Week 18

-

WILDCARD WEEK

Individual Assignment

Desig and produce something with a digital fabrication process (incorporating computer-aided design and manufacturing) not covered in another assignment, documenting the requirements that your assignment meets, and including everything necessary to reproduce it. Possibilities include (but are not limited to) composites, textiles, biotechnology, robotics, and cooking..

Design and produce something with a digital fabrication (INDIVIDUAL ASSIGNMENT)

This week I tried to make a "fabric" with MDF. This is not actaully mi original idea, I saw something like that on internet. Becuase I was never worked with this material before Fabacademy, I wanted to try things with it.

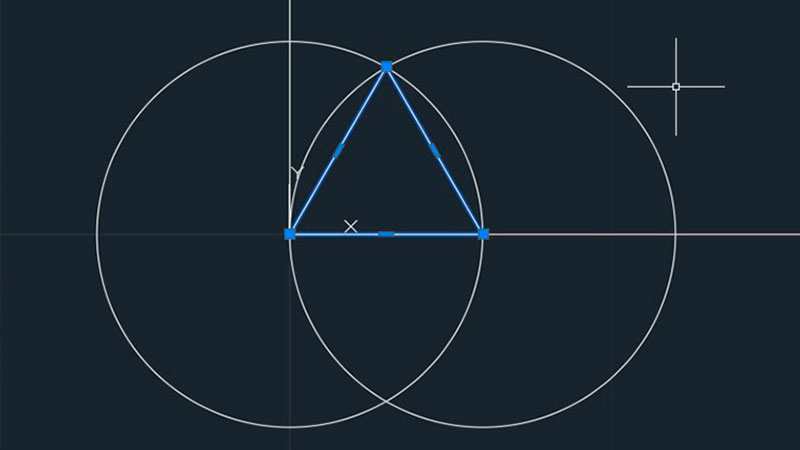

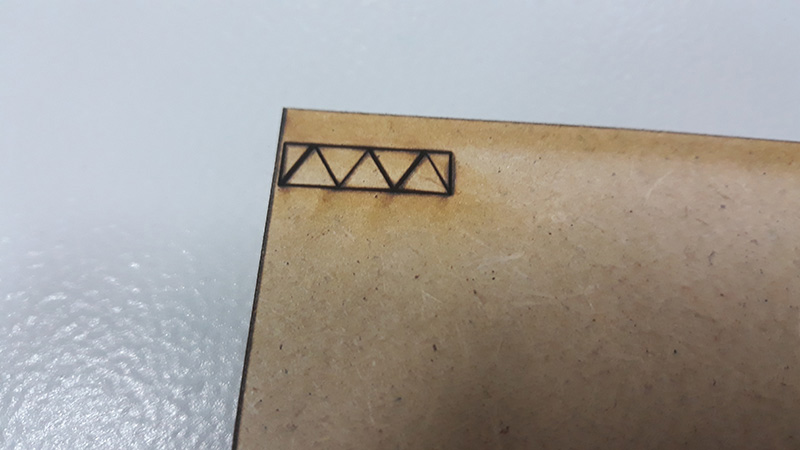

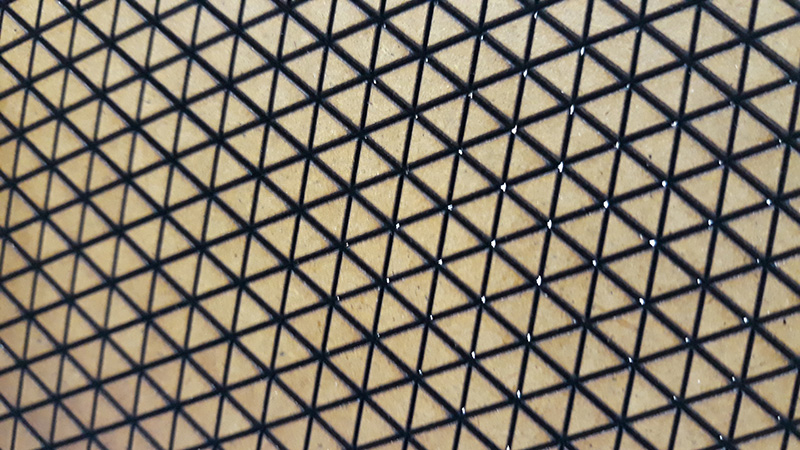

My first step was cut partially some triangles. I mean, I was trying to set the laser, to made a cut not through all the thickness. The idea was removed the triangles from the machine once, not each one.

My first try was successful, but I realise that was not scalable. For large quantities of triangles, lift all of them once, would be impossible.

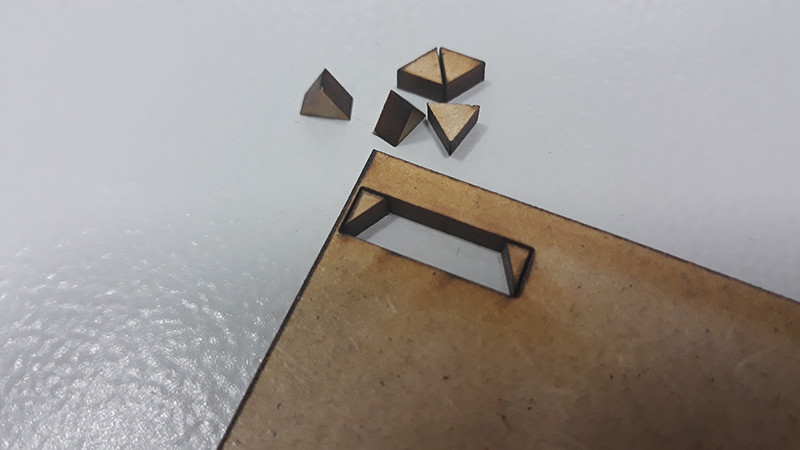

To make this process viable, I decided to use some backing. So, I used adhesive tape on the bottom side of the MDF board. That can retain the small triangles joined until I can used the silicone to made a permanent joint.

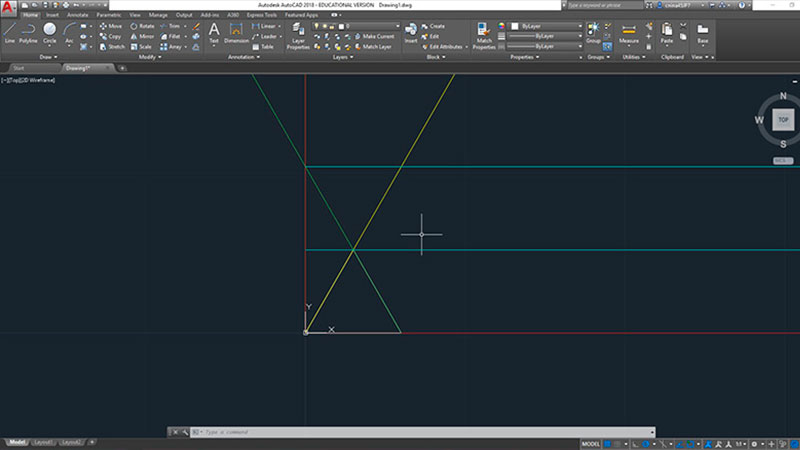

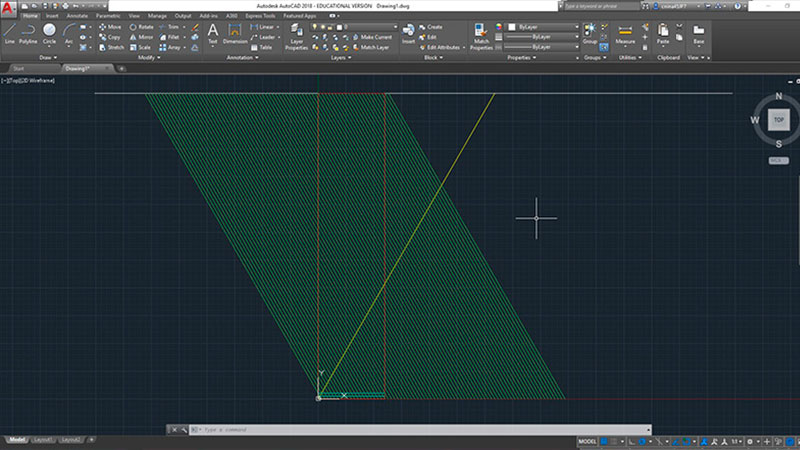

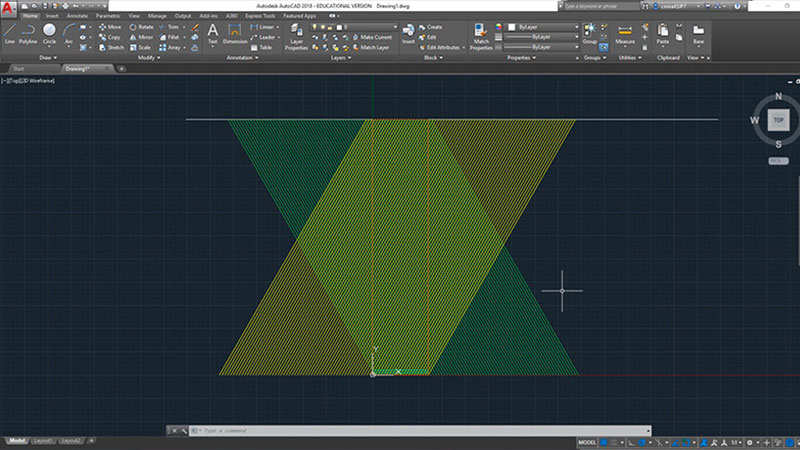

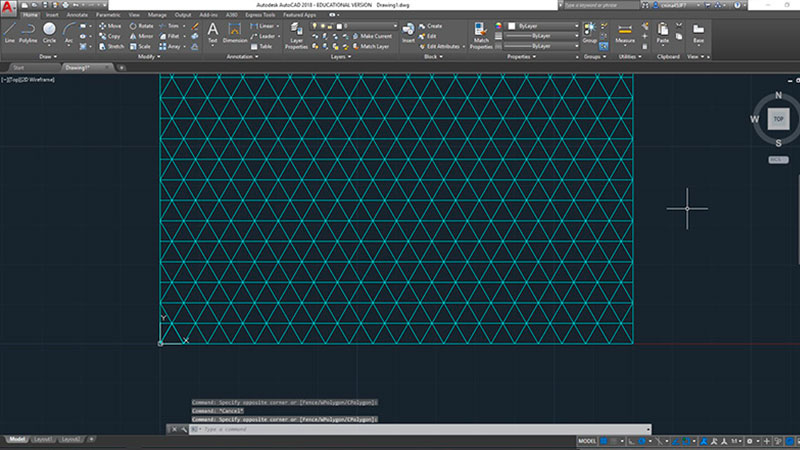

Taking in count the size of the material, I designed (in Autocad) the pattern to be cutted.

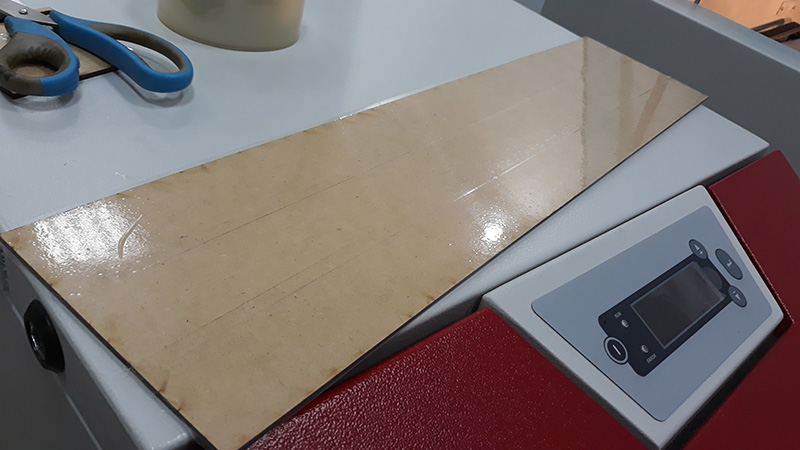

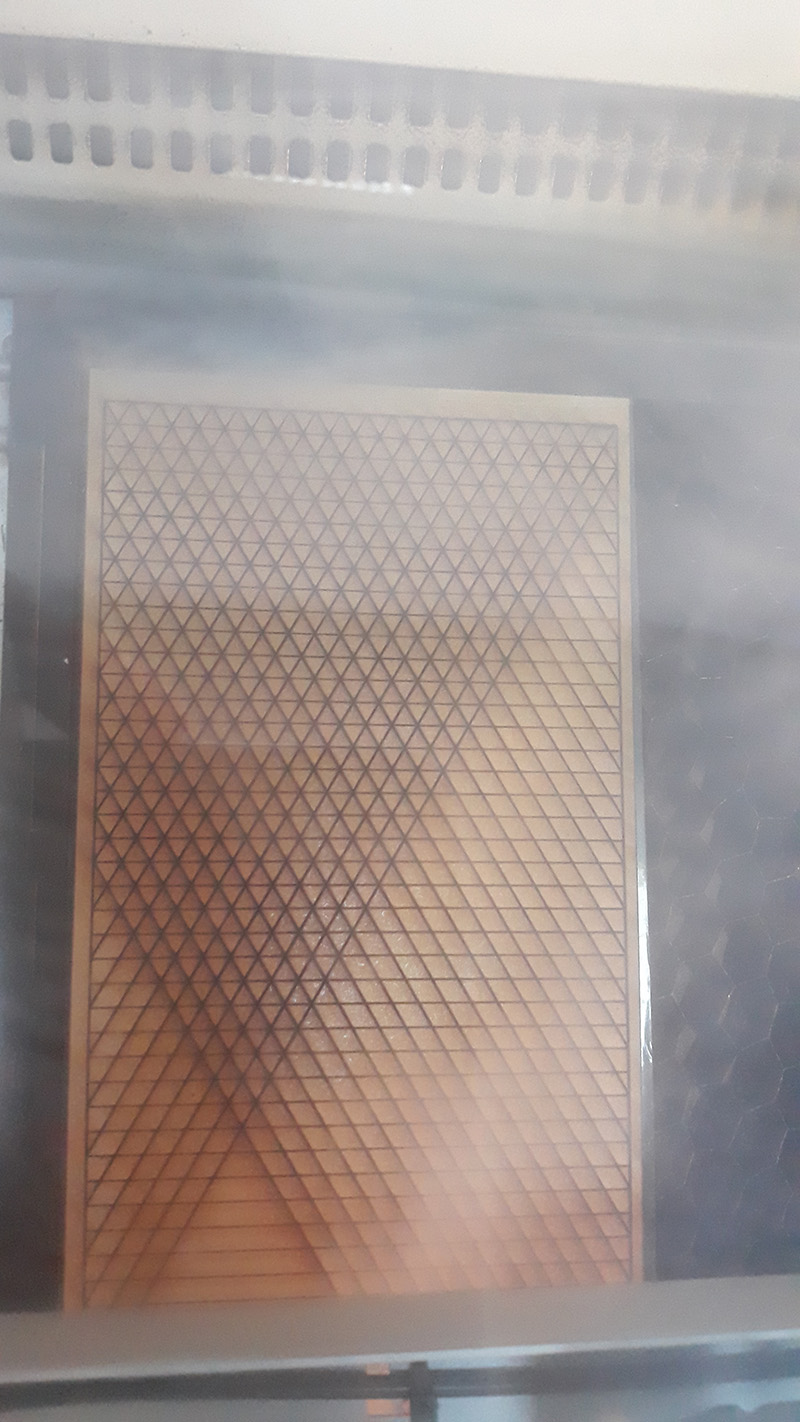

After that, I started with the cut of the pattern.

To guarantee a nice handling I left a frame around the pattern. This way I could remove the entire board at once.

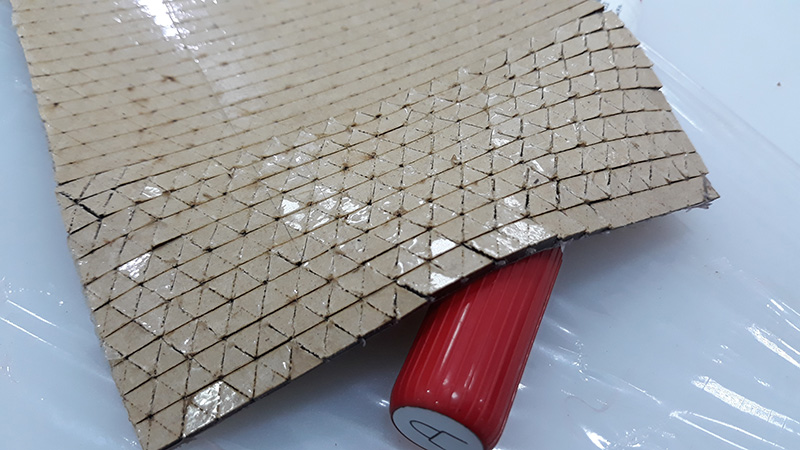

The triangles was cutted and the backing meets its goal.

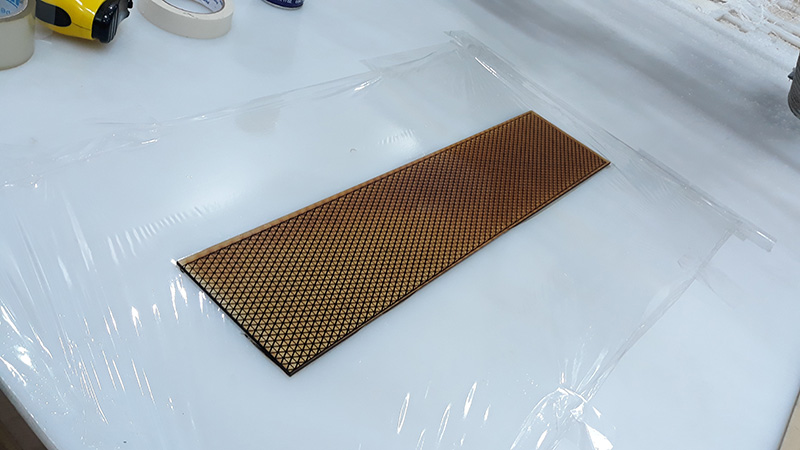

The next step, was cover a table with a plastic film and place the board of MDF with the cutted side up.

After that I prepared the silicone rubber. This is RTV silicone with catalyst. The commercial name on the local supplier es "Silicone F-30 PLUS". The ratio is 3% on weigth of catalyst for weight of silicone.

Once the silicone was ready, I covered the MDF to fill the slots between triangles and left a thin layer over the MDF.

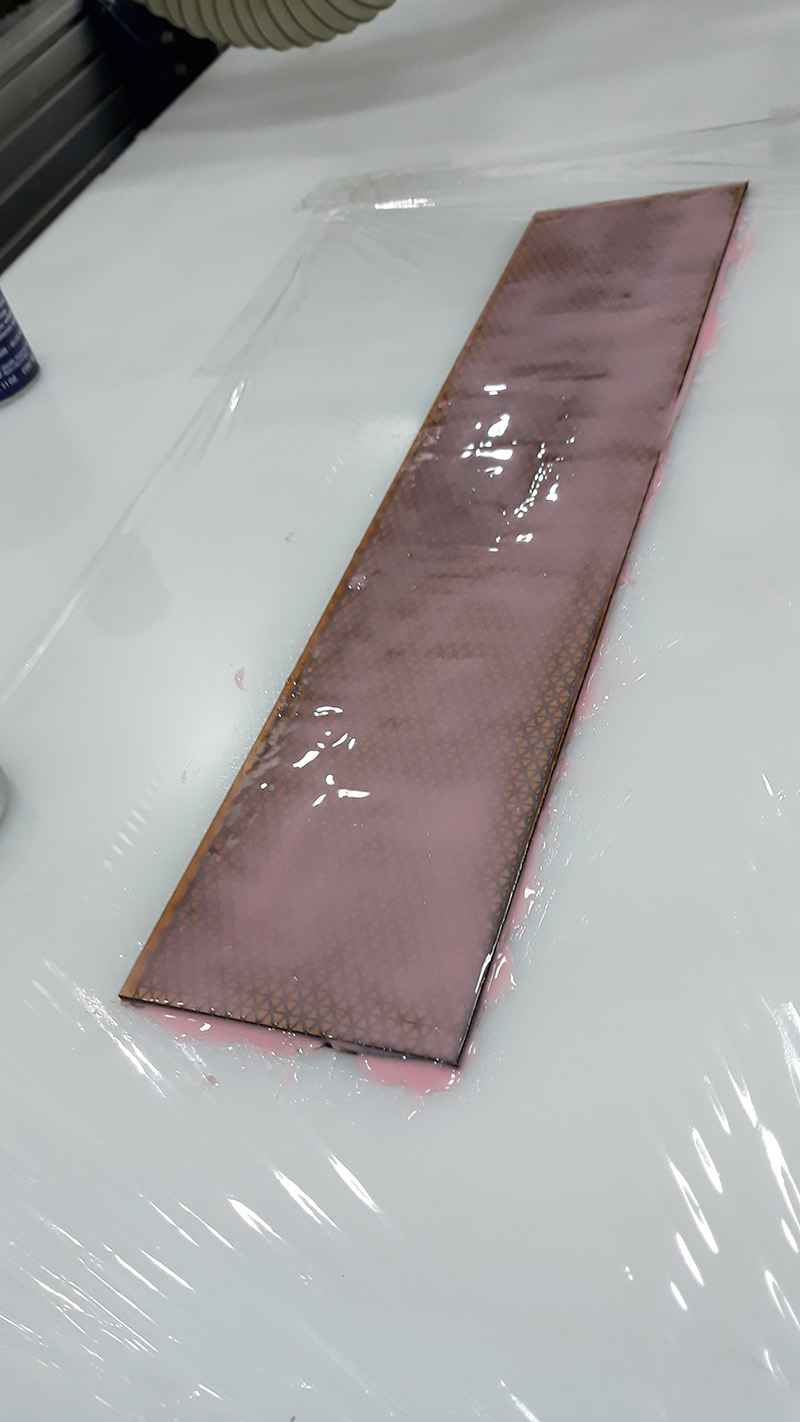

I had to prepare more silicone, to left a silicone layer over all the board.

Finally I was get it.

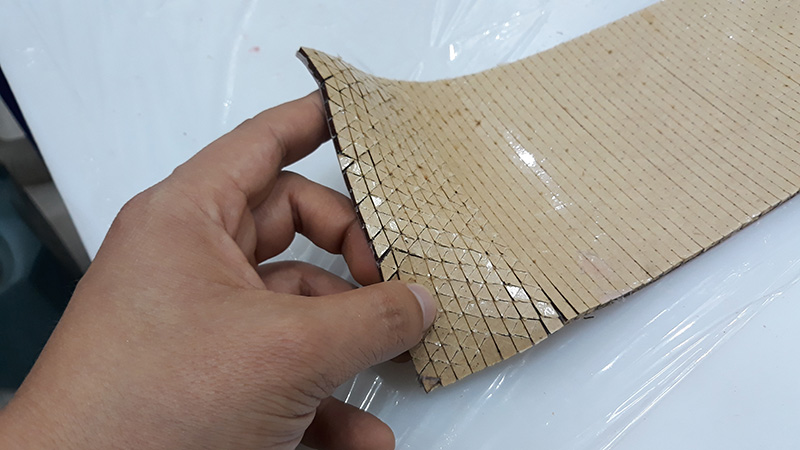

After the silicone rubber cures, I could see the result.

The MDF triangles was joined by a backing layer of flexible silicone.

This way, we have MDF fabric.

Things to be improved:

-Some parts of the MDF was no cutted enough. Maybe the machine bed is not horizontal at each zones.

-The backing layer of silicone would be more homogeneous if I used a boundary, like a MDF frame acting like walls to the silicone.

Files of this assignment:

<<< Go to Week 17 assignment | >>> Go to Week 19 assignments