Molding and Casting

DotComClassroom.com

dotcomclassroom.com - Copyright © 2015

Video Tutorials

Special Offers

Internet Marketing Tips

Software:

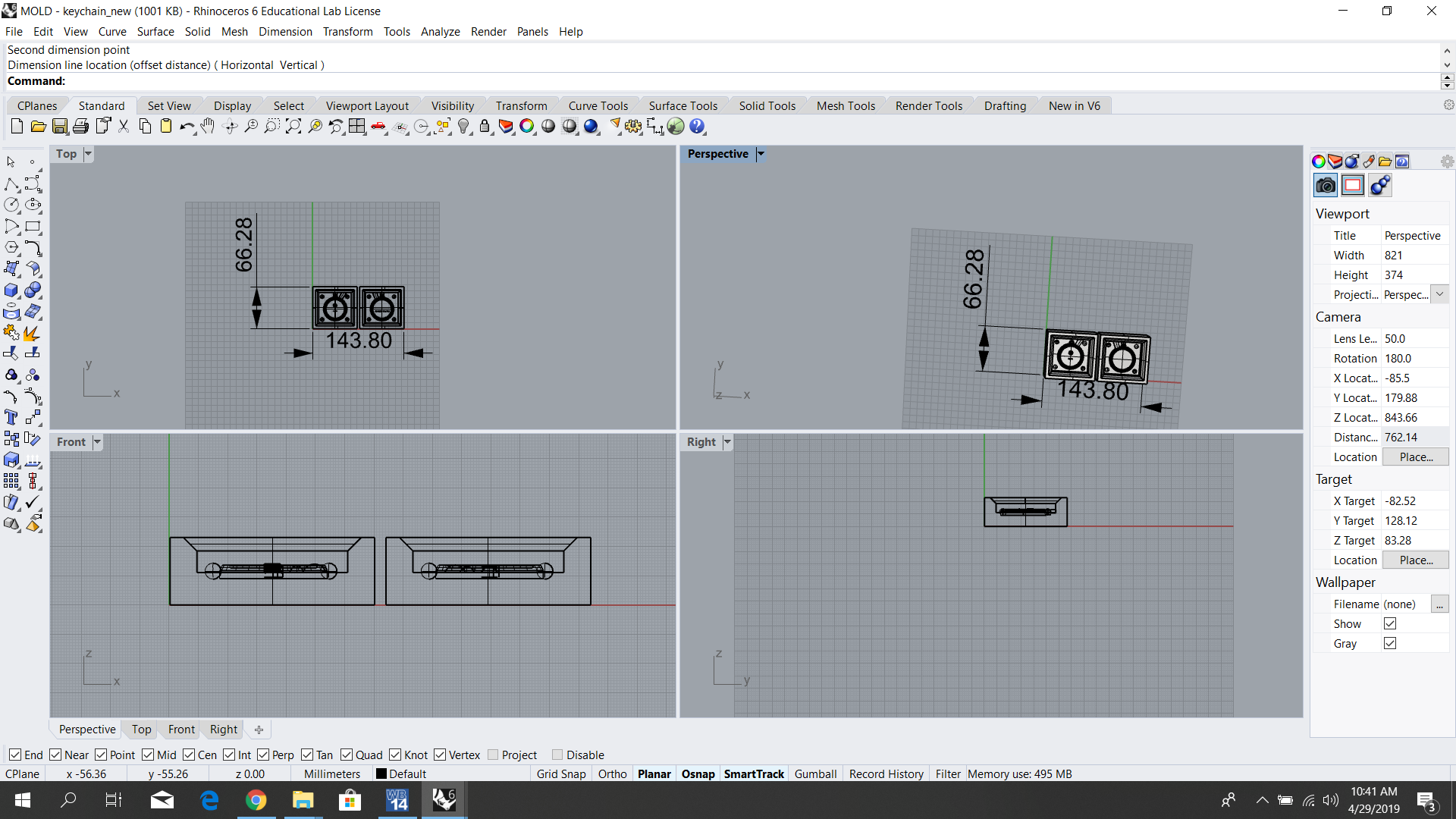

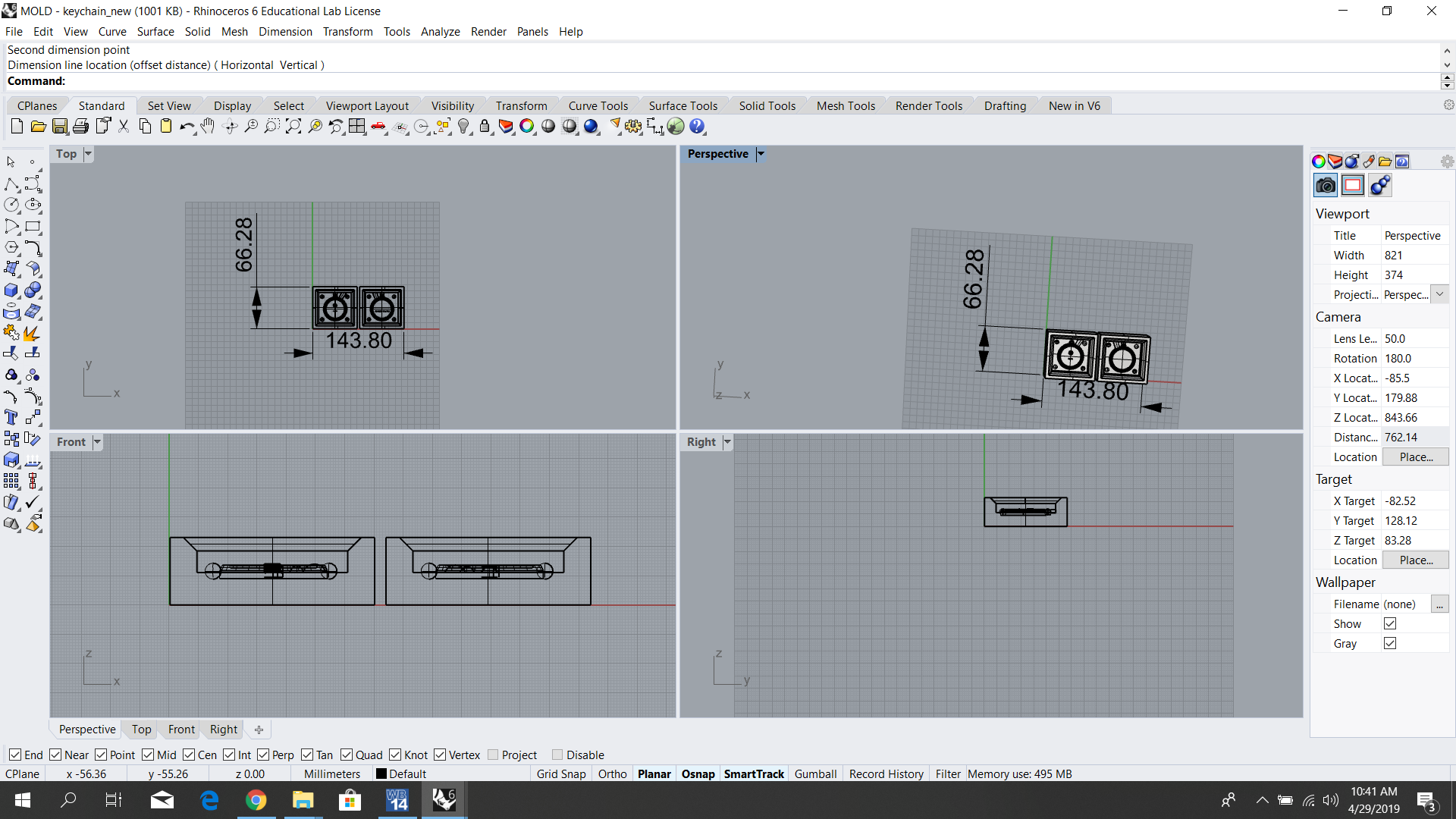

Rhyno 6

Hardware and Machines:

Roland MDX-50

The Assignment of the Week

group project: Compare the performance and development workflows for other architectures

individual project: Read a microcontroller data sheet. Program your board to do something, with as many different programming languages and programming environments as possible.

Learning outcomes:

Identify relevant information in a microcontroller data sheet.

Implement programming protocols.

Have you:

Documented what you learned from reading a microcontroller datasheet.

What questions do you have? What would you like to learn more about?

Programmed your board

Described the programming process/es you used

Included your code

Embedded Programming :

Molding my first object

I never try molding and casting before and was really excited to try it out, the possibilities behind this process are really interesting and can be used in various field.

First thing I did was to inform myself about what kind of sillicone and casting material I needed for my small project. Luckily for me, I have two awsome users of the lab that are really used to work with molding and casting process. So I call them and scheduled a time with them so they could give me some information about what to buy.

Since it was my first time, I wanted something that I could work with a while before it gets rigid, so I look at all the sillicone available into the smooth-on chart and find that the moldstar 30 seems pretty good for me. Indeed, the moldstar 30 have a pot life of around 45 min wich is plenty of time to work with and dry in about 6 hours.

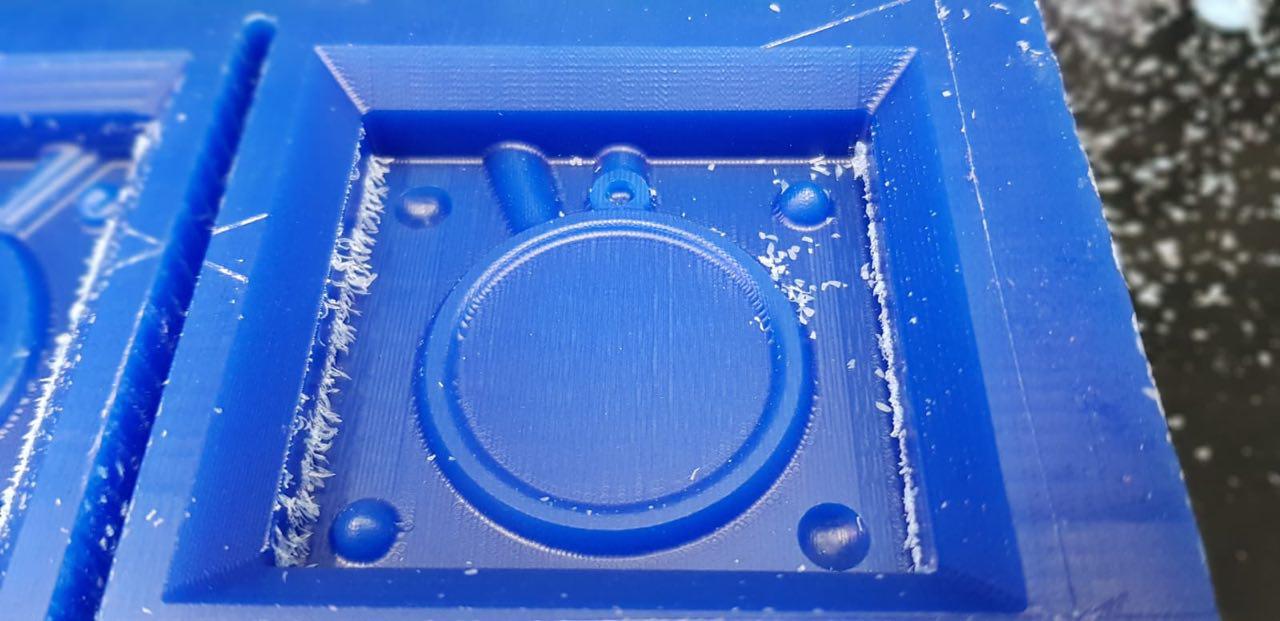

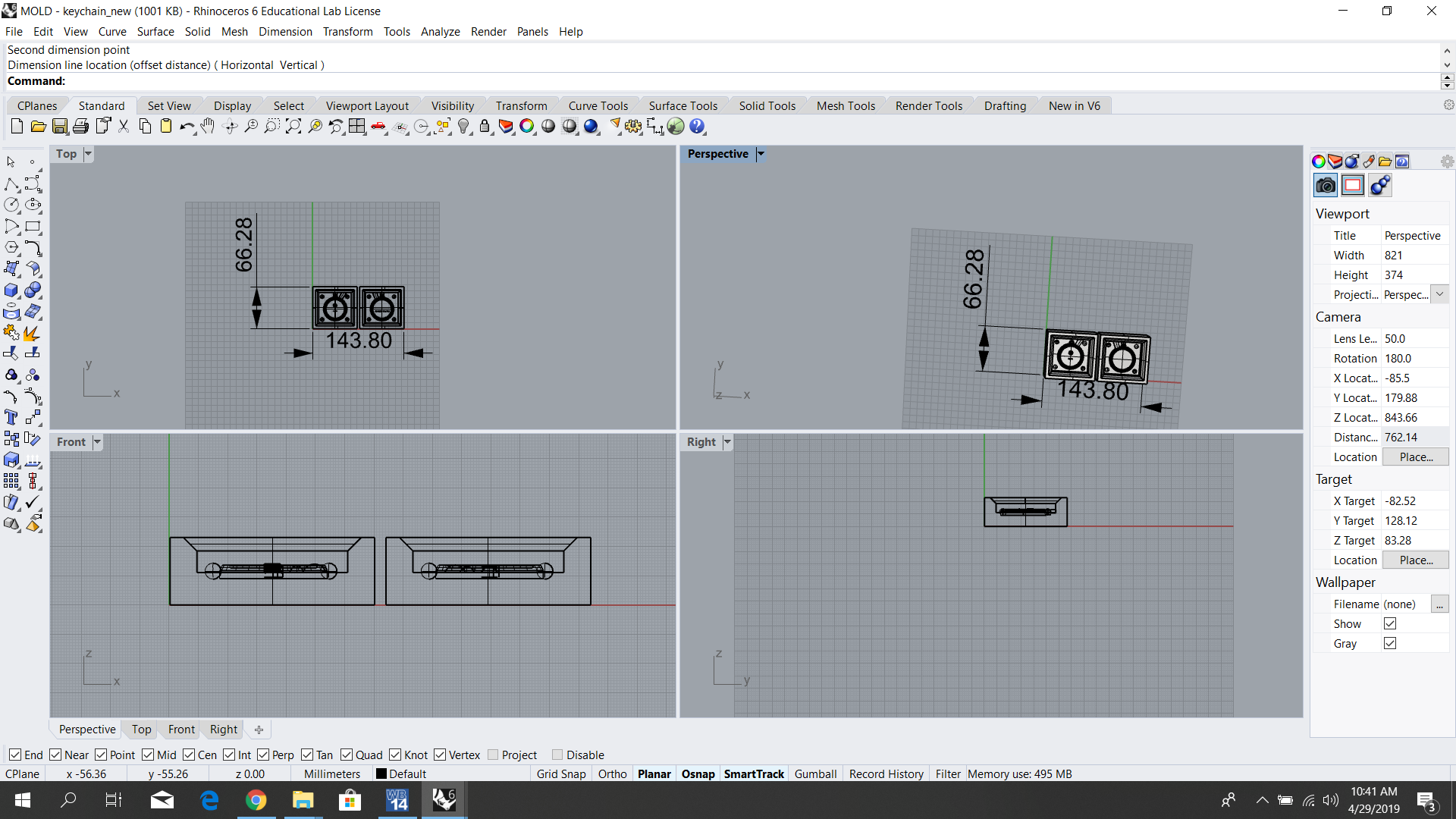

I decided to do it with holes and it worked quite good AND I exported the 3D mold model to a .stl file for the milling process.

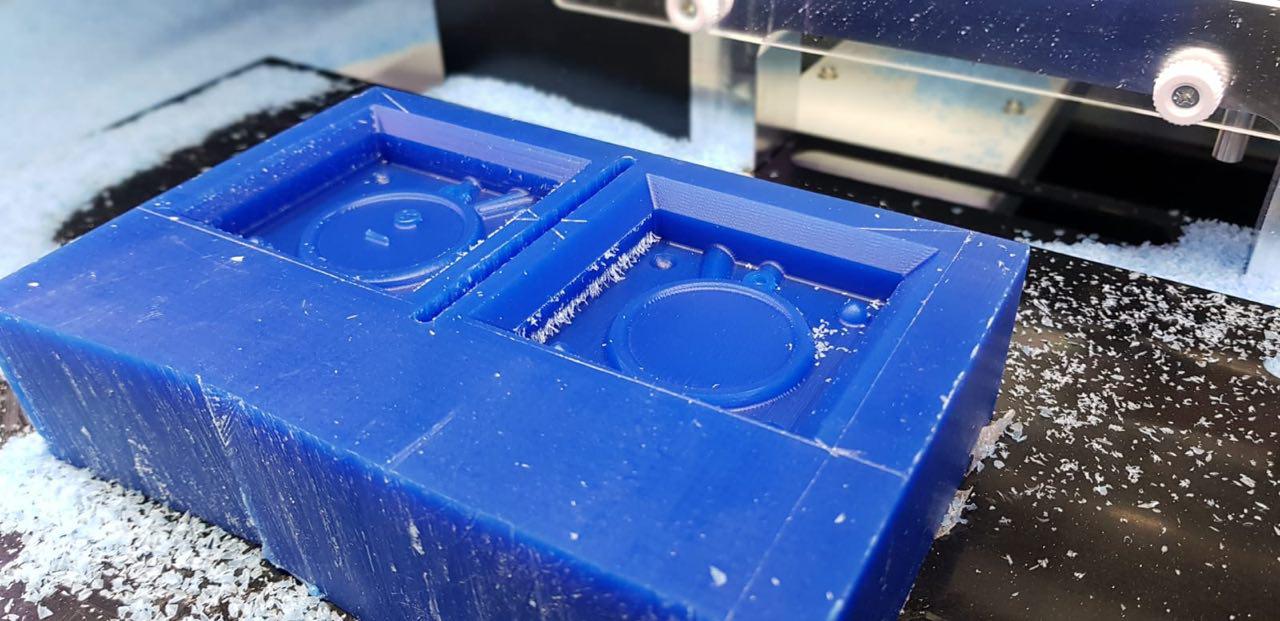

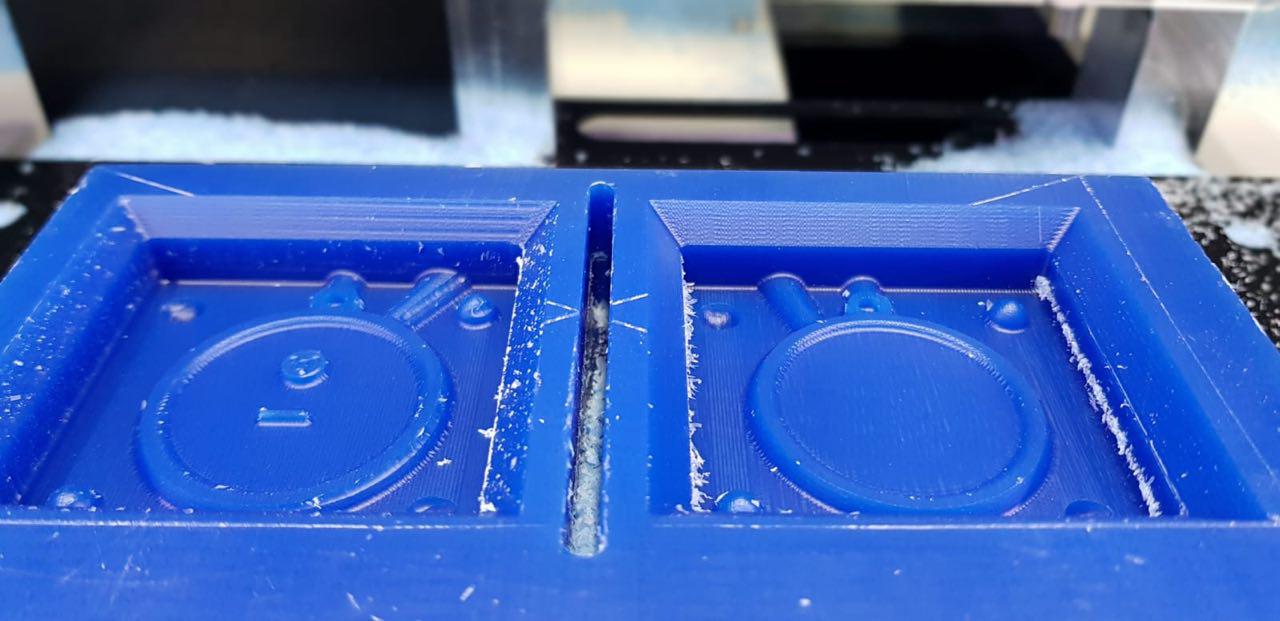

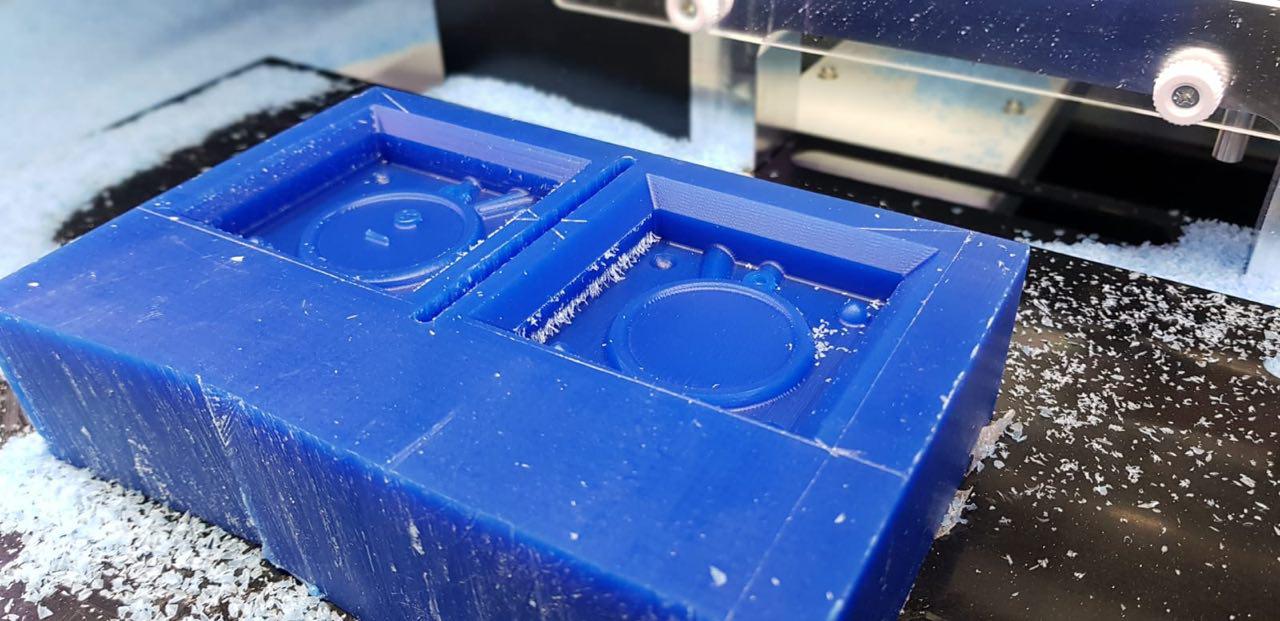

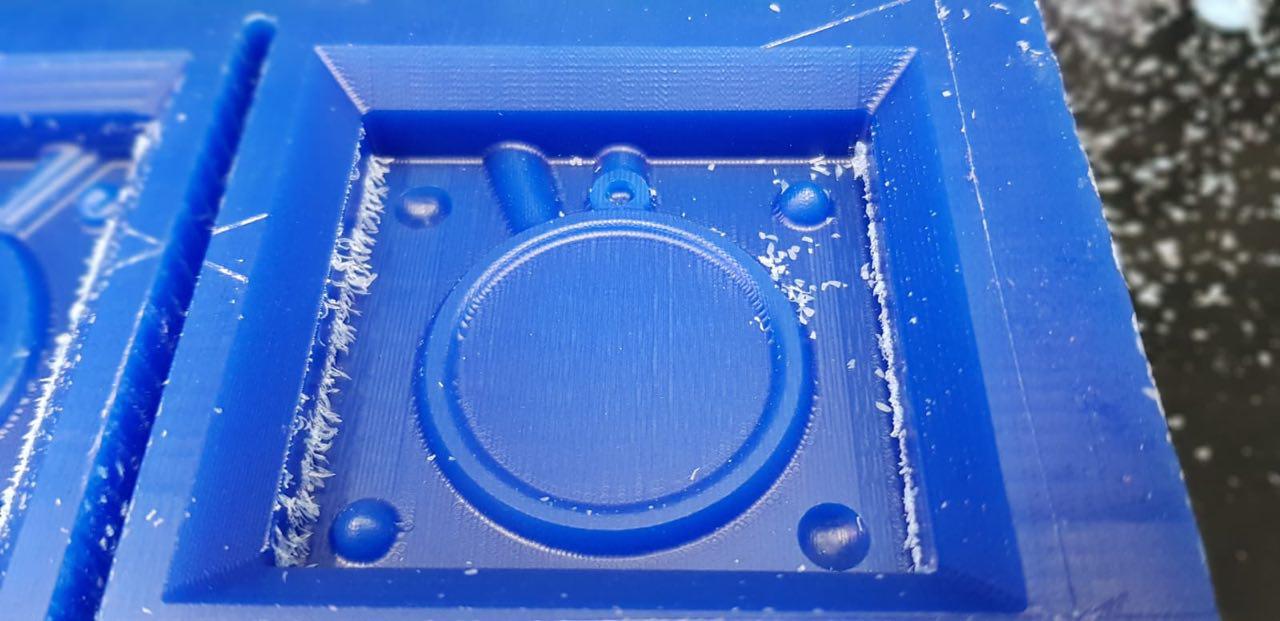

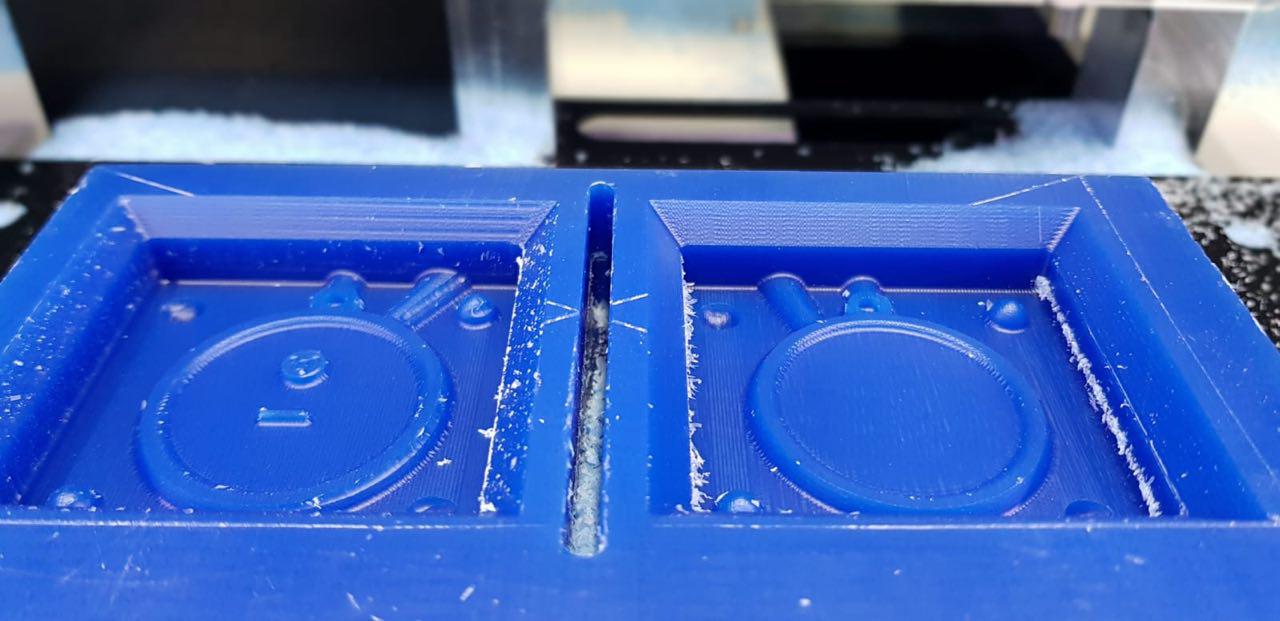

2_MILLING PROCESS

For the milling process I used the Roland MDX-50 machine and the Modela Player software (Tutorial).Step by step:

1) Open .stl model and select milling machine.

2) Select material you will use. In my case WAX .

We need to create 2 process: Roughing and Finishing process for final and better details. The steps are the same but you need to change the milling bit diameter: 1/16 4FL LONG for the roughing process and 1/8 2FL BALL for the finishing.

3) Create a New Process [Roughing or Finishing]

4) Choose type of proces

5) Choose the toolpath to create

6) Define the cutting area

7) Set the origin and the cutting parameters

8)Go Milling!

FINAL RESULT

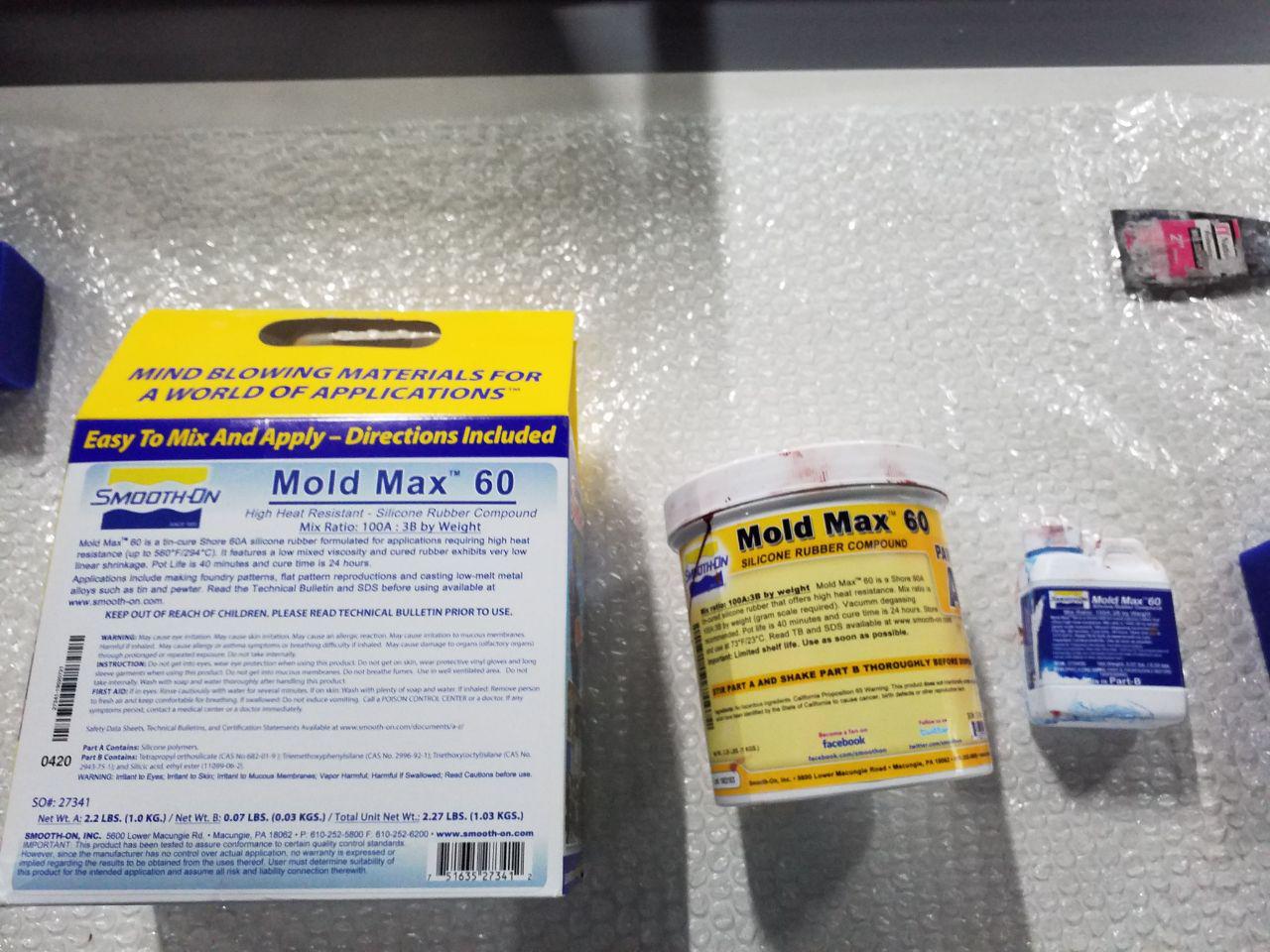

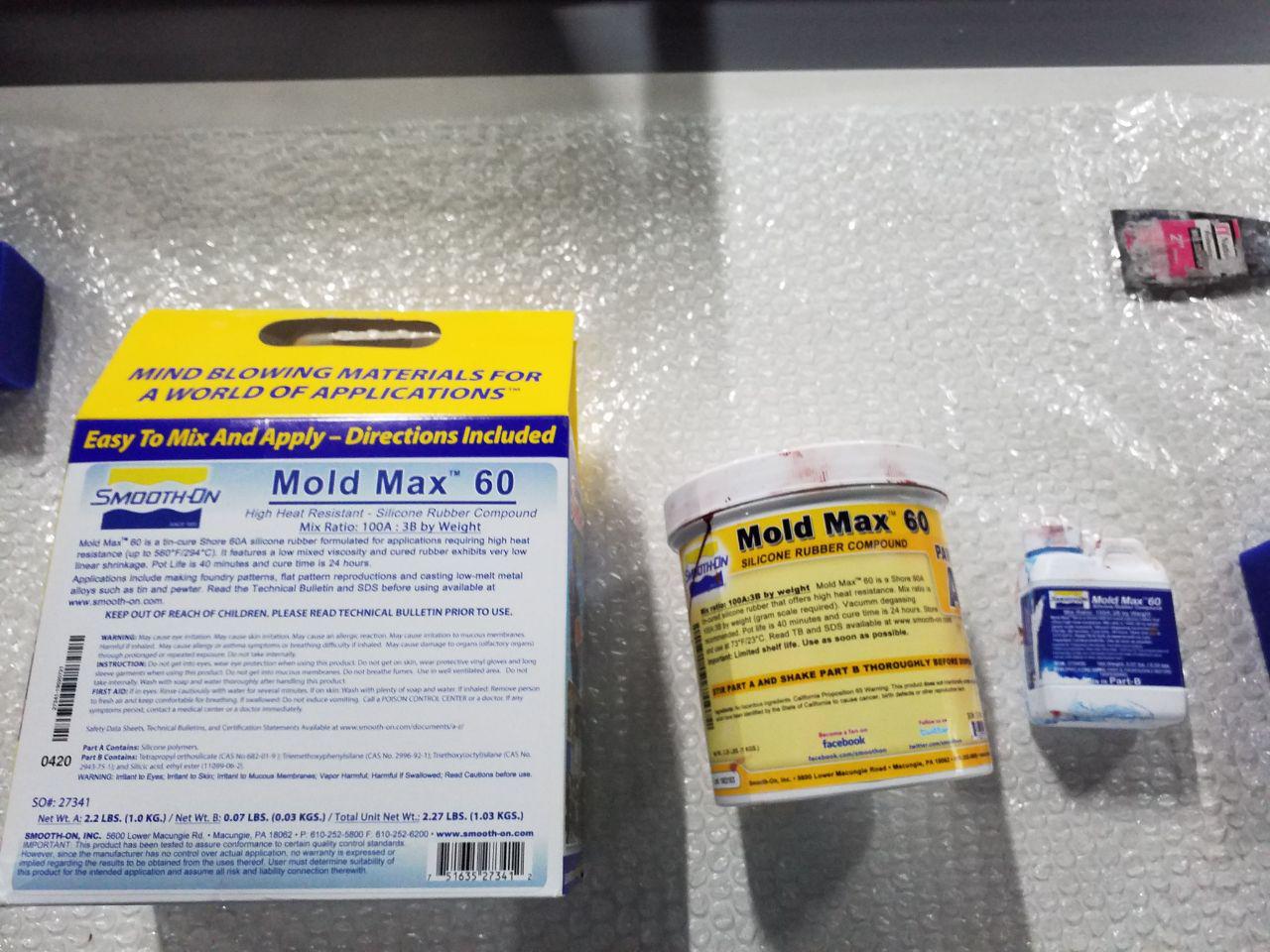

Product/Chemical Name: Mold Max® 60 Part A:

Hazards Identification - Not hazardous according to United States Occupational Safety and Health Administration (OSHA).

Inhalation - Remove source(s) of contamination and move victim to fresh air.

Eye Contact - Flush eyes with plenty of water. If irritation persists, seek medical attention.

Skin Contact - In case of skin contact, wash thoroughly with soap and water; remove contaminated clothing and launder before reuse.

Ingestion - Do not induce vomiting unless instructed by a physician. Contact physician immediately.

After first aid, get appropriate in-plant, paramedic, or community medical support.

Flash Point - 300 °F.

Handling Precautions - Minimize breathing of vapors and avoid prolonged or repeated contact with skin. Wear proper protective equipment. Use good general housekeeping procedures.

Storage Requirements - Store in cool dry, well-ventilated area.

Protective Clothing/Equipment - Wear chemically protective gloves to prevent prolonged or repeated skin contact. Wear protective eyeglasses or chemical safety goggles, per OSHA eyeand face-protection regulations 29 CFR 1910.133 and European Standard EN166. Contact lenses are not eye protective devices. Appropriate eye protection must be worn instead of, or in conjunction with contact lenses.

Toxicological Information:

Eye Effects: Irritation

Skin Effects: Irritation

Carcinogenicity: None Determined

Mutagenicity: None Determined

Teratogenicity:None Determined

Product/Chemical Name: Mold Max® 60 Part B:

Hazards identification

Harmful if swallowed

Irritating to eyes, respiratory system and skin

Harmful to aquatic organisms may cause long term adverse effects in the aquatic environment

Inhalation - Remove source(s) of contamination and move victim to fresh air. If breathing has stopped, give artificial respiration, then oxygen if needed. Contact physician immediately.

Skin Contact - Eye Contact - Flush eyes with plenty of water. If irritation persists, seek medical attention.

Skin Contact - In case of skin contact, wash thoroughly with soap and water; remove contaminated clothing and launder before reuse; seek medical attention if rash develops.

Ingestion - Do not induce vomiting unless instructed by a physician. Contact physician immediately.

After first aid, get appropriate in-plant, paramedic, or community medical support.

Flash Point - 150 °F.

Handling Precautions - Minimize breathing of vapors and avoid prolonged or repeated contact with skin. Wear proper protective equipment. If ventilation is not sufficient, wear proper respiratory equipment. Reseal partial containers. Use good general housekeeping procedures.

Storage Requirements - Store in cool dry, well-ventilated area.

Protective Clothing/Equipment - Wear chemically protective gloves and aprons to prevent prolonged or repeated skin contact. Wear protective eyeglasses or chemical safety goggles, per OSHA eye- and face-protection regulations 29 CFR 1910.133 and European Standard EN166. Contact lenses are not eye protective devices. Appropriate eye protection must be worn instead of, or in conjunction with contact lenses.

Toxicological Information:

Eye Effects: Irritation

Skin Effects: Irritation

Carcinogenicity: None Determined

Mutagenicity: None Determined

Teratogenicity: None Determined

Smooth-Cast 300 Series Safety DataSheet Review:

Product/Chemical Name: Smooth-Cast 305 Part A:

Hazards identification

Harmful by inhalation

Irritating to eyes, respiratory system and skin

Carcinogenic effect: Limited evidence

Harmful danger of serious damage to health by prolonged exposure through inhalation environment

Inhalation - Remove source(s) of contamination and move victim to fresh air. If breathing has stopped, give artificial respiration, then oxygen if needed. Contact physician immediately.

Eye Contact - Flush eyes with plenty of water. If irritation persists, seek medical attention.

Skin Contact - In case of skin contact, wash thoroughly with soap and water; remove contaminated clothing and launder before reuse; seek medical attention if rash develops.

Ingestion - Do not induce vomiting unless instructed by a physician. Contact physician immediately.

After first aid, get appropriate in-plant, paramedic, or community medical support.

Flash Point - 262 °F.

Handling Precautions - Minimize breathing of vapors and avoid prolonged or repeated contact with skin. Wear proper protective equipment. If ventilation is not sufficient, wear proper respiratory equipment. Reseal partial containers. Use good general housekeeping procedures.

Storage Requirements - Store in cool dry, well-ventilated area.

Protective Clothing/Equipment - Wear chemically protective gloves to prevent prolonged or repeated skin contact. Wear protective eyeglasses or chemical safety goggles, per OSHA eyeand face-protection regulations 29 CFR 1910.133 and European Standard EN166. Contact lenses are not eye protective devices. Appropriate eye protection must be worn instead of, or in conjunction with contact lenses.

Toxicological Information:

Hazardous Component: 4,4’ Methylene, bis(phenylisocyanate)

Product/Chemical Name: Smooth-Cast 305 Part B:

Hazards Identification - Not hazardous according to United States Occupational Safety and Health Administration (OSHA).

Inhalation - Remove source(s) of contamination and move victim to fresh air.

Eye Contact - Flush eyes with plenty of water. If irritation persists, seek medical attention.

Skin Contact - In case of skin contact, wash thoroughly with soap and water; remove contaminated clothing and launder before reuse.

Ingestion - Do not induce vomiting unless instructed by a physician. Contact physician immediately./li>

After first aid, get appropriate in-plant, paramedic, or community medical support.

Flash Point - 262 °F

Handling Precautions - Minimize breathing of vapors and avoid prolonged or repeated contact with skin. Wear proper protective equipment. Use good general housekeeping procedures.

Storage Requirements - Store in cool dry, well-ventilated area

Protective Clothing/Equipment - Wear chemically protective gloves to prevent prolonged or repeated skin contact. Wear protective eyeglasses or chemical safety goggles, per OSHA eye- and face-protection regulations 29 CFR 1910.133 and European Standard EN166. Contact lenses are not eye protective devices. Appropriate eye protection must be worn instead of, or in conjunction with contact lenses.

Toxicological Information:

Acute Inhalation Effects: None Established

Acute Oral Effects: None Established

Reproductive Toxicity: None Established

Mutagenicity: None Established

Teratogenicity: None Established

Sensitization: None Established

1_DESIGN A MOLD

I wanted a chocolate minion mold, I've designed a one-sided mold.

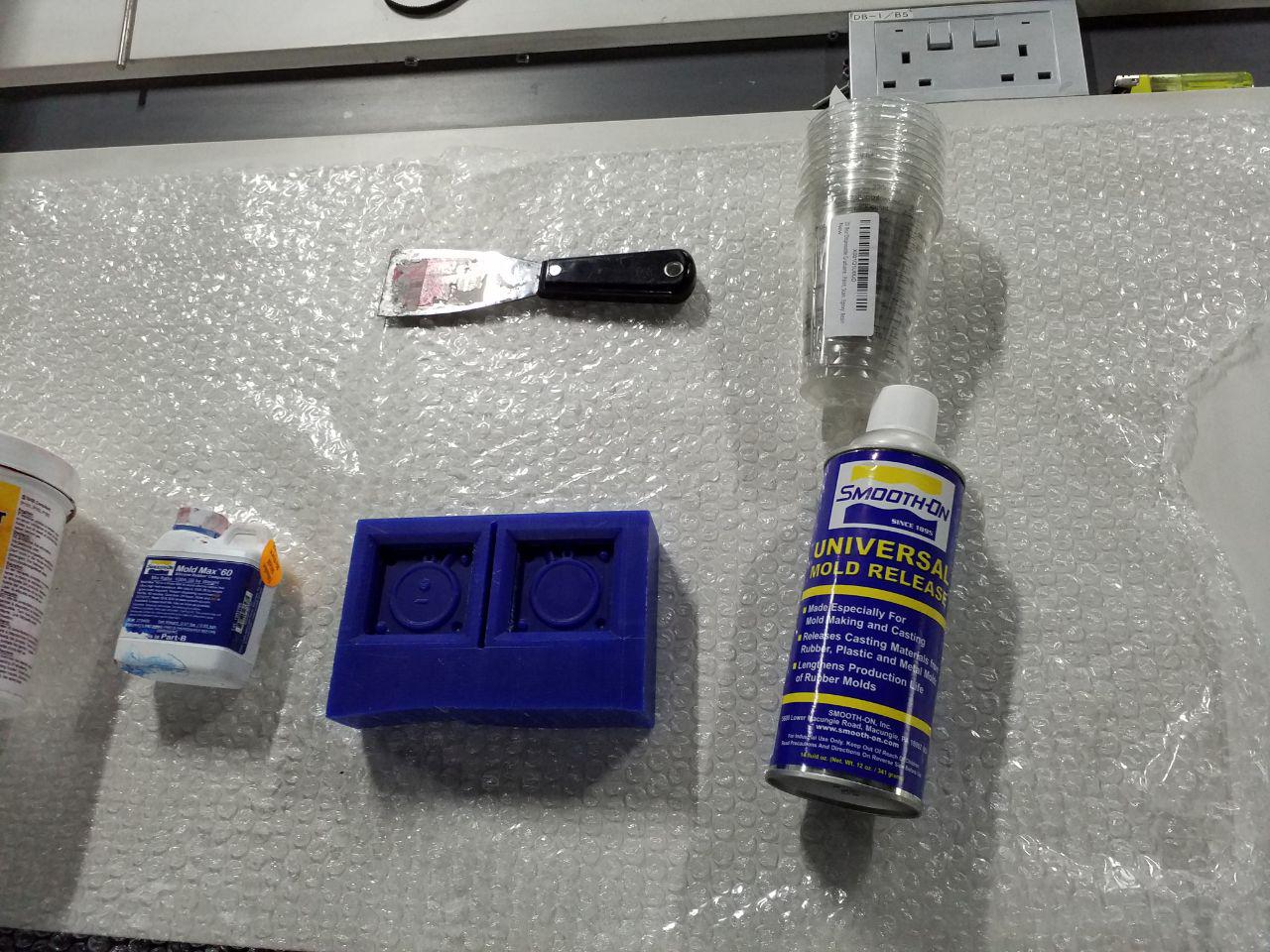

3_THE MOLD

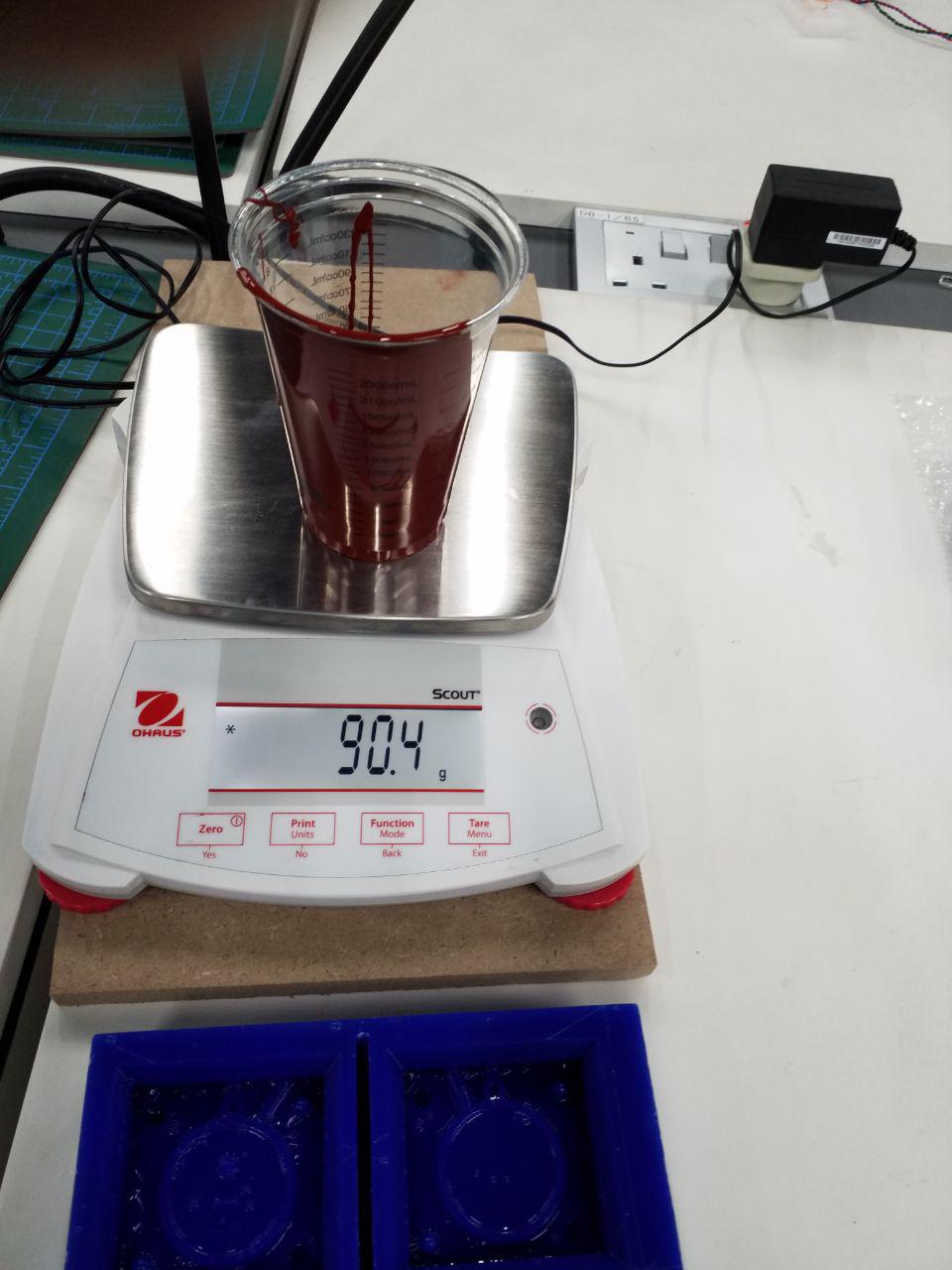

For the mold I use the Smooth-on® Mold Max 60 Silicone Rubber for food related applications. Again, it's important to read the product datasheet.

Step by step

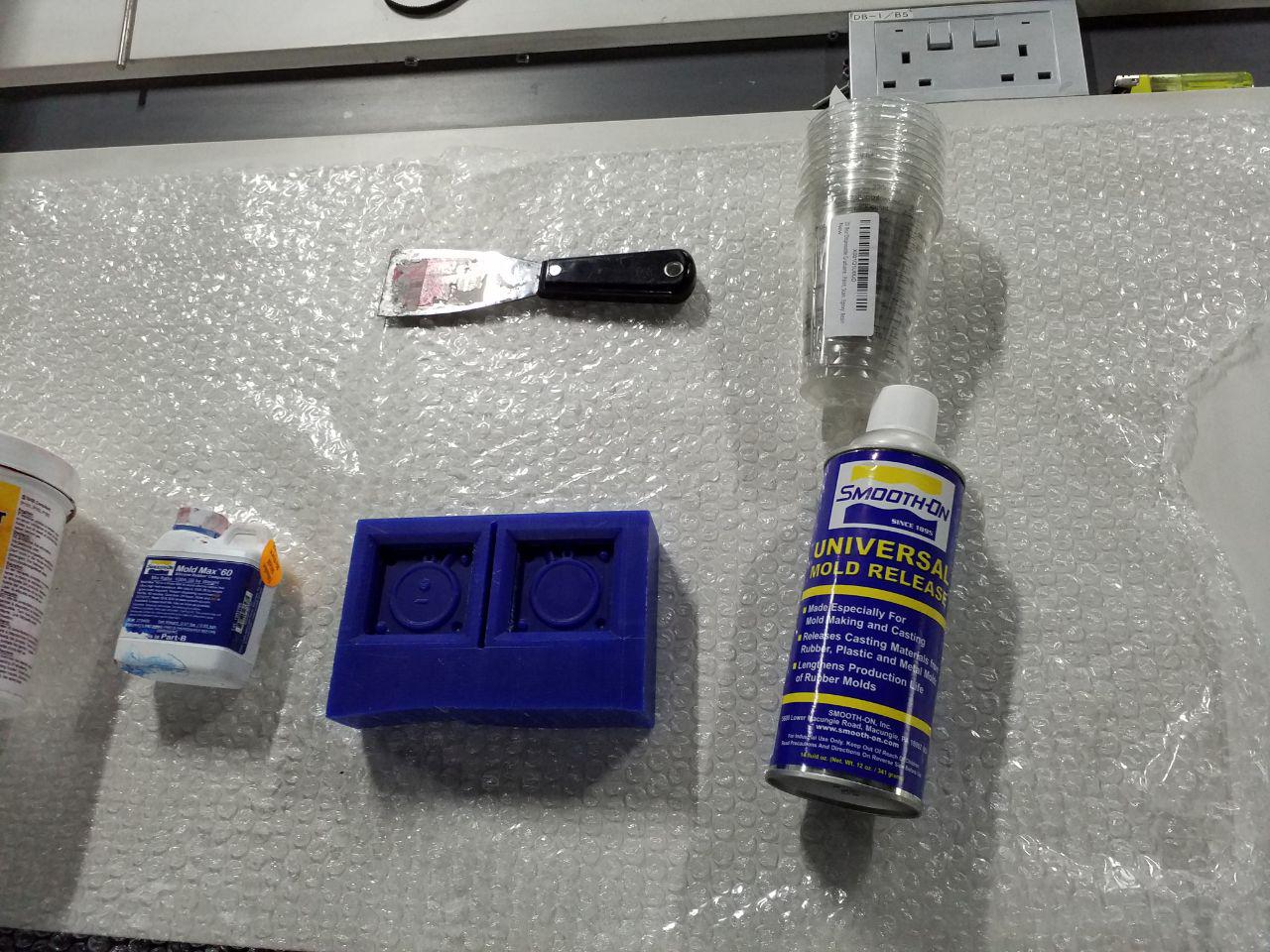

1) Prepares the workspace with all the tools you need:

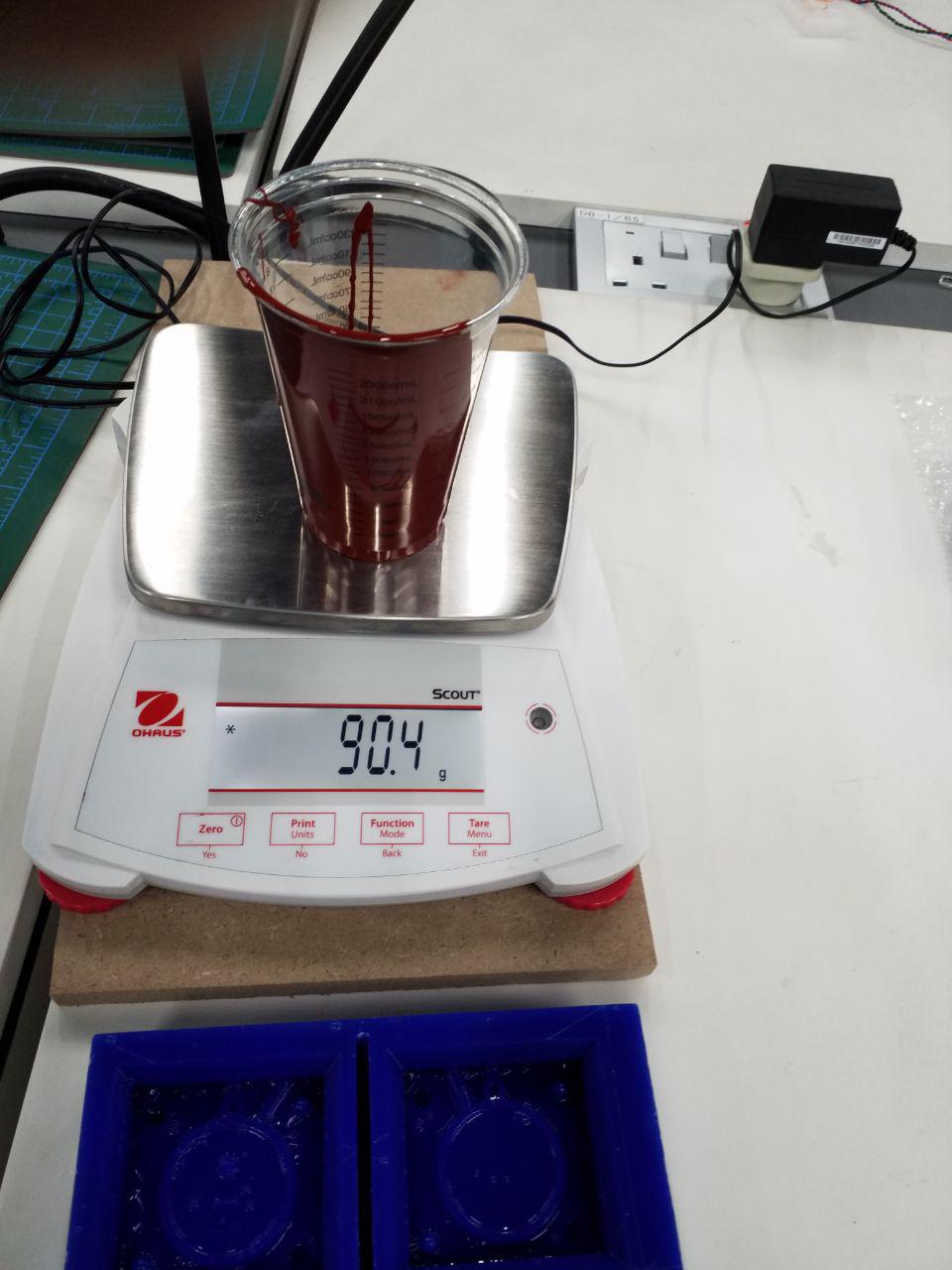

a plastic cup for mixing,a wooden stick to mix,gloves,weighing machine ( for measure the mixing) , and mold material.

Some tips before starting the mixture:

- Use transparent cups for mixing and see how is it going.

- 1 cm (min) silicon on top of material when you put inside the wax mold.

- Security! Take care of you!

- Mix with energy!

- Fill a cup with water,to get an idea of how much liquid we need for creating the mold.

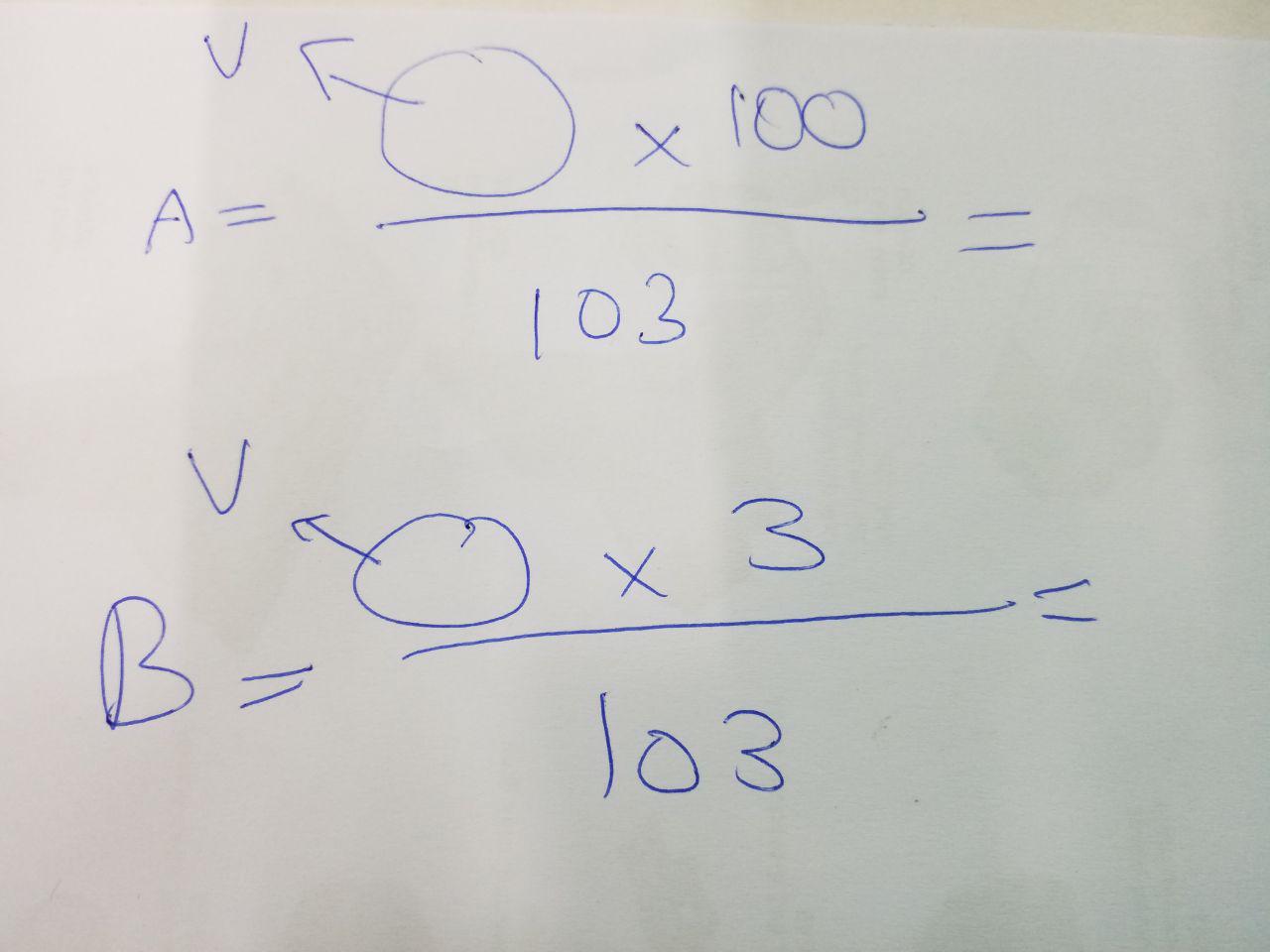

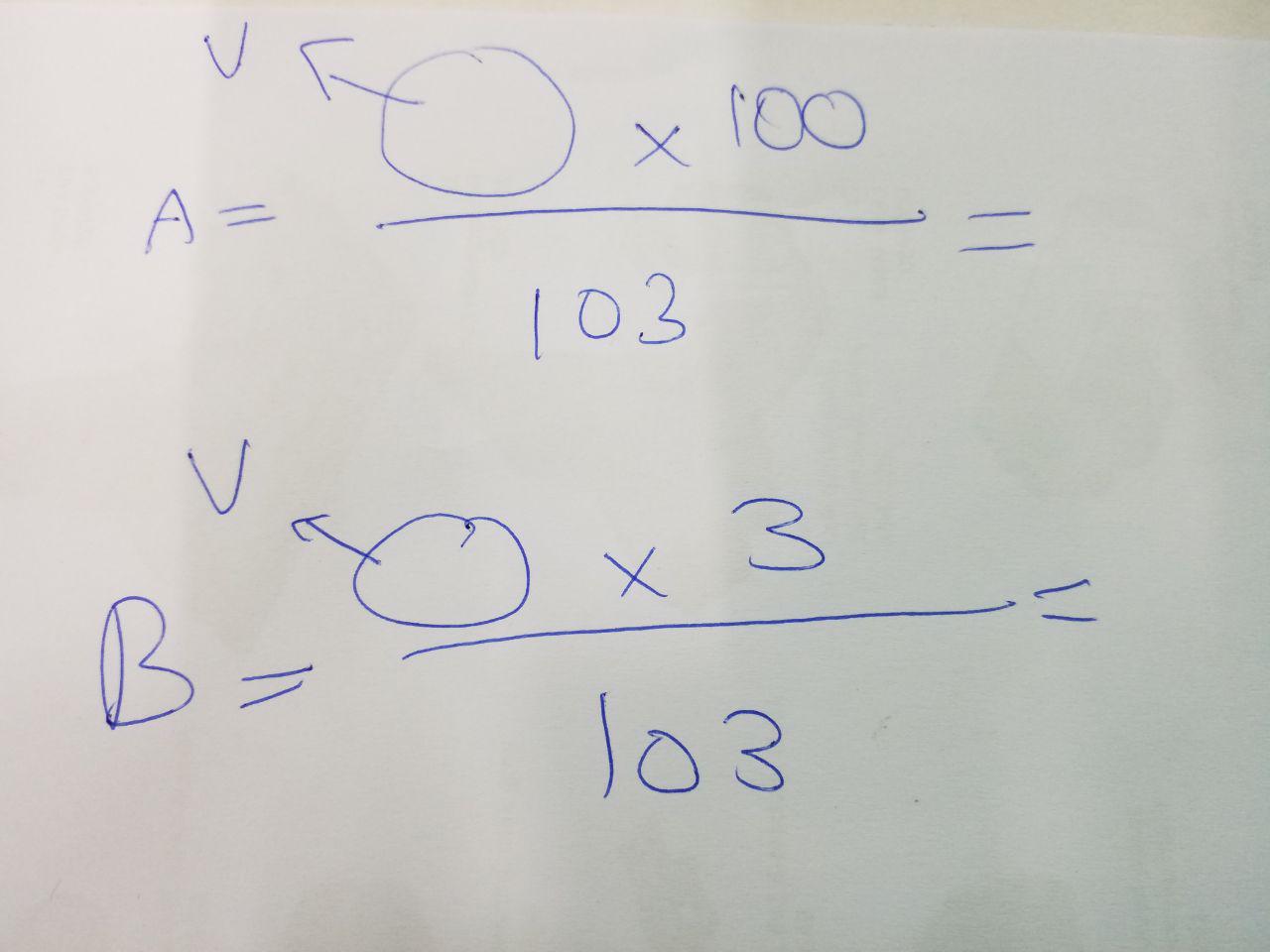

2) Mixing Ratio: in my case, 100 part A to 10 part B. Mixture, 5 min at least!

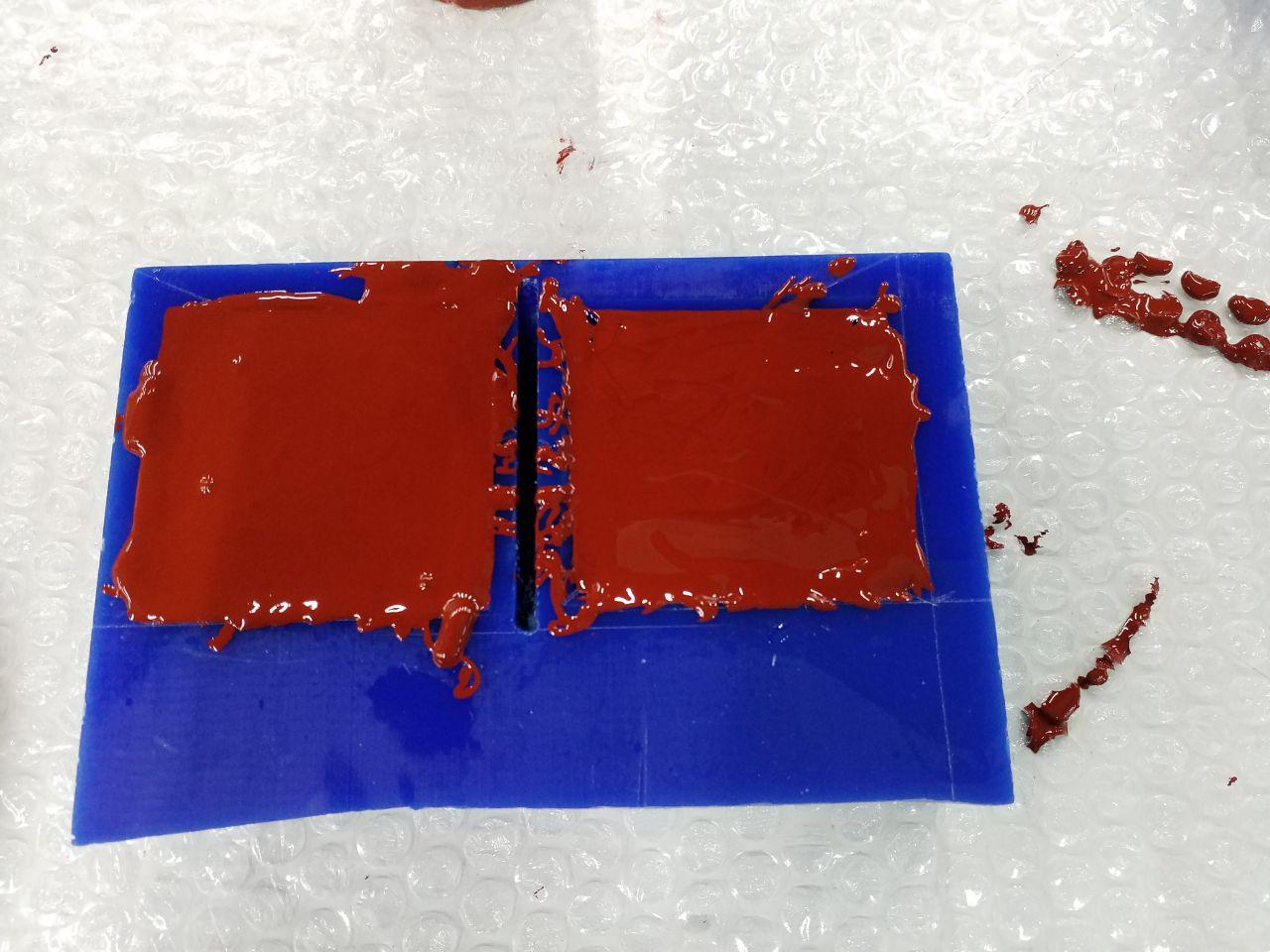

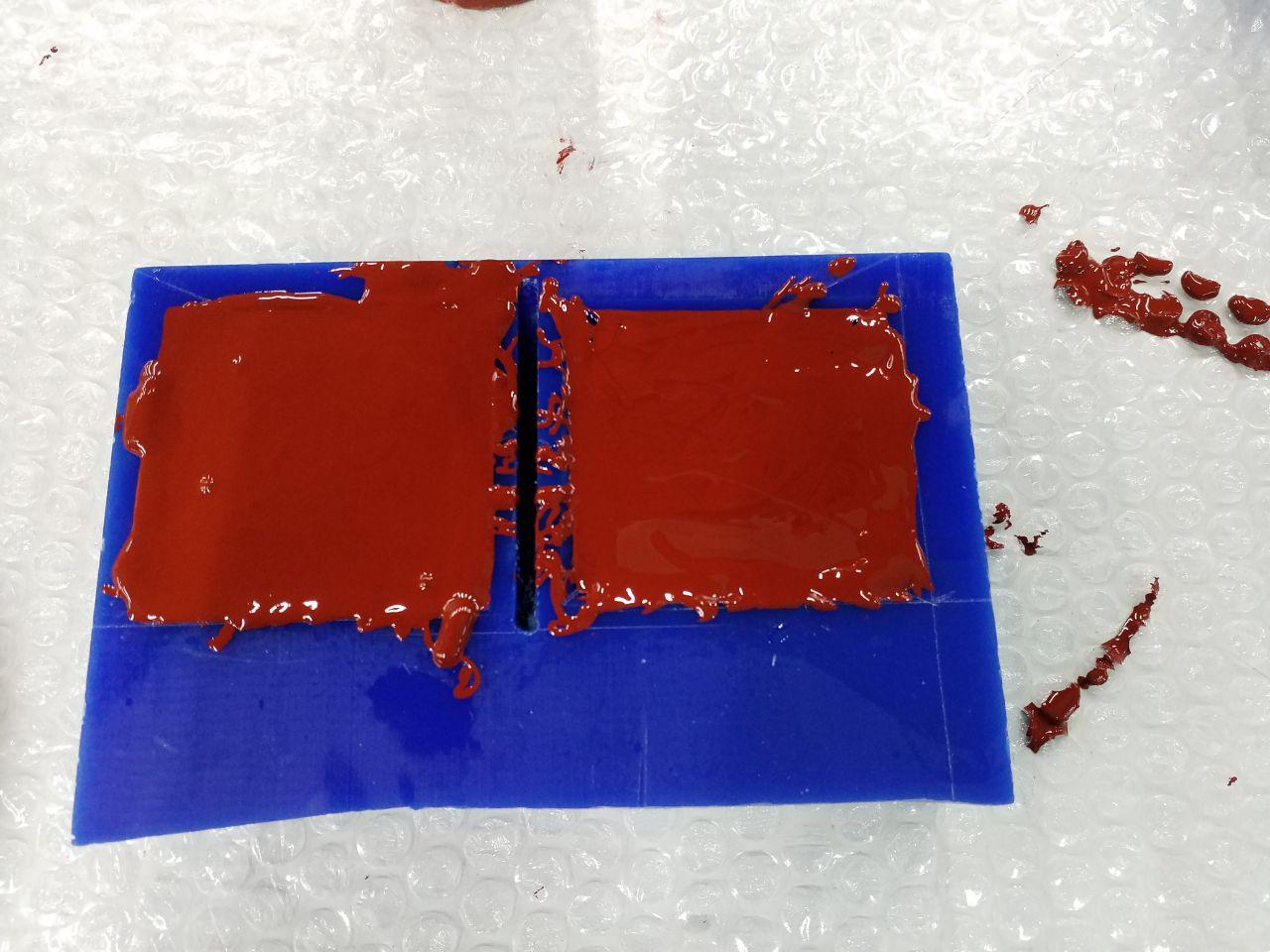

3) Pour the mixture into the mold wax

4)Wait 24h (in my case) before extract the silicon mold

5)

4_THE CHOCOLOTE

Smooth- Sil® 940 - USER INSTRUCTIONS After the rubber mold has cured for 24 hours , it is introduced into an oven for 4 hours at a temperature of 100 °. Allow to cool and wash the mold cavity thoroughly with soap and water, rinse well and allow to dry before use.

And finally...

DOWNLOAD FILES

3D model