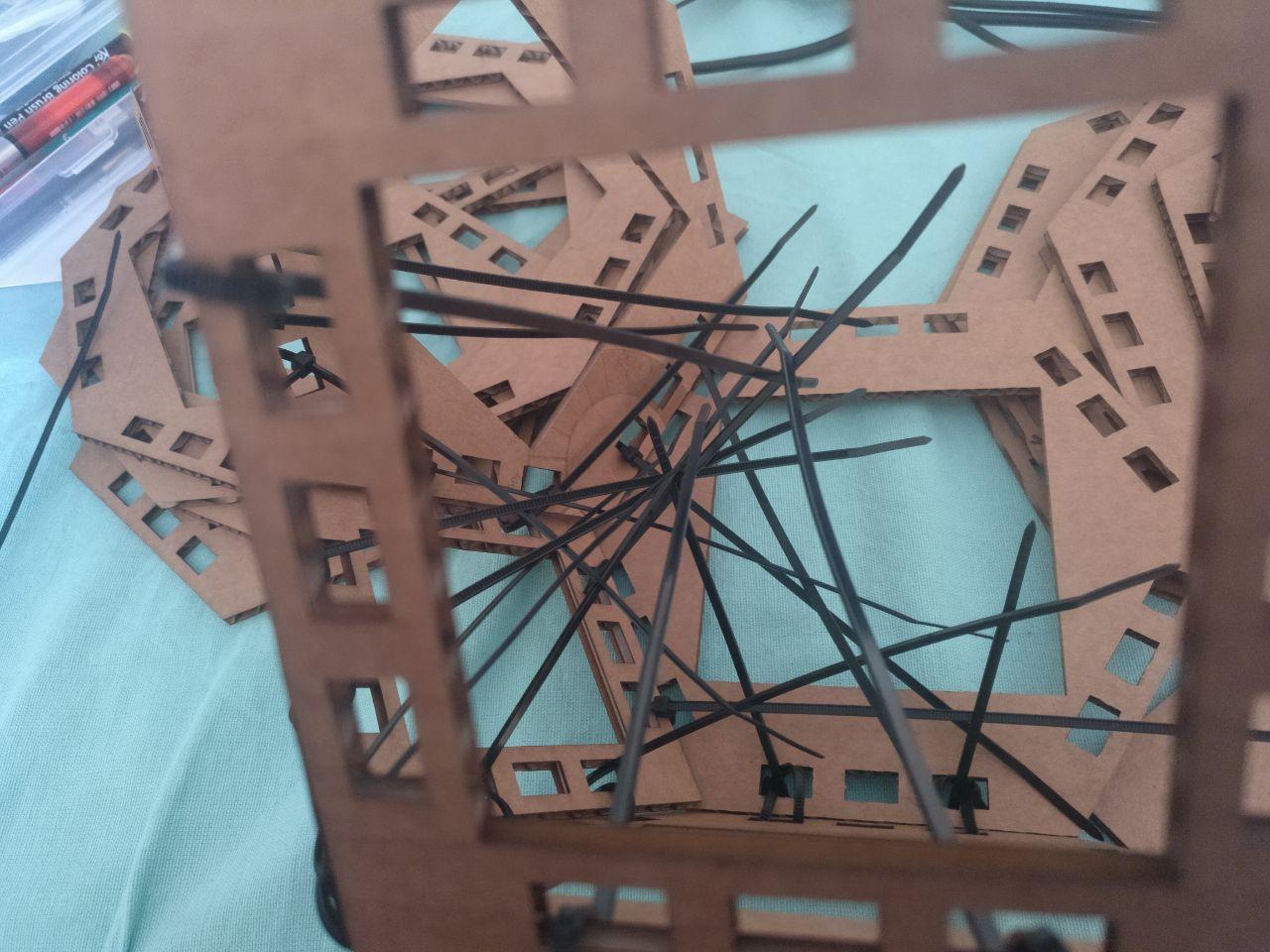

first cutted prototipe

first cutted prototipe

It was too small and too thin and it wasted space in between pieces. It also helped me to adjust the power and the speed of the laser. (small trotec, 4mm cardboard, 40 power, 1 speed, 1000 Hz frecuency)

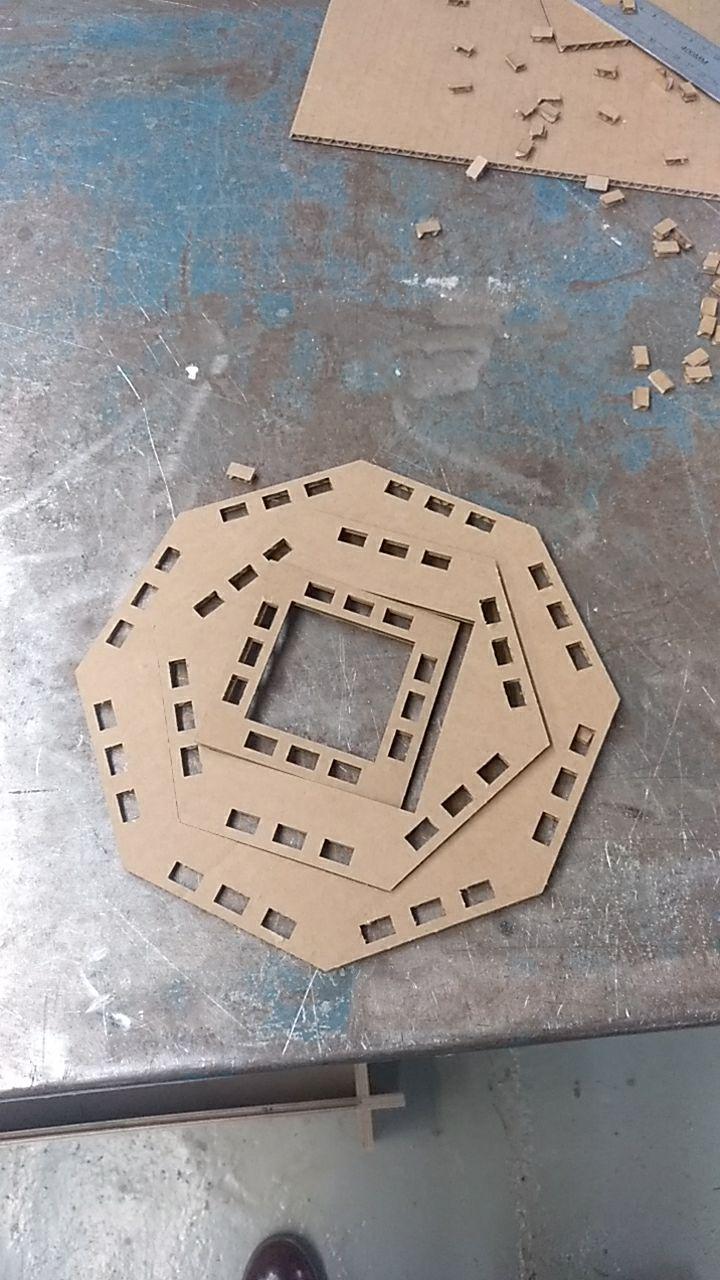

here you can see the wasted material

here you can see the wasted material

I also tweaked the design a bit to put the squares and the hexagons one inside another. And I added the Octagon just for fun and testing other sizes. (Octagon can be used also with combination of triangles and make somethink like this)

So I cutted

After I cut the pieces and I was happy with them, I noticed there were a lot of little holes of waste that I don’t want to be burned by the laser, so I cleaned it by taking out the bed.

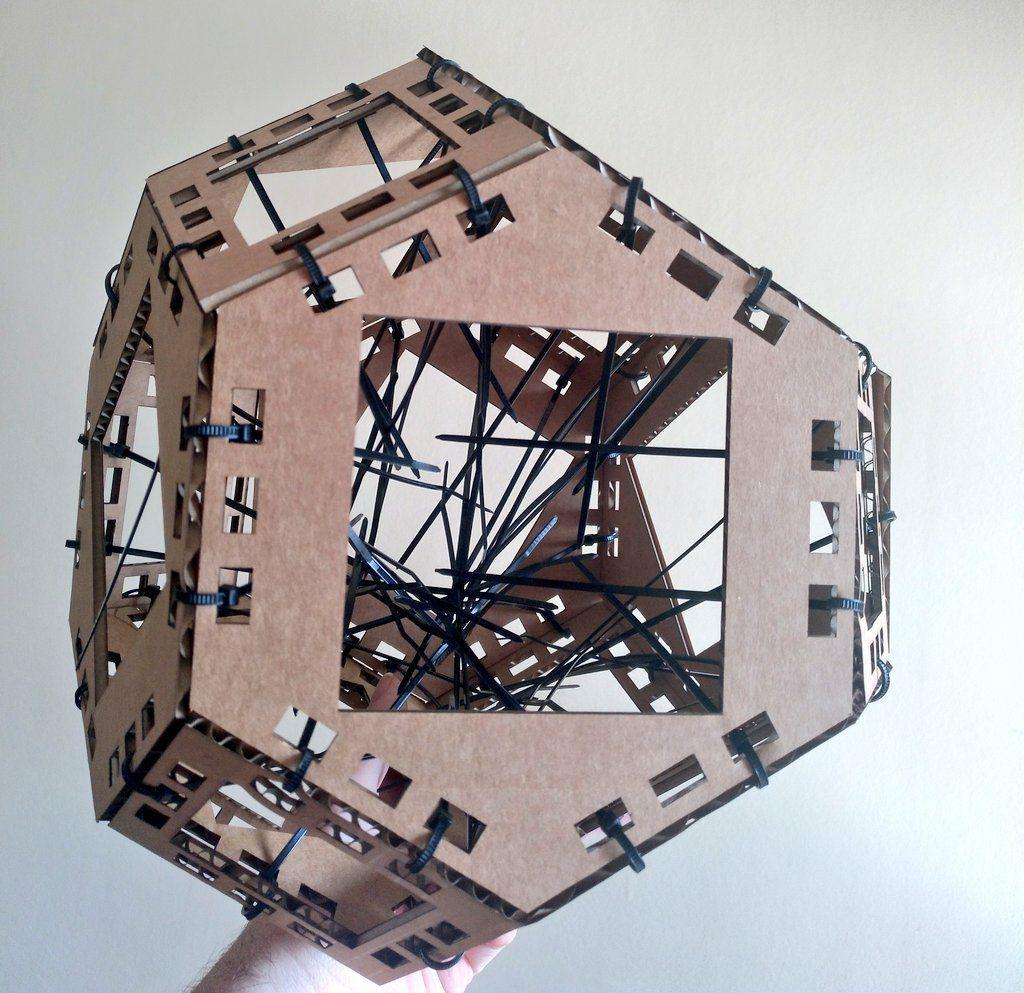

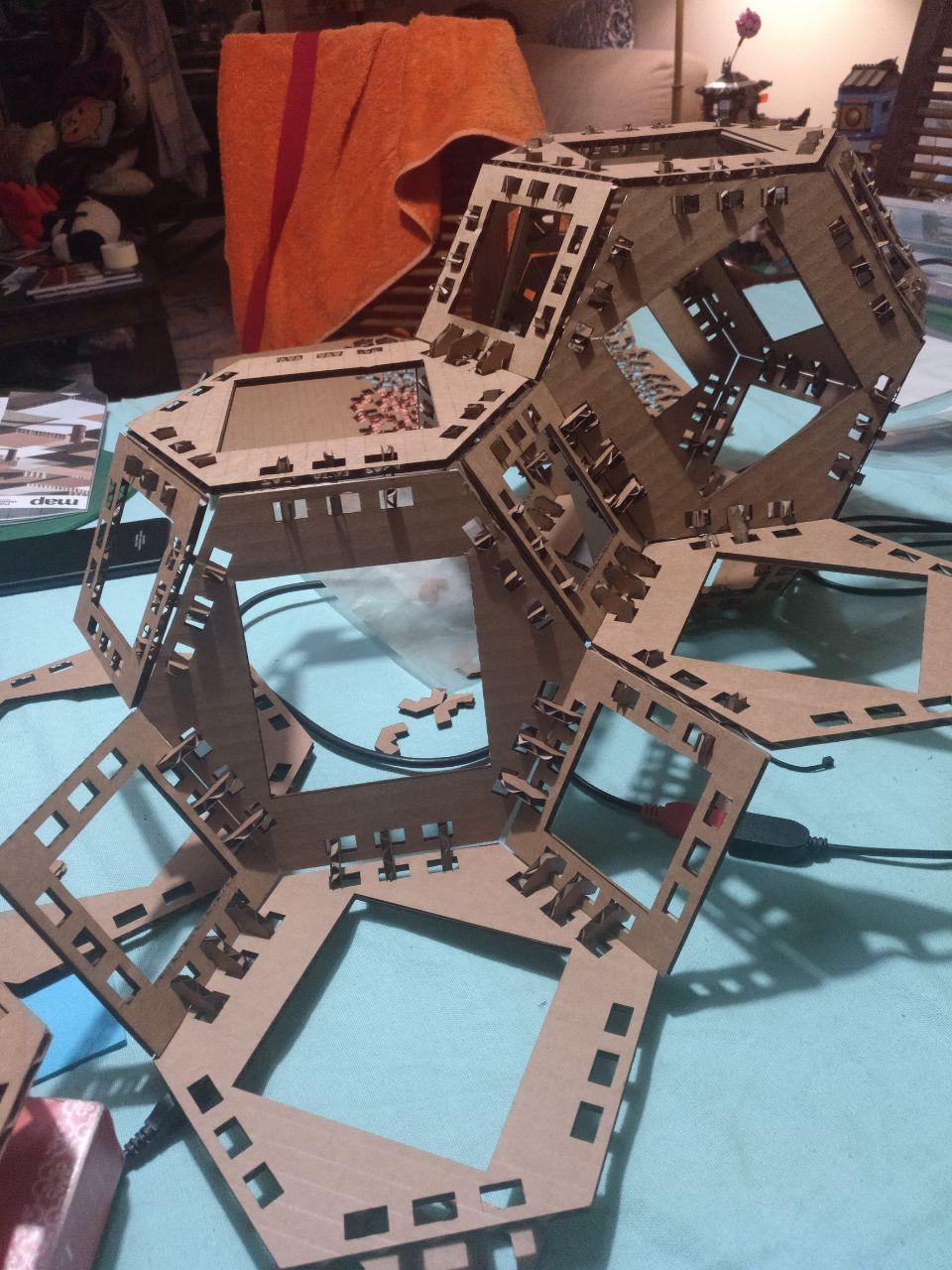

I could cut all the faces of the poliedron and make a couple more. The weekend I assembled the pieces with plastic stripes (in a way so I could reuse the stripes since I don’t like to make waste).

Assemble complete!

Assemble complete!

Extra sides for you!

Extra sides for you!

Designing the joint¶

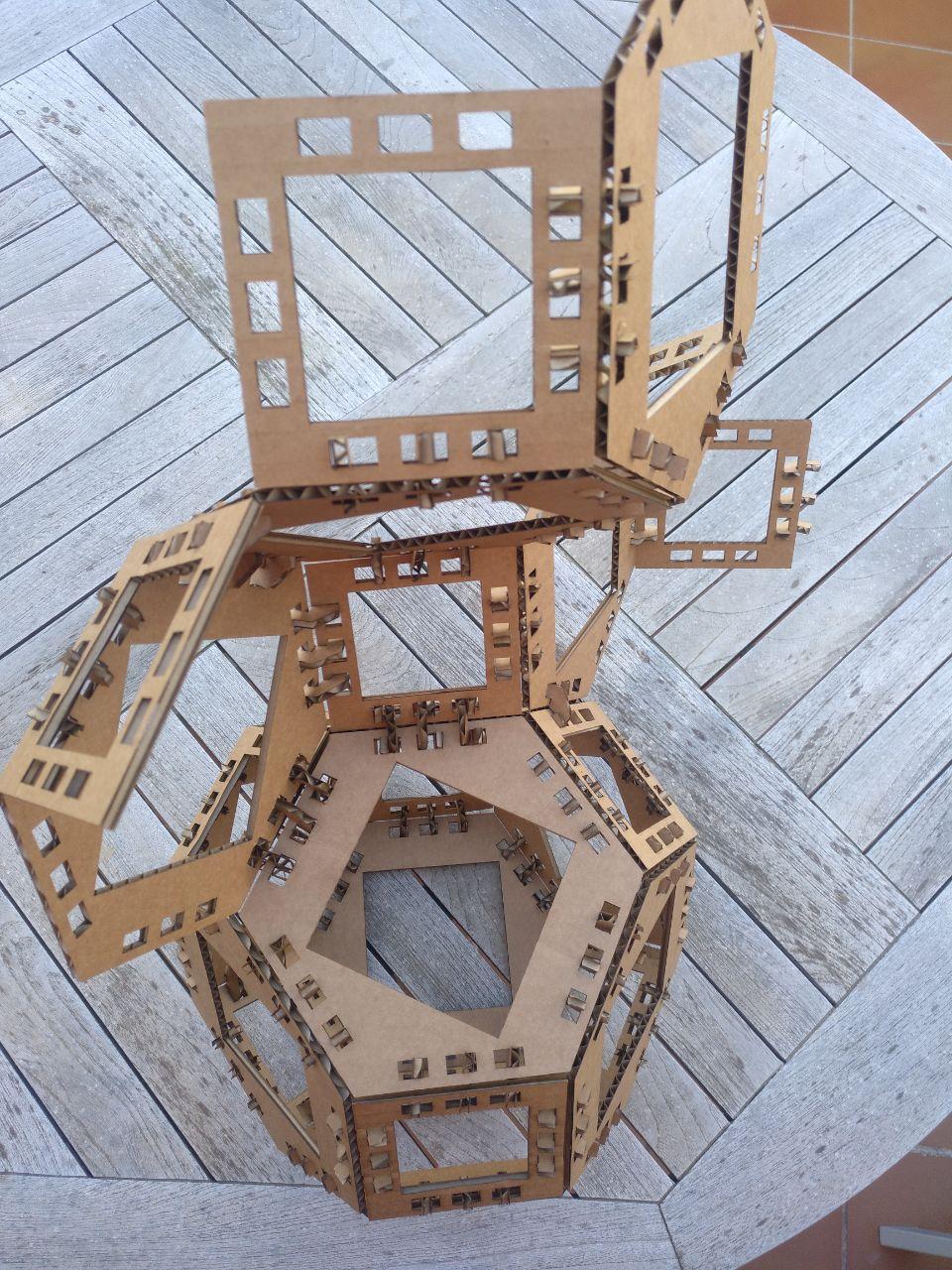

This was a bit tricky for me since in Grasshpper I had to make the dots be moved and arrange so I could make the polyline. I added a click with a arrow shape to fit better 2 of the sides and now one of the parameters was the angle between the faces that was a constant of 120 degrees. It was easy to confirm that after I mounted the first prototipe with the stripes.

In this case I was ignoring the kerf in porpuse because I was using cardboard and I’m relying on the flexibility of the cardboard and hopped that the arrow was enough to fit properly.

After a first test that fitted Hurray!

yaaaaay

I made another test to see how it works with more angles and also cut a couple of faces more. (Now without octagons)

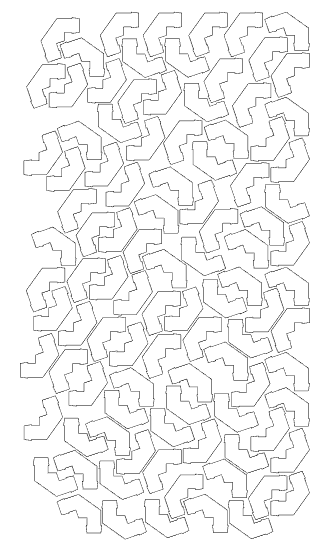

Now I counted that I needed 108 joints in total for the poliedron. So I installed Deepnest.io and, boy that was amazingly useful to make 100 copies fittet properly.

Nesting it’s so cool they can make from this:

This:

So I cutted them and some more faces and I mounted them at home ant I have my space tesellation.

descriptive image

descriptive image

descritpive image

descritpive image

Here the plastic stripes that can be used once again.

Problems¶

-

One thing I couldn’t figure out it’s how are the points of the holes situated that was depending of the offset so with the different number of sides it was a little different. In this case was close enough but it need to be tweaked for extarpolate for other polygons so the holes are properly situated.

-

Cardboard can resist a couple of fits but it’s easily degraded.

-

The joints are fragile. They work fine together but when you mount and desmount the joints start to degrade at the third time you use them.

-

The design it’s not properly parametrized to change properly the angle of the joint (I used a mirror tool so it has to be tinkered)

Useful links¶

What I’ve learnt¶

-

Kerf it’s important when you have precision but you can dodge it with specific materials.

-

Grasshopper it’s long to do things but it’s rewarding and since it’s code it’s more reusable than drawings.

-

Deepnest.io it’s as amazing as they say. And the image they make it’s sometimes beautiful for other meanings.

-

Cardboard is an anisotropic material, specially in small pieces like the joints.

Possible outcomes¶

- Make other joints with other angles (90 degrees, 60, 135 degrees)

Design files¶

Remember to use download link as.. to download the files.

Me thinking of space tesellation: