4. Computer controlled cutting¶

This week I worked on vinyl cutting and laser cutting, creating a press fit construction kit as this week’s product.

Research¶

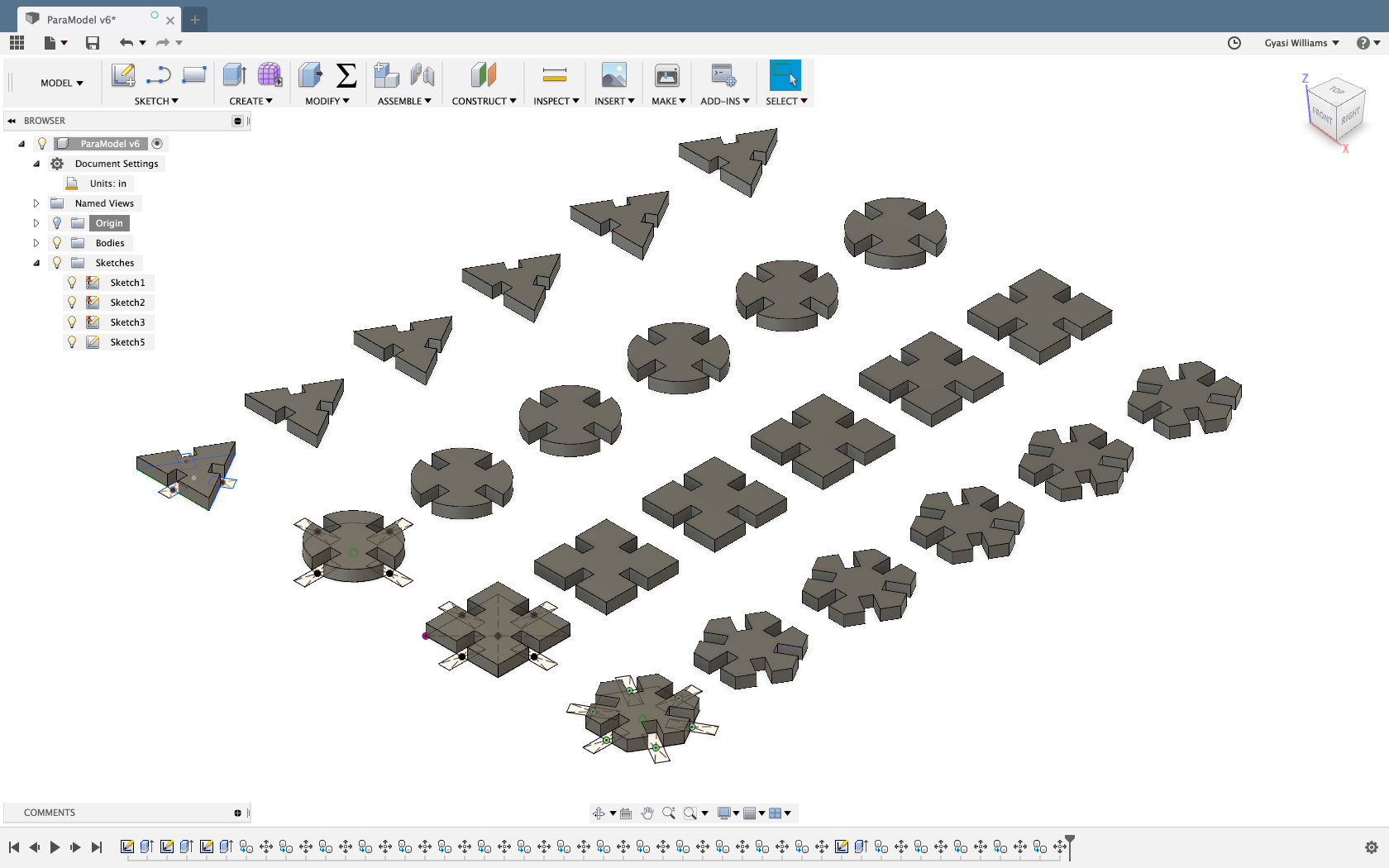

Though somewhat familiar with Fusion 360, I watched a lot of tutorial videos, particularly around parametric design and modeling. I wanted to ensure that I understood how to properly use parametric design and modeling.

Useful links¶

Vinly Cutter¶

A simple vinly cutter cut…

Laser Cutter - Press Fit Construction Kit¶

I was able to get a pretty good handle on parametric design from the tutorials. There were challenges, however, keeping the geometry of my designs consistent when I created the slots for the connections. Before I figured out which constraints to use for my pieces, they often would move or change shape while I was dimensioning my work. I was ultimately successful.

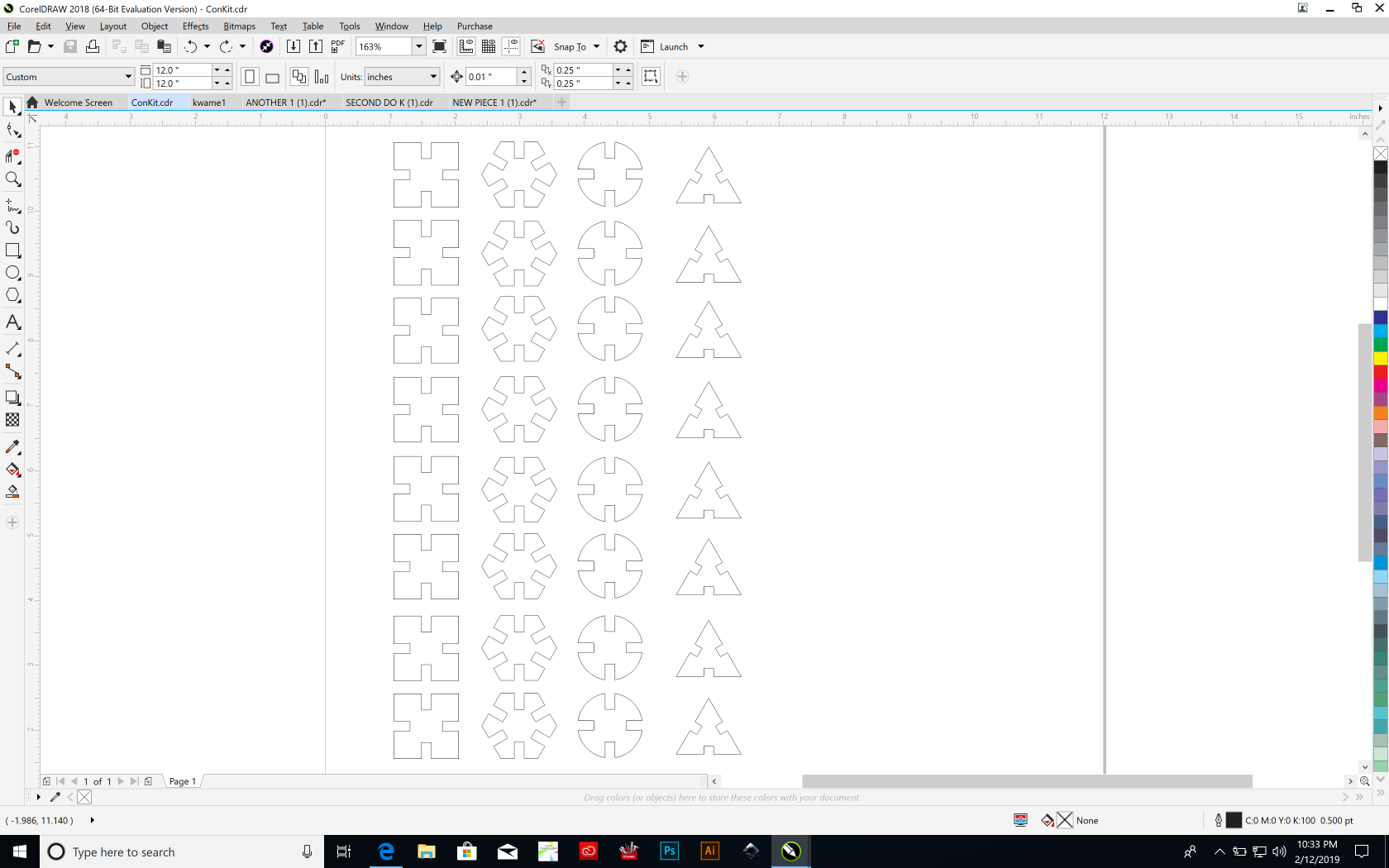

In order to cut the pieces, I migrated the 2D version of my shapes from Fusion 360 into CorelDraw, using the .dxf format. The transition was relatively seamless. Once the .dxf was opened in CorelDraw, all that was required was cutting extraneous lines, then welding the remain shape into one solid piece (using the weld function).

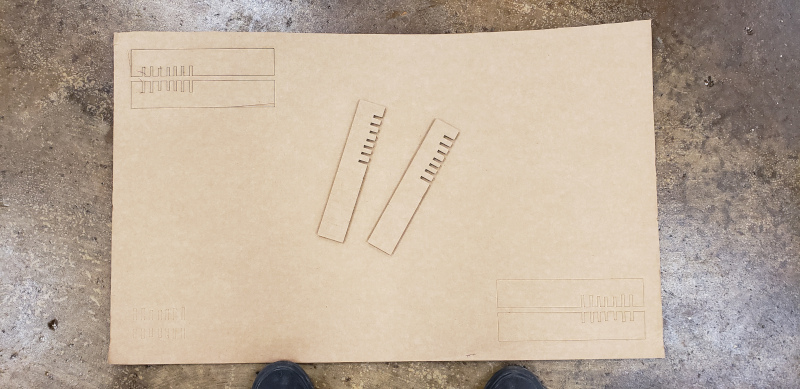

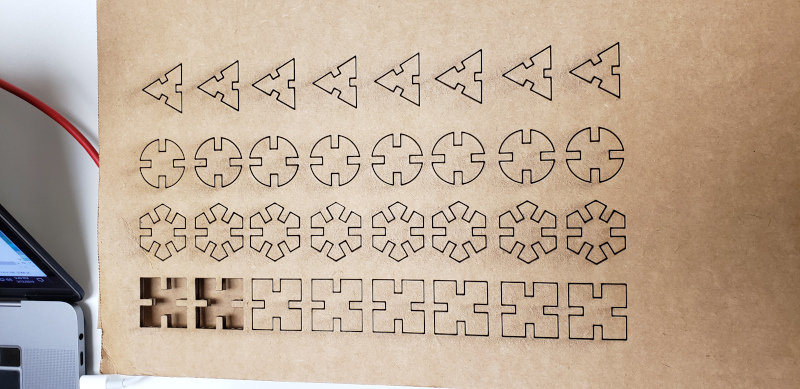

Before I could successfully cut my pieces, however, I needed to confirm that the slot size that I chose was a firm fit. I tested the following slot sizes (in inches): 0;155, 0.154, 0.153, 0.152, 0.151, 0.150, 0.149. The first four sizes actually worked, but I found that 0.152 was the tightest acceptable fit. See my test cuts below:

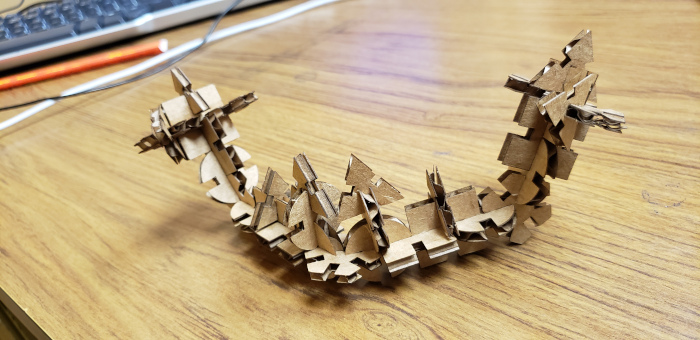

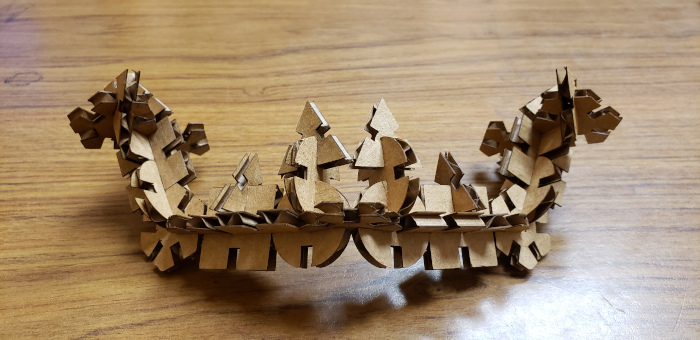

Here are my cuts! I chose to do a lego-style press fit kit.

..an initial construction…

..and another.