1. Principles and practices¶

This week has been a first step towards learning how fablabs and fabacademy work.

Final project proposal¶

Working at the Haute Ecole Francisco Ferrer, in the department of Electronics, I’m in contact with other colleagues from other department who are interested in adding intelligence to their projects, eg smart textiles. Therefore, having though how to bring such projects into life, I decided to join the FablabULB on own initiative to accelerate the process and to take up the challenge

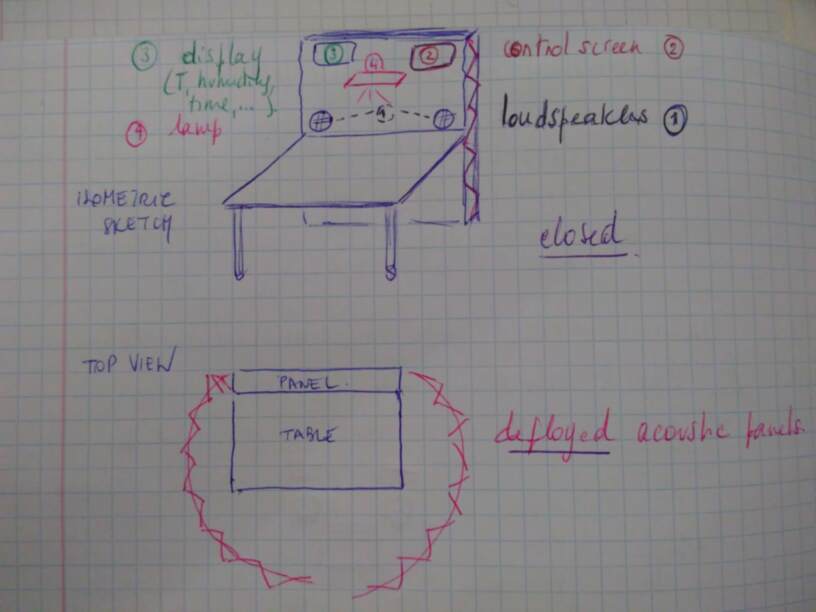

After brainstorming with colleagues from the applied Arts category, we decided to go for the “alcove office” , consisting of acoustic panel that can be automatically deployed around a desk, incorporating new technologies into the material itself. This would be a “première”, first real collaboration between the two departments (Applied Electronics and Applied Arts)

In a first instance, there could be a electrical/mechanical system to deploy the panel. In a second instance, the mechanism could be implemented in the material itself. This will be a challenge for the fabricademy!!

This system would be used in open space offices, where receiving or giving a phone call can be sometimes difficult or uneasy, forcing the person to move to a closed workspace. So, deploying the acoustic booth would allow the person to remain at his/her desk and still have a more intimate conversation.

And the interest to do it in the frame of the FabAcademy is that this project would use several techniques covered in the courses, at first glance: * Electronic system: microprocessor controlling the motors deploying the booth, and collecting ambiental data ( eg temperature, noise,…) * CNC milling of the supporting frame * laser cutting of the booth (tissue or felt, or…) * 3D printing of some supports

The costs will be evaluated in the development process.

Inspiring ideas: