Computer-Controlled Machining

DotComClassroom.com

dotcomclassroom.com - Copyright © 2015

Video Tutorials

Special Offers

Internet Marketing Tips

Software:

VCarvePro ShopBot Edition

DeepNest

CAD

Hardware and Machines:

CNC Router

PRSalpha| Cutting Machine

The Assignment of the Week

Individual assignment:

Make something big

Learning outcomes:

Document the process of design and production to demonstrate correct workflows and identify areas for improvement if needed

Have you:

Explained how you made your files for machining (2D or 3D)

Shown how you made something BIG (setting up the machine, using fixings, testing joints, adjusting feeds and speeds, depth of cut etc)

Described problems and how you fixed them

Included your design files and ‘hero shot’ photos of final object.

group assignment

test runout, alignment, speeds, feeds, and toolpaths for your machine

INTRODUCTION TO: ShopBot

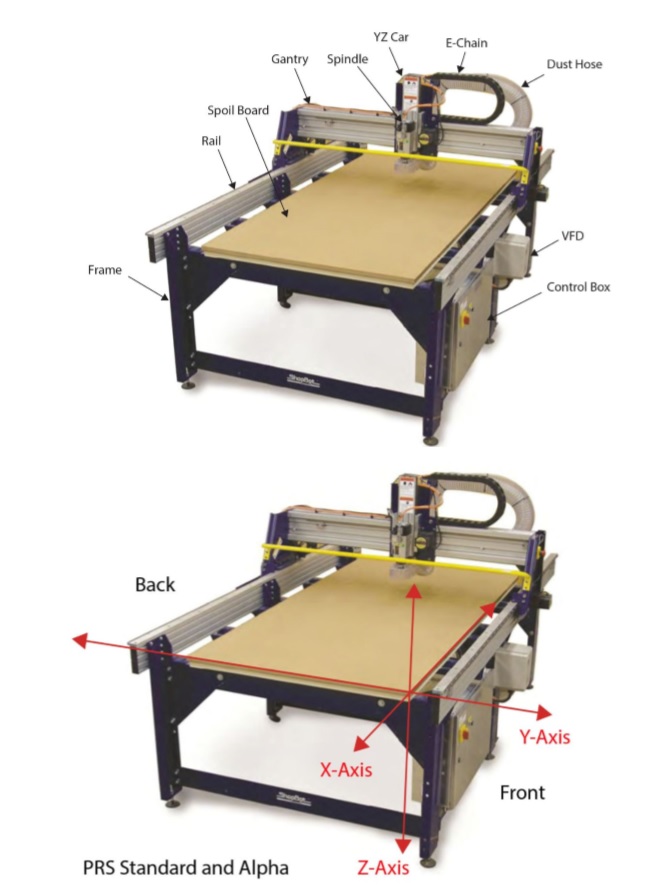

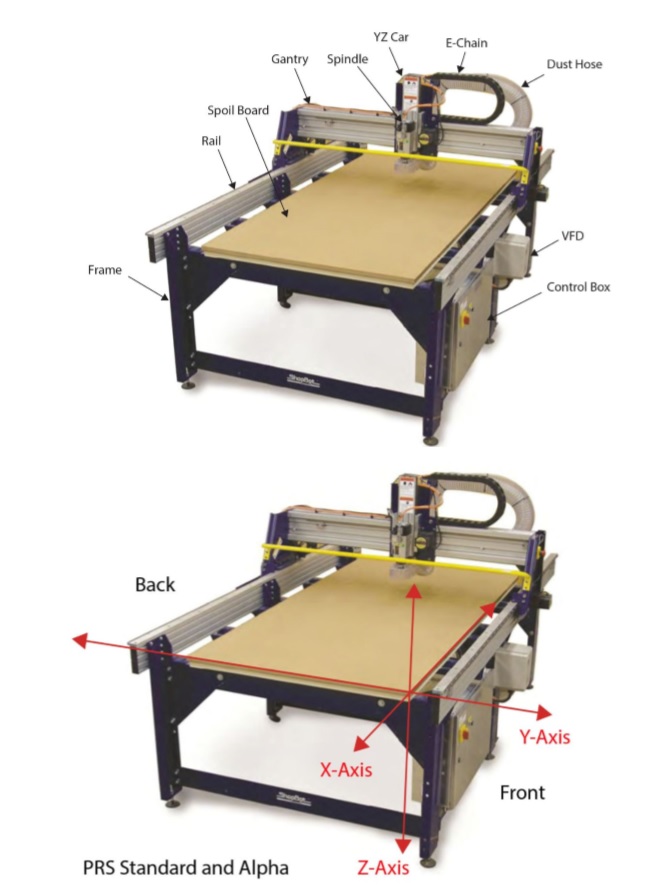

3D cutting, machining and sculputuring can be used in many different types of projects. ShopBot CNC tools are fully 3D capable, as are most CNC routers(this capability is technically described as 3-axis interpolation, which means that moves are made smoothly in 3D space using diagonals and curves). Full 3D CNC involves both designing in 3D and during cutting simultaneous CNC motion in x, y, and z axes. In 3D shaping, the CNC cutter tip follows paths at 3D angles or in 3D curves in order to mill or curve complex shapes into the materials. This tutorial covers topics required to get started with a ShopBot PRS, safety, how to start the machine, how to use the software, and how to start cutting your 3D model.

Get Cutting

Get Cutting

This assignment is focused on the converting the CAD drawing into the real-life objects.

The CNC (Computer Numeric Control machine) is the machine which takes the input of design files

and the machinable material like wood, wax, acrylic, composites, the output will be the fully designed

files which can be assembled to make the usable products.

In this assignment it's time to make something which is life size and can be used by myself in my day to day activities.

I was thinking about the things that I simply make which can be usable in day-to-day life.

Cad Drawing:

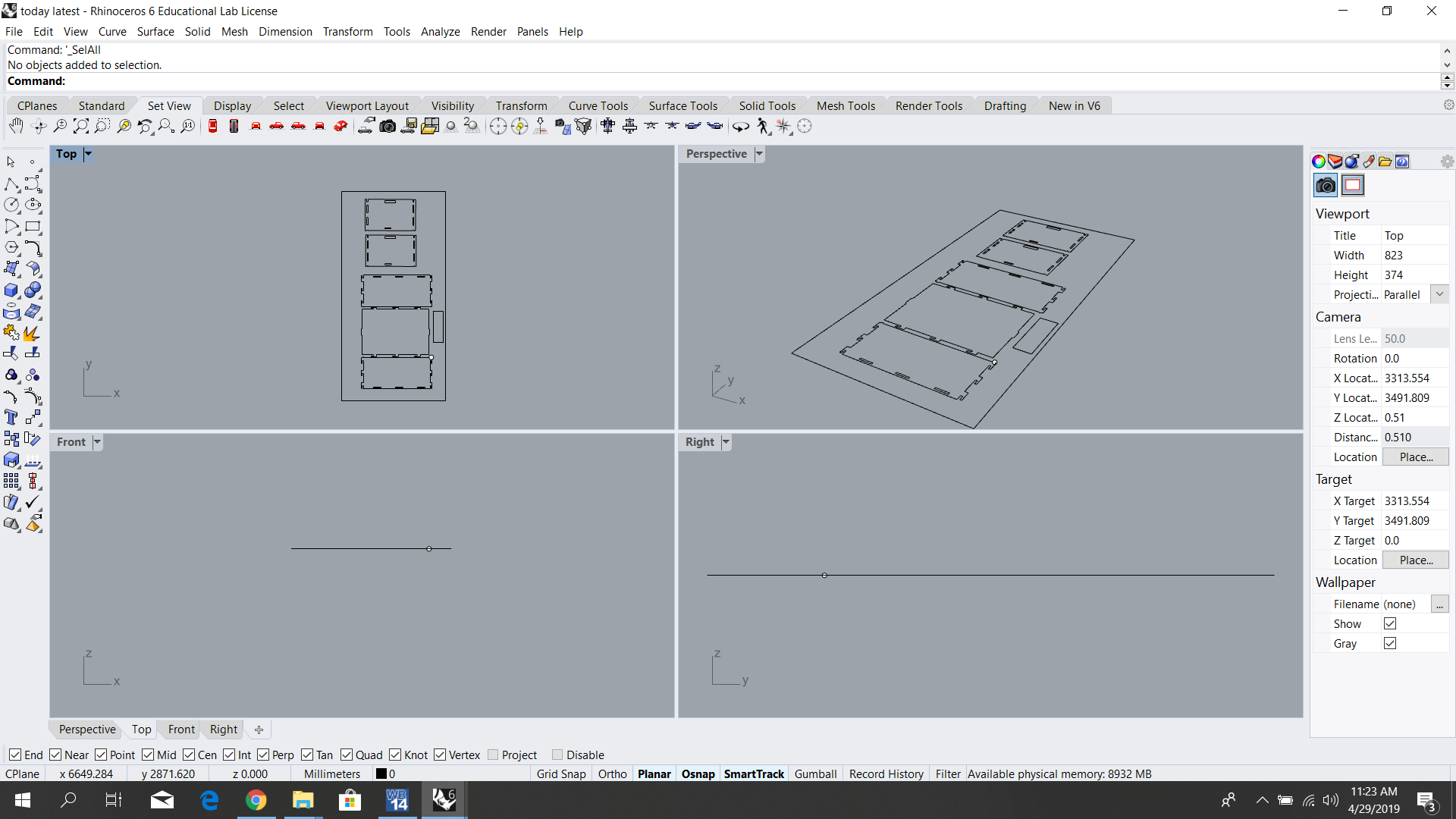

Started with a design. For CNC milling, there are many approach in design. I'll show you XXXXXXXXX, that starts from 3D

to get to the milling plans. I did the design with Rhino 3D. The objective is to make a toys box for my daughter Mariam.

Testing the Design :

It's time to make it 2D which can be used by most of the machine softwares.

Also, when you have DXF files which can be opened in the software for further modifications if required.

To avoid wasting a full wood plate, I cutted in a 3mm thick plywood with the laser cutter, reducing the design.

Then comes the milling...

I used a 12mm plywood to make the toys box for my daughter. For program the CNC Router machine I use "ArtCam".I exported the dxf file to XXXXXXXXXXXXXXXXXXX

Then I started by editing an existing design and importing the vector to inkscape

and once the design is completed I shared it with my local instructor for more assurance, so after I obtained the green light I by choosing the mill (4mm) and creating the tool paths:

The first path is clearence tool path to fit the top piece.

The second path is a cutting path, tha is going to cut on the line interior.

And the third path is like the sencond but is going to cut on the line exterior.