6. 3D Scanning and printing¶

Assignment¶

-

Group assignment

Test the design rules for 3d printers -

Individual Assignments

- Design and 3D print an object that could not be made subtractively

- 3D scan an object (and optionally print it)

Group Assignment¶

3D Printing¶

Research¶

What is the shape that can not be made subtractively ? It is not merely a matter of 3D compared to 2.5D. Utilizing xyz axis actuator or special tools, even laser cutter can create 3D models directly.

- Laser rotary engraving on glass bottle

- 3D milling human face

So I examined a model in which multiple parts are intertwined internally.

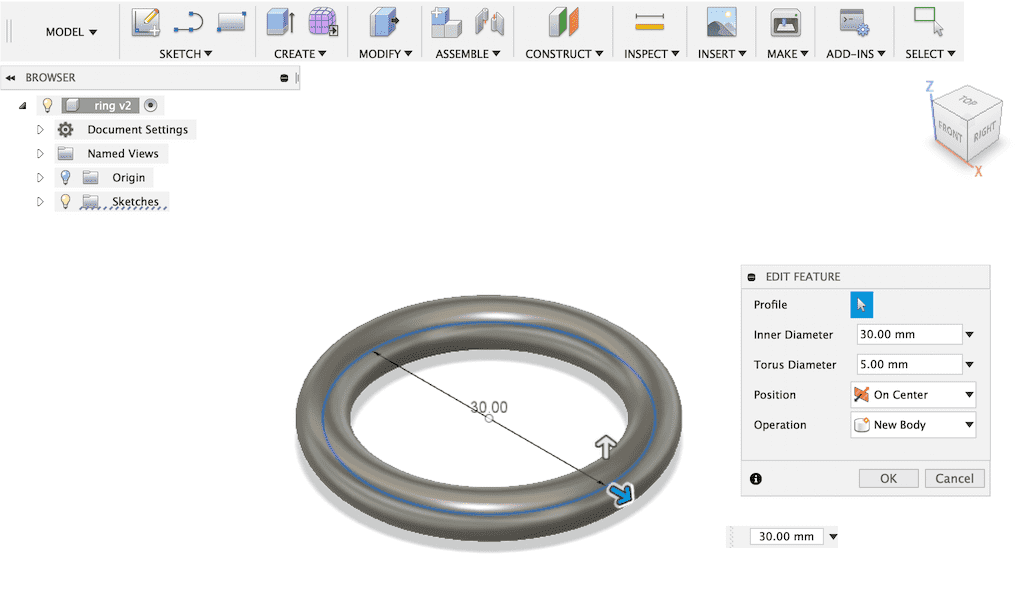

3D printed Ring¶

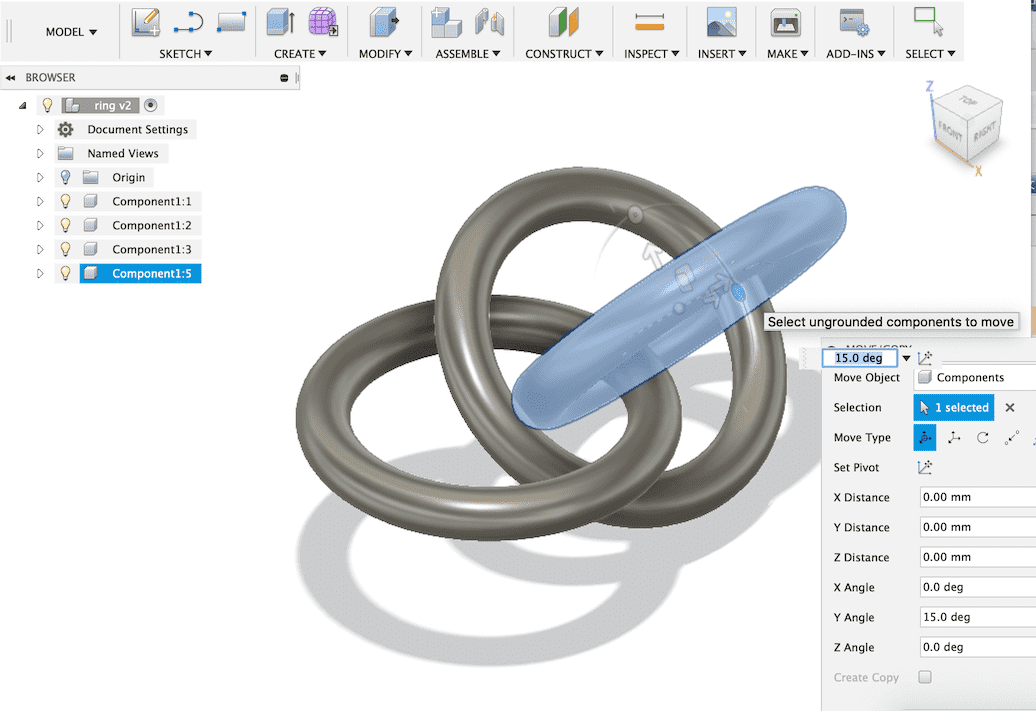

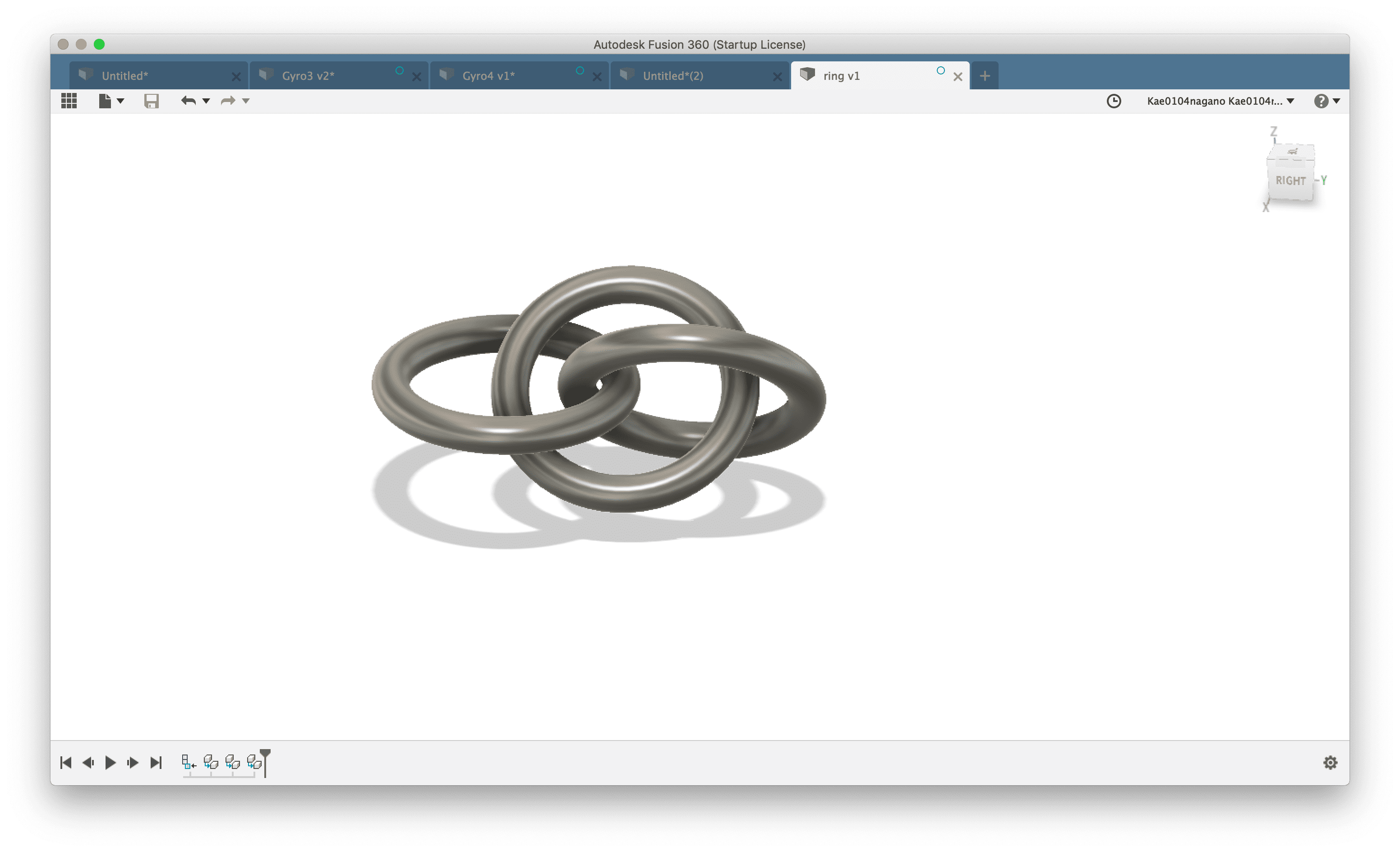

First, using Fusion 360, I designed a simple model in which three rings are intertwined like a chain.

Created small 30mm torus to save print time.

Created component from the torus body, then copied it. Changed the angle of copied component to entangle.

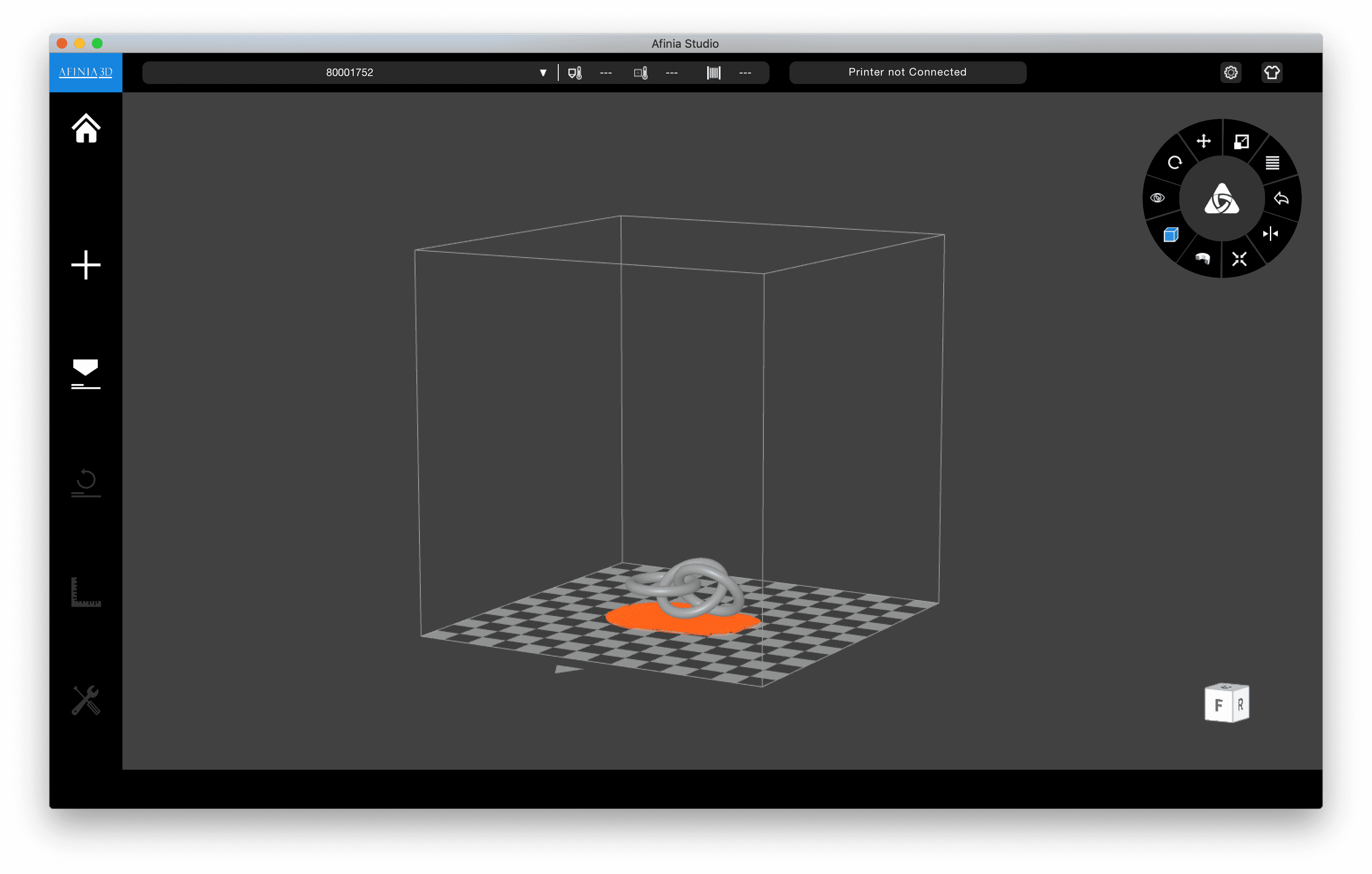

Then printed using AFINIA H480. The printing time of the model depends on the parameter setting as follows. So we should choose it depends on the purpose.

- Layer thickness 0.15mm, Fine mode, Infill is dense >> 4H24M

- Layer thickness 0.35mm, Fast mode, Infill is sparse >> 53M

For this printing, I chose the following parameter to print fast.

parameter

- material: PLA

- Layer Thickness: 0.2mm

- Infill: normal

- Quality: Fast

- Raft: yes

- Support: yes

- printing time: 30min

Though it was easy to remove the support materials, small burr remained around the ring. In order to make it smooth, sanding is necessary.

3D printed Gyro¶

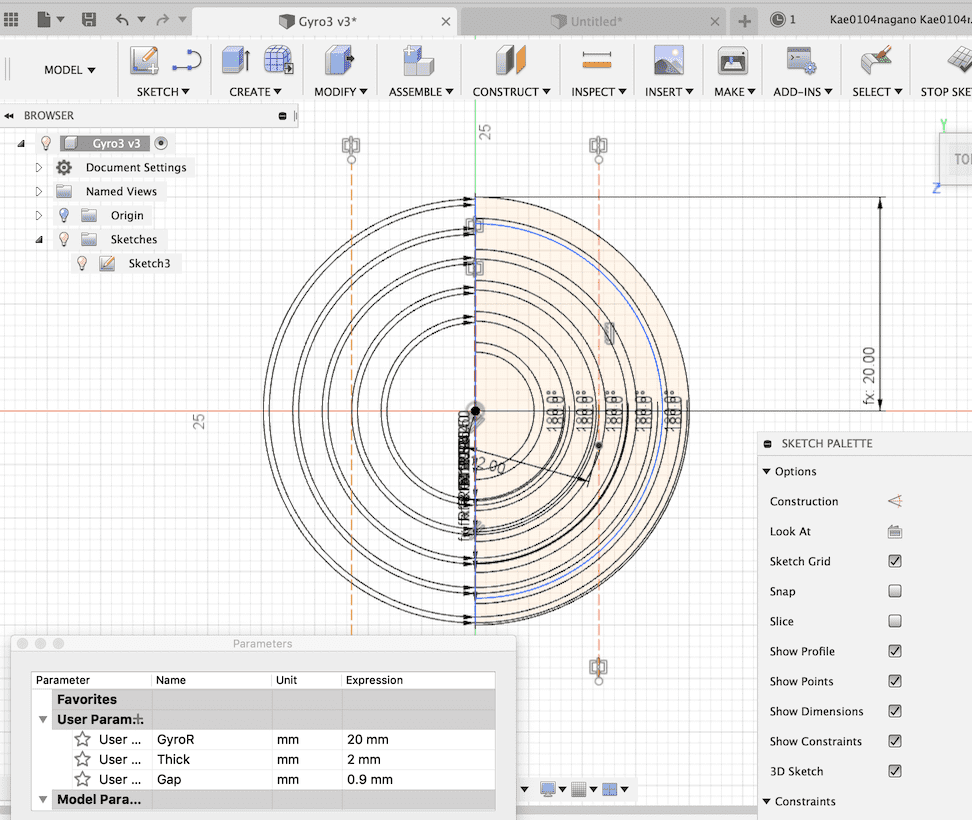

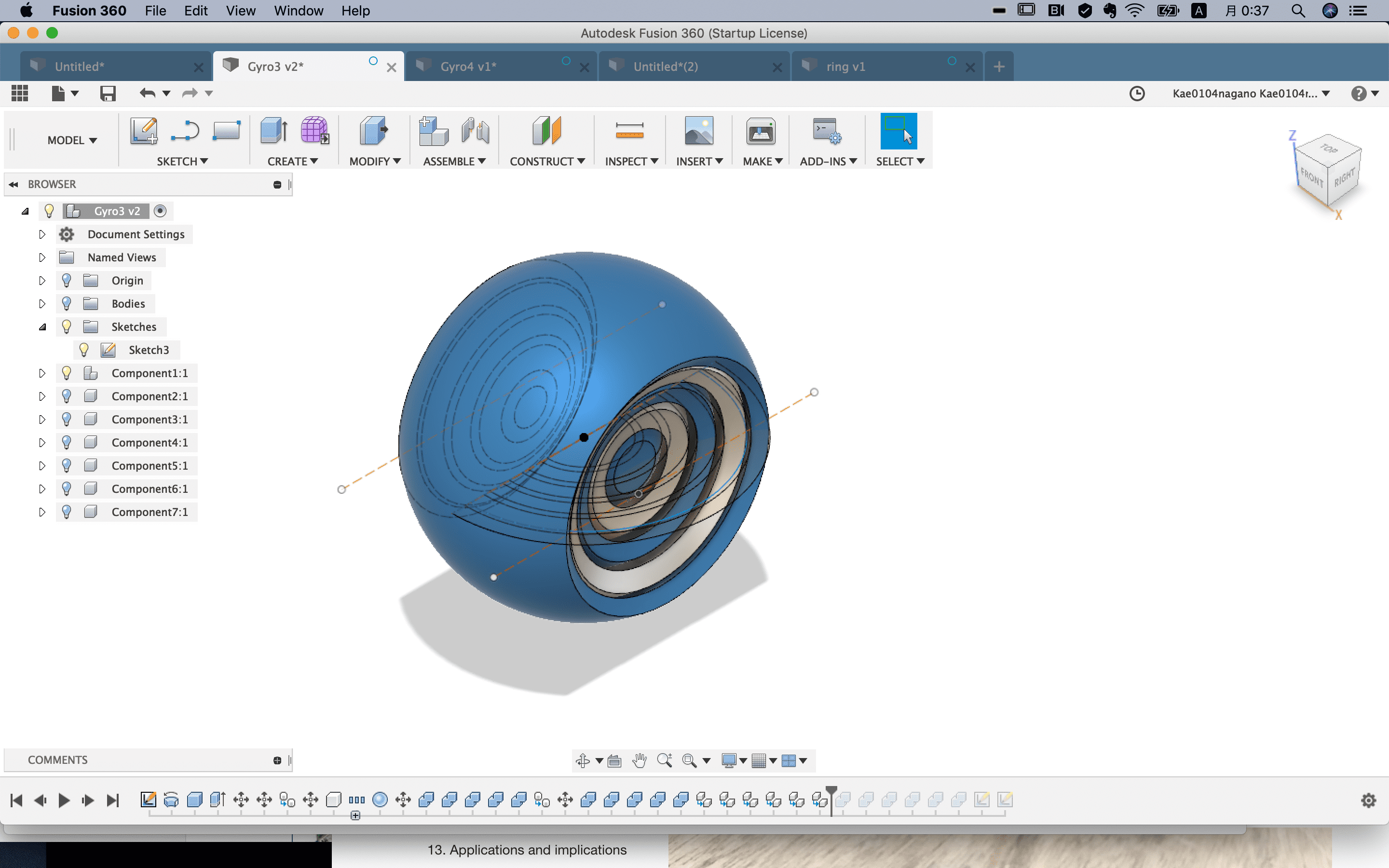

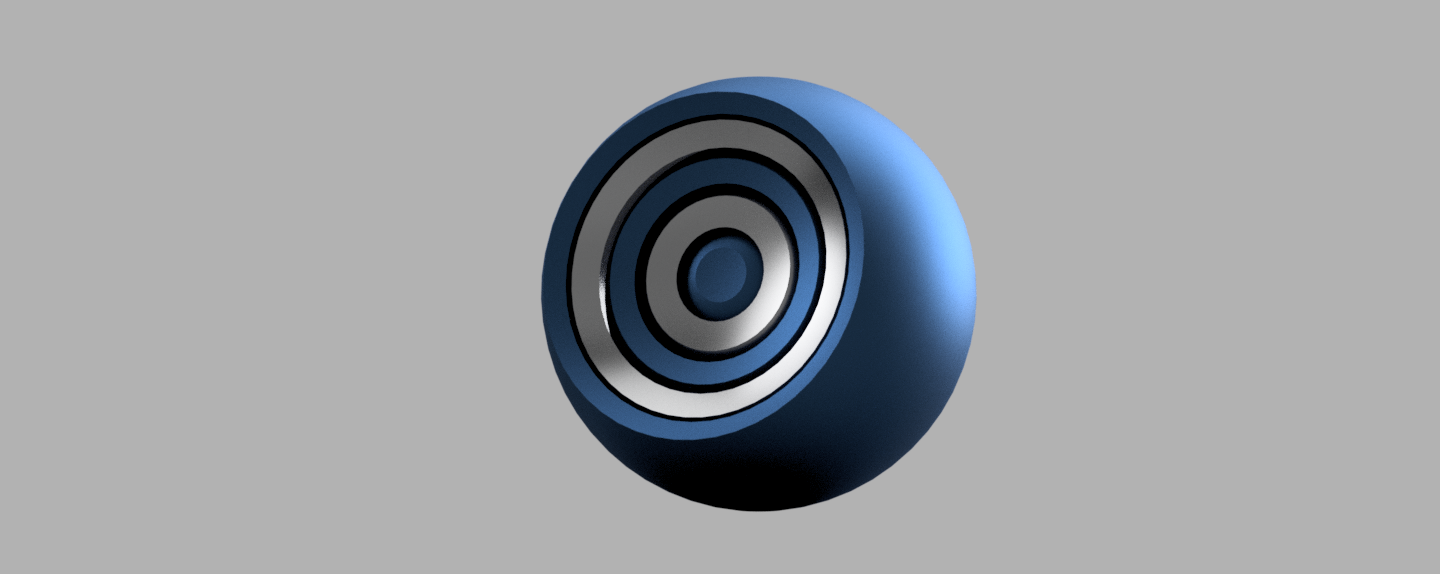

I tried another model inspired by the Gyro of Thingiverse below.

I designed the model which multiple parts are layered inside and print at once and rotate.

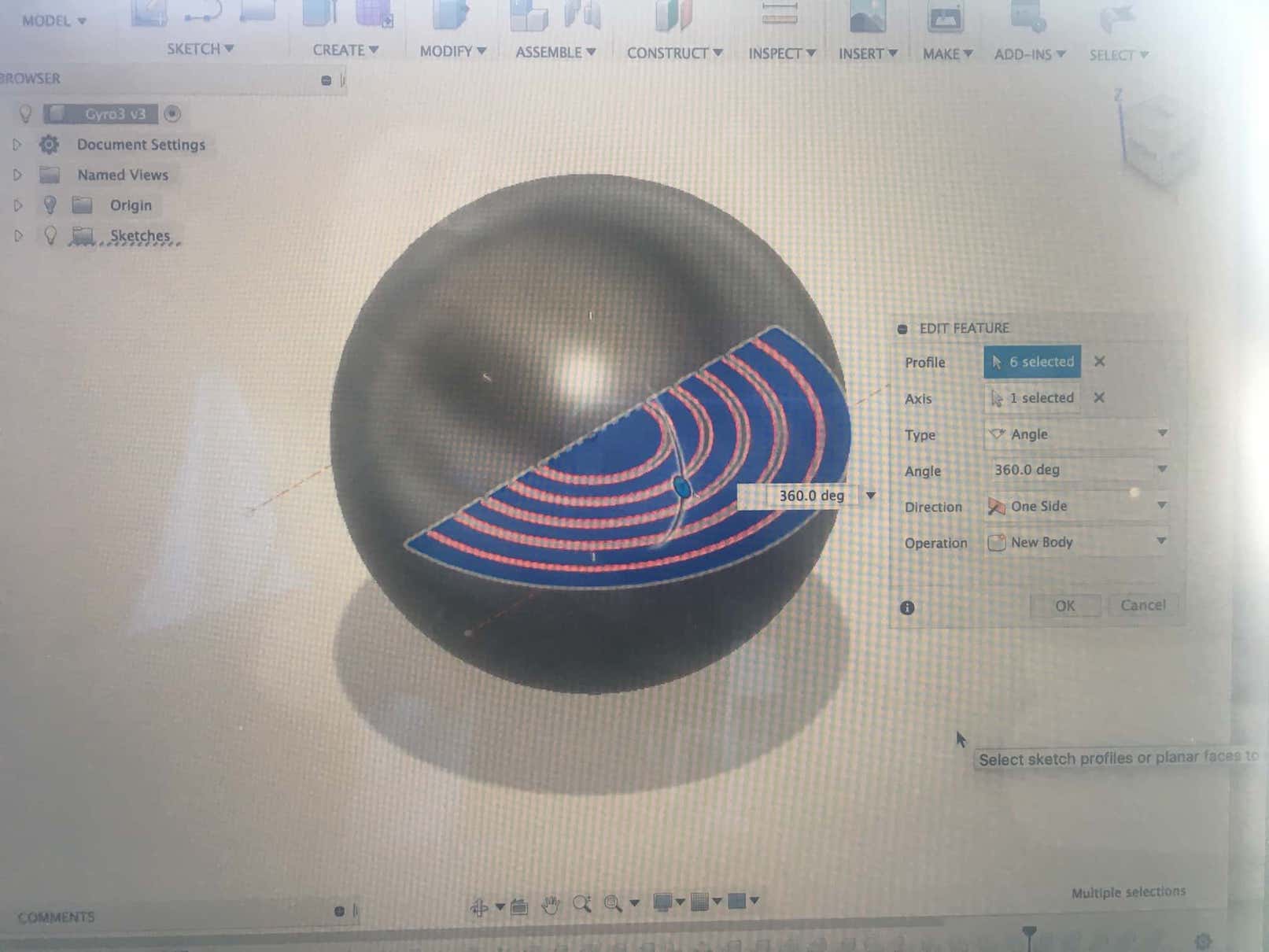

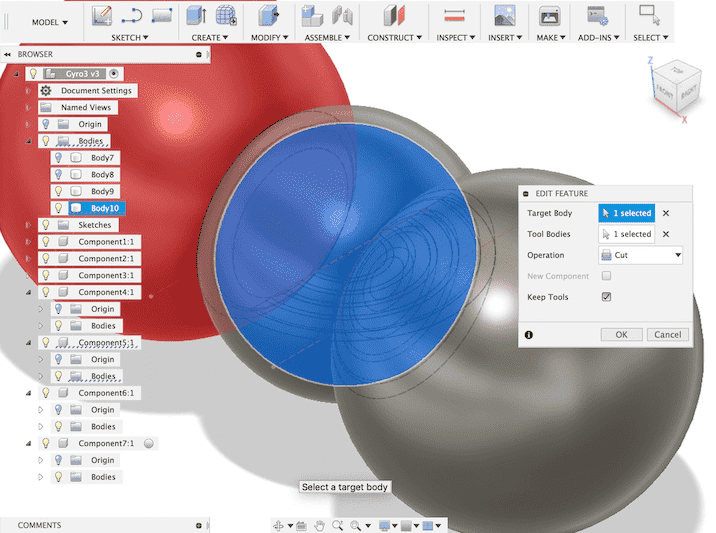

Sketched multiple arc with 0.9mm gap.

Revolved 360 degree.

Combined with spheres with cut operation.

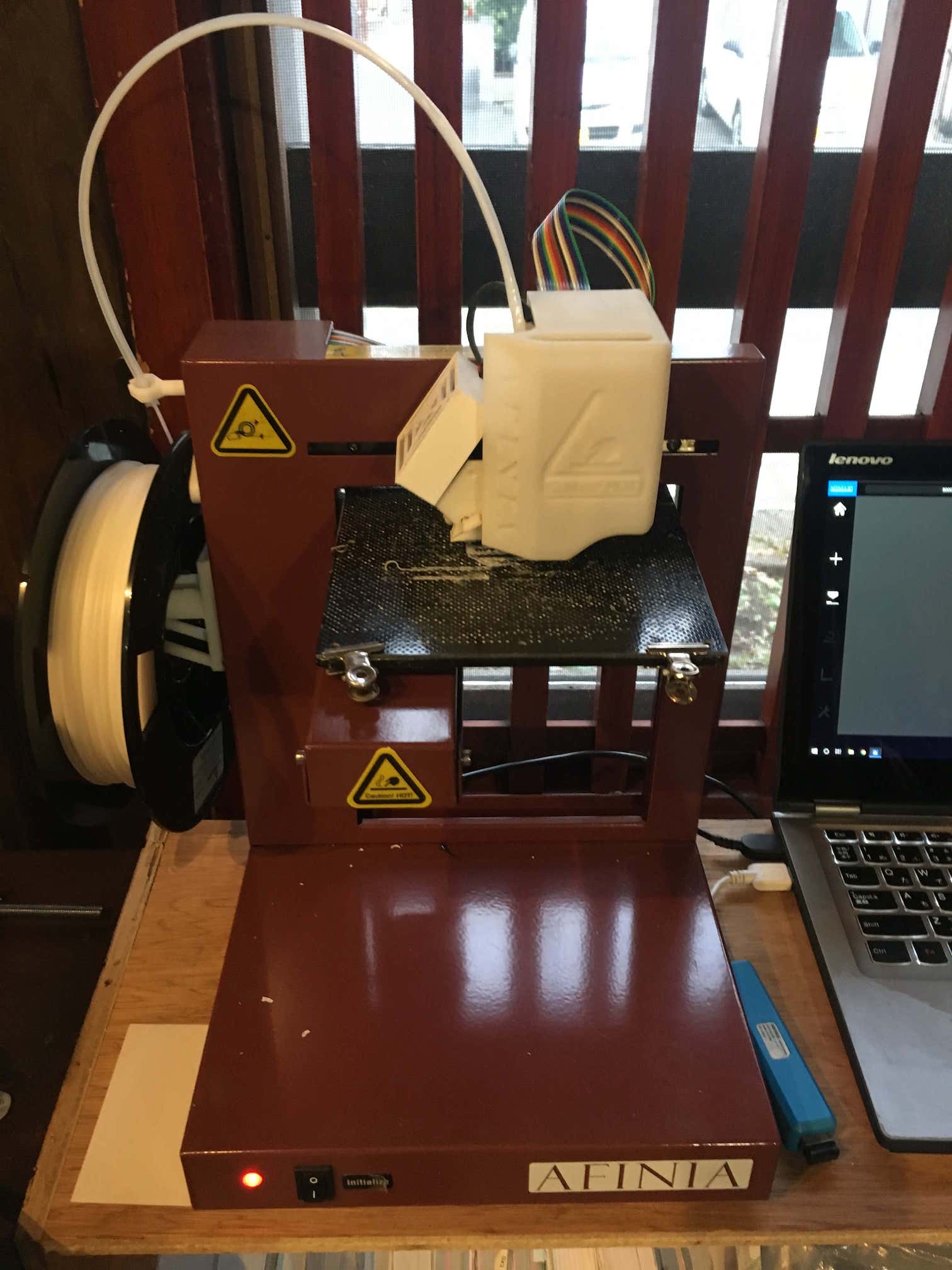

I used Up Plus2 which is almost same model as AFINIA H480. First I printed with support material, but I could not remove the support properly.

Back side of the model with support material

So I tried no support setting and printed successfully.

parameter

- material: ABS

- Layer Thickness: 0.2mm

- Infill: normal

- Quality: Normal

- Raft: yes

- Support: no

- printing time: 30min

Scanning¶

SENSE¶

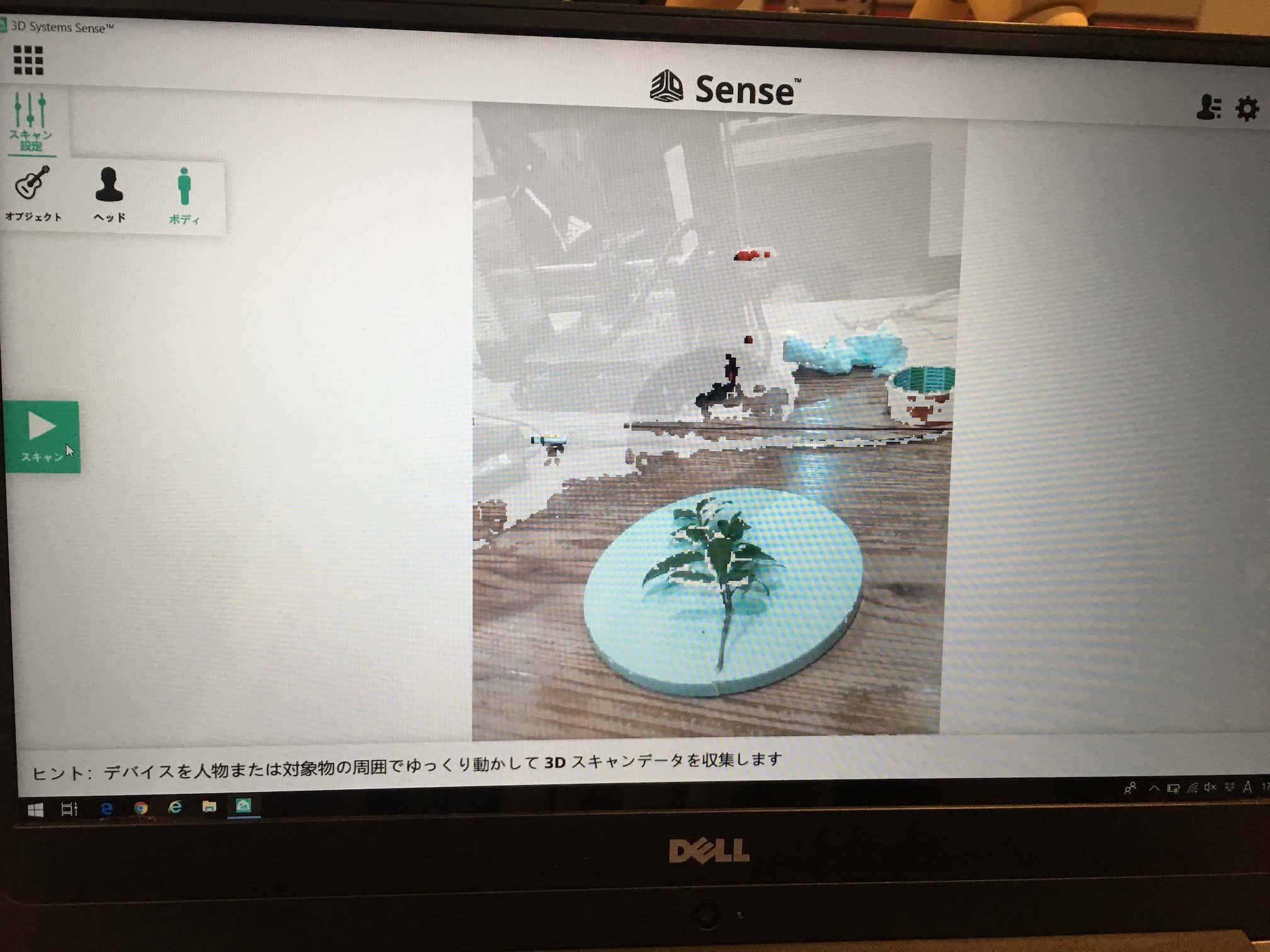

I examined the scanner SENSE of 3D system, that detects objects with depth sensor.

Spec:

- Scan volume: Min:20cm x 20cmx 20cm / Max: 2m x 2m x 2m

- Spatial X/Y resolution@0.5m: 0.9mm

- Depth resolution@0.5m: 1mm

- Operation range: 0.2m - 1.6m

- Field of view Horizontal: 45° / Vertical: 57.5° / Diagonal: 69°

The application provides three choices to optimize the scan.

- Object: any item other than a person

- Head: a person’s head and shoulders

- Body: a person’s full body

Since I wanted to scan organic things , I prepared a camellia branch and chose “Object” mode. I first holded the scanner with hand, but lost tracking happened so often. According to the manual, lost tracking occurs when I move too fast while scanning or when the object falls outside of the camera’s view. So I decided to use a tripod and turntable.

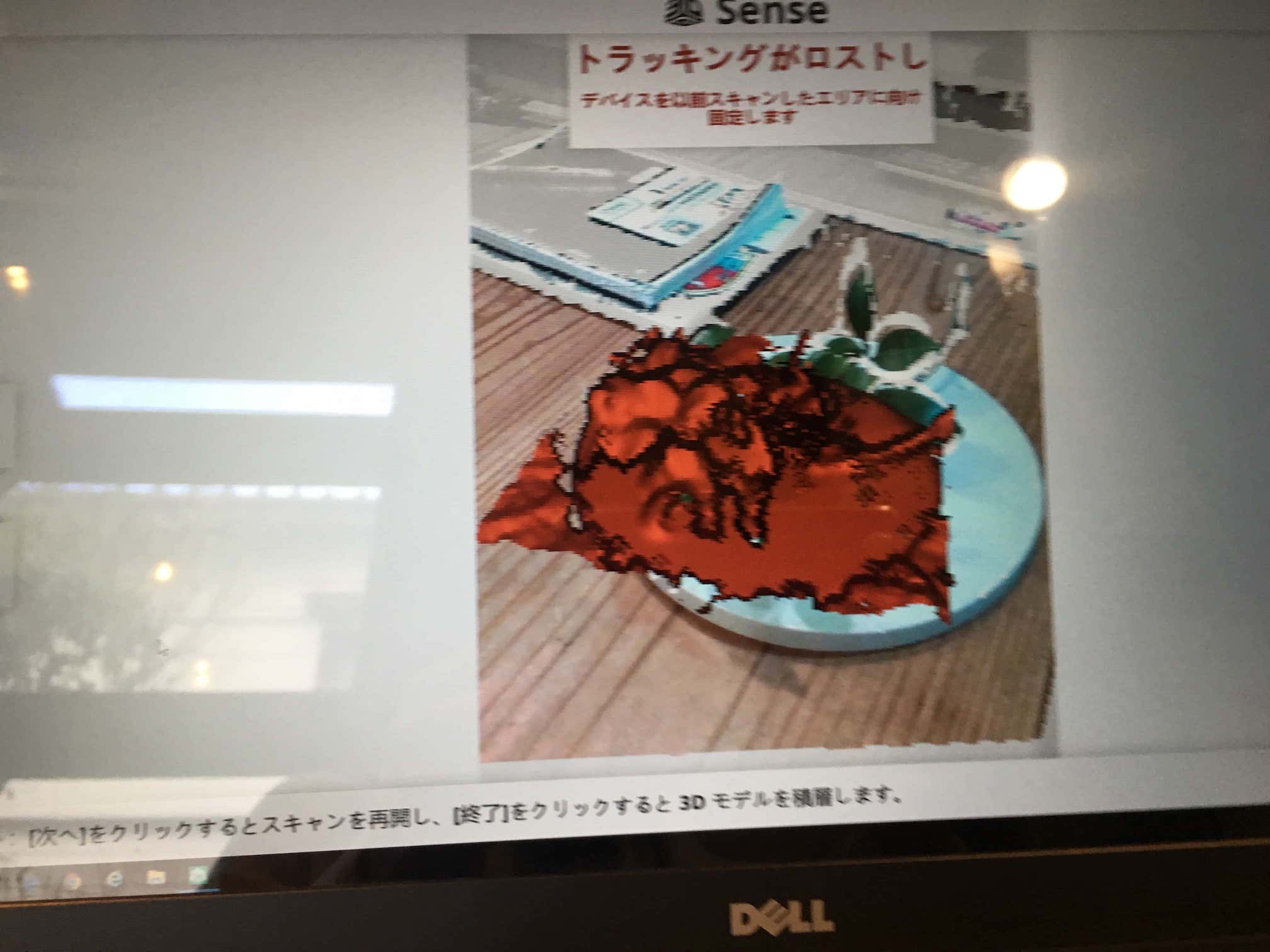

In spite of the perfect setting of tripod and turntable, lost tracking still happened. (red image below indicates the lost scanning)

The result was as follows. Though the texture was not bad, leaves looked flat. This kind of complicated organic object seemed difficult for scanning.

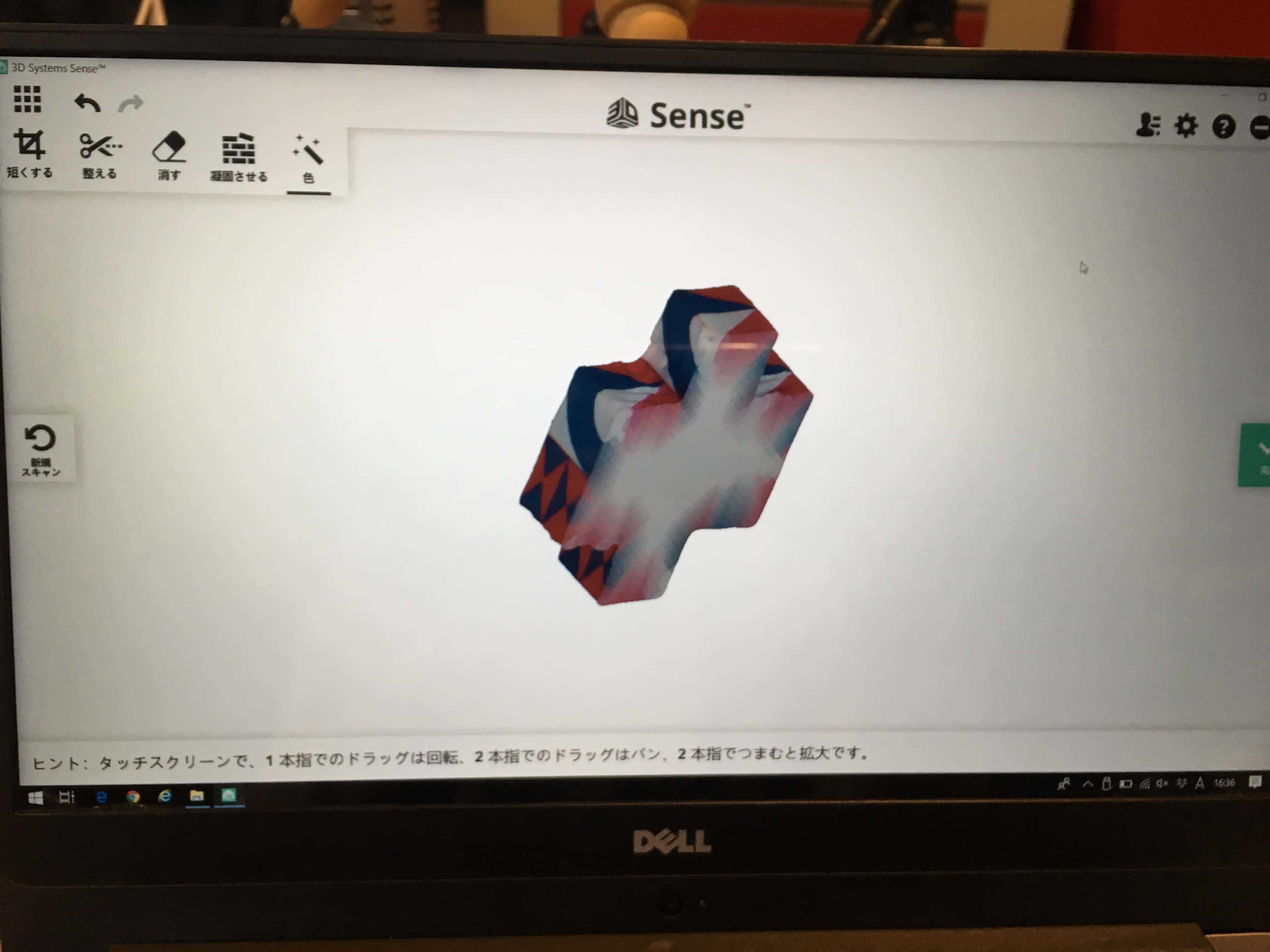

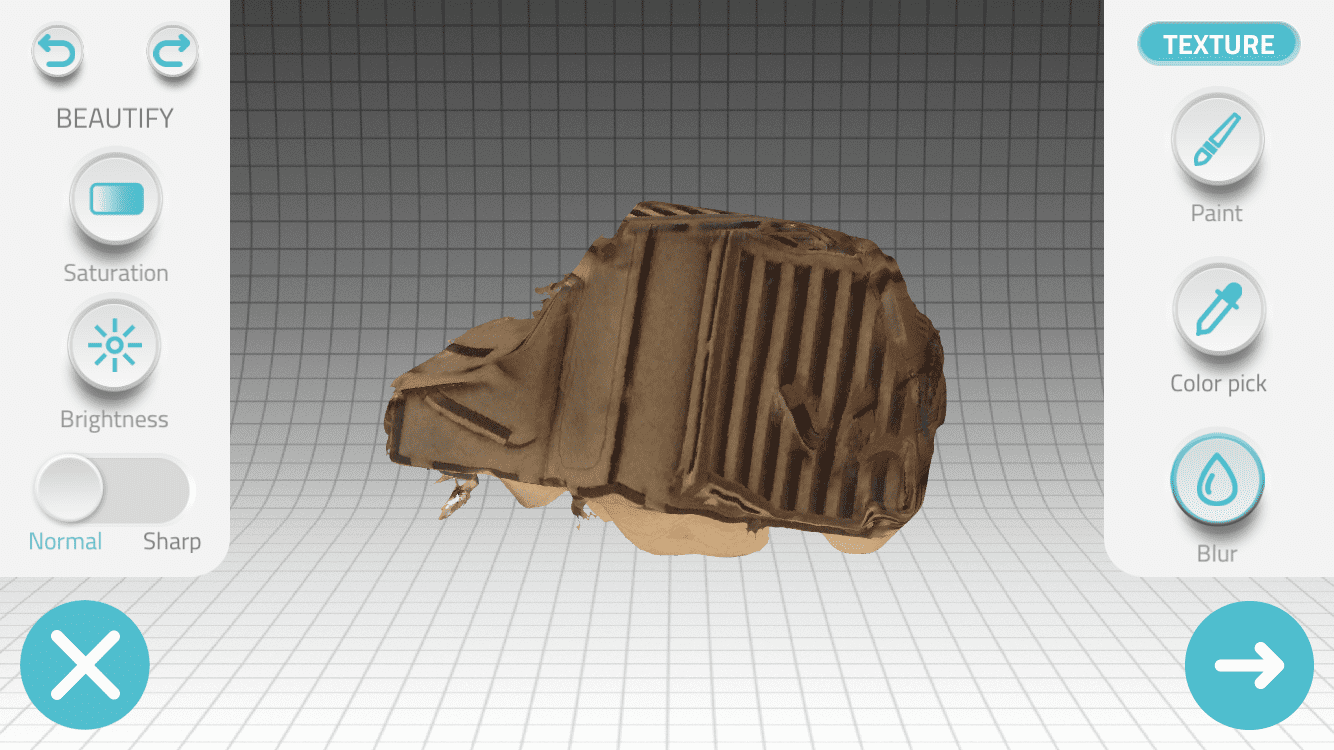

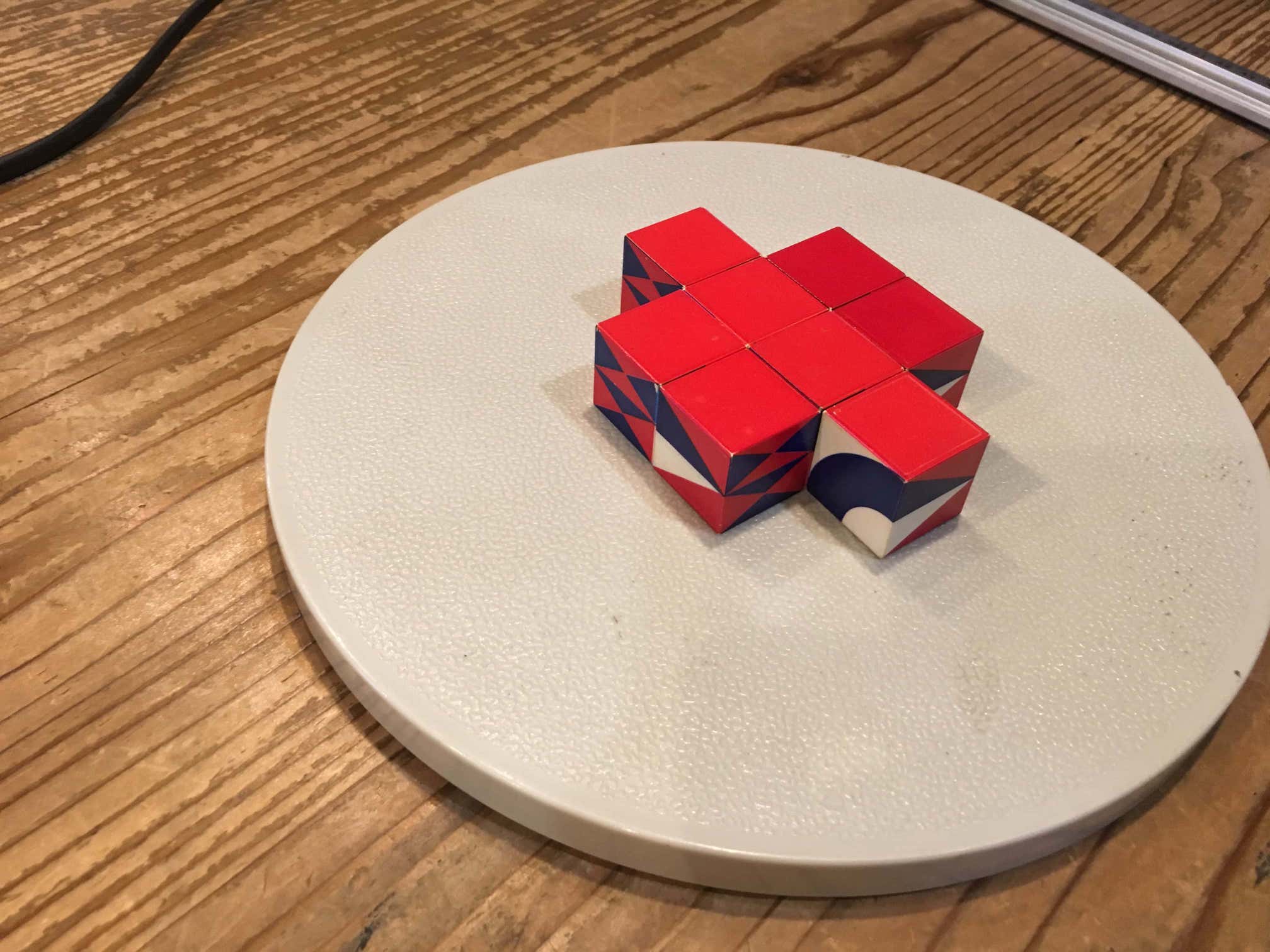

Then I tried simple blocks.

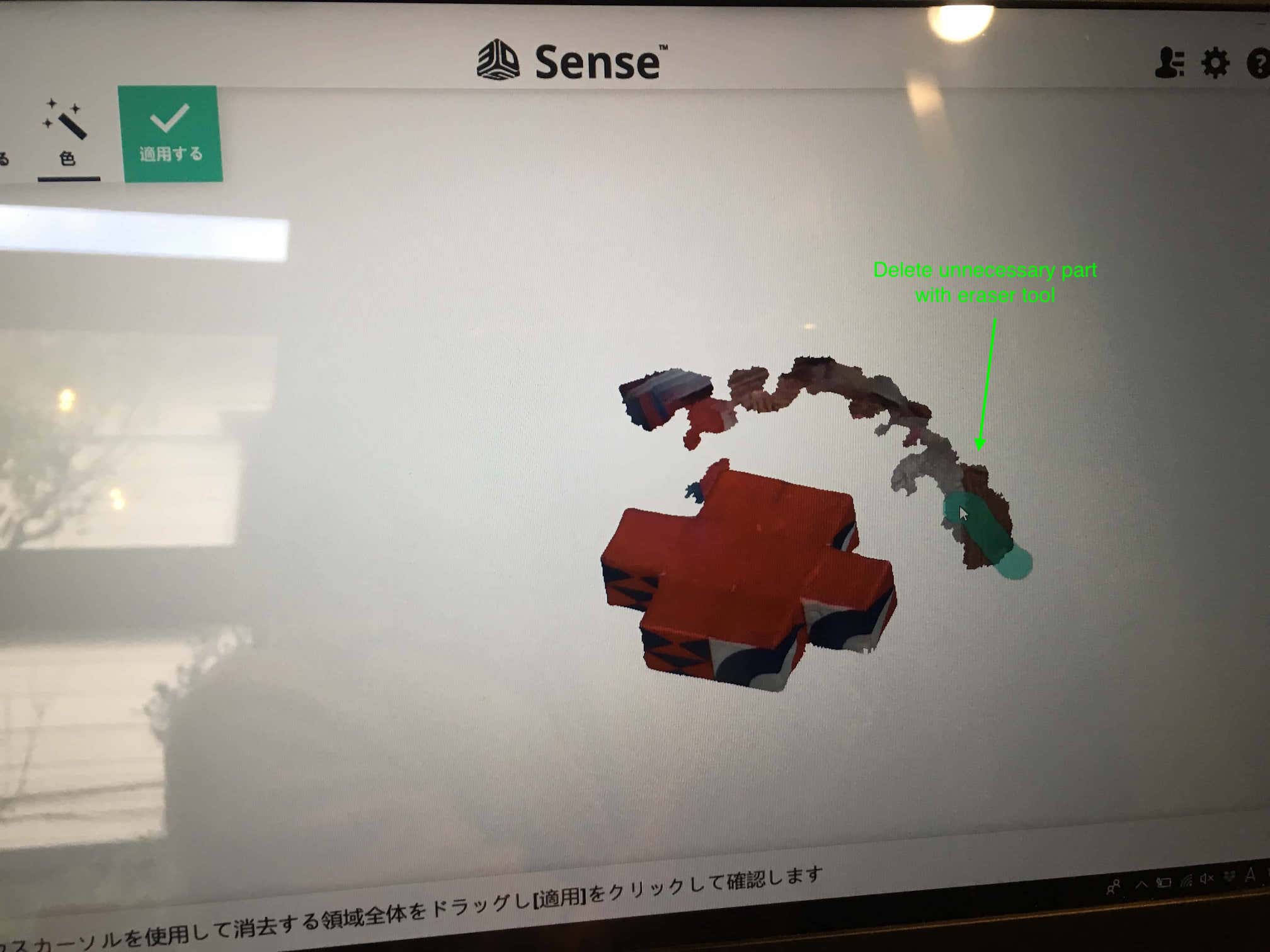

The result was better than camellia leaves. I removed unnecessary part using eraser tool of the application.

Fixed the hole on the back for 3D printing.

I saved the file as OBJ format, then imported to AFINIA application, however the file was rejected. So I converted the file to STL format with Meshmixer, then tried to import ( I scaled the model to 25% for time saving). I imagined

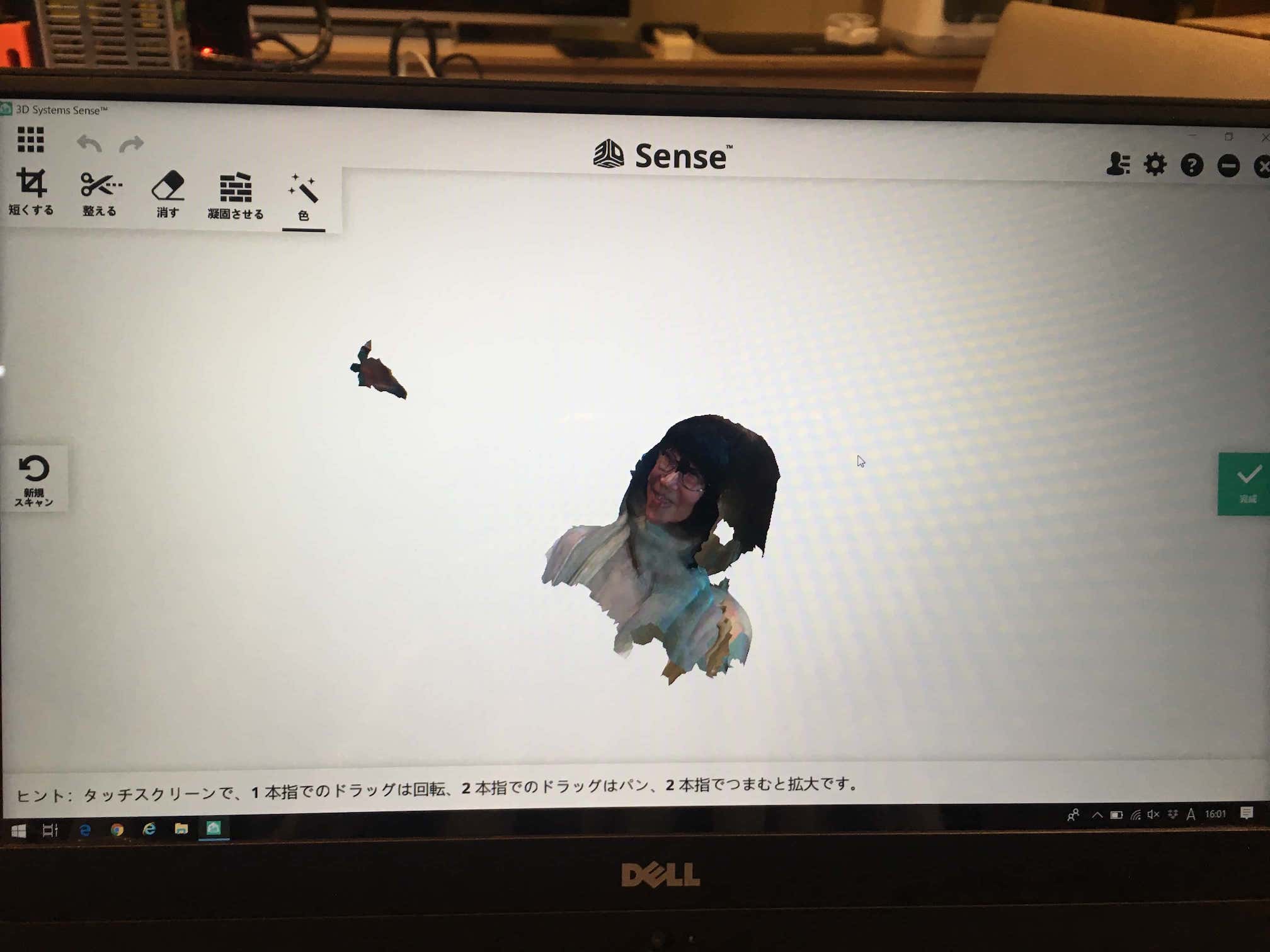

I also tried to scan myself with “head” mode of Sense. It seemed easier than small object, but perfect scanning was difficult. In case of other student’s scanning, texture of over wrapped part was distorted.

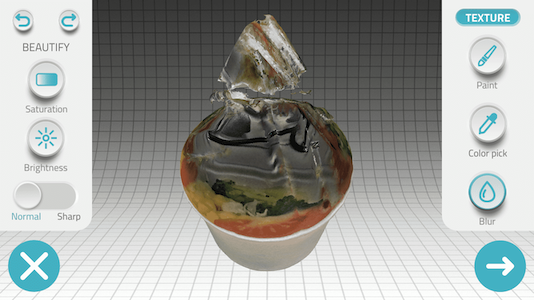

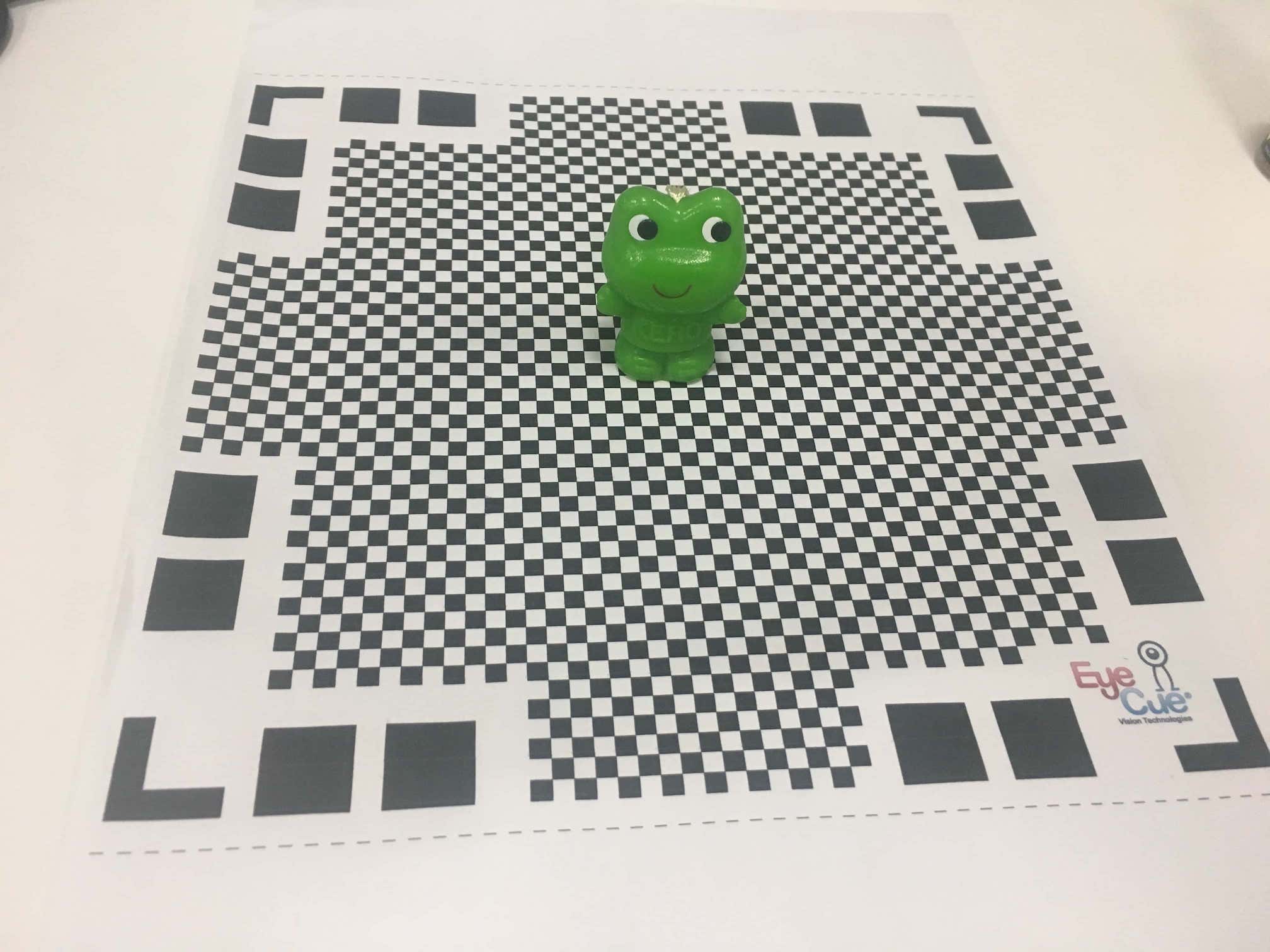

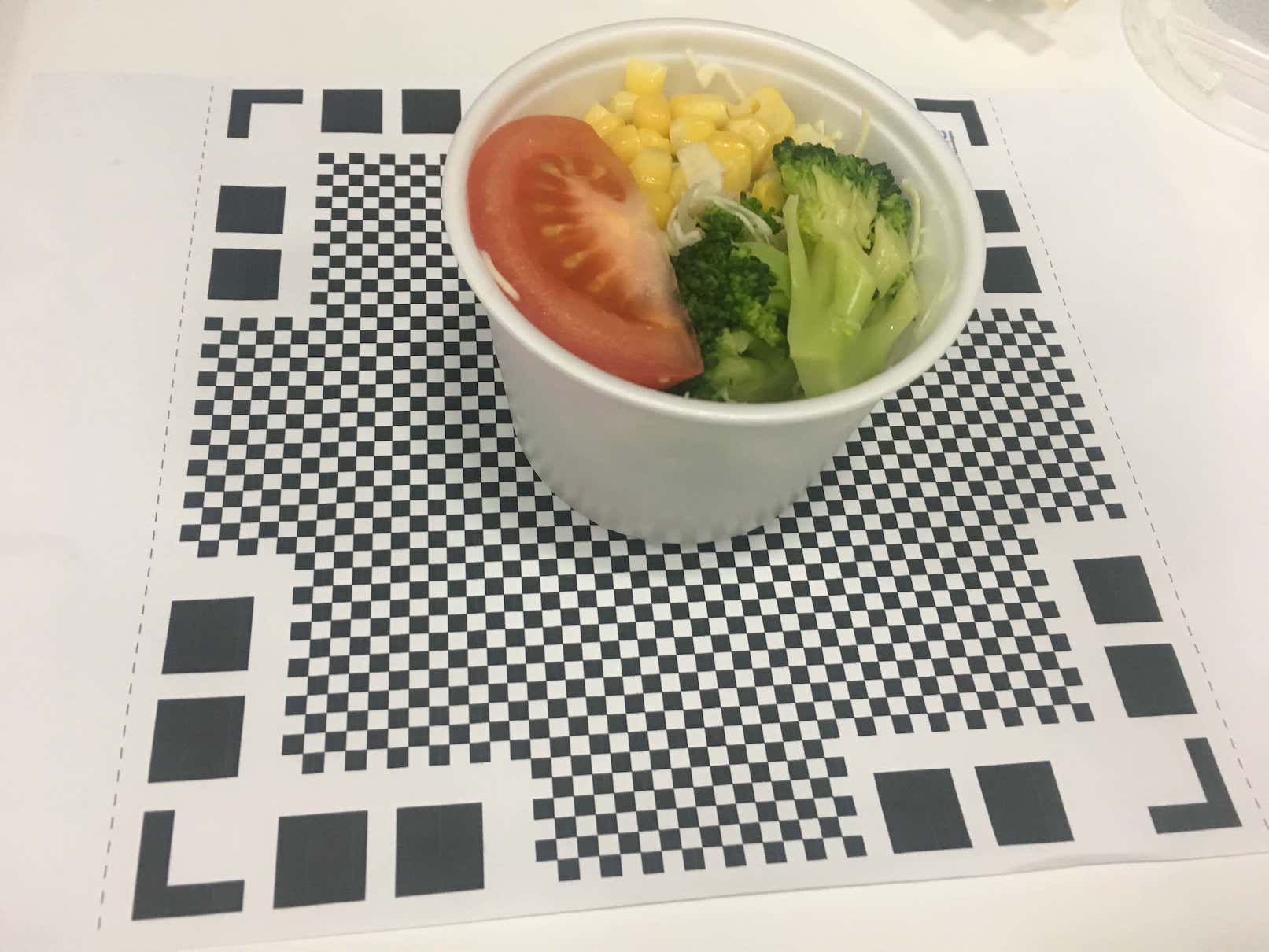

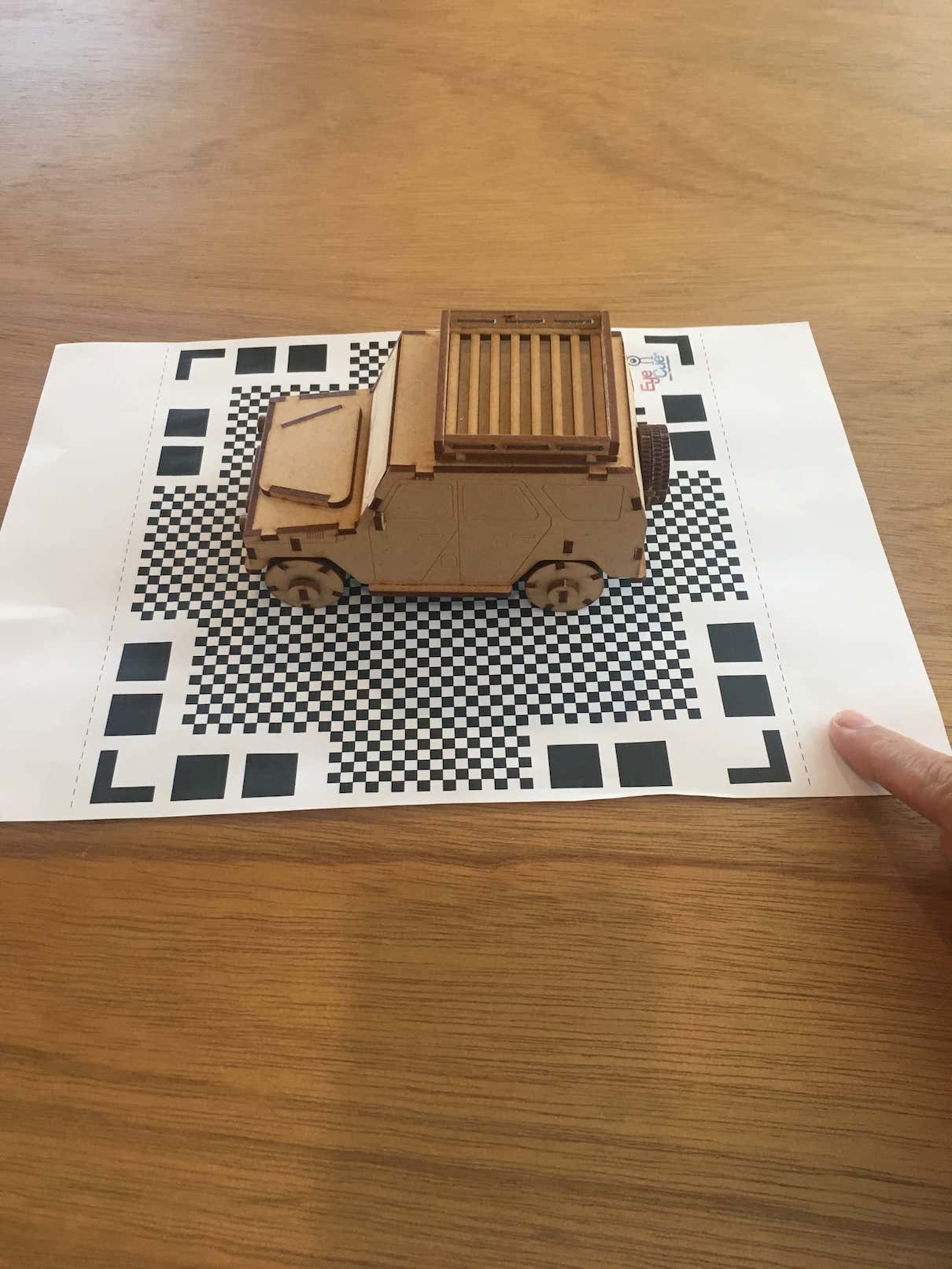

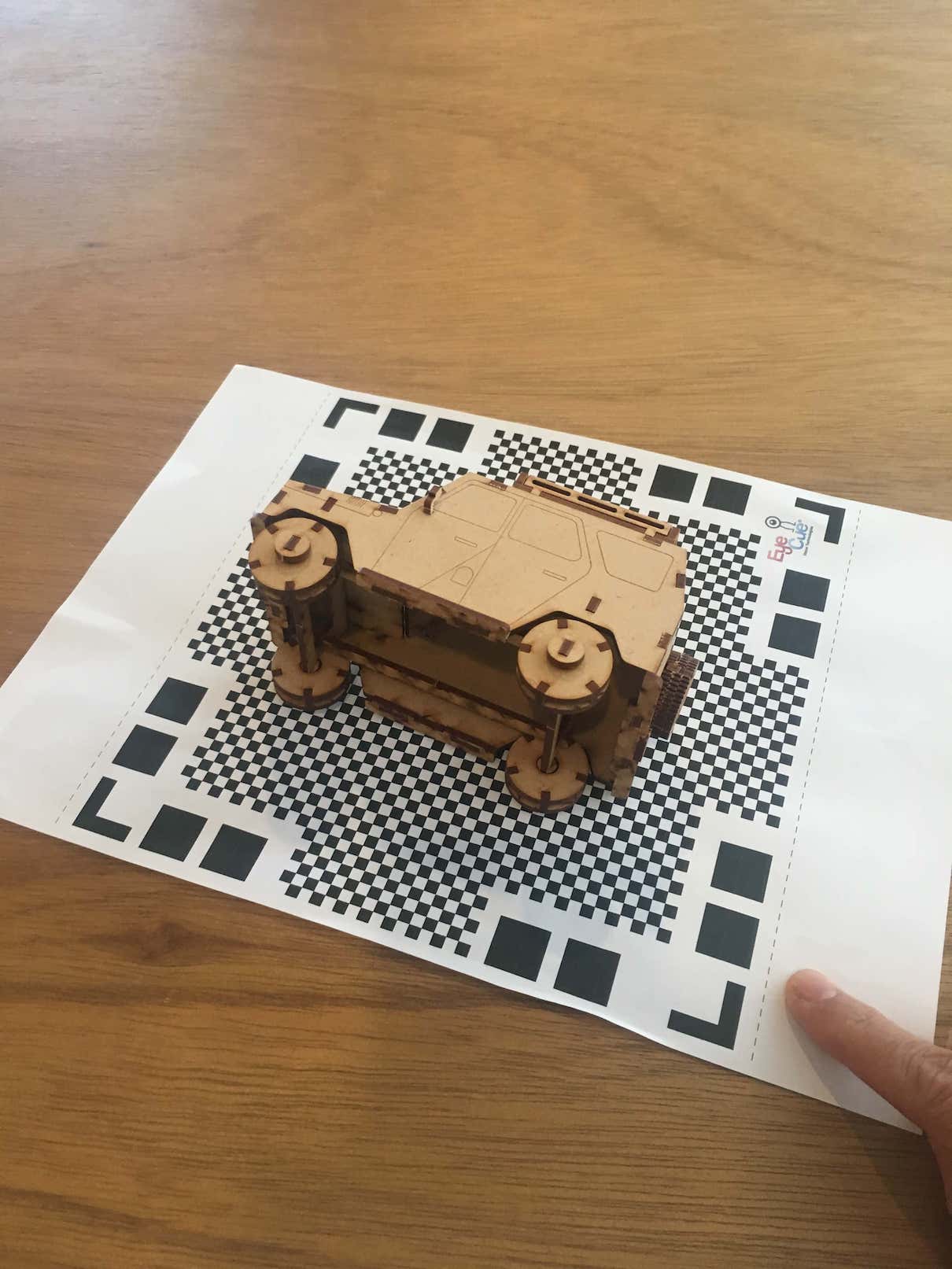

Qlone¶

I tried iphone app of photogrammetry software Qlone. The app is free, but Exports are in app purchases. The app is free, but exports are in app purchases. I was interested in the app because it uses AR marker sheet that I can print. I imagined it easy after being tired of Sense’s lost tracking.

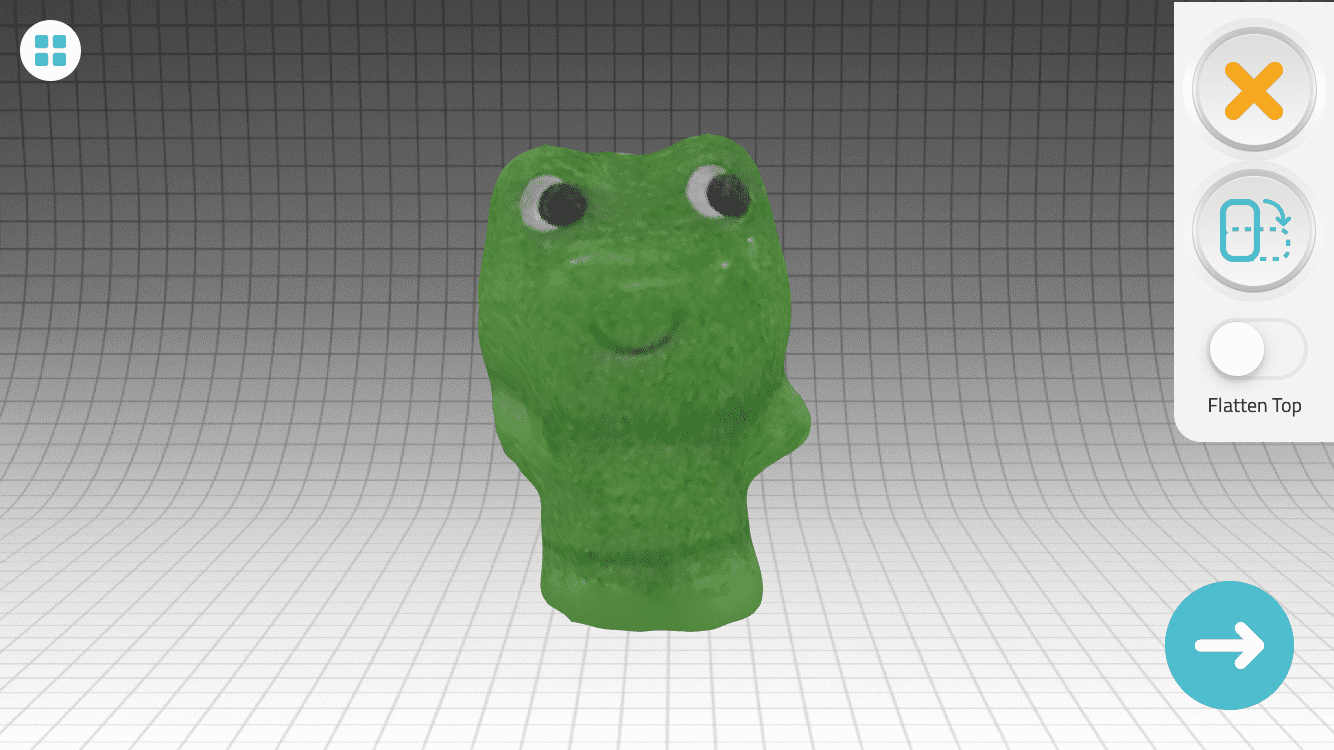

Lost tracking was less than the Sense and the result was good. So I tried more complicated objectts.

As the top of the salad was distorted, I tried the Qlone’s function that I can merge two different poses of the same object to have a better overall result.

The result was not what I expected. Off course I tried the salad, but it did not improved. The Qlone app is convenient and useful for simple model, but I need more evaluation time for more complicated objects.

Learning outcomes¶

-

3D Print I learned how to use 3d printer and tested the design rules. The FDM printers are easy to use at home and office as low cost, no chemical solvent. The merit is to Print complicated object such as layered, jointed parts at once. However it takes long time. Since the time depends setting parameters such as layer thickness and infill, it is necessary to choose best parameters according to the purpose. It will be useful if the control software can partially change the parameters. For example 0.15 mm layer only for thin part and 0.3mm for other part.

-

3D Scan Scanning was harder than I imagined. The best scan examples I usually see on web sites seems difficult for me. Needs long tuning / post editing. I want to 3d print the attachment tool for Sense to keep proper distance and angle.